Heated floors under the linoleum

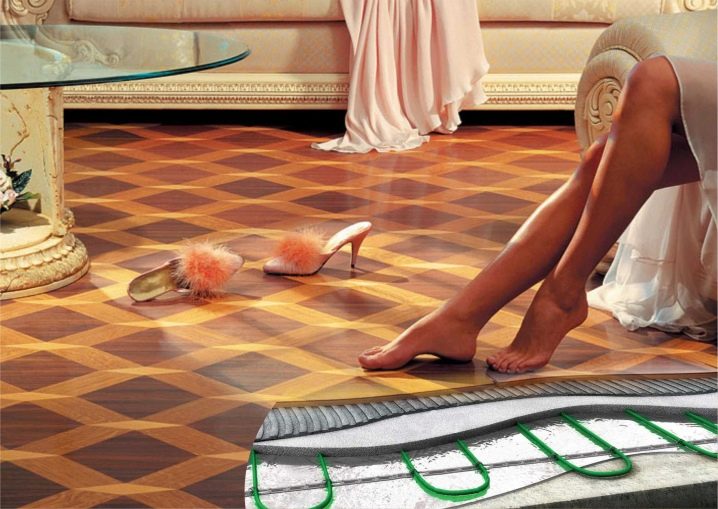

Despite the large variety of modern materials for the floor, linoleum remains a popular option for flooring today. If there is a task to make warm floors under linoleum, saving on the coating itself, it is worth considering linoleum with special care, as in this case the quality of the floor itself will depend on its characteristics.

Is it possible to lay the floor product on the heated floor?

There is a lot of controversy about whether it is possible to lay this type of coating on a heated floor. Some argue that this should not be allowed in any case due to the fact that the coating material releases toxic elements when heated.Others say about the fragility of linoleum, that because of the heating, the coating material will deform and this will inevitably lead to cracks and irregularities.

However, progress does not stand still. And fortunately, he touched the production of linoleum. New technologies allow you to create a material that is not afraid of temperature fluctuations, and the composition of such coatings will not have toxic properties. Therefore, the answer to this question is unequivocal - modern linoleum can be used to cover a heated floor along with other materials. The main thing is the right choice of this material and heating technology.

About heating, let's say right away: under the linoleum you need to install infrared film fields. This type of heating will be softer and more comfortable. This technology will ensure compatibility of the selected coating with the use of heating.

When choosing a coating, you need to learn that linoleum must be made of a material that provides thermal insulation. Otherwise, the effectiveness of floor heating will be minimal.

It is also extremely important that the material from which linoleum is made is safe for humans, toxic and climatically inert.Usually the safety class is indicated in the product quality certificate, which will not be superfluous to request from the seller before purchasing. In addition, the documents for linoleum should indicate that this material can be used to cover the floor with heat.

If you do not pay attention to these facts, you can buy inappropriate linoleum, and during operation the floor will emit an unpleasant odor associated with toxic compounds that make up the material. You may also notice that such a floor will blister and crack.

Which linoleum is better to choose?

Indeed, many reviews that linoleum, being exposed to heat, shrinks. This happens due to the fact that when installing a film infrared floor and covering it from above with linoleum, the heating level may exceed 30 ° C, which is unacceptable for linoleum, so you will need to adjust the temperature yourself and set limits. During the operation of the floor, the optimum temperature of preheating without harm to the coating will be 27 ° C.

As for the linoleum, you should choose the optimal thickness. So, for a heated floor suitable material flooring medium thickness with a protective coating.

When choosing linoleum for a heated floor, you need to focus on some of the limitations that have already been mentioned. And paying attention to health, you should carefully examine the composition of the selected material in order to avoid a mistake.

Depending on the composition, linoleum is:

- Natural. Made from natural materials such as wood fibers, pine resin and wood oils. This option will not only be environmentally friendly in its essence, but, among other things, will have antibacterial properties (due to the content of antibacterial agents in the composition of resins and oils). Such coverage would be ideal for a home where small children and animals are located. In addition, this type of material is inert to alkalis, so it can be cleaned with soap solutions, and also it is not flammable.

- Polyvinyl chloride. Made of polyvinyl chloride, coloring elements and various fillers. The substrate of this type of linoleum may have sound insulation. As a rule, these are fabric materials and foam bases. This material, as well as natural, is very hygienic, inert to acids and alkalis, has a low thermal conductivity and high abrasion resistance.

