Florentine mosaic: manufacturing

A striking decorative technique that can bring unique chic to the interior or exterior is the use of mosaic. Originating in the Ancient East, this complex, labor-intensive art experienced periods of flourishing and oblivion, and today it occupies a worthy place among the methods of decoration of rooms and furnishings. Mosaic is a typesetting image of pieces of stone, ceramics, smalt, colored glass. One of the many techniques of making mosaics is called Florentine.

History of technology

It originated in Italy in the 16th century and owes its development to the famous Medici family, whose representatives always patronized artists and masters of applied arts. The Duke Ferdinand I di Medici founded the first professional workshop, inviting the best stone-cutters from all over Italy and from other countries.Extraction of raw materials was not limited only to local resources, because purchases were made in Spain, India, countries of Africa and the Middle East. For the workshop was collected a huge collection of semi-precious stones, stocks of which are used today.

Making mosaics brought huge profits and was considered a strategically important production for Italy in those years. For three centuries, these mosaics were popular throughout Europe: the palaces of rulers and nobles certainly used luxurious Florentine "pictures of stone" in their decoration. Only by the middle of the XIX century, this type of decoration gradually went out of fashion.

Formation and development of style in Russia

The complexity of the technological process, the duration of production (the master worked on individual works for several years) and the use of semi-precious stones made this art an elitist court. Not every royal court could afford the content of such a workshop.

Russian craftsmen have mastered and developed this technique under Queen Elizabeth Petrovnaand many of their works competed adequately with Italian designs.The development of this style in Russia is associated with the name of the master of the Peterhof cutting factory, Ivan Sokolov, who was trained in Florence. He masterfully used Siberian jasper, agate, quartz. The memories of his contemporaries were preserved, where flowers laid out of stones seemed alive and fragrant.

The main centers for working with the Florentine mosaic are the Peterhof, Yekaterinburg factories and the Kolyvan stone-cutting factory in Altai. Russian stone-cutters are beginning to widely use the beautiful Ural gem malachite, which has an expressive pattern, and high-hard Altai minerals, which can only be processed with a diamond tool.

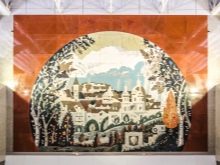

In the future, it was the artists of the Kolyvansky factory that created one of the largest panels (46 square meters in area) made for this technique for the station in Barnaul.

Many beautiful mosaic "paintings" adorn the walls of the Moscow Metro and make it the pride of the capital.

Special features

The Florentine method of laying mosaic is distinguished by high-precision fitting of parts, when there are no visible seams and joint lines between different stone elements.Thorough grinding creates a perfectly flat, uniform surface.

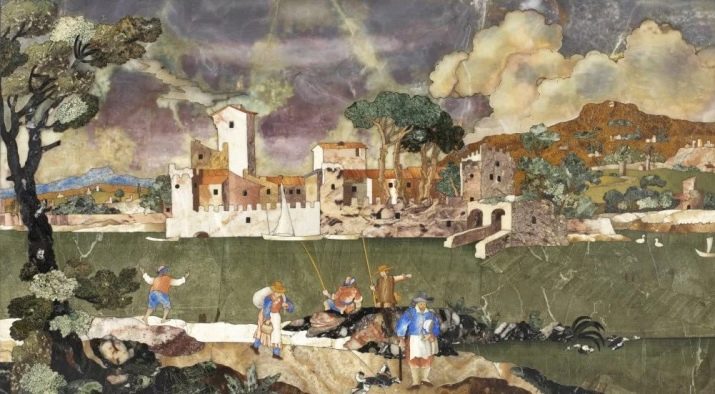

Created from natural stones, this mosaic is amazingly durable, bright colors do not fade with time and do not fade from sunlight. Smooth color transitions allow you to achieve similarities with this picture, and not with inlay. Very often, Italian masters used black marble for the background, in contrast to which other stones lit up even brighter.

