How to glue the linoleum?

Linoleum is often used as a floor covering in residential premises. High-quality installation can be done independently. To do this, you need to know how to properly glue the linoleum and what glue to choose for this.

Advantages of the method

There are three ways of laying linoleum:

- Gluing on special adhesive compositions;

- The flooring without rigid fixation, the material is pressed only by the baseboards around the perimeter;

- Partial temporary fixation on adhesive double-sided construction adhesive tape.

Fixing on glue is recommended by manufacturers of linoleum coatings, if the room is more than 20 square meters. It must be remembered that the manufacturer gives a guarantee only for glued material.

Linoleum must be glued when heavy furniture is standing and often moving in the room. So you can prevent the deformation and damage.Sticking minimizes wear and tear, the floor will last 40% longer.

In the offseason, linoleum is subject to compression and stretching when the temperature and humidity drops. This can be avoided if the linoleum is properly secured with glue.

Apply glue to the edges, in the doorway and the junction of the canvases especially carefully. It is in these places that you need a strong connection.

Types of coverage

In order to choose a method for fixing a floor product to the floor, one must resort to its categorization.

According to the material of manufacture, there are two main groups of linoleum: natural and artificial. Natural linoleum is made from natural raw materials and is considered environmentally friendly and safe. It is fire resistant, anti-static, wear-resistant, easy to maintain. Its disadvantage is low plasticity, in connection with this there are difficulties during transportation and installation.

Artificial linoleum may consist of polyvinyl chloride, nitrocellulose, rubber, alkyd resins. PVC coating has received the most common use in the repair.

According to the degree of wear resistance, the following types are distinguished:

- Household;

- Specialized;

- Semi-commercial;

- Technical.

Semi-commercial and household linoleums are laid in residential premises. Technical linoleum has a high wear resistance and is used in rooms with high traffic.

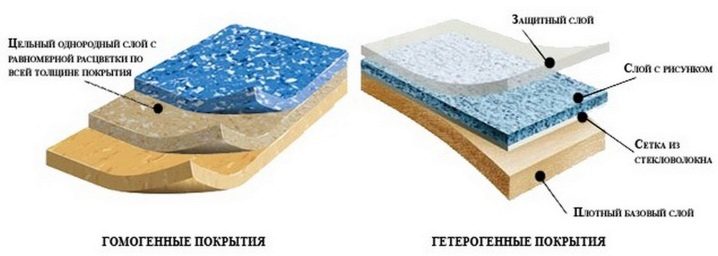

The structure of linoleum can be:

- Homogeneous. This is a solid material throughout the structure.

- Heterogeneous. The product has several different layers - a protective layer, base, insulation, substrate.

In linoleum, there are different bases:

- Without a base, this thin product requires a high degree of flatness of the subfloor. It has moisture resistance and wear resistance.

- On foamed base - flexible polystyrene foam, suitable for laying in rooms with high humidity, thickness - about 3 mm.

- On a fabric basis - consists of a jute or felt substrate and the top PVC layer. The total thickness is 5 mm, has thermal insulation properties.

It will be optimal if you choose a suitable adhesive mixture with the vinyl when purchasing.

What to stick?

The question of how to glue the linoleum is considered separately in each individual case.

The choice of fixation method depends on:

- the number of canvases;

- sexual base;

- types of linoleum and its foundations;

- pass load level;

- temperature and humidity in the room.

A temporary method of fixing linoleum - on double-sided tape. One of the advantages can be noted quick installation - glue the strip of linoleum on the floor, remove the protective layer and press the linoleum. Minus - after the time the adhesive layer of the adhesive tape dries out, the adhesion ceases to be reliable. Construction tape can mount a flooring up to two years.

A universal method of attaching linoleum - on liquid nails. This adhesive is suitable for any materials and surfaces, forms a fairly durable layer. Gluing on liquid nails is advisable to point to small areas.

On the glue "Moment" you can glue the edge of the linoleum coating. It is also suitable for gluing Relin (elastic coating containing rubber).

For gluing the flooring on the old linoleum or tile used universal contact adhesive brand KS. In the composition it contains silicates, mineral additives, which give the glue frost-resistant, fire-resistant properties. The adhesive has a high adhesion property with smooth surfaces with low adhesion.