- Alkyd It is a material consisting of natural components in combination with alkyd resins and various polymers. Like polyvinyl chloride, this type of linoleum has a very good sound insulation and low thermal conductivity. However, when using it, it should be borne in mind that this material shrinks in length.

- Nitrocellulose. This linoleum consists of recycled cotton cellulose fibers with the addition of asbestos, gypsum and red lead. Nitrocellulose has excellent thermal insulation and durability. But due to the fact that it uses toxic components, as well as due to its easy flammability, this type of material is unsuitable for covering a heated floor.

- Rubber. It consists of two layers: the top one is a rubber interlayer in composition with various coloring pigments, bitumen and other synthetic elements, and the bottom one is a layer of crushed rubber. This type of material is very moisture resistant and durable. However, like nitrocellulose linoleum, this type is not used for heated floors for already known reasons.

In addition to the composition of linoleum, when choosing it, you should pay attention to its base and thickness:

- Materials without base are very thin (up to 2 cm). They are chosen for notoriously clean rooms.The life of the floor with such coatings is small and reaches an average of 5 years.

- Materials on foam or any other basis are much thicker than the first (up to 4 cm). They are very durable and wear resistant. They, as a rule, cover the bathrooms and kitchens. However, it is worth noting that if the room is large and it is not possible to cover the entire floor with a single sheet of linoleum, then the resulting joints should be sealed with special solutions or a welding cord.

As already mentioned, in order to avoid purchasing unsuitable material, always check the approval marking and get acquainted with the information in the material certificate.

Types and heating device

The feeling of comfort when staying indoors is the main reason for choosing a warm floor. In addition, such heating systems allow you to control the consumption of electricity in the apartment and save energy. The principle of operation of electric floor heating is based on the conversion of electrical energy into heat. This can be achieved in two ways: using a special electric cable (this type of floor heating will be called “cable”) or using a heating film (film type floor heating):

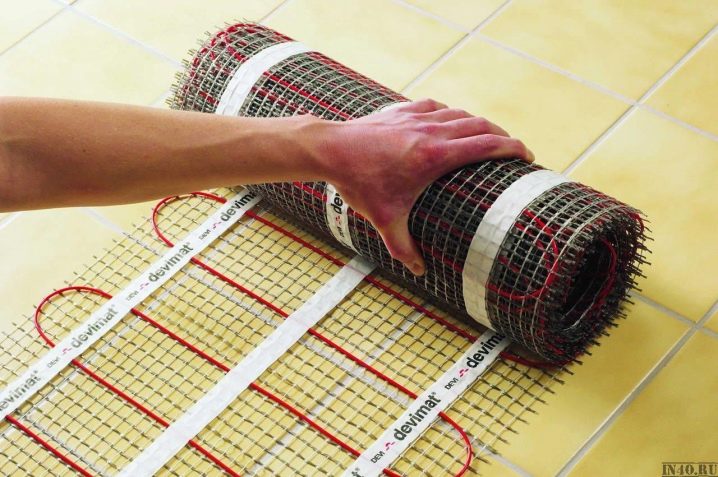

- There are several types of cable for heated floor: self-regulating and resistive. The degree of self-regulation and control of electricity will depend on the selected cable. When providing the floor with a cable-type heating system, pre-level the floor, cover it with a special polyethylene film, put on it a heat insulator of the chosen type, and a reflector on top of it (sometimes the last two elements are combined in one layer).

The cable laid on the prepared floor must have a closed system (usually a zigzag with a loop size equal to the perimeter of the room). If you plan to make a heated floor with heating control, then a temperature sensor is pre-assembled to the floor, and its wires are brought into the wall where the thermostat is located.

Due to the fact that the power of this type of heating significantly exceeds the power of other types, when installing this system, it is allowed to close it with a coupler or just to fill the floor.

However, the thickness of the filler floor and screed should not exceed five centimeters, otherwise the electric heating will not be provided.

- Film electric heating, as opposed to cable, is allowed to be installed only without a screed, just a thin layer of the floor is enough, because the power of this system cannot be compared with cable.

When the floor is ready, the floor has been poured and, if necessary, a screed, you must wait a while until the floor is completely dry, sometimes it takes even a whole month. After drying the floor, proceed to its finishing coating with linoleum.

