How to lay linoleum on plywood?

Linoleum is often chosen as a floor covering, because it is an affordable, practical, moisture-resistant material, easy to clean. It can be laid on any type of base. Therefore, when laying linoleum, you must comply with certain requirements for the quality of the subfloor.

Special features

This elastic and flexible material can be selected for different styles of interior, since there is the presence of various colors, patterns and textures.

Linoleum is placed on almost any type of floor. In this case, the complexity of laying is only on an uneven basis.

For quality work, the base should be:

- Clean. It is necessary to remove all the garbage, vacuum;

- Durable. All unreliable structures are not suitable for flooring;

- Dry.Moisture will not allow high-quality fix PVC product;

- Flat. When the floor has irregularities and other defects, soft material will show all the shortcomings of the sexual base.

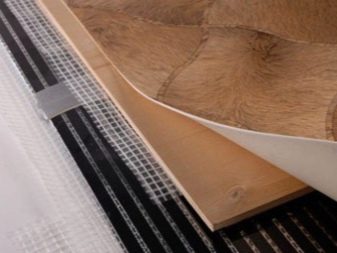

To eliminate irregularities surface sheathe sheets of plywood. The use of plywood is justified by the speed and ease of installation, its good characteristics as a substrate under the floor covering.

To put linoleum on plywood, you need to observe all the steps and subtleties of the flooring. Only in this case you can get a smooth, durable, wear-resistant coating.

Floor types

Concrete and wood are used for the construction of the sexual base: the floor is concrete and wooden.

Rough concrete floor is in any apartment in a brick or panel house. Reinforced concrete slabs serve as interfloor overlappings. They do not have a perfect flat surface, so they make a cement-sand screed on top. Also, the concrete screed produced on the ground in the basement of houses, garages.

Reinforcement is used to prevent the screed from cracking when the layer is thick.

Typically, the composition of the solution include cement, sand, water, plasticizers in different proportions.

Advantages of a concrete floor:

- strength;

- durability;

- tightness;

- fire resistance;

- low cost;

- versatility.

The disadvantages of such floors include:

- high noise conductivity;

- low heat capacity;

- hardness, not flexibility;

- sand cement screed dries long.

Often in private homes you can find a wooden floor, if difficulties arise in the installation, cost and delivery of reinforced concrete floor slabs. The wooden floor is mounted from wooden boards and beams of various sections. The wood should be smooth, flat, well dried. The flooring of the floorboards is carried out on the logs or beams of the floor.

Wood flooring is different:

- durability;

- frost resistance;

- ecological clean;

- thermal insulation qualities;

- heat capacity;

- natural aesthetic appeal.

Wood is afraid of water, because of this, compression and expansion of wooden flooring can occur. To combat the humidity of the board covered with a special moisture-proof compounds. Another disadvantage is low fire resistance. The tree burns well and supports fire. Therefore, it is imperative that all components of the wooden floor are treated with flame retardant impregnations.Compared with concrete screed, wood flooring is more expensive in cost.

The construction of the wooden floor is held on the ceiling beams, to which the logs are attached, and floorboards are mounted to them.

In the space between the floor and lags, you can put a vapor barrier and insulation.

What plywood is better to lay?

Wood chip products will help to make a quality substrate under the floor covering. This sheets OSB, particleboard, fiberboard and plywood. To choose the best option for flooring on a subfloor, you need to know the strengths and weaknesses of the materials.

Fiberboard does not have the required thickness, therefore, will not perform the leveling function.

The sheet of a chipboard, in comparison with plywood, possesses the worst moisture protective qualities. Plate OSB consists of compressed chips, which protrude and stand out, making the surface not perfectly flat. A sheet of plywood consists of glued strips of wood veneer. Thickness depends on the number of veneer layers. It has a smooth surface and bending resistance.

