Choosing a substrate for linoleum

If the need to use the substrate under the laminate is beyond doubt, then there are different opinions on the subject of linoleum. Let us see in which cases it is advisable to use an additional layer, and when not. This article will discuss the varieties, advantages and disadvantages of an insulating material for different bases, as well as the nuances of laying linoleum with the substrate with your own hands.

What it is?

The substrate is a layer of insulating material that separates the topcoat from the subfloor - lag or / and boards, plywood, concrete base. The material has a structure that determines its nature of origin, the form of release in the form of rolls or plates with different thicknesses of 2-12 mm and possibilities.When choosing a substrate for linoleum, it is important to consider the type of the coating itself, in particular, the type of its base layer.

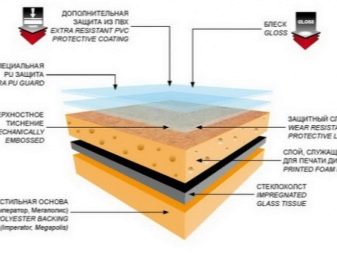

Modern linoleum is baseless with a homogeneous structure, the scope of which is utilitarian premises, commercial and public buildings and the main one - its types are used mainly in houses and apartments. Among the main coatings there are models based on foamed PVC, fabrics, nonwoven fabric - printed / felted felt, TZI with a combined base layer.

The most effective coatings are considered varieties of multilayer linoleum with a composite base layer. These are models on a duplicated basis: felt + polyvinyl chloride foam and high-strength products with a calendered base, differing in a single structure of the base layer of polymer raw material, pressed with a decorative abradable coating.

In some cases, the use of the substrate under the linoleum is fully justified, while in others the additional layer can be a source of discomfort when walking. In order to understand whether an insulating material is necessary for you, first we will deal with its main functions.

What is it for?

If you use a substrate, then in different situations an additional layer:

- Acts as a dynamic pressure absorber. When the draft base cannot boast of a perfectly flat surface without minor flaws, in order to hide them, insulating material must be enclosed.

- Compensates for minor flaws in the subfloor with slight drops of up to 2 mm / m2, preventing premature wear of the front cover due to the additional stress caused by surface tension due to bends and fractures.

- Isolates moisture, which is important for apartments located on the first floors. The reason for cold floors is the unheated, damp basement below.

- Absorbs sounds and helps preserve heat. The comfort of the linoleum operation is largely influenced by the noiselessness of the floor covering in combination with its heat insulating ability.

The downside to the use of the substrate is the creation of a certain softness of the floor due to it. Despite the fact that for some people it is comfortable to move on such a floor, while others are against it, installing heavy furniture on soft flooring is always fraught with negative consequences.Bulky storage systems can become uneven, which will cause the structures to skew, and pieces of furniture with legs under pressure will deform the linoleum, leaving strong dents.

In the case of laying linoleum is to abandon the use of extruded polystyrene foam. This material in the form of panels, having a thickness of from 10 to 20 mm, is ideally suited as a substrate for laminate. But not for such a soft coating like linoleum. If you put a panel under it, the floors will turn out to be unsteady, providing unpleasant sensations when walking. The use of MDF panels eliminates this problem.

When buying high-quality basic linoleum, the meaning is lost in the additional use of the substrate.

Since most often the preparation of a wooden base, as well as a concrete screed, implies the use of cut-off waterproofing. So, taking into account the pros and cons of the substrate, the need for its use is always determined by specific circumstances.

Kinds

The classification of substrates is rather arbitrary, so the main criterion by which they are divided into types is the material of manufacture.It can be natural, synthetic, combined type. Regardless of this, all materials differ in about the same low thermal conductivity, with a slight difference in its performance from 10 to 15%.

From jute

Jute substrate produced using coarse textile fabric, the manufacture of which are vegetable fibers. Under the general concept of jute should understand annual spinning plants.

Pros:

- Eco-friendly.

- Possesses high elasticity and rigidity.

- Provides good sound and heat insulation.

- Resistant to fire, mold and fungus, as the fabric is treated with flame retardants and antiseptic compounds.

- It simply fits and masks the defects of the subfloor.

- Durable.

Minus: expensive.

From flax

The advantage of using a linen substrate is a good natural ventilation under the front cover and concrete base, thanks to the excellent "breathing" properties of flax. This guarantees the absence of problems with fungus, mold and pathogenic beginnings, the starting factors for the development of which are accumulation of moisture in combination with stagnant air.

Other advantages:

- Ecological purity.

- The presence in the composition of impregnation, preventing fire.

- It is a good heat and noise insulator.

Minuses:

- Not resistant to deformation.

- It has medium hardness and durability.