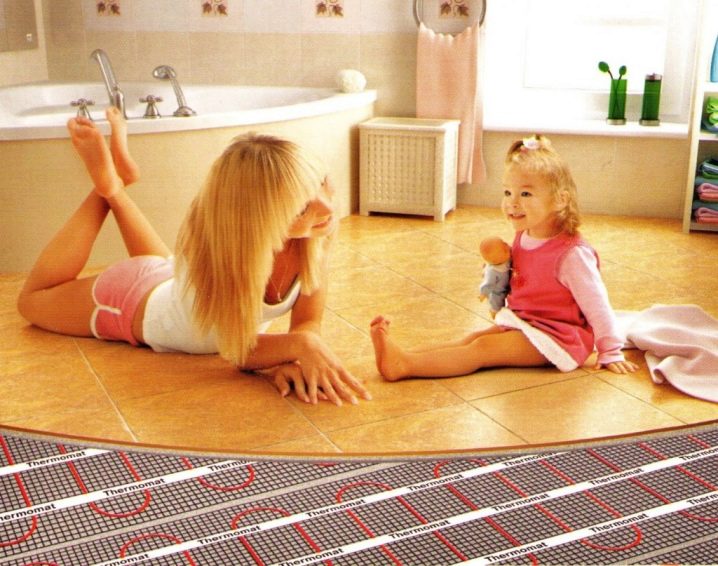

Recently, infrared (IR) film underfloor heating is popular (some people call it “tape heating”). This type of heating is perhaps the most versatile, since it can be used both for linoleum and tile, and even for wooden parquet. However, infrared floor heating will cost impressive money, but at the same time have environmental friendliness and safety, maintaining comfortable conditions in the room and not creating a threat to the health and lives of people and animals.

The infrared floor system is represented by a carbon polymer in the form of carbon rods placed on the surface of the film. These rods have the function of temperature self-regulation, therefore the floor will never overheat and the coating, whether linoleum or laminate, will not deform and will not crack.Such electrical systems are mounted on glue or on the screed above.

Another advantage of this type of heating is that its installation is available to almost anyone with a basic knowledge of electrical engineering. It is not necessary to call the master to install such a heating system under linoleum, which can also be laid on its own. Accordingly, the level of spending is sharply reduced. In addition, during the next repair, this source of heating can be easily dismantled and replaced with another, more modern or completely removed.

And to further reduce heating costs, you can consider the option of local heating, cutting the IR tape into areas and placing them only in those parts of the floor where heat is required (for example, in the working area of the kitchen, in the area of the bath or toilet). When mounting the IR tape as a floor heating, first lay the substrate - heat reflector on the floor. Cut heater strips are laid on the floor surface, after which a layer of glue is applied to them or a thin screed is made. After the simple procedures are performed, proceed to finishing the floor covering with linoleum or other selected material.

In general, a warm floor under linoleum can be used as an independent heating system, but only if the building structure is made of high-quality heat-insulating materials or you can resort to this in an area where there are no severe winters, and the seasons are not as bright as for example, in central Russia.

See how to install a warm floor with your own hands in the next video.

Mounting methods

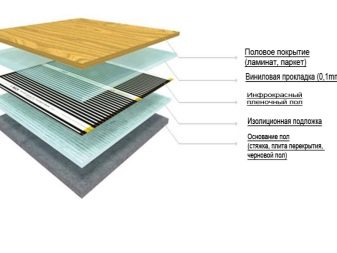

Regardless of which heating system is chosen for linoleum, in general the floor will look the same.

The design of this floor is multi-layered and includes:

- Heat insulator. The thickness of its layer will depend on the initial heat of the floor and the height of the floor.

- Next, put a layer of metallized substrate. This material will reflect the heat well, not letting it go down. As this layer, it is preferable to choose a lavsan coating, since, for example, aluminum foil may break down over time.

- The top layer of the selected heating element. Each heating system requires a special fixation. IR tapes are attached with glue or duct tape, electrical cable and water heating pipes - clamps.

Laying the heating system requires special attention.Since at this stage it is necessary to correctly place the heating elements, choose a step, determine the measuring points of the floor temperature and bring the thermostat to the right place on the wall.

After the heating elements are securely fastened, the floor is covered with a layer of metallized mesh from the same lavsan. It will not only reflect the heat rays, but also make the structure more rigid and stable, which is important for a thin screed (when using the floor, compression of heating elements may occur, this can damage the entire floor heating system). Such a grid in some cases is also a grounding device. To do this, fragments of the grid are connected with wires and lead one of them to the grounding bus in the floor.

