What is homogeneous linoleum and where is it used?

The most popular flooring is linoleum. It was created more than a hundred years ago and every year it becomes more and more perfect. Linoleum has come a long way - from tarred fabric to a coating that is resistant to household and industrial influences. The average term of his service is at least 10-15 years.

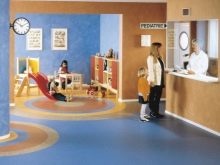

A new word in the flooring said homogeneous linoleum, which according to its characteristics turned out to be an ideal option for high-traffic areas, commercial facilities and children's educational institutions.

What it is?

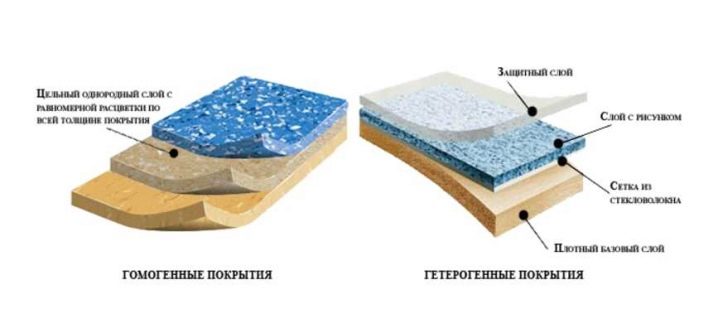

Homogeneous is homogeneous linoleum. It received its name for the fact that its structure is uniform throughout its thickness.It does not have layers as heterogeneous, so the pattern is one and cannot be erased. That is why it is in special demand in children's playrooms, in hospitals, schools and other places where floors are exposed to a high abrasion load.

Judging from the point of view of performance, it can be said that this type of linoleum is everlasting. The pattern of a homogeneous coating does not lose its appearance, the decrease in thickness in certain places (pushing furniture with legs, abrasion near doors, etc.) is easily corrected by increasing coverage even at home.

The important point is the absence of joints between the canvases, since the coating is soldered using special welding for linoleum. There is no dirt and debris between the joints; no bumps and creases are formed.

Special features

Homogeneous linoleum consists of:

- PVC (polyvinyl chloride);

- plasticizers to give it a special elasticity and springiness;

- dolomite (a mineral that not only significantly increases the refractory characteristics of the coating, but also has a devastating effect on insects with a chitinous cover);

- chalk and lime;

- quartz sand (to give the coating resistance to abrasion and chemical attack, as well as giving the coating softness of shades).

To give the coating even more strength, a layer of polyurethane and polyacryl is applied on top of it. This is the only layer that is not built into the structure of linoleum, so it tends to wipe. To restore it, special-purpose formulations are used. It is possible to use linoleum without them.

There is also natural homogeneous linoleum, which is made from jute, linseed oil, resin, wood flour. In the composition of this linoleum natural materials occupy 99%.

A feature of the material that makes up this coating is the possibility of its recovery during operation. This is done with a grinding machine.

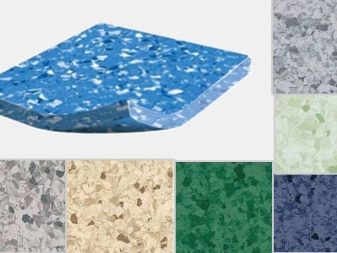

Kinds

Homogeneous linoleum is divided into subspecies by the presence or absence of the base, in thickness and class of wear resistance.

Linoleum based on fiberglass or polyurethane foam is softer and warmer. Fiberglass used for the production of a homogeneous coating, is composed of stone chips, metal dust and plastic granules.This linoleum is almost impossible to break, push. Polyurethane affects softness.

The main difference between reinforced linoleum is the price, this option will cost twice as much as usual.

The wear resistance of this coating is in the class of commercial linoleum: 33-34, 41, 42-43 units. Thus, any coating of this type is suitable for use at home.

Each linoleum has a letter mark, which indicates the potential degree of wear:

- T (the highest category of durability);

- P (average);

- M (low);

- F (minimum).

Some types of linoleum are marked with resistance to fading (pictogram of the sun) and the formation of antistatic electricity (pictogram of lightning).

In terms of thickness, two types of homogeneous linoleum are distinguished: 1.5-2 mm and 2-3 mm. The thicker the linoleum, the more elastic it is.

.

What is different from heterogeneous?

Differences of homogeneous linoleum from heterogeneous lie in the very method of manufacturing a coating:

- the main difference is that homogeneous linoleum is homogeneous (1 layer), heterogeneous consists of 4-5 layers;

- a pattern on a homogeneous linoleum applied throughout its thickness, on a heterogeneous layer located on the paint layer;

- the service life of a homogeneous material is at least 25 years, heterogeneous - 10-15 years;

- homogeneous coating is completely resistant to fire due to the presence in the structure of quartz sand and dolomite, melts heterogeneous under the influence of fire;

- homogeneous linoleum is not wider than 2 meters, heterogeneous can be up to 5 meters wide;

- homogeneous coating allows flooring with overlapping walls, heterogeneous - no;

- homogeneous linoleum cannot be rolled too tight;

- single-layer coating is easier to cut and easier to create complex, including mosaic patterns. Multi-layer coating allows you to create combinations of large pieces.

How to choose?