From cork

For its production involve the crushed bark of cork wood. Cork is an intermediate derivative of wood, which explains the content of lignin and the product of the vital activity of a honeybee, wax, due to the presence of cerin. Just these components gave cork the hardness and resistance to moisture, and its elasticity is due to the unique content of many natural ingredients.

Pros:

- High sound and thermal insulation properties.

- Hypoallergenic.

- Good leveling ability.

- Resistance to the formation of rot, mildew and fungus.

Minuses:

- Excessive softness, and it is almost always undesirable when working with linoleum.

- The presence of restrictions on flooring in high humidity conditions.

- High susceptibility to deformation under the pressure of heavy objects.

- The need for strict adherence to styling technology.

- High price.

The moisture resistance of a cork does not mean at all that the material is completely immune to moisture.The substrate has a porous structure. The principle of operation of flax and jute is similar to the work of a mineral wool heat insulator, whereas in a cork it is similar to foam plastic.

From pine needles

A relatively new type of insulation material. It is made from the remnants of the processing of wood of coniferous trees and is characterized by high sound insulation characteristics, coupled with an excellent heat retention property. The coniferous substrate has a specific odor, which does not leave a trace over time.

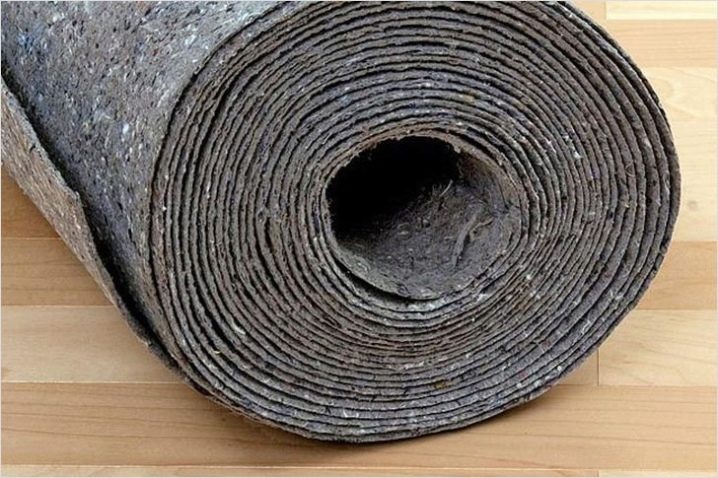

From the combined materials

Production of substrates of the combined type involves the use of flax, jute, wool fibers in different combinations: flax + jute, flax + jute + felt, cork crumb + bitumen / rubber as a binder.

Weak sides:

- Absolutely no waterproof properties.

- Low ventilation capacity of the material due to its high density.

Strengths:

- High wear resistance.

- Naturalness

- Zero exposure to deforming effects.

- Favorable combination of high noise insulation performance and low thermal conductivity.

Foamed base

Compared to all existing analogues on the market, this variant of insulating material for linoleum is considered the most inexpensive. The feasibility of using a polypropylene substrate is determined by the permeability of the premises, taking into account this factor, the service life of the material can vary from 5 to 10 years.

Pros:

- Very simple installation, which comes down to laying the strips with a small overlap on each other and fixing them with adhesive tape.

- The possibility of trouble-free replacement of old material with a new one.

Of the relative disadvantages should be noted excessive softness due to the small thickness of the substrate. On the one hand, this eliminates the damage to linoleum with heavy furniture, but on the other hand, it can be inconvenient to walk on it. Feelings in this case are similar to those occurring when moving on a lint-free carpet.

From foil material

This is a form of foam based substrate. The composition of the material is izolon / polystyrene in combination with aluminum foil, which serves as a thermal reflector. The scope of foil material is the organization of floor heating systems. Pros - strength and moisture resistance.

From DVP / OSB

Creating a substrate of these sheet materials due to the need to align the wooden base or concrete base as part of preparations for laying linoleum, when you can not do the traditional wet screed.

A plus:

The possibility of rapid elimination of uneven grounds, to save time.

Minuses:

- Low sound and thermal insulation characteristics.

- It is imperative to carefully seal the joining of sheets with each other. Otherwise, unsealed seams can cause cracking of the floor covering, especially when using linoleum economics. For this reason, when laying on a wooden surface, a layer of roll substrate is formed.

So, laying the budget baseless household cover implies the mandatory use of the lining. When laying insulated linoleum with a foam base layer, as well as models with a fabric base, there is no urgent need for a substrate. Multi-layered types of linoleum with a textile base have their own substrate of any material.

Which is better?

When choosing a substrate, they are repelled from the purpose of the room in which they plan to install linoleum and a variety of flooring.The substrate that is best placed under the base of the existing linoleum and directly on the ceiling material is chosen.

