Laying linoleum

In facing the floor is of great importance flooring material. Among the masses of varieties, such as laminate, parquet, parquet and ceramic tiles, linoleum occupies a special place. It is an alternative to all types of coatings, stands out favorably on their background, has a number of advantages and differences.

Laying linoleum is a separate topic, knowledge of which will allow floor covering to be carried out quickly and without visible defects.

The importance of the material

Laying linoleum depends on the type of material. If we approach the choice based solely on external data, during the operation of a floor covering it may turn out that it is not intended for this type of room and does not correspond to the permeability of a particular zone. The raw material has obvious differences due to the thickness, the protective layer, the substrate material, and external characteristics. It varies in service life, degree of practicality, resistance to moisture and frequent cleaning.

In addition, the material type is different: the premium nature of the texture is subordinated to the class, shade and a certain pattern.

Advantages and disadvantages

The choice of flooring is based on studying the characteristics of the material, which consist of strengths and weaknesses. This allows you to understand the degree of relevance of laying linoleum in this room and determine its service life.

Among the positive characteristics of linoleum are the following.

- Simple installation and versatility of use in different types of rooms (you can lay in the living room, kitchen, children's room, study, hallway, home library, toilet, bathroom, hallway);

- The variability of the width, so that you can simplify the lining of the floor and perform a seamless technology, lay a canvas with a solid sheet;

- A huge selection of colors for status materials, so that the look of the room at the end of the repair will be special, hinting at the welfare and fine taste of the owners of the house;

- Anti-static material structure and fire resistance, due to which it does not attract dust and is resistant to burning;

- Big service life at the due level of a protective layer (lasts for 10-15 years and more);

- Resistance to moisture, wear, pressing under heavy furniture;

- Good sound insulation properties, which allows to reduce the noise level of annoying extraneous sounds;

- Compatibility with the "warm floor" system and uniform distribution of warm air throughout the room, making it possible to step on the floor with your bare feet;

- Different price range, which allows you to put on the floor coverage, taking into account your own preferences and the planned budget for the purchase.

The unique property of linoleum is compatibility with different flooring finishes: it can be combined with ceramic tiles, parquet and parquet tiles, complemented with laminate, framed with porcelain stoneware. This way of installing the floor gives a lot of opportunities for design and allows you to beat the lack of space, zone the room, giving it an unobtrusive organization.

The combination involves the use of materials of up to three types of different color and texture, which is convenient, allows you to hide the defects of styling by means of powders and decorative plinth.

Minuses

Laying linoleum - a rational investment.However, with a lot of advantages, the material has several negative nuances.

- The cost per square meter of material increases with increasing thickness of the protective layer;

- Among the range presented in the sale, not all raw materials are natural: not all buyers are comfortable with synthetics;

- The greater the weight, the more difficult the transportation of the material and the greater the possibility of violating the integrity of the coating in the process of careless delivery;

- Depending on the quality and class, linoleum can dry out with constant temperature drops, which leads to a loss of elasticity of the material;

- Laying should be carried out as accurately as possible: non-compliance with the technology can cause waves to form on the floor surface.

Not every type of linoleum is easy to use: if you leave air under it, the coating may swell. If the area of the room is more than the maximum permissible width of the canvas, joints can not be avoided.

Joints - sore place styling. They are weak, exposed to moisture, so to extend the service life you need to take care of the flooring as carefully as possible: you can not fill it with water, it is important to immediately remove dirt from the surface until they become part of the pattern.

Types of linoleum

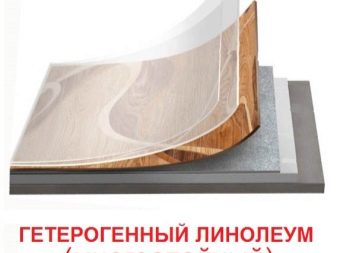

So that the work did not reveal negative moments, surprises, and the flooring was the best, it is important to know the types of linoleum, which are determined by its structure. Linoleum is a polymer-based finishing material, which often consists of polyvinyl chloride (PVC), has a dense structure and a porous base. It can be homogeneous, consisting of a single layer, or heterogeneous, multi-layered.

The first type combines all the layers into one, so it is dyed through and erased rather slowly. The second type allows you to clearly see the different layers, looking at the cut of linoleum from the side.

Each type is unique in its own way, allowing you to choose a decent material for floor covering. The only thing they are distinguished by a protective layer, which is more in heterogeneous varieties.

In addition to polyvinyl chloride linoleum, companies offer for sale other types of flooring, among which the following are in particular demand.