Fixing on a special glue is the most reliable way of fixing.

Under a certain type of linoleum fit different adhesive compositions. There are three groups of adhesives:

Water dispersion

Dispersion adhesives are well recommended for gluing household linoleum, as they are easy to use, without a strong smell, they dry quickly. The composition contains water, latex, carboxymethyl cellulose, acrylic, chalk, polymers and various additives. Dispersion adhesives are ideal for the base of wood and concrete. It is important to ensure that the glue is not frozen because it will lose its properties.

The main types of water-dispersion mixtures:

- Acrylate is used for gluing baseless linoleum, on fabric and PVC base. It is viscous in composition because it contains latex, CMC, chalk. Popular acrylate adhesives - PVA, polynom;

- Bustilat is suitable for linoleum with a warm wool felt base;

- Gumilaks choose when fixing natural linoleum, because it has a minimum moisture content. It consists of natural components - latex and rubber.

Mastic

Mastics are used for strong adhesion of artificial types of linoleum with a concrete base.

They are divided into:

- Dispersion mastic glues linoleums with a warm fleecy base;

- Bituminous mastic is used to fix linoleum on a fabric basis;

- Rubber mastic is a universal adhesive for baseless linoleum on any basis.

Mastic firmly fixes the base and hides minor defects due to the thickness of the layer. It also acts as a waterproofing layer. Mastic is used for sizing with a large area.

Reactive polymeric compositions

The reaction adhesive chemically reacts with the coating, which ensures the strength of the joint. The reaction compounds are toxic, fire hazardous, have a strong odor. It is used to connect technical types of linoleum, because the adhesive layer is durable, moisture resistant, able to withstand heavy loads.

In domestic conditions, reactive adhesives are used for cold welding of linoleum seams.

Reaction type adhesives are divided into:

- Type A glue is produced for docking new linoleum;

- Type C glue the old deformed joints up to 5 mm thick;

- Type T is used by professionals for polyester linoleum.

Drying glue seam type A in 15 minutes, type C in 30 minutes.

Mounting methods

Linoleum is a soft and flexible material.When it is glued, there are certain requirements for the basis of the floor.

It should be:

- Durable. Chipped pieces of concrete or unfortified, squeaky wooden flooring should not be present.

- Dry. Wet base will not allow high-quality glue coating.

- Flat. All drops and nervousness will be printed on the laid floor material.

- Clean. If dust and debris remain under the linoleum, the floor will not be even in this place. Additionally, it is desirable to degrease the surface.

PVC product can be laid on any base, if it meets the basic characteristics. During the gluing of the flooring, the temperature of the air should be above 18 degrees, and the humidity should be below 70%.

When repairs are carried out in the winter, the linoleum roll must adapt to the room temperature for several days.

It is necessary to spread the roll in advance so that the coating straightens out, the creases and bends along the edges disappear. The duration of exposure in a warm room - 2-5 days.

After straightening the cloth, the product is fitted to the floor surface. On the edge of the wall, cut off the excess with a sharp knife or scissors, leaving a gap of 1 cm.If the laying involves more than one web, then you need to combine the drawing, and at the junction to make the minimum gap.

On concrete

Concrete basement is checked for irregularities, pits and holes, measure the level of surface differences. If there are small single irregularities, they are rubbed with a cement mixture or putty, allowed to dry. In case of significant defects, the floor will have to be poured with a cement screed, drying may take a long time depending on the layer, ambient temperature and humidity level in the room.

When there is no time to wait for the concrete base to dry, level the floor with a liquid mixture. Under linoleum use polyurethane mixture. The fill thickness of the self-leveling floor is less than 1 cm, it dries quickly and after two hours it hardens. In 24 hours, PVC coating can be laid on the self-leveling floor.

After drying, the concrete is primed, if necessary, cleaned of dust and debris. Primer improves grip. Laid out the canvas, give rest.

Mastic has an ideal adhesion property to concrete. To apply the mastic, the edge of the canvas is folded over, a uniform layer is applied to the concrete with a spatula.Then the cloth tightly pressed to the concrete, smooth, expelling air from the middle to the edge of the room. Repeat the application of mastic for the other side of the canvas. At the end, conduct sealing of the joints.