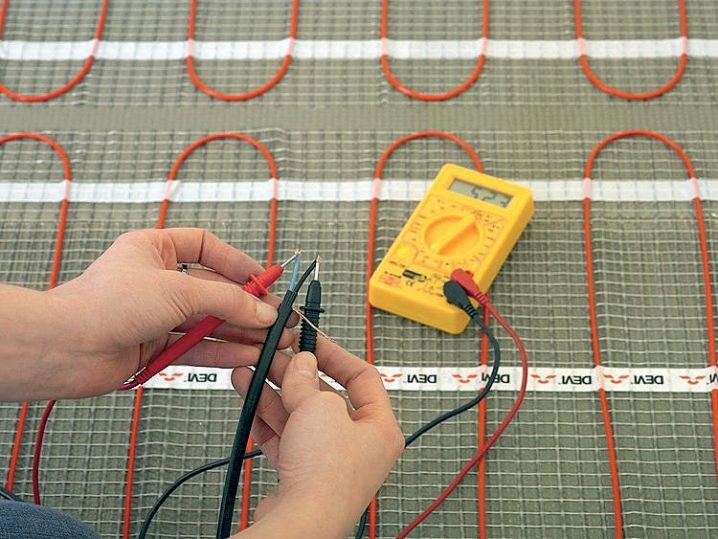

Before you begin to screed a warm floor, it is imperative to check its performance. Turning on the heating for some time, you need to check all parts of the structure, and make sure there are no closures in the system. If malfunctions are revealed, it will be easier to eliminate them now than when the floor is covered with concrete.

To fix the created structure, a warm floor coupler is used.The composition of the screed is a common water-cement base with plasticizers. However, when mixing, it is necessary to select the component composition of the solution in such a way that, as a result, the coating has such characteristics as:

- Lack of porosity composition. Voids and pores can contribute to heat loss, therefore, the effectiveness of a heated floor decreases sharply, and financial costs increase.

- Good ductility and crack resistance. When operating the floor, placing heavy furniture on it, cracks may form on the surface of the screed, which ultimately will lead to the disruption of the integrity of the heating system and its disabling.

- Uniformity and high speed setting of the solution. This will eliminate unnecessary residual stresses in the structure of the floor, which also affect its quality and service life.

There are two types of screed compounds: wet mix and dry mix. Wet mixes include cement, sand and other concrete compositions. And in addition to dry mixes, plasticizers are added.

To prepare the mixture for screeding, you need to choose the strongest cement types (for example, M-400 or M-500), since the screed layer will be thin and its strength will depend primarily on the strength of the screed material.For greater strength choose coarse sand. As plasticizers choose branded ready-mixed.

All components of the mixture are placed in a concrete mixer, gradually add water, achieving the desired consistency. It is possible with stirring to add a special polymer composition - fiber. Stirring is carried out carefully so that all the above characteristics of the finished mixture are achieved, and the floor is strong and reliable.

For better heating without heat loss, you can use ready-made mixtures. Although they cost more than a homemade base, but using them can save a lot of electricity in the future. And the heat just will not be wasted.

Layer applied cable for cable or infrared systems should be no more than 2-3 cm for water pipe allowed up to 5 cm. Neatly placed on the surface of the floor composition is perfectly aligned with the construction level so that when covering the floor with linoleum, it does not lead to distortion pattern, and it will look at least not aesthetically pleasing and will lead to uneven wear of the coating.

When the screed has dried, go to the floor covering with linoleum, selected on the basis of the recommendations given in this article. Laying linoleum does not require advance preparation and can be done independently.

It is only required to have an idea about the distinctive features of its installation on various floor surfaces:

- If the floor surface is represented by a concrete base, the situation is simpler. First you need to make sure that it is smooth, that there are no cracks and gaps. Eliminate these inconsistencies, if any, and then lay a layer of waterproofing between linoleum and concrete. A polyethylene film is used as this material. It is allowed to overlap two consecutive layers. When the concrete floor is insulated from moisture, proceed to the linoleum.

- If you are laying on a wooden floor, you should first prepare it: remove old paint with a trowel, grind rough irregularities with a milling machine, putty the joints and cracked cracks with the help of building putty. To reduce the time to prepare a wooden floor without the above preparatory work, you can put the linoleum on plywood or on a sheet of chipboard.