When choosing, pay attention to quality certificates and compliance with GOST standards. Little-known companies are changing the proportional composition of the coating, adding more lime and even kaolin, reducing the percentage of the most important component - polyvinyl chloride. This reduces the cost of the product and its durability. During long-term operation, whitish spots begin to appear in places of high cross-country ability (it shows lime).

To avoid buying low-quality goods, you must first familiarize yourself with the average price for this coverage,and in the store to conduct a simple test for flexion. If in the place of the fold you saw a white strip, then linoleum does not meet the standards. A break in the place of the fold indicates a large amount of lime, much more than is required by quality standards.

If you need household homogeneous linoleum, then choose the 33-34 class, its characteristics are excellent for the house and the apartment.

Piling

The most important part when laying a homogeneous covering is leveling the floor. This linoleum is very sensitive to a flat surface, it is so soft and pliable that it fills very well all the grooves in the floor. Of course, its performance will not be greatly reduced, but the aesthetic appearance will suffer. On such a floor will be the slightest unevenness.

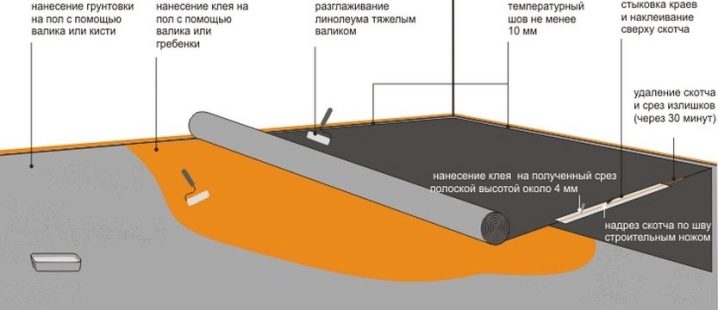

Homogeneous linoleum is put on glue (preferably the same manufacturer as the coating itself). Glue consumption depends on the base - if it absorbs liquids well, then at least 1 liter of glue per 4 square meters of room will be required. If the base does not absorb so well, then 1 liter per 6 square meters.

At first, the coating goes through all the stages as regular linoleum: keeping it rolled up indoors for 24 hours, then the same amount of time in unfolded form.The edges of linoleum are cut near the walls or put on it. The institution on the walls is used in educational institutions so that children do not soil the lower part of the wall. For this method of laying used flute skirting. It has a sloping ramp at the base of the wall, which does not allow the linoleum to be pressed through. The baseboard, which keeps the cover at its edge, is attached to the wall at a height of up to 10-15 cm.

If the coating on the wall does not start, then it is cut off at a distance of 0.5 cm from the junction of the wall and the floor. If for some reason it is impossible to remove the plinth, then the linoleum is placed in the joint with the plinth.

If you put homogeneous linoleum at home in a small room and you will not have joints, then you can use double-sided tape to fix.

Applying glue at home is carried out with a notched trowel under the edges of linoleum, which are bent to half its width. After one part of the web is glued, the air bubbles are dispersed from the center to the edges, the second part of the web is glued.

Since homogeneous linoleum has a width of not more than 2 meters, the joints can not be avoided. For perfect docking you need to do an overlap of 2-3 cm on the first canvas.The joints are additionally glued by cold welding or (in commercial establishments) are sealed by hot welding.

After laying, be sure to tap the entire surface of the floor with a mallet. If there is a dull sound in some place, air has accumulated there. It can be removed by extrusion to the edge (point of joint) or pierced with an awl.

Joints are processed no earlier than two days after installation. With the help of a construction knife and a ruler, a linoleum edge is cut. If you can not simultaneously cut through two blades, then cut the second blade exactly along the line left by the knife.

Place the joint with masking tape, press it tightly with a rubber roller, so that there are no air bubbles. Cut the adhesive tape at the junction with a knife with a round blade, insert the needle of the tube with cold welding deep into the seam and move it along the seam, slightly squeezing the glue. An indicator that you are doing everything correctly is a 5 mm wide welding layer on the surface of the masking tape. This means that the required amount of glue is present in the seam. Scotch is removed at an acute angle after 30 minutes.

Hot welding is performed using the apparatus and a special cord.For this, the distance between the blades must be such that the welding cord goes through. After the cord is installed, its protruding part is cut off with a knife, and the surface is heated by the apparatus. The junction becomes invisible.

Examples and options

Homogeneous linoleum is a great way to create a beautiful pattern on the floor. If you can calculate the required amount of material yourself, then this is fine, if not, contact the designers or use the program for calculations. In it, you can choose your favorite pattern, drive in the area of the room and it will calculate how many square meters of coating of different colors you need.

A great option - a combination of cold and warm colors. For example, blue squares with brown and sand stripes, imitating weaving. To lay out this pattern, you will need masters working in this technique. This is an additional item of repair costs.

You can choose a simpler pattern in styling, but no less attractive from the outside. For example, contrasting circles on the floor, in the center of which is an employee’s workplace, can be a great way to zoning office space.

You can lay out a beautiful pattern in the center of the room, and leave the rest of the space monophonic. This will immediately give the room a special charm, but it does not require much effort on laying out the pattern.

It is even easier to create a chess pattern on the floor of squares of different colors. Effective and affordable, even at home.

Differences between homogeneous and heterogeneous linoleum can be viewed in the video below.