On wooden floor

The wooden base is tested for strength and evenness. Fix the fragile, creaking floorboards and check the level of differences on the plane. There should be no paint on the boards, as a chemical reaction may occur with the components of the adhesive. Afterwards, stains will appear on the laid canvas. Remove the old paint can be a grinder or a tool that corrodes the paintwork.

If all the parameters meet the desired characteristics, then make the layout and tracking of the linoleum, its fit.

Water-dispersion adhesives are suitable for gluing linoleum to wood. The cloth is folded over, the glue is spread over the entire surface with a spatula. Linoleum is laid and carefully rolled down so that there is no air left under the coating. Similar work is carried out on the remaining floor surface.

When the floorboards are uneven, the floor must be leveled with wood chip material.For this purpose, chipboard, oriented strand board is used. The best material for leveling the floor is plywood. It is thinner, more moisture resistant, does not crumble during installation.

The plates are fastened with screws to the wooden floor. The cap of the screw must be drowned in the material so that it does not protrude above the surface. All the joints between the sheets are filled with wood putty, after drying they are sanded.

If the roughness of the wooden planks is insignificant, then you can put cheap sheets of hardboard. But in rooms with high humidity it is not recommended to lay linoleum on fiberboard. It tends to form waves and defects due to low moisture resistance. Laying on a hardboard is possible - a more moisture-proof analogue of fiberboard.

Glue the flooring on the chipboard and OSB should be glue to the COP, bustilatom, PVA and other specialized adhesives based on water. Gluing on plywood corresponds to the technology of laying on wood.

When wood paneling is over, you can proceed to laying and gluing the flooring. Installation takes place in the same manner and technology, as with a wooden floor.

On the old coating

New flooring can be glued to the old linoleum. This method is convenient because it does not need additional preparation of the base. Old linoleum serves as an additional heat and sound insulation substrate.

When the base is flat and durable, the surface is simply cleaned of debris and dirt. In case of small defects, they should be eliminated - glue air bubbles, joints, edges, cracks and seal up with sealant. To improve grip, the old base can be sanded and impregnated with a primer.

The gluing technology is standard - dispersion glue with good adhesion or contact glue is applied on the floor with a notched trowel with a layer of 2 mm, the cloth is pressed, rolled. Then everything repeats for the other side of the room.

When the old floor base in poor condition, cracked, its fastening was carried out with nails, then it must be dismantled. If you want to glue the linoleum to the metal, then you should use liquid nails or contact glue.

How to glue the edge?

Appearance of a covering can spoil badly glued edges and seams of joints. Bustilate is used for sutures.Even if the busilate gets on the front side, it will not spoil the coating, as the composition is transparent and not noticeable.

To glue the edge of linoleum, you need to bend it back, apply bustilat on the floor. We press the edge so that there are no air bubbles from below. It is advisable to leave the load on top before drying. Then you need to attach a plinth or a threshold bar.

For fixing the joints used reaction types of adhesive joints - they differ from the main adhesive composition. Cold welding seals seam. One tube lasts up to 20 meters.

The technology is simple - a masking tape is attached to the joint, it is cut through the seam, the glue is squeezed out by the nozzle along the entire joint. After hardening, the strip of tape with the remaining liquid is removed.

Professional Tips

Manufacturers of PVC coatings recommend applying an adhesive layer over the entire area of the room. In practice, in small rooms, it is enough to glue the linoleum near the threshold or fix it with a strap. In living rooms with a small cross-country capacity and an area of less than 10 square meters, repairmen advise to use construction double-sided tape to fasten the covering with the base.

If laying the flooring is done independently, then it is not necessary to cover with a glue a large area immediately. Repairmen advise to glue it gradually, in small volumes, carefully pressing the canvas to the floor.

Professionals do not advise laying linoleum directly on the cement screed, since concrete is a cold material and it will not be comfortable in the room with such a floor. For heat you have to put carpet on top. Ideally, an additional floor heating system is installed in the concrete. Another option for thermal insulation of the screed is to lay plywood or OSB slabs with a waterproofing layer on top.

When easy disassembly and access to communications under the floor are important, it is not necessary to glue PVC material during the repair. There are special fixing fluids that have good stickiness. If necessary, the floor covering can be quickly removed.

For detailed instructions on how to lay linoleum on your own, see the video: