What is mastic for linoleum?

Despite the variety of modern flooring (carpet, laminate, flooring, tile), linoleum is still very popular. In many ways, this is due to its qualities such as wear resistance, water resistance, as well as a large selection of design options and an affordable price. Not the least role is also played by the relatively uncomplicated installation of this coating and its ease of maintenance.

Features of selection and styling

It is no secret that a beautiful perfectly level floor sets the tone for the whole room, is the basis of comfort and convenience. The use of special mastic under linoleum will ensure reliable contact of this flooring with the base on which it is placed. The result is a comfortable flat floor surface that will be much less susceptible to damage and, accordingly, will last longer.

It is necessary to select mastic only after linoleum has been purchased, and you should definitely ask the seller what materials your linoleum is made of and what its basis is.

The choice of mastic depends on its type (household linoleum is used for the house - alkyd, PVC), as well as the surface on which it will be laid.

- For linoleum without base, synthetic rubber or bitumen mastic is used;

- For linoleum on a heat-insulating basis dispersion mastic will be suitable;

- Linoleum on a fabric basis is well fixed bitumen mastic.

The range of adhesive mastic in building stores is large enough, so you need to carefully study the recommendations on the label, what type of coating is suitable for this tool and, if necessary, consult with the seller.

When laying you need to follow the following procedure:

- Maximize the surface on which the linoleum will be laid;

- Clean it from debris and dust. It is important to note that the surface of the base under the linoleum must be completely dry;

- Apply primer (for better contact of the bonded surfaces).In this case, the primer must comply with the mastic. The primer can be made independently by diluting a certain amount of mastic with an appropriate solvent. So, for dispersion mastic water is taken, and for bituminous or rubber - gasoline.

It is important to remember that the mastic from synthetic rubber and resin is flammable and explosive, so you need to apply it only with a plastic spatula.

- After drying the primer with a spatula (better toothed) apply a thin layer of mastic on the surface of the base. It is not necessary to distribute it over the entire surface if the area of the room is small. For rooms less than 12 square meters. m it can be applied around the perimeter with a strip of 25-35 cm wide, retreating from the edge of the walls by 2-3 cm.

In a larger room, the mastic can be applied as a grid over the entire area of the room. If the base is porous, then after the mastic has dried it will be necessary to apply another layer.

- Then, after waiting for some time (this is indicated in the instructions for use for each type of mastic), you can glue the sheets of linoleum to the floor surface, carefully laying them and smoothing from the center to the edges.

- After that, you need to press them well to the floor using a special roller or a small roller. To sustain the time (approximately one day) so that the linoleum adheres well.To do this, it is not recommended to walk or load it with any objects.

In due course any floor covering wears out, and then there is a question or about restoration of an old covering, or about its full replacement. The attractiveness of linoleum lies not only in its practicality and price, but also in the fact that its minor repairs and restoration can be carried out independently.

How to remove dents?

It must be said that if it is correct, according to the instructions, to lay linoleum, then this will avoid such misunderstandings as folds, bumps, creases, and so on. But if this has already happened with your coverage, you can try to eliminate the defects that you have created. Waves and bubbles that appeared on a large surface area shortly after installation most likely indicate that the linoleum was immediately fixed with baseboards, preventing it from lying on the floor properly.

In this case, you can do the following:

- Release the room from the furniture.

- Remove the baseboards.

- If the linoleum abuts against the walls, the edges should be cut so that they do not reach the walls by about 2 cm (after installing the baseboards, this will not be noticeable).

- The coating is left to rest for at least a day, after which it is rolled by a small roller, roller, or some other suitable heavy object.

- If swells remain after this, they should be smoothed and glued to the base with mastic or glue.

- Install skirting boards.

It is possible to cope with single small “bubbles” by making a neat longitudinal or cross-shaped incision in the middle, after which this place is pressed for a while with a heavy object. Under the sheets lined up in such a way, start the necessary amount of glue and glue them to the base of the floor.

Dents left over from furniture or anything heavy can be removed by heating the linoleum in this place with the help of a building dryer and then rolling it well in different directions with a roller.

If there is no hair dryer, this can be done with the help of a hot iron. It is necessary to act carefully while using a cotton napkin or cardboard folded in several layers in order not to burn the linoleum.

How and what to glue?

Advice to lay linoleum on the most even surface is sometimes neglected, assuming that the coating will lie flat.Indeed, after laying, for example, on a concrete floor with pits, even if small, linoleum will visually hide them, but will not fill the void. As a result, there is a potential danger of pushing the coating in this place.

Through damage under the linoleum water can fall, from this it can swell and become moldy.

So that you do not have to change the entire floor covering, areas with defects can be repaired at home on your own.

At the points of sale of linoleum there is an opportunity to purchase a repair kit (solvent, repair composition and color scheme). With it, you can eliminate a small (up to 10 mm) puncture or scratch on the coating. For this purpose, a color-matched and selected amount of solvent is added to the repair composition. The finished mixture is filled with a puncture or close up a scratch, then gently remove the excess.

If the repair kit could not be found or damage is more serious (for example, a big hole or burned), repair such areas using PVC glue (cold welding). This method allows you to securely glue the joints of linoleum, while receiving a colorless durable seam.

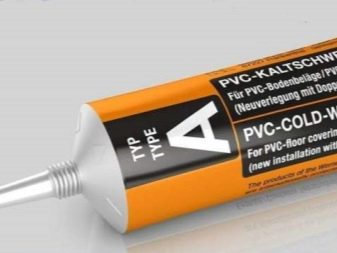

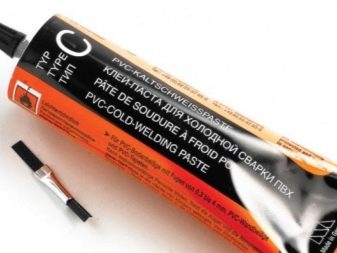

For independent work at home, two types of PVC glue are usually used.

- Type A It has a liquid consistency and is used for gluing the seams of new linoleum. It can also be used to close up a small hole (up to 1.5-2 mm) or a puncture. The procedure is the same as when using a repair kit, only the masking tape is stuck to the place of damage. This is done so that the glue does not get on the surface of the linoleum. Then, just above the injury site, a small hole is made in the adhesive tape, through which type A glue is poured. After waiting for the glue to harden, the adhesive tape is removed. Excess sticking glue is carefully removed from the surface of the coating.

- Type C more viscous compared with glue type A: it has more polyvinyl chloride and less solvent. It is perfect for working with old linoleum. With it, close up punctures or holes the size of an average coin. It is not necessary to use adhesive tape when working with it, since this glue barely spreads.

Plot linoleum with a big hole or burning will have to patch. Especially for such cases it is recommended to preserve the remains of linoleum after laying - then you can choose a piece that is suitable in size and pattern.

The procedure for applying a patch to a damaged place is as follows.

- The selected piece of linoleum to attach to the damaged area and the maximum fit to the picture.

- Without removing the new piece, cut both canvases along the contour of the necessary patch. It will be better to cut if you use a metal ruler, pressing it, as it should, to the canvas along the cut surface.

- To remove the damaged part of the web, clean the surface of the base under it with an emery cloth.

- Spread the base with mastic and glue a new piece of cloth, cutting it off quite a bit around the perimeter so that it freely enters the remote section of linoleum. Cold weld the seams. If in this place the linoleum was not glued to the base, on the patch only the seams are treated using cold welding.

- On the received patch to put the goods and hold for about a day.

Torn linoleum can be repaired with PVC glue (cold welding), type C.

- Clean the area to be repaired, remove burrs and fringe from the edges of the torn edges (clean with emery paper or cut with a painting knife).

- Lift the torn coating and squeeze out C-type glue into the resulting space, then distribute it over the surface of the base along the entire gap.

- The edges of the gap as tightly as possible to connect with each other and press to the base.

- Leave to dry by putting the load down.

- After drying, the surface is cleaned from traces of repair and masked with protective mastic of a suitable color.

Successful examples in the interior

If the coating is damaged in such a place that it can not be hidden under the furniture or a rug, it can be closed with an application of pieces of suitable materials. Here you can show imagination: it can be either a geometric figure of a contrasting color, or an image of a flower, a butterfly, and so on. On top of the application need to apply varnish for linoleum.

If there are sufficiently large remnants of linoleum, then the damaged place on the coating can be replaced by a strip of linoleum of a suitable shade, having treated the joints with cold welding.

Views and reviews

By appointment mastic for linoleum may be different.

Protective

Used for rubbing the finished floor. Caring mastic for linoleum with regular use protects it from premature wear: burnout, cracking and abrasion. In addition, they give the surface a matte or glossy shine (depending on the type),anti-static properties and reduce surface glide.

The floor covered with mastic is easier to clean, it does not penetrate deep into the dirt, and it is more protected from scratches.

Ideally, the protective mastic is better applied to the linoleum immediately after it was laid, but if it did not work out this way, you can do it later and in the future try to apply it to the coating every two to three months.

Adhesives

Used for bonding linoleum to the base. Although the mixture for fixing can be prepared independently, many choose the easier way and buy ready-made mastic in hardware stores.

Modern industry offers a sufficient choice of various mastics based on natural astringent components.

- Cold is popular with many consumers. bitumen mastic, as it is suitable for fixing different types of linoleum.

- No less popular lime and bitumen mastic: quick-hardening and waterproof, it provides excellent waterproofing and protects the apartment from below from leakage in case of a water supply or heating pipe.

- Bituminous-rosin and bituminous-latex mastics used for fixing PVC linoleum on the basis of wood or concrete.Those who used bitumen-latex mastic, note that it does not reach for the tool, it easily lays down in a thin even layer and can be used even in a cold room.

- For linoleum on a fabric basis, the optimal choice can be bitumen mastics, for example, "Isol", "Bixie". They are explosion-proof and harmless, however, a significant drawback of them is the slow set of strength (about a month). Therefore, linoleum can not be loaded at least a week after fixation with these mastics.

Proper installation of linoleum with adhesive mastic and care for it with the use of protective mastic will allow your floor to last for many years, while maintaining an attractive appearance.

How to eliminate the swelling of linoleum from the furniture standing on it is described in the following video.