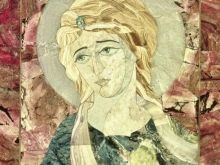

Natural rich coloring of a stone: transitions of his tones, streaks, spots, strokes are the main graphic means of this technique. The favorite materials for the production of Florentine mosaics were highly decorative stones: marble, jasper, amethyst, carnelian, chalcedony, lapis lazuli, onyx, quartz, turquoise. Italian masters invented unique technologies for their processing, for example, the effects of temperature allowed the stone to acquire the desired color. Heated marble pieces became a delicate pink shade, and chalcedony increased the brilliance and brightness of colors.

Each stone plate was selected by the master not only in color but also in texture: for a mosaic with emerald foliage, it was necessary to find a stone with similar green veins, for the image of fur - a mineral with a pattern imitating its villus.

Florentine mosaics were actively used in church decoration for finishing floors, niches, portals, and also decorated objects of a secular interior: tabletops, furniture items, various caskets, trinkets. Large panels, like picturesque canvases, adorned the walls of the ceremonial halls, classrooms and living rooms.

Manufacturing method

The process of making Florentine mosaic can be divided into three stages:

- procurement operations - the choice of high-quality raw materials, marking of the stone and its cutting;

- a set of mosaic elements - there are two ways: direct and reverse;

- Finishing - finishing and polishing products.

Choosing a stone is very important to know and take into account its properties., because the direction of the cut depends on it. Each mineral has individual optical characteristics, in a special way it shimmers in the light and has its own structure. The stone is necessarily moistened with water, then it becomes bright, like after polishing, and you can understand what the finished product will look like.

Selected stones are marked and cut on a special machine. During this process, cold water is poured abundantly to cool the saw and carefully monitor compliance with safety regulations. Elements are cut with a margin on the processing of joints.

In our digital age, laser cutting is increasingly being used, transferring the drawing from a computer without error and with the necessary margin.

The Florentine masters cut the necessary fragments from thin, 2-3 mm thick plates with the help of a special saw - a kind of onion from a bent elastic cherry branch with a taut wire. Some craftsmen continue to use this authentic tool today.

Finishing of individual parts along the contour is done on a grinding machine using a carborundum circle or diamond faceplate, manually refined with diamond files.

When assembling elements into the overall picture by the inverse method, the mosaic fragments are laid face down along the stencils and fixed from the inside out with an adhesive composition to the substrate (for example, fiberglass or tracing paper). This technology is convenient for creating a large-scale project: large parts assembled in such a way from small elements are then assembled locally. This method also allows you to grind the front surface of the mosaic in a workshop.

The technique of direct dialing is the laying of fragments of a picture immediately on a permanent basis. Old masters laid out pieces of sliced stone plates on a leveled reinforcing layer. Today, direct dialing, like the reverse, is most often done in workshops on a fiberglass backing, and then transferred to the object.

The assembled product is processed using polishing and polishing pastes. Different polishing compositions are used for different types of stone, depending on the physical and mechanical properties of the mineral.

The finishing finish gives the stone a delightful brilliance, reveals all its modulations and shades.

Using Florentine mosaic today

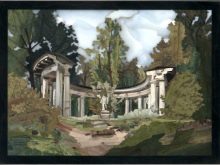

Architects have long appreciated the high decorativeness of Florentine mosaics. In the Soviet period, the use of various types of mosaic for public spaces was flourishing. Most of the panels were made of smalt, but the Florentine method was also not forgotten and was actively used. And since this technique is the most durable, since the years have no power over the stone paintings, they still look like new.

In modern interiors, properly selected Florentine mosaic will not look like an alien and outdated element. Magnificent patterned panels for walls and floors in the hall, bathroom, kitchen can be entered both in classic style and in modern style, they will enliven strict high-tech or loft. Mosaic canvases will look great in the decoration of the pool or terrace in a country house.

The small forms of this mosaic also look interesting: decorating boxes, mirrors, gift writing sets for the cabinet and so on.

This technique is also widely used in jewelry: large brooches, earrings, rings, pendants with a patterned stone pattern carry the special attractiveness of natural material.

Despite technological progress, the Florentine mosaic method still remains laborious and man-made, so these works are quite expensive, and the price of the best examples is comparable to the cost of the masterpieces of classical painting.

Even more about the art of "stone painting" in the next video tells the master.