General guidelines for using different types of substrates:

- Linen / jute substrates should be considered exclusively in warm rooms. In addition, they are good to use when a new coating is laid on the old linoleum.

- Low room permeability is a reason for using synthetic substrates.

- The most versatile type of substrate is cork. It is compatible with any base and all types of linoleum.

- Natural substrates cannot be used in rooms with high humidity and temperature conditions. Impregnation in this case will not save, so do not do without the organization of waterproofing. For this purpose, involve a thick plastic film.

It is important to take into account that the model of linoleum differs in the class of wear resistance, therefore:

- Laying a commercial coating implies the formation of an additional layer of flax, and under a heated floor - from foiled material.

- When laying semi-commercial linoleum, a more dense substrate of the combined type or from jute is needed.

- For an apartment that uses less wear-resistant household types of linoleum, jute / cork substrates are desirable.

Many masters insist on the use of the substrate, regardless of the type of linoleum - basic or baseless. Because, in addition to the functions of sound insulation, thermal insulation and leveling of small irregularities of the floor, an additional layer eliminates direct contact of the coating with the base.

Base Requirements

Concrete bases, even when the screed has fully matured, retain moisture inside. The change in moisture emission is influenced by a combination of external factors — these are moisture and temperature regimes and atmospheric pressure. A flooring with a special base will be affected by this destructive impact, and the use of the substrate will reduce it to the minimum possible.

On plywood, fiberboard, OSB, you can use the most common roll substrate. Materials for needles, cork, parkolaga are suitable for laminate - this is kraft cardboard + bitumen + cork chips, isoplat, tuplex.

How can I lay?

You can lay the insulation material by hand. When laying a soft flooring it is important to choose the right thickness of the additional layer.Try to ensure that the thickness of the substrate does not exceed the thickness of the front coating, although ideally they should have the same thickness.

The smooth surface of the subfloor is a guarantee that the substrate will successfully cope with the tasks assigned to it, one of which is to increase the duration of coating operation. The best way to prepare a concrete floor - self-leveling screed, and wood - flooring sheet material.

How to prepare the substrate?

Before laying the rolled material, it is unfolded and left to rest for a day at room temperature. If this is neglected, the substrate can change its size even in a fixed state, which will cause the formation of waves on the coating.

Which side to put?

When forming a layer of foiled material, its reflective side should be on top. Penoizol have a smooth side up, and corrugated to the floor.

How to enclose?

The connection of individual fragments of insulating material involves two methods of fixation: they can be glued to special compounds or fastened using double-sided tape.The technology of laying the rolled material, sheet or in the form of panels has its own nuances, although in any case the laying of the cloths is performed end-to-end on the primed base. Adhesive tape is glued at the joints of adjacent sheets / cuts and along the edges.

Tips for choosing

To choose the right substrate, you need to consider the compatibility of different types of linoleum and substrates.

What types of insulation material are suitable if you use linoleum models:

- With foam base - any type of substrate.

- On a fabric basis - cork / jute substrates: such tandems reduce heat loss and improve sound insulation.

- With a duplicated base - any kind of substrate, with the exception of material from polyethylene foam.

- With calendered base - needles from needles, jute or combined type.

Judging by the user feedback on the quality of various types of substrates, the best material for the house at the moment is a cork substrate, which has a cellular structure. Each cell contains air, which contributes to the uniform distribution of the load created by large-sized furniture over the entire area of the front surface.In winter, she does an excellent job of keeping the heat indoors, so you can walk on linoleum barefoot. Due to its high sound-absorbing ability, it is not audible neighbors on the lower floors.

As for the cost, the purchase of a foam substrate is cheap, the optimum thickness of polyethylene foam is 2 mm, and the most expensive of natural materials is needles and cork.

Successful examples and options

For a smooth concrete base, you can consider the option of a substrate of fiberglass - a rather elastic and durable noise-insulating material. Due to the small thickness, the leveling ability of this material is completely absent, but due to its high acoustic characteristics, it is possible to achieve good sound insulation in the room.

The combined cork substrate containing tar or rubber is distinguished by improved hydrophobic characteristics and resistance to fungus, mold and rodent damage. Materials with a combined composition help to create a comfortable microclimate in the room with optimal humidity and temperature conditions.

Felt under linoleum substrate is used in rare cases due to excessive softness of felt. Nevertheless, this material is great for arranging a nursery, if it is not planned to do a frequent rearrangement of heavy furniture there.

The old wooden base perfectly aligns the substrate of plywood. An alternative is to use OSB plates.

The best way to use a jute substrate is to create a multifunctional flooring in apartments on the first floor.

If you need to create a healthy microclimate indoors, then a linen substrate will effectively solve this problem.

On whether you need a substrate for linoleum and how to lay it correctly, see the following video.