Plywood is considered the best substrate for an elastic material, because it has the following characteristics:

- acceptable price;

- possesses high covering abilities;

- durable, wear-resistant;

- evenly distributes the load on the floor;

- good sound absorbing properties;

- thermal insulation properties.

It is necessary to take into account the disadvantages of plywood and try to minimize them during the installation phase. Sheet of plywood exhibits its water-absorbing properties upon contact with water, as a result, it leads to the deformation of the coating and the appearance of mold.

Since plywood is a wood material, it also burns well, like wood. Another disadvantage - is subject to expansion and contraction, depending on the temperature and humidity in the room.

To avoid deformation from the penetration of moisture into the material, apply a moisture-resistant brand of plywood. Pre-assembly treatment with antipyretic agents will help reduce the flammability of the material. The change in the size of the plywood sheet must be taken into account during installation. When laying the plywood on the floor, it is necessary to leave compensating gaps between the sheets and between the wall.

When choosing plywood are guided by its thickness and moisture resistance.

In residential areas, you can put the usual birch plywood brand FC, and in the kitchen you will need moisture resistant. Depending on the load, choose plywood with a thickness of 12-16 mm. It is laid on a concrete or wooden floor.If plywood is supposed to be laid on logs, then the thickness is needed 18-20 mm.

With a plywood backing, linoleum will last longer because it meets all the requirements for a flexible flooring material.

Surface leveling

Plywood is laid for leveling on a concrete and wooden base.

Leveling the concrete base with plywood will save time and effort compared to screed. Before leveling, you need to estimate the level of height differences using a level or rule. In a wet room lay a layer of waterproofing. On concrete, plywood is either glued to the floor, or fixed with anchor bolts and nuts.

When gluing produce a primary full layout of plywood sheets throughout the area of the room. For ease of installation, a large panel is cut into 4 parts. Then make the adjustment, not forgetting about the compensation gaps of 1 cm. The placement of the sheets is carried out in such a way that there is no contact of the four corners at once.

The layout should be numbered so that there is no confusion.

All plywood is removed and the concrete is primed for better grip. After drying, proceed to gluing.Gradually, a small layer of spatula put a layer of bitumen mastic or universal polyurethane glue, put sheets of plywood on it in accordance with the scheme.

For better fixation, additionally fix dowels at the edges in 5-6 places. Dowels need to drown in the material, and cover the grooves with putty for wooden structures.

The glue-free fixation method involves drilling holes in the concrete for anchor bolts in accordance with the layout scheme.

This method is used when there are large differences on the surface, but there is no time to make a cement screed. It allows you to adjust the level of plywood sheets, thus leveling the rough concrete floor.

Up to 16 anchor bolts, but not less than 9 per 1 square meter, are spent on a sheet of plywood of various sizes. An anchor is installed in the hole in the concrete, a bolt with a washer and a nut is screwed into it. A sheet of plywood is placed in the drilled holes above the washers. By means of nuts it is regulated on level strictly horizontally. By the same technology fit the remaining sheets.

Before plywood is laid on the plank floor, it is tested for strength and evenness.Assess the condition of the boards, replace the rotted floorboards with traces of mold. In addition, they fix fragile and creaking boards with nails or screws of 5-7 cm. Nails must pass through the board and be fixed in the lag holding the floorboard. All sticking nails must be drowned in the floor so as not to stick out. All protrusions and knots are hewn with a plane or grinder.

There are two ways of laying plywood base - without the use of lag and lags. Without lag, plywood is laid out directly on a wooden base. In advance, plywood sheets are cut into 2-4 pieces so that there is no deformation when the humidity changes. Plywood parts are stacked in a staggered manner with an offset, not forgetting about a gap of 0.2-0.5 cm between the sheets and between the wall of 1-1.5 cm.

With the help of a screwdriver, screws are screwed at a distance of 25 cm. Screws are taken on a tree, 3-4 cm in size. They need to be deepened so that they do not protrude above the surface and tear the soft material. These grooves must be putty putty on wood.

When the height of the ceilings allows the use of logs and the wooden base is too uneven, they make laying of wooden beams.For logs, they take a bar of 50 by 70 mm in size, making the distance between them at 40-60 cm. Check that all the logs are at the same level and fix them to the boards.

It is desirable to process all wooden parts with glue so that over time the floors do not creak.

The thickness of the plywood sheet should be 18 mm, it depends on the distance between the lags - the bigger it is, the thicker the sheet.

When laying plywood need to ensure that the edge of the sheet was located on the log.

Sheets are fixed with screws, deepening by 2 mm, then putty. At the end of all works, plywood floor is covered with fire and moisture-proof composition.

How to lay?

Plywood substrate prepared, and you can lay linoleum. The entire surface must be cleaned of dust and debris. Only then roll into the room. If the repair takes place in the winter, the roll is kept in a warm room for 1-2 days, so that the temperature and humidity of the material will be equal to the environment.

PVC product spread out over the entire surface as it will fit, give it a bed for 2-3 days.

It is necessary that the canvas straightened, all dents and creases disappeared.

After the web is straightened and set loose, it is adjusted.One edge of the product is aligned with a straight wall. The remaining edges of the linoleum are fitted and trimmed along the walls, leaving a gap of 1 cm. If there are obstacles in the form of pipes, then they need to be accurately measured and determined where to make the cut. Prepare a template hole on cardboard or paper, which is transferred to the canvas and neatly cut.

When it is necessary to lay two canvases and more, it is necessary to combine the drawing and process the joints.

To make the joints with a minimum, imperceptible gap, two canvases overlap each other by 2-3 cm. Then two layers are cut at once, using a sharp knife and a rule, or an iron ruler. The joints must be fixed to the base, otherwise you will not avoid bent edges

Laying linoleum is a simple matter; you can put it by hand without the help of professionals. If the linoleum is not fixed, then proceed to the mounting plinths.

How can I fix?

If you attach the linoleum to the sexual base, it will last 40% longer, and the wear rate will decrease.

Fixing to plywood is necessary in such cases:

- the area of the room is more than 20 square meters;

- heavy furniture will move around the room;

- laid more than one canvas.

Linoleum can be glued and fixed with double-sided construction tape. In a room of less than 10 square meters, fixing on double-sided tape along the perimeter and in the doorway is recommended. In other cases, apply the adhesive method.

Gluing to plywood is carried out by different types of glue, depending on the type of linoleum and its base.

Water-based adhesive compositions - water dispersion adhesives are suitable for plywood.

Glue Humilux is used for bonding natural linoleum, because it contains natural components - rubber and latex. It is possible to glue PVC a product on a warm felt basis with glue of bustilat. Baseless linoleum, on the fabric and PVC-based glues on acrylate adhesives.

Clay selected, now proceed to gluing. Half of the canvas is rolled into a roll, glue is applied to the plywood base with a notched trowel or roller, depending on the consistency of the mixture. Gradually roll the canvas, tightly pressing and rolling to the adhesive layer so that no air bubbles remain. Similarly, carry out work on the remaining surface.The glue dries during the day and you can proceed to the installation of baseboards and door sill.

After gluing the main fabric to the floor, proceed to sealing the joints. To do this, use the reaction adhesive type A.

Application technology is simple:

- masking tape is attached to the joint along the entire length;

- a tape is cut through the seam;

- using a needle nozzle squeeze the adhesive into the joint between the sheets;

- remove tape with residual adhesive liquid.

This method of cold welding will make the joint invisible and durable.

Successful examples and options

Plywood flooring is the ideal base for linoleum.

On large areas, the flooring is glued to plywood, so increase the durability and service life of the material.

Linoleum for the kitchen - the best solution for flooring. It is easy to clean, not afraid of water and you can pick up any color for the kitchen.

PVC products simply cut and laid in rooms with a complex configuration, a large number of thresholds.

For details on how to glue the linoleum on plywood, see the video.