What to lay linoleum: the choice of the base

Linoleum is an affordable and versatile floor covering. Before repair, the question always arises - what to lay under the linoleum, how to prepare the basis for laying the linoleum coating. To understand this, you need to get acquainted with the characteristics and features of floor covering.

Coverage Features

Everyone wants to make their home cozy and comfortable. Each room of the apartment or house is responsible for its purpose and method of use. Therefore, for the room you need to choose the floor covering that meets its purpose. Popular floor coverings - linoleum and carpet.

In the bedroom and living room, when you want softness, comfort, warm atmosphere, you should think about the carpet. It is distinguished by comfort and convenience.The carpet is like a carpet or carpet, only geographically occupies the entire area of the room. The main feature of the carpet is its domestic and hygienic disadvantages. It needs careful care and cleaning in order not to become a breeding ground for bacteria, fungus, dirt, and mites.

Linoleum has long been a favorite way to cover the floor. He received his recognition for his positive qualities: durability, ease of maintenance, speed of installation, moisture resistance, variety in the choice of colors and patterns. High-quality and wear-resistant types of linoleum can replace tile, laminate, parquet. It is laid in kitchens, hallways and other areas where fast floor cleaning is needed.

The main disadvantage of this coating is a synthetic material and a feeling of cold comes from it. With the last minus you can handle with the help of the substrate.

Abrasion resistance is an important point in the selection of linoleum. There are household, semi-commercial and technical types. In the home environment used household and semi-commercial linoleum

Linoleum is divided into: baseless, foamed, warm base. The warm thick base of felt or jute has shock-absorbing and heat-insulating properties, does not need an additional substrate.A thin product will highlight all the features of the floor, in which case the lining is necessary.

Functions

Laying under the linoleum is used to mask minor irregularities, dents, cracks of the genital base. If the surface is a little uneven, and there is no time and opportunity to level the floor, then the substrate will be a suitable way to solve the problem. If you spread the gasket, it will help to visually make the floor even, especially with thin linoleum.

In apartment buildings, there is often a problem with the isolation of sounds and noise. If you lay another layer of sound insulating lining between the two bases, the audibility will decrease.

To protect the external coating from dampness, cold of the concrete screed and unheated lower-level rooms, they enclose an insulating mat. She will cope with humidity and will keep heat in the room. The substrate serves to protect the linoleum from premature wear.

Types of substrates

The market offers diverse types of substrates. It is quite difficult to choose for a non-professional what type is suitable in his repair. Consider what they put under the floor base:

- Jute.Natural textile material made from fibers of bast jute. The fibers are treated with fire retardant to give the material its protective properties against water and fire. Jute is able to absorb excess moisture without decomposing, and after drying there is no smell of damp.

- Bung. Cork lining is made from oak bark. The bark is crushed, pressed under pressure. It is produced in the form of rolls with a thickness of 2-4 mm and sheets up to 1 cm. It is a completely natural material, bactericidal and environmentally friendly. The cork floor will be soft and warm.

- Linen. Linen lining is composed of flax fibers. Flax is similar in its characteristics with jute. An important property of flax is the ventilation between the base and the top cover. This will help eliminate the putrefactive processes, the multiplication of bacteria and fungi.

- The combination of natural materials. A mixture of natural fibers of flax, jute and wool will provide climatic comfort in the room. Available in rolls and has a high density.

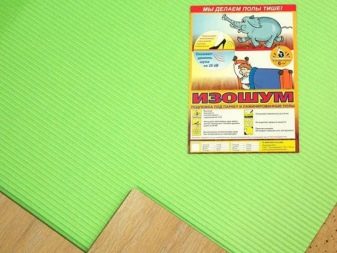

- Akufleks - a synthetic nonwoven cloth in the form of rolls. Akuflex is used as a high-performance sound absorber and impact noise.The material allows air to circulate, which prevents an increase in humidity.

- Infrared floor. Infrared radiation comes from carbon heaters, is an excellent way to quickly heat a room. Heated floor will make a comfortable and safe atmosphere in the house. Let out rod and film types of infrared systems. Film floors are easy to install, do not make a coupler, and immediately spread out linoleum.

We consider some substrates in more detail.

Foam backing

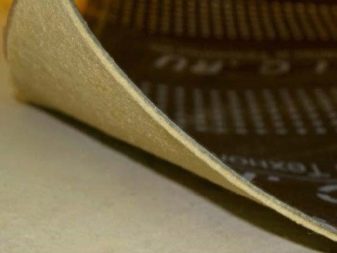

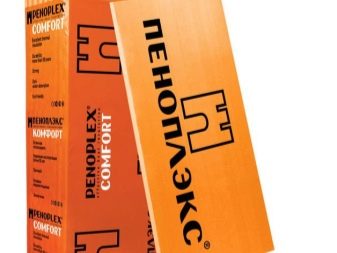

It includes a whole group of synthetic linings: penofol, extruded polystyrene, izolon, expanded polyethylene, penoizol, expanded polystyrene. Penofol is made from foil and polystyrene or isolon. Foil product gives increased heat-reflecting qualities.

Company "Penoplex" produces extruded polystyrene foam. It has high water-repellent hydrophobic and insulating properties. Laying foam under the soft surface has a significant disadvantage - the furniture will push the material, the floor will be shaky.

Foam artificial pads moisture-proof, durable, absorb sounds. Weighty minus - it is lined, which leads to deformationafter some time loses its function. The disadvantages of the polymer lining can be eliminated by laying the product, not exceeding 2 mm in thickness. The service life of the foam substrate depends on the intensity of floor wear.

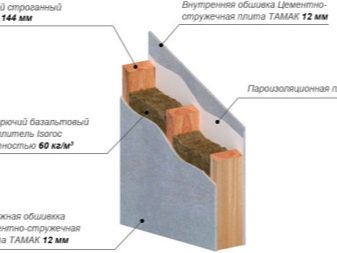

Wood chip products

This group of products includes: chipboard, fiberboard, OSB, plywood. Available in the form of plates of different sizes. The main advantages are affordability, quality, fast leveling of large areas. The presence of moisture in the operation of wood products leads to swelling and destruction of the plates.

The wood-shaving plate is made from waste of the woodworking industry. Sawdust, chips, chips are pressed with resins under the influence of pressure and temperature. A popular method of plasterboard flooring causes its affordability and ease of processing. Cons chipboard - crumbles when re-screwing screws, it consists of toxic synthetic resin.

Hardboard is a high-strength fiberboard. Fiberboard used for lining the floor, have high moisture resistance.Hardboard is often used for leveling, because it is affordable, versatile, easy to style. But the thickness of the plate imposes restrictions for use on an unprepared base.

Oriented strand board consists of three to four layers of pressed long shavings with synthetic resins. The strength of the plates gives multidirectional laying layers. Ease of processing and installation of OSB allows you to sheathe the floor with ease.

Plywood is a glued plate of wood veneer. The number of layers of veneer (from 3 pieces to 23) gives the product a different thickness and strength.

Plywood is often used when laying floors, because it is durable, lightweight, inexpensive, dimensional-stable. But the plywood flooring should be protected from water.

Cement particle board and gypsum fiber sheet

A separate kind of chip sheets are DSP and GVL.

Cement-bonded chipboards consist of wood shavings and a special cement mortar. DSP is resistant to fire, humidity, temperature extremes, there are no harmful substances to human health in the composition. The difficulty of installation causes a large weight of the plates and low strength during deformation.

Gypsum fiber sheet is a mixture of cellulose waste paper and gypsum. GVL is an improved analogue of drywall. Drywall is fragile, but the wood base gives gypsum-fiber sheet strength. It is a warm, harmless material, fireproof, maintains comfortable humidity in the room.

How to choose by type of floor?

Linoleum is an unpretentious and versatile material, it can be laid on different types of floor. But the basis for linoleum must meet a number of signs - the surface must be strong, even, clean and dry. Compliance with these conditions will extend the life of the substrate and linoleum.

The time for preparation of the foundation and the scope of work depend on the quality of the initial basic framework. According to reviews of repair professionals, a concrete base for linoleum is the most preferred.

Consider the types of floors on which the substrate and linoleum are laid. Determine which substrate is better suited to a different sex base:

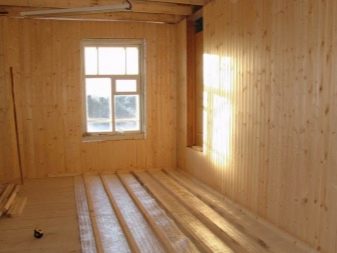

- Wooden. Wood flooring is often covered with linoleum. Pre-assess the status of floorboards, their deflection, squeaky floorboards additionally fixed.Laying from natural raw materials - jute, linseed, combined, cork - would be ideal for an even and dry wooden floor. If the boards are rotten and there are traces of mold, it is necessary to replace part of the floorboards and treat them with an antiseptic. In this case, use acuflex for better ventilation. IR thermofilm can be put to get rid of moisture and better warm up. When choosing a litter, a detailed inspection is conducted on the subject of chipping, potholes and crevices. If there are significant irregularities and defects in the boardwalk, where sanding and puttying on wood will not help, sheets of hardboard, chipboard, plywood, gypsum fiber board, OSB are used.