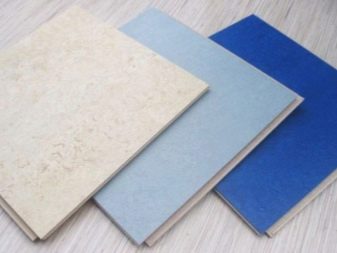

- Naturalmade from oxidized linseed oil, resins of deciduous trees, wood flour, limestone, jute and color pigments of natural origin (plain linoleum with a lifetime of up to 40 years, excellent bactericidal properties and practical qualities);

- Alkydwhich is characterized by a woven base, the presence of alkyd resins and various pigments in the composition (it is distinguished by a high level of sound and heat insulation as compared to linoleum from polyvinyl chloride, however it is fragile and subject to the formation of cracks);

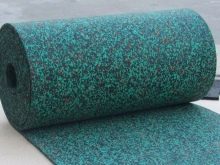

- Rubber, which is a product of rubber waste processing with the addition of a new rubber top layer (a material resistant to moisture, characterized by high elasticity).

By type of durability and purpose of linoleum is divided into three types.

- Domestic;

- Semi-commercial;

- Commercial.

What is the difference?

Household flooring - A cheap class of material that is faster than analogs is erased, it looks simpler, it has a smooth surface, and has no texture. His colors are more often stylistic, in the form of ornaments, they do not differ in premiumness and relief.

The material is suitable for areas with low permeability, eventually erasing in the most working areas of the canvas.

Semi-commerce better than domestic counterpart, stronger, more resistant to abrasion. It looks more expensive, has more solid colors for parquet, laminate, marble and tile.The coating is resistant to high weight loads and is intended for flooring in residential buildings, studios, salons, shops.

The material may have a smooth, relief surface, often has anti-slip and is designed for areas with medium and high traffic.

Commercial linoleum - premium flooring grade of this material. Its front side is practically the same as the semi-commercial counterpart. It is quite solid, can have anti-slip, anti-bacterial impregnation, often has natural components in its composition, which increases its cost.

This linoleum differs in price and weight, which depends on the protective film.

The model range of a floor covering can be added with different effect. In addition to protection against slipping and fire resistance, the cloths are treated with antistatic impregnation, performed with a 3D effect. The texture can be rough, resembling the structure of wood boards.

By type of base linoleum is a foam or felt base. This factor determines the need for a substrate. If linoleum has insulation, the substrate is not needed: the felt will perform the function of sound and heat insulation, and at the same time hide the unevenness of the floor.

Protection

Protection - the main difference between linoleum different classes.If the sellers in the store respond quite extensively, what is the difference, in reality everything is simple: household, semi-commercial and commercial linoleum have a different thickness of protective film located on top of the canvas (from the front). That it saves the surface from the loss of attractiveness of appearance and determines the different level of weight load on the surface of the canvas. To understand the difference, you should look at the linoleum side.

- In the domestic class, the film is almost invisible and is 0.1-0.2 mm;

- At semi-commerce protection is better: 0.3-0.4 mm;

- Commerce is safer: its protective layer is from 0.6 mm to 1 mm.

To choose the right, you can focus on the weight: if you take the canvas of the same width, the weight of the household canvas will be the lightest, while commercial linoleum may be very heavy. And the interesting thing: the thicker the protective layer, the thinner the foam base of linoleum. Sometimes, of course, there are exceptions, but more often the thickness of commerce is minimal and reaches no more than 3 mm.

This fact is a negative point that can harm the installation: despite the thick layer of protection, with a minimum of thickness, all the disadvantages of the floor surface are visible.

Lay such linoleum can be exclusively on a flat, almost perfect surface.

To choose the best type of material, optimally convenient in laying, you should take a closer look at the half-size: its characteristics are enough for the floor to be perfectly flat and the surface not to be erased even in areas with high maneuverability. Commercial linoleum was originally created for industrial premises. However, its high resistance to stress has been noted by many buyers, so today, commerce is often an ornament to the floor of apartments and country houses. Many users like it much more than laminate, which in the case of high humidity swells.

If you want to buy a commercial grade flooring, it is better to pay attention to the option with a protection of 0.6-0.8 mm and the maximum possible thickness. So the weight load will be maximum, and the unevenness of the floor will not stand out.

Linoleum under the tile

Tiled linoleum is an analogue of the rolled variety and a kind of alternative to ceramic tile. By structure, it is no different from linoleum in the usual way. Here the same classification, the presence of household, semi-commercial and commercial categories, the similarity of the composition of the layers and a similar level of thickness of the protective film.

The difference is in appearance: linoleum tiles are fragments of the same size and shade, which are laid like a ceramic floor covering.

The raw material is so similar to tile that outwardly at first glance it can be difficult to distinguish it.

Otherwise unchanged: characteristics are similar to the roll analog, service life depends on the quality of installation, durability of the coating is determined by the intensity of operation of the working surface, a flat surface depends on calibration, seams are performed as desired. This type of installation allows the combination of material of different textures: tile linoleum can be combined with an analogue of a different shade and color, supplemented with tiles and less often with laminate.

