How to perform the joint of linoleum with other floor coverings?

Today, for the arrangement of flooring can be used various coatings and materials. One of the most common options is linoleum, which is easily stowed and processed. But there are options when you need to form a quality joint of linoleum and tile. This problem can be solved in several ways, the main thing is to choose the most optimal one.

Ways to dock

Linoleum can dock with various materials, among which the most common are:

- laminate;

- ceramic tile;

- floorboard.

Docking of these coverings can be done between the floor of the kitchen and the hallway, for example, where different zones are created. Sometimes these materials are found in the same room according to the designers' idea.

Linoleum can be connected to the floor with other surfaces in several main ways:

- Plane alignment. This option allows you to get a smooth connection, located on the same level. Often this approach is used if the difference between heights is more than 1.5 -3 cm.

- Joint sealing. This technology involves smoothing the transition to eliminate discomfort when moving.

It should be noted that all these methods are universal and are suitable for almost all types of flooring that need to dock with each other. When choosing one of them it is important to take into account the specific values of the height of each layer and the final result that you want to get.

To get a quality joint is quite simple. This can be done with the help of such approaches and tools:

- Direct docking. For this, linoleum is trimmed in such a way that the material fits tightly against another flooring. So that the sheet does not rise with time, it can be glued to the floor with the help of special compounds.

The most difficult process here is high-quality trimming, which must be done very carefully.The best option would be the imposition of linoleum on tile or laminate. Then in the place of joining an even cut is formed along the entire length of the sheet.

- The use of decorative thresholds. These designs are special strips or profile, which is equipped with grooves for hiding linoleum and smoothing joints. They can be used both in the corridor under the door and on the open surface.

The shape of the thresholds often does not have sharp corners, which does not allow injuring the legs during movement. This method is one of the most common, as it allows to get a quality joint practically between any floor coverings.

Material for slats

Decorative powders are a type of profile that differs in shape and design. They are made of several types of materials:

- Aluminum. Material perfectly maintains big loadings and is easily processed. To give it a different design, it is covered with special paints or other substances. This allows you to simulate different styles and colors of surfaces (gold, wood, etc.).

- Brass. The slats of this metal are the highest quality and expensive. The material is practically not processed, as brass looks very good. But over time, the metal may tarnish, which requires periodic rubbing it with felt or other similar substances.

- Plastic. The cheapest powders, which are used quite rarely. But they are indispensable when you need to get a joint of complex shape. To do this with metal structures is almost impossible. To form such curves, the plastic is heated before laying and bent in the right direction.

- Rubber. Thregs of this type are relatively rare, but they bend very well and withstand heavy loads.

- Tree It goes well with linoleum and laminate. Therefore, the thresholds of it will be the best solution in the formation of joints.

Methods of fastening thresholds

Decorative slats are used very often in the formation of joints of linoleum and floorboard. Fixing such structures can be done in several main ways:

- Bonding. This method involves the installation of strips on a special glue to the floor.Very often it is resorted to when working with ceramic surfaces. This is due to the fact that it is much easier to glue the nut to the tile than to drill a hole in it for fasteners.

- Through fasteners. This technology involves the use of screws, which are screwed into special holes in the profile. Therefore, each of the manufacturers equips the strips with special holes through which all this happens.

- Secret fixture. This method also involves the use of screws. But at the same time their installation is carried out in the basis of a level. After fixing, it closes with a special decorative lining. Externally, fasteners after that are generally invisible.

Action algorithm

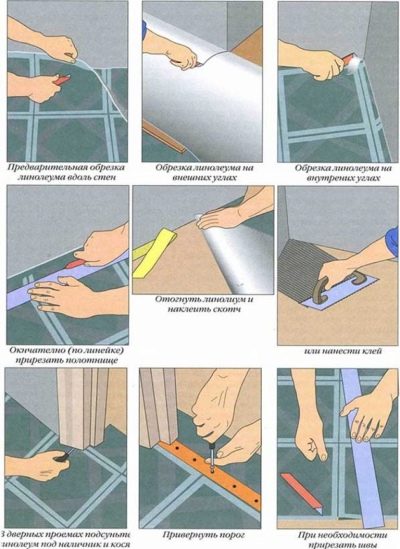

The docking technology is relatively simple and can be performed independently. The process of obtaining high-quality seam can be divided into several successive stages:

- Firstly analysis of the difference between linoleum and other floor covering. If this value is quite large, then you need to take care of the alignment of the surfaces. Often a similar phenomenon occurs between linoleum and laminate.In order to form a single plane, plywood is placed under the rolled material, which is best nailed to the floor.

- The next step is the formation of a joint with a minimum gap. To do this, the material must be cut along the entire length of the seam with a sharp knife. The better you do it, the better the transition will look.

- At this stage, choose the method of docking. If linoleum is in contact with the threshold, then you should simply glue it to the floor, and fill the gap with sealant to get a flat surface. In another case, it is easier to combine materials with decorative strips. Therefore, you need to choose the shape and size of such a profile. Please note that there are thresholds that can level drops up to 1.5 cm.

- When all materials are selected and the linoleum is trimmed, coatings can be docked.. To do this, cut the desired piece of the nut and inserted into the seam between the layers. In this case, linoleum and laminate can hide in a special groove. As for the tile, the profile simply covers it from above to hide the seam.

After completing the laying of the nut, it is fixed to the floor by one of the previously discussed methods.If the surface is concrete, then for the installation of self-tapping screws, you first need to drill holes in the concrete under the dowel. If you want to form an uneven seam, then use plastic or rubber strips.

As you can see, docking linoleum with other materials is quite simple and fast. It is very important to use high-quality component materials. This will extend the life of the flooring and ensure comfortable movement on it.

The method of direct joining of linoleum - in the video.