If the base of the floor is a parquet of the type of paving, it is better to lay over the sheet types of the substrate for the preservation of linoleum.

- Concrete. A smooth concrete floor will be an excellent base for linoleum with a base. It is better to lay baseless linoleum on foil-coated penofol or cork substrate. Large elevation differences, pits are aligned with cement screed or cement-bonded chipboard. It is necessary to fill the floor with concrete and let it dry. Long-term drying is necessary, since any floor covering should not be laid on wet concrete.As a substrate for concrete, foamed polymeric gaskets, jute, cork, and aqulex are optimal.

- Bulk. Self-leveling floors are a flat, smooth surface without joints, so they are ideal for laying linoleum. The minimum thickness of the self-leveling floor is 1.5 mm, the maximum is 0.5 cm, so it dries quickly, unlike cement screed. Bulk floor is used only on a solid concrete base. As a basis for linoleum using polyurethane mixtures.

- Tile. Do not dismantle old ceramic tile, as it can be a good basis for linoleum. Check the strength of tile laying and the presence of cracked seams. Chips and fallen pieces of tiles are sealed with a leveling compound, the joints are rubbed to evenness. The substrate can serve flax, a combined material, akuflex.

- Infrared. Infrared floor heating system can be put on any basis. It is necessary to mount the heating floor on a foil-reflecting heat substrate. IR film floors spread on the surface, then roll the linoleum.

Features of laying different materials

The peculiarity of the installation of various products is the requirement for the base. For all types of materials when laying should be kept clean and dry in the room. It is necessary to free the room from furniture, to dismantle the baseboards.

The wooden base should be treated with a primer with an antiseptic, visible damage to the boards and seams are puttyed with wood putty. Then stack the selected type of substrate. The rolled lining from natural raw materials is fixed with staples of a construction stapler.

If you decide to lay sheets of chipboard, OSB or plywood, you must calculate the necessary material. Then the frame is assembled. Lags are attached to the floor with screws and screws. Plates are laid so that the joints are staggered. Sheets are screwed with screws to the frame.

Installation of hardboard fiberboard orgalita is made with screws on wood or nails without mounting the frame.

Cork litter requires an even base, therefore, primary leveling of the flooring is carried out. Cork rolls should lie in the apartment for a couple of days in order for the substrate temperature and humidity to even out.

Cork does not require an additional waterproofing layer if it is placed on a wooden base.

Waterproofing should be laid on the concrete screed (usually polyethylene is placed) when there is an unheated basement at the bottom of the room. Then the rolled cork substrate is rolled out, the strips between themselves are fixed with construction tape. To prevent damage to the cork, installation and subsequent installation of linoleum is done carefully, with care.

The concrete base is leveled with a cement screed or with a self-leveling floor (with slight differences in height). Before applying the sand-cement mortar surface is treated with a primer. How long the screed dries depends on the ambient temperature and humidity, in the warm season it is necessary to air the room more often. Laying the substrate is after complete drying of the floor.

Penofol spread foil up, the joints between the rows are sealed with foil tape.

Installation of a rod-type IR floor is too labor-intensive to install, so it is easier to choose a film version of a heated floor. You should not place a thermal film under the furniture, because infrared radiation heats the surrounding objects. Thermo-reflective litter unfolds, attached with scotch tape.Then the IR film is spread, connected to the scheme with clips and the wiring is connected to the thermostat and the temperature sensor. Grounding can be done for floors.

Linoleum should be allowed to rest and straighten up before laying, no matter what type of substrate is used.

Advantages and disadvantages

The choice of lining material is determined by its characteristics, pros and cons during use. We define the main strengths and weaknesses of each type of lining under linoleum.

|

View of the |

Benefits | disadvantages |

|---|---|---|

| Jute |

|

high price |

| Bung |

|

|

| Linen |

|

softness |

| The combination of natural materials |

|

|

| Foamed Polymer Substrates |

|

|

| Chipboard materials |

inexpensive products. |

|

| DSP and GVL |

|

installation features |

| Akuflek |

|

|

| Infrared film substrate | additional heat source |

|

Next, watch the video on how to independently lay the roll substrate on the floor of concrete.