The parquet is inappropriate here: an excessive amount of small details can disturb the nobility of the floor covering, thereby adding to the room a sense of confusion.

How to calculate the required amount of material?

Today, for the convenience and simplification of construction work, there are special calculator programs. They help to calculate the correct amount of raw materials, saving customers from unnecessary expenses.However, this invention is not always necessary, because in any case it is necessary to carry out measurements of the room. In order not to be mistaken, it is important to take into account the maximum distance in length and width, checking it at several points of each of the walls.

If there is an assistant who can hold the tape measure, it is even more convenient: since the measurement accuracy will be greater, because the edge of the metal tape will not slide and move.

All data should be immediately recorded on paper, depicting a schematic drawing of the room in which the installation is carried out. This is important in order to take into account the direction of the pattern and additives allowance on the threshold, another ledge (for example, for a battery, a niche) or docking with the floor covering of the next room.

You need to focus on the largest indicators (this also applies to asymmetric types of premises). To the obtained measurements add 7 cm in length and width. This eliminates the risk of material shortages. If the canvas is not solid, they are repelled from the length, taking into account the allowance of 7 cm, are guided by two lengths, while not forgetting to give an allowance for the docking.

Foundation preparation

Floor preparation is an important condition for installation. The final aesthetic perception depends on the quality of performance of this stage. It is not enough to buy a beautiful cover - it needs to be properly and carefully laid.

The process involves several working moments.

- Preparation of the room (completely free the room from the furniture);

- Dismantling the floor plinth and door trim (if any);

- Assessment of the condition of the floor, its alignment in height, getting rid of cracks, dimples, bumps.

What matters is the type of installation. For example, if linoleum is placed on a concrete base, the surface should be perfectly flat.

If it is planned to lay it on fiberboard, the floor can be trimmed by means of a mixture of cement and sand in the right lobes, masking point cracks. If the quality of the mixture leaves much to be desired, you can use Tserezit or Eunis tiled glue as the cement composition. Their consistency is perfectly balanced, the mixture is stirred without lumps, masks the floor surface smoothly and does not crumble after drying.

Experts recommend adding PVA glue to the mixture: it improves the quality of the composition, so masking and leveling the surface will not crack, which is important for the reputation of each master.

It is not recommended to level the surface with gypsum-based rovniteli: if there is high humidity in the room, the similar rover will quickly move away from the floor in layers.It is designed for walls and does not provide for a weight load, so these experiments are devoid of common sense.

If, for some reason, water gets under the linoleum, this rover will nullify the entire installation by adding work to rewire the coating.

After the floor is leveled, it is vacuumed, eliminating dust and residues of cement composition. It is important that it is dry and clean: if there are remnants of the mixture on the surface, the floor under the linoleum in these places can creak and create unsightly bumps. Then you can start laying.

Preparation for laying

The preparatory stage of laying linoleum depends on the method of laying out the material. Usually, linoleum is laid without a bend on the wall, although often the canvas is wrapped on the wall, giving it the appearance of a kind of narrow skirting board. The second method is used for finishing the flooring of a commercial type of industrial premises. It's easier to clean the floor without touching the wall. In this case, it is important to calculate the allowance for the linoleum plant on the wall.

When performing the flooring without bending, it is important to correctly trim the canvas. It is customized for the particular room in different ways: right next to the plinth or with a small gap to the walls.

- The first method allows you to leave the plinth before laying, but needs an exact contour of linoleum and its tight fit to the bottom edge. The plinth can be selected according to the color of linoleum.

- The second option is the best solution: often under the influence of different temperature regimes, linoleum can stretch, so it needs a little space (0.5 cm) to lie flat without forming a wave against the general background.

You can lay linoleum on different floors.

- Parquet;

- Hardboard;

- Hardboard;

- Concrete floor;

- Old linoleum.

The following tools may be needed for installation.

- Roller;

- Metal slats;

- Ruler with a corner;

- Cutting tool (construction knife);

- Tool for welding;

- Spatula (for the adhesive method);

- Primer;

- Mastic;

- Cold welding glue (joint sealant).

Technology laying involves the preparation of linoleum. Since the linoleum is in the roll for a long time, it must lie down before installation. Before direct laying it is spread on a flat surface and left for 2-3 days. During this time, the canvas takes an even position and allows you to make a more accurate fit to the measurements of the room.

Soundproofing the floor in the apartment

To the surface of the floor was smoother and warmer, under sound insulation put linoleum. This may be a rough floor on the logs, leveling and insulating the base, or a sound insulating slab, which is made when arranging a new screed. However, the simplest version of sound insulation is a substrate for linoleum, which is made of different materials and often complements the preparation of the floor on the heat and sound insulating base.

