Frost-resistant linoleum: applications

Frost-resistant linoleum is well suited for arranging outdoor platforms and those that can be exposed to low temperatures for a long time. Modern technologies allow to produce materials that can be used at sub-zero temperatures for 15 years.

Types of coverage and characteristics

Today in the shops you can find several varieties of linoleum, which will be highly resistant to all sorts of weather factors:

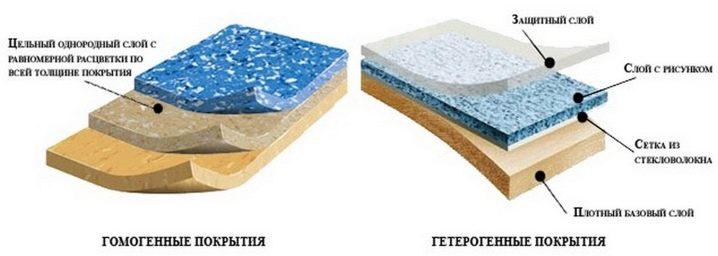

Homogeneous linoleum

Homogeneous linoleum is a uniform and single-layer throughout its thickness product. Homogeneous linoleum perfectly withstand the greatest loads and will not bend under the most significant weight.It consists of chalk, dolomite and quartz sand, polyvinyl chloride, various plasticizers and coloring pigments. This product is a fire-resistant profile, not afraid of temperature changes. Such frost-resistant linoleum is resistant to moisture and the action of chemical reagents.

Heterogeneous linoleum

Heterogeneous material consists of different layers:

- Its base is expanded polyvinyl chloride, which has a characteristic density and elasticity, and various modifying components are added to the elasticity of the material.

- On top of the main layer is high-strength fiberglass, which qualitatively protects the base from serious impacts.

- The next is a layer with a pattern to create an aesthetic look of linoleum.

- The most recent is a protective layer, which ensures wear resistance.

Heterogeneous linoleum has heat and sound insulating properties, quietly tolerates the effects of strong chemicals.

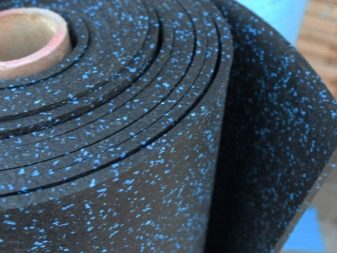

Relin

Another type of product - rubber, but more often it is called relin. It also has several layers:

- As a basis here comes a layer of rubber, which has been recycled. Such a basis tolerates heat and frost, humidity, and the effects of acids.

- A layer of finish is applied on top of it (with the exception of technical linoleum, when bitumen is introduced into the composition and the product comes out more plastic).

The material for public spaces has a very high density rubber coating that is resistant to frost or heat. Relin for sports grounds is similar to the public, but more rough and elastic. Linoleum from rubber for medical purposes is characterized by the presence of an antistatic agent. Also applied to it is a layer with antibacterial effect of natural rubber.

Advantages and disadvantages

Each type of linoleum has its advantages and disadvantages, so it’s best to thoroughly familiarize yourself with its quality characteristics before purchasing a particular material:

- The most important advantages of Relin - long service life and impeccable reliability.. He makes a great variety of unpleasant factors of exploitation. Relin is considered the most frost-resistant type of linoleum, since it does not lose its elasticity at a minus temperature outside the window and therefore does not crack. That is why it is the most popular street linoleum.

- Among the positive features of homogeneous linoleum is to highlight its resistance to reagents.. The material does not catch fire, and will not support the combustion process, and when reflowed it actually does not emit harmful substances. It can easily move special equipment without minimal traces of damage to the product. It is considered the second in frost resistance. He is not afraid of moisture, which eliminates the possibility of damage to this coating in the cold.

- The main advantage of heterogeneous material is its low price compared to homogeneous products. This is a material with a choice of drawings and colors, with its help you can easily select the most interesting design option for any room. This linoleum is laid in different ways, and not only with the help of full gluing. However, such flooring is called the most intolerable to frosty weather.

Polyvinyl chloride without special additives becomes extremely harsh when the frost can crack and break because of this.

In some cases, such linoleum in the cold can even warp.

However, companies today produce a heterogeneous material with a frost-resistant effect. It is denoted by certain symbols.In this case, substances are introduced into the material that increase its resistance to negative temperature. Frost resistance here can be determined by the number of cycles both freezing and thawing, which this material can tolerate without signs of damage.

Which to choose?