Using this option, you can achieve a more even base under the linoleum. For a wooden base does not require waterproofing, as the tree itself perfectly absorbs and removes excess moisture.

After the surface of the base of the floor is prepared, it must be carefully primed to avoid rotting and mold formations in the future.

- If the floor surface is laid with tiles, it is also possible to close it with linoleum, the main thing is to clarify the nuances, as in this case correctly lay new surfaces on the tile. Since this material is rather slippery, it has joints and an uneven surface, linoleum may not hold very well, however, there is a way out for this case. Pre-putty the seams between the tiles, primed the surface and put on it the jute substrate, so that the linoleum does not slide on the tile. To eliminate this situation, you can also use cold welding and additionally fix the coating with a plinth.

Laying linoleum

If linoleum was acquired in the winter or was in a cold room for a long time, before laying it down, it is necessary that it lay in a warm room for at least 24 hours and restore its natural elasticity.Linoleum sheet rolled out on the floor and measure the desired length and width, corresponding to the dimensions of the floor itself. It is necessary to add about 10 cm to the measured values to run under the plinths or, if there is a pattern on the surface of the material, you need to make a margin for each fragment of this pattern so that the floor looks harmonious during the final installation.

There are two methods for laying this material:

- On a dry floor surface.

- On glue.

If the room is small, such as, for example, a kitchen in a “Khrushchev” or a loggia, then dry installation is allowed. For larger premises, this method will not work. Here you need to use glue or mastic for construction work. The surface of the floor is coated with a roller dipped in a special glue. The reverse side of linoleum is also treated with glue.

After the linoleum is spread and fixed on the floor surface, the baseboards are mounted, adjusting the remaining part of the material under them, fixed with corners and caps.

Scope of use in the home

The system of a heat-insulated floor allows to use it practically in any premises, saving at the same time money on a heater and space under batteries in the apartment.

In addition to these advantages, heated floors have other obvious advantages:

- heating the room with a warm floor gives a feeling of comfort;

- heated floors prevent the occurrence of mold, as heat spreads over the entire space of the room and does not allow moisture to accumulate;

- comfortable microclimate of air due to the individual mode of heat through thermoregulation;

- does not require additional cleaning, because it is enough just to clean the floor without having to clean the batteries;

- warm floor is safe for young children, as it does not give the possibility of a burn, like a regular radiator;

- the absence of heaters outside allows you to perform any layout in the room, and the interior of the apartment looks much more spacious and aesthetic;

- if desired, and the lack of heat can be combined with conventional batteries;

- with proper installation of such a heating system will last a long time.

Since modern apartments are very expensive, anyone tries to appreciate every square meter of their home and tries to equip it so as to use all the useful space of the apartment. This is one of the reasons why people are increasingly using underfloor heating.A very good choice in favor of heated floors - their installation on the balcony and loggia.

Firstly, it will allow to go out to the balcony in the cold season without worrying about your health, secondly, it will provide an opportunity to expand the space of the apartment by combining the loggia and balcony with a common room or kitchen, and thirdly, it will provide additional housing a room that can be used, for example, as an office or recreation area.

Such a solution will not only create comfort, but also bring individuality and modern style to the familiar interior. Despite the fact that the integration of the space of the balcony and the room will require considerable effort, as the wall and the window frame are inevitable, this solution will bring much more positive and functional aspects. Among other things, when choosing a coating on such a floor, less material and time will be required to install it, since there will be no need to cut additional pieces, make patterns under a small balcony. By doing a complete sheet of linoleum, you can solve the problem of the floor in the common room and on the balcony, simultaneously.

A happy pet owner will be useful to use these heating systems as local floor mats, so that they can comfortably warm themselves in cold winter evenings, without jumping to the owners on the bed.

How to care?

This article has listed many positive qualities of floor heating systems. It is worth paying attention to the rules of their operation, which in themselves are also a constant plus.

When caring for such a floor, there are no particular restrictions, but some things still should not be neglected:

- In no case should you clean the warm floor with a linoleum coating with concentrated alkaline solutions, and you should not clean the stains with coarse-grained powders, this can not only scratch the material, but also spoil the design on the product.

- Wash the floor when necessary, using a vacuum cleaner or a well-wrung damp cloth. Particular attention should be paid to baseboards as the main dust collectors, especially in the space between the corners.

Thus, the warm floor is not only a comfortable temperature in the house, but also a modern interior, comfort and well-being, regardless of the weather outside the window.