This stage is a necessity of installation, however not all types of material are suitable for work. It is worth paying attention to the raw materials with elastic structure and high resistance to bursting.

These include the following.

- Membrane sound absorbing materials;

- Single-layered teksaund from aragonite and flexible polymers (it happens on a felt basis);

- Tear resistant glass fiber with no harmful impurities;

- Izoshum (shumostop) with hydro and thermal insulation properties;

- Izolon is a derivative of polyethylene foam;

- Cork substrate of compressed ground crumbs;

- The substrate of jute fibers.

Preparing the base and taking care of the warmth of the coating and sound insulation, proceed to the installation.

DIY assembly process

Installation technology depends on the type of surface. In small rooms with dimensions of up to 20 square meters. m. linoleum is not glued to the floor surface. Flooring without glue is the easiest and is called dry. The main condition is a dry surface. Linoleum is placed on the floor, the edges are cut, the edges are attached to the base (if this is a hardboard or wooden base, they can be nailed with a nail at a distance of about 5 cm).

So that the edge does not collapse over time, it is fixed by means of aluminum strips, making holes in them for the size of the nail heads.

In the case of a concrete base, pre-drill holes for plugs into which they will then be screwed. However, if the house leads, over time, screws can rise to the top, disrupting the harmony of an ideally even floor. In this case, simply attach the linoleum around the perimeter. The joints are glued, sometimes nailed.

The second option looks less beautiful, so if you can buy a whole sheet, you should forget about saving: a monolithic floor is more practical.

Step by step instructions for laying linoleum on glue involves two methods.

With separate drying

Before laying, the back side of the material is treated with a primer. This minimizes the number of bubbles that impede flawless operation. It is important to prime the base with a uniform layer without gaps and give the linoleum and base a drying time of about a day. Each surface is dried separately without contact. Then on the wrong side of linoleum over the primer put mastic.

After that, linoleum is determined on the floor surface and smoothed the flooring, using a special roller for optimum adhesion, rolling it over the surface and uniformly pressing the canvas to the floor.

To properly lay the material against the wall, you need to use a spatula, pressing the linoleum around the perimeter.

When there is little space

If it is not possible to dry the linoleum and the base of the floor separately, you can lay the canvas on the floor and bend at least half a meter. Priming is carried out in parts, after which glue (mastic) is applied to the floor surface, although for reliability it is better to add adhesive to the back side of the linoleum. To glue was not much, it is distributed over the surface with a spatula,removing excess.

Sticking a floor covering, it is rolled with a special heavy roller or rubbed with corkboard. This eliminates air bubbles and promotes even distribution of the adhesive between the floor and the back side of the coating.

Seam processing

A solid sheet of material pressed plinths. However, if the coating has joints in a visible place, they are glued by means of “cold welding” using special glue. The tool is designed to fill the seams, it is transparent or the color of the material. It is used with a welding machine. In addition to the "welding", you can apply for joining seams tape linoleum profile. She squeezes together the coating inserted into it from two sides.

Laying linoleum tiles

With regards to tiled linoleum, its laying implies leveling the floor, otherwise fragments will stand out from each other. After preparing the floor, it is primed, it determines the center of the room To do this, pull the thread diagonally from the corners of the room. The first tile is placed in the center: glue is applied to its back side, while retreating from the edges of the fragment.

It is important to roll each billet.After all fragments are glued, a sealant is applied to the surface of the coating.

Professional Tips

To the type of flooring pleasing to the eye, looked professional and solid, you can take note of a few tips from experienced craftsmen.

- When laying marble-like or one-color linoleum with joints, it is preferable to lay the canvas in the direction of light: this way the coating will look monolithic;

- To glue the joints, you can use double-sided tape;

- Primer is better to acquire deep penetration: so the adhesion of the two surfaces will be maximum;

- Using the oil-chalk mastic, the base can be primed with linseed oil;

- If the mastic is bituminous or rubber-bituminous, instead of the primer, you can use mastic diluted with gasoline in a ratio of 1: 3;

- It is impossible to immediately roll out the roll and lay the material on an uneven floor: quality work does not tolerate haste (both the material and the floor need to be prepared);

- If linoleum moves away from most of the base, it lacks mastic: you need to carefully remove the linoleum, clean it from adhesive, re-primed and laid.

Experts pay attention to the fact that for some types of floor coverings, trademarks develop their adhesives. This factor matters: if you ignore the recommendations of the manufacturer, put linoleum on another glue, you can spoil the structure of the material. If this happens, a carpet that can be used to close the floor will help save the case.

However, this is not so simple: the carpet should be put solely on tightly glued to the floor linoleum. If it slips or has a lot of bubbles, this defect will not be covered with any carpet covering.

How to lay linoleum on a concrete floor, see the following video.