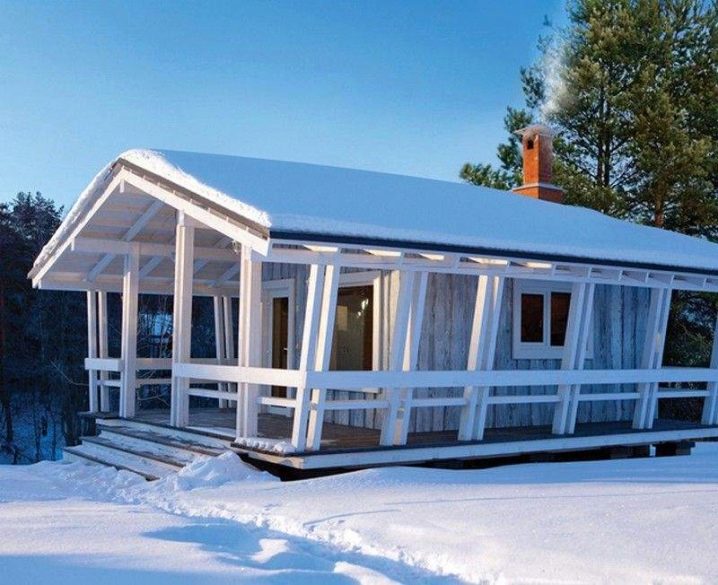

Many buildings that are located on land plots are operated only during the winter season of the year.

- Frost resistant coating for giving or arbor can be a great competitor to popular ceramic tiles. Such a product does not fear water; it tolerates many cycles of freezing and thawing without reducing the quality of its properties and the loss of its aesthetic appearance.

- A frost resistant coating is good and for open balcony. In this space, there are fewer requirements for the effects of low temperatures, but there are often stagnant spaces, and there is the possibility of fungal growth. On the balcony there are often fluctuations in temperature, and there is the problem of excessive moisture. Therefore, the use of such a coating ensures good water resistance of the floor.

It is best to lay plywood sheets under frost-resistant coatings to avoid the possibility of floor rotting.At the edges of such a floor must be fixed plinths, which along the entire length must be holes for ventilation.

- Such linoleum perfectly will approach for glazed loggia without heatingwhere the effect of frost is much less, but the demands on the tightness of space increase. The coating will not let moisture through to the base of concrete, thereby preventing the development of the fungus - after all, housewives often dry laundry on the loggias and balconies and the appearance of puddles of water on the floor is simply unavoidable.

If you want to pick up cold-resistant material to the country house, then you should know that this is a covering that is excellent for rooms where heating is used only from time to time. This product is not afraid of either frost or condensation that constantly appears during frequent heating, or the mechanical effects of footwear on the heel.

The floors of this material perfectly cope with any difficulties, and for a long time retain a beautiful view.

If you need to finish the vestibule of a cottage, terrace or veranda in the country, porch, it is better to choose a single-layer material or its version of rubber. Homogenous product is perfect for closed spaces,and relin can be operated in the open air. You should not forget that for the material having one layer, the equal floor is necessary. If there are uneven places on the floor, they must be removed. Rubber products do not have these restrictions, any floor will do.

Relin is used much more often in public places and in industrial buildings. They usually cover the floor in warehouses and similar spaces for which temperature fluctuations are common. With this product you can insulate the floor in the garage or in the open area in front of the house. Apply it to create high-quality coverage for various kinds of sports facilities.

If you believe the reviews, then such linoleum can be easily laid in the cold season in cold rooms without fear of damage.

Even in the coldest conditions such linoleum does not crack and takes the correct form, while maintaining the necessary elasticity. If necessary, the material is combined with the anti-icing system.

Tarkett company produces one of the most popular types of cold-resistant linoleum under the brand Idilia Nowa. Such a product is resistant to moisture and ultraviolet radiation, has anti-slip elements.

About the features of Tarkett Idilia Nowa linoleum you can learn from the video.

Laying on the floor

Frost-resistant coating when laying on the floor is usually rolled out or immediately glued to the base with special glue with frost-resistant properties, and often do it with their own hands, without the help of experts.

In order to make a high quality linoleum bed, first prepare a base for this material. The basis of concrete is best covered with a layer of special plywood, which has moisture-resistant properties. She will play the role of an insulating base for linoleum. If a warm floor is installed, then a special screed with electric elements is applied on the base.

For high-quality thermal insulation of floors on which you want to lay linoleum, you can use penoplex - an excellent material of the new generation with high heat-saving characteristics. This environmentally friendly material is not subject to rotting, it is convenient to work with it under various climatic conditions without protection from various precipitation.

Many ordinary people wonder whether it is possible to lay linoleum on a wooden surface? This is of particular concern to the owners of wooden cottages, which are rarely heated. In fact, there is no fundamental difference, what will be the surface on which you want to put a frost-resistant material.The main requirement that must be strictly followed is a flat floor surface.

The material is rolled out on the floor, leaving it indoors or on the balcony in such an expanded form so that it “acclimates” for about a day. During this time, the product gains temperature. Laying the product ends with the installation of soft baseboards.

Successful examples and options

For modern balconies, homogeneous linoleum, which is not afraid of frost or heat, which has an increased level of wear resistance and retains its shape even with serious mechanical effects, is best suited.

Relin can cover the floor in rooms without heating and many other spaces with severe fluctuations in temperature. With this product you can equip the garage with high quality.