Linoleum by cold welding: process features

For many decades, linoleum remains one of the most popular flooring for residential premises. Among its many advantages is the possibility of installation without the help of specialists in repair, however, some nuances of laying linoleum, such as the correct connection of the joints. still require some specific knowledge from the performer.

Compound Types

If you need to connect two sheets of linoleum, you should get an idea of all possible docking.

Currently, installation of seams is possible using the following means:

- Mastic;

- Hot welding;

- Cold welding.

By mastic, which is used when working with linoleum, imply a kind of multi-part adhesive paste (mastic based on bitumen is usually used). The direct purpose of such a "putty" is both the fixation of the main surface area relative to the floor, and the gluing of the material joints together. Adhesive mastic should not be confused with a protective one, the function of which is to keep linoleum in good condition and prolong the time it is used.

The use of mastic directly for joining surface joints is a proven method, which still has a certain popularity.

The main "trump card" of this method is the high strength of the docking.

However, one must be prepared for the fact that preserving the integrity of the product in the event of its dismantling is impossible. In addition, the joints with mastic require some additional preparation: in addition to cleaning the edges of the cloths from dust, it is recommended to degrease them.

The second way to securely glue the seams of linoleum is hot welding. As the name implies, the principle of connection is based on the processing of cloths with a stream of hot air and the subsequent adhesion of surfaces softened by heating.To weld the seam with hot welding, a special tool is needed - a heat gun (welding heater) with a filler rod, which fills the gap between the panels and then weld the linoleum.

Despite the high strength and full tightness of the packs, obtained by coupling the joints in this way, it is not popular among non-professionals for a number of reasons. First, the purchase of a heat gun significantly increases the financial cost of repairs, but it is not advisable to replace this narrow-profile tool with a soldering iron, which is found in many homes (the seam will be intermittent and uneven). Secondly, the welding of seams with the help of air heated to 400 degrees is possible only when working with dense and rigid linoleum, since the soft one will simply melt and be hopelessly spoiled.

In addition, working with a welding torch requires considerable assiduity and attentiveness, and most importantly, a certain skill and experience, which a beginner in repair cannot simply have. Another obvious disadvantage of hot-weld docking is a rather coarse joint as the final result of the work.

The most optimal and simple way to quickly and accurately glue the joints of linoleum, is the last kind of its connection - cold welding. The adhesion and fixation of the webs occurs through the active dissolution of the material and its transformation into a monolith after solidification. This method of work has a number of advantages over its counterparts.

First of all, the use of cold welding does not involve the acquisition of a special tool, as well as the possession of professional skills. All that is required for mounting is a tube of liquid glue (a fine needle tip is included in the kit) and a firm hand.

All installation work, including preparation for docking and its final stage, is simple and fairly quick. Full drying also does not take long to wait: after two hours, the seam can be attacked without fear, and after 8 hours comes full solidification (for comparison, the adhesion of the joints obtained by the method of hot welding occurs only after a day).

The second indisputable advantage of cold welding is its versatility: this method of joining is suitable for any material and classiness (operational purpose) of linoleum.

Repair of the old coating with this glue is also possible: cold welding is often used to process the seams of the patch installed at the site of the damage.

In addition, in comparison with the seams obtained during installation with mastic or hot welding, the joints made in this way are much more solid and neat, which means they are less visible with the naked eye. It should be noted that they are no less durable than the soldering produced by the heat gun.

Another "advantage" of cold welding is the ability to create joints of any shape.

This method is indispensable when installing panels covering turns from a room to a room or when working with the floor of a dwelling of non-standard planning.

Despite many strong arguments in favor of butt welding with cold welding, There are some restrictions on its use.. So, it is not recommended to use this clamp for joining multilayer linoleum or coating with insulation, since the seam in these cases will be clearly noticeable. In addition, the glue that is used for this method of joining, has a high toxicity and is harmful to the respiratory tract,therefore, working with cold welding, it is necessary to strictly monitor the stable supply of fresh air to the room, and also not to forget about the respirator and hand protection with gloves.

Types of glue

Having made your choice in favor of cold welding as a means of fixing the seams of linoleum, you should pay attention to the presence of three types of suitable glue.

- Type A;

- Type C;

- Type T.

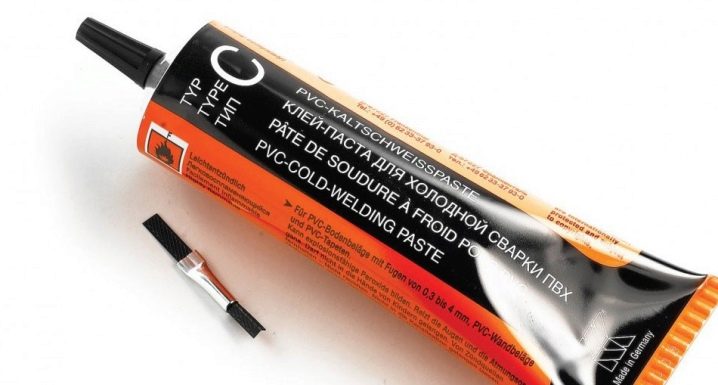

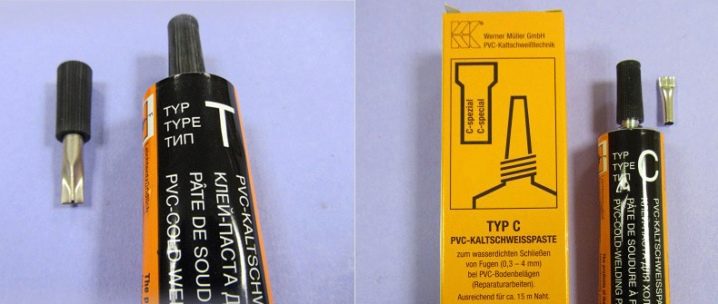

Not having significant differences in the principle of operation, characteristics and composition (the majority of such sealed and waterproof adhesives are made on the basis of tetrahydrofuran and PVC with the addition of plasticizers), each type of cold welding has its own narrow purpose.

- Type A best suited for mounting a new or hard coating (ideally made of polyvinyl chloride). The fine needle of the tip is adapted to penetrate and fill the gaps with a width not exceeding 2 mm, the edges of the panels should be perfectly smooth. Having a large part of the solvent in its composition, type A welding has a sufficiently liquid consistency, therefore, working with it, one should not show haste. The seam obtained by this type of cold welding is neat and with the right location to the source of natural light (the joints should be perpendicular to the window) imperceptible.

- Unlike type A, type C used mainly for gluing the diverging seams of the old coating. Possessing a thicker consistency, this astringent glue allows you to join even widely separated panels: the gap between the joints can be from 2 mm or more. The supply of glue is made from a wide "spout", but working with such a tube does not require special scrupulousness, since after drying, the excess is removed with a sharp knife. Hardening, cold welding type C does not lose its elasticity, and the resulting seam is characterized by high elasticity.

In comparison with type A, this type of cold welding provides less reliable fixation of the joints between them.

- As for welding type T (the letter in the name in this case reflects the shape of the nozzle tube), this adhesive is used mainly for splicing linoleum on a felt lining or for multi-component products based on PVC and polyester. Among the advantages of T-type glue are the high reliability and elasticity of the seam, as well as the invisible eye line connection of the panels. However, working with such glue requires a certain amount of experience; therefore, if its use is justified, it is best to abandon the self-assembly of the coating and entrust the work to a professional.

As for pricing, the cost of cold welding glue ranges from about 140 to 450 rubles per tube of about 100 ml (material consumption is indicated on each tube). Among the brands that received the best reviews among professionals are Sintex (Spain), Homakoll and Forbo (all of Russia).

Focusing on the varieties of glue for joining the coating, one should not forget about the purchase of fixing agent directly for the floor. Already mentioned bitumen mastic can be such a fixer. Coupled with the type of cold welding that is needed in a particular situation, this glue allows you to securely glue the material to the floor and ensure durable fixation of the coating even under high load on it.

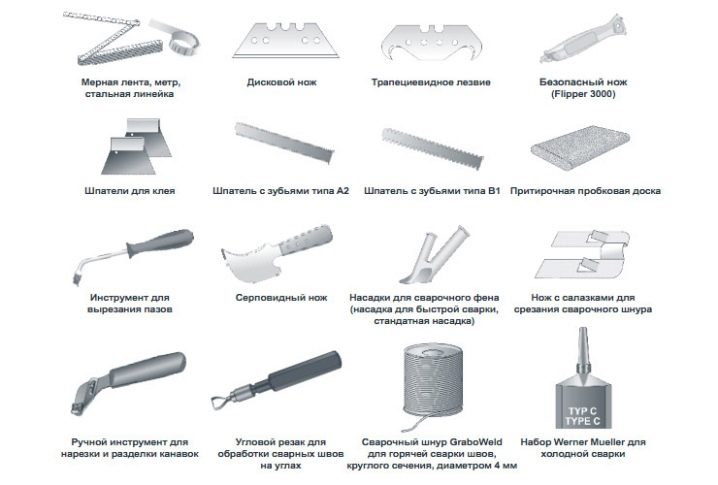

Preparation of tools

For the installation of linoleum joints by cold welding it is recommended to use the following tools:

- cloth to clean the edges from dust;

- wide masking tape to protect the flooring from glue ingress;

- plywood (put under the cover when it is cut along the joint line);

- long metal ruler for applying a cut line;

- clerical or wallpaper knife;

- gloves and respirator to protect hands and respiratory organs from toxic substances of glue;

- narrow roller for smoothing seam.

Features of the process: how to weld?

The most important tool to be used in the work is directly cold welding of the selected type. Despite the fact that on each tube of glue there is a detailed guide to its use, there are general principles of action that allow competently carry out the joining of seams. First of all, it should be remembered that the gluing of the joints is carried out first of all, even before fixing the main surface area. The next thing that needs to be taken into account when working is the observance of the highest possible cleanliness both during the preparatory work and during the gluing process itself.

Timely cleaning of the material from dust and dirt is the key to the accuracy and durability of the seam service.

Cutting the material with your own hands, you must make sure that the edges of the panels are smooth. No matter how powerful solvent is glue, ideally it will be impossible to weld non-ideal edges with its help. In addition, in the final alignment of two pieces of linoleum, due attention should be paid to matching the pattern of the coating, if any.

Step-by-step instruction

The most important guarantee of a truly successful installation of flooring joints is the exact observance of step-by-step instructions.

Weld formation

In order to properly form the future seam, first of all it is necessary to get absolutely smooth edges of the panels. To achieve this without additional effort allows the simultaneous cutting of two pieces superimposed on each other. The edges are put overlap, in order to avoid damage to the floor under them plywood is enclosed. Further, to prevent uneven cutting due to trapped dust between dirt and dirt, the edges of linoleum are thoroughly cleaned with a damp soft cloth and dried. Having leveled the sheets, they are cut with a stationery knife along the line of preliminary marking, applied with a long ruler and a pencil. When juxtaposing pieces of material, one should strive to make the joining as tight as possible, so that the width of the future seam is kept to a minimum. Now you can proceed to the next stage.

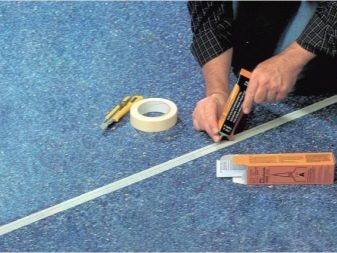

Surface preparation

To protect the rest of the linoleum surface from glue, a wide masking tape should be applied along the entire length of the joint. Next, the tape is cut with a sharp knife along the entire length of the future seam.Another option is to protect the linoleum from accidental ingress of the adhesive: an adhesive tape is attached to the edges of each of the panels separately. After completion of the work on the protection of the coating, it is set to fixing it relative to the floor (this can be done with mastic, glue or double-sided tape). After that, it is recommended to iron the fixed surface with a narrow roller and wipe it again with a damp cloth, not forgetting to leave time to dry the cleaned places.

Before applying the glue, some experts recommend heating the joint, and this can be done by ironing the seam with an iron through a metal plate, but this stage of installation is not strictly necessary and remains the choice of the artist.

Adhesive application

To prepare for the glue application stage, it is necessary to shake up the tube and clean its tip, which is then gently inserted into the gap between the sheets. Glue should be fed gradually, gently and without haste, pressing on the tube, holding it with one hand and the needle itself with the other. As soon as the flow of glue manifested itself, the spout of the tube begins to gently lead strictly along the junction, while the glue strip must be at least 3-5 mm wide. Only then will welding completely fill the gap and thoroughly dissolve the edges of the webs.There is another method of applying glue to the canvas: first, the edge of one piece is coated with glue, then it is attached directly to the floor, and the same operation is repeated for the second cut of material, after which the two sheets are shifted as closely as possible to each other and flattened with a roller.

Finishing work

2 hours after applying the adhesive, remove the masking tape at an acute angle and remove the protruding adhesive residue with a scraper. It is important to remember that it is recommended to do this after the fixer has hardened; it is simpler and more accurate than carrying out the cleaning work on the fully dried out seam.

What to look for?

As with any repair work, with your own hands, when installing the joints of linoleum, you should carefully consider the installed SNiPs. First of all, it is necessary to remember about safety and to protect hands and respiratory organs from evaporation of toxic elements of glue.

Gloves and a respirator should be worn all the time.

You should also familiarize yourself with the instructions for use of a particular adhesive and follow its instructions step by step. In addition, to achieve maximum neatness and tidiness of the joint, carry out final cleaningwork is recommended in several passes, as the tension of the seam, which occurs during the removal of excess, can lead to the formation of recesses in the joint.

Compliance with these rules and simple step-by-step instructions for working with cold welding of any type will make it easy to install the joints of linoleum and enjoy the quality result for many years.

Examples and options

This photo shows the result of splicing the joints of linoleum by cold welding of type A.

Here is the final type of linoleum with several joints obtained by cold welding.

Type C welding is suitable for repairing detached edges.

From this video you will learn in more detail about laying linoleum.