How to choose the thickness of the floor tile?

When choosing a tile for flooring, several parameters and characteristics of the material should be considered at once. However, only a few know that the thickness of the floor tile is one of the most important criteria by which to choose this coating.

Value

Most often, the thickness of the tiles pay attention almost the last. However, it is precisely this characteristic that largely influences the indicator of the strength of the product, and hence, the wear resistance and durability.

At the same time, reinsuring and buying the thickest tile is also not always reasonable and rational - the foundation of the floor can not withstand such a load. In addition, an excessively bulky floor covering, where a layer of glue is also added to the thickness of the tile, can causethat closets and interior doors will stop closing Therefore, the choice of tile thickness should be taken with great responsibility.

Main settings

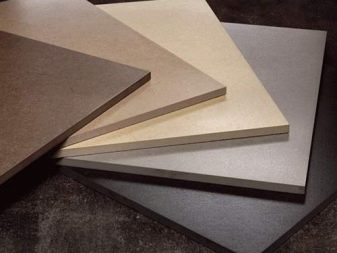

Currently, manufacturers offer several options for the thickness of floor tiles, which are combined into three groups:

- thin;

- average;

- thick.

Products of the first group, having a thickness of 3 to 5 mm, are more suitable for wall cladding, but recently they are also used for arranging the floor. The advantages of such tile material include the fact that it has a low weight, it is easy to lay and at the same time it does not create any obstacles for door structures.

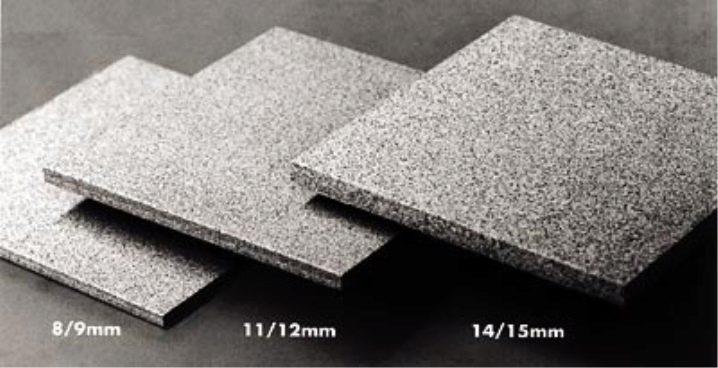

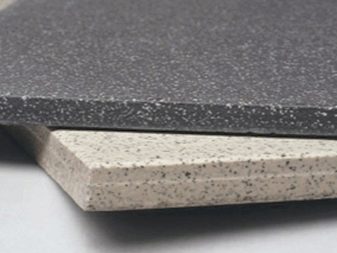

The average or standard tile thickness is considered to be from 6 to 15 mm.

Thick items include items of 2-3 cm. By its strength, such a tile surpasses all previous ones, but it also has significantly larger dimensions and weights, which in some cases is considered a disadvantage.

It is noteworthy that the thickness of the tile may slightly differ from the one declared by the manufacturer (the deviation is up to 0.5 mm). At the same time, the parameters of elements may not coincide even within the same batch.All this must be considered before choosing the material for facing the floor.

In general, with respect to the ceramic elements of the floor cladding, two regularities are applicable:

- The thicker the tile element, the more expensive it is.

- The greater the thickness of the product, the greater the rest of its parameters (length and width).

An exception to the second rule can be a mosaic - having rather “modest” length and width indicators, it is up to 8 mm thick, which allows it to withstand considerable loads.

Manufacturers Standards

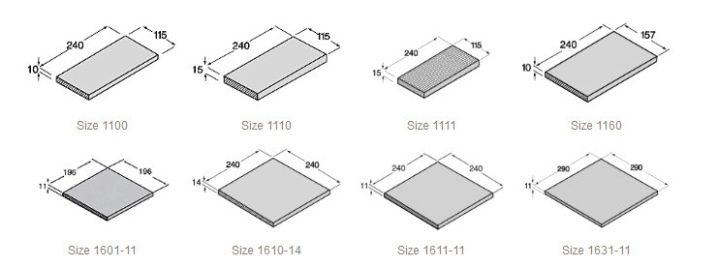

Since today there are no uniform standards for the thickness of ceramic elements, each manufacturer sets its own.

So, the most popular tile from Atem may have a thickness of from 7.5 to 9.5 mm. In this case, the parameter may vary depending on the collection.

Firm Azori, in turn, produces tiles with dimensions 333x333x9 and 505x201x9.

At the company Altacera your criteria. This manufacturer offers ceramic elements 418x418x8 mm.

Non-standard thicknesses can be found at the company's products. Kerama marazzi. Here there is a tile that has a size of 7.8 or 8.3 mm.

Tile material with the most optimal thickness of 9-10 mm is offered by Italian manufacturers Cedir and Settecento.

The same applies to the minimum or maximum thickness index - each manufacturer can have completely different ones.

Purpose

The main criterion for choosing the thickness of the tile on the floor is the purpose of the room where the product will be used.

In this regard, it is important to know that all ceramic tiles are divided into several classes:

- 1 class - tiles designed for rooms with a minimum load - for rooms that are not made to enter into massive shoes. Such premises include, for example, a bathroom.

- 2 class - material for rooms, where they also walk exclusively in soft shoes or even without it. This can include any accommodation.

- 3 class - a variant of ceramic tiles, which can also be used for homes and apartments. Such a product will easily withstand the load from walking on it in slippers.

- 4th grade - the type of tile that will be appropriate in high-traffic areas. It can be offices, halls of public institutions and other crowded places.

- 5th grade - a versatile material that can be laid in almost any room with any degree of load on the floor.

In addition to ceramic tiles, porcelain is often used to cover the floor. Its main difference from the usual tile is in manufacturing technology. Due to the fact that it uses more pressure (400-500 kg / cm2) and elevated temperature (1200-1300 ° C), it has improved characteristics, and in particular, durability. The latter is to a great extent achieved due to the thickening of the elements.

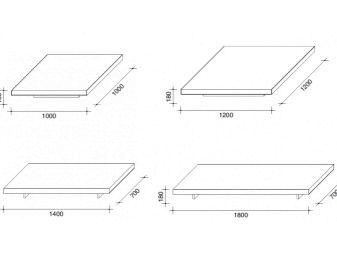

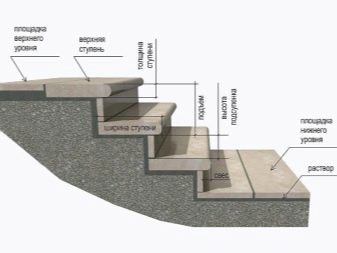

The thickness of slab porcelain products varies from 13 mm to 25-30 mm, which allows it to be used on verandas, steps and even for paving garden paths. Perfect porcelain tiles for arranging flooring in garages, utility rooms and even in parking lots.

Massive granite can be laid on the base without the use of adhesive. Mass and dimensions will not allow elements to shift. However, in this case, laying on the basis of a sand cushion is necessary.

Another type of tile, which has recently become widespread, - material under the tree. Such elements quite authentically imitate parquet boards both in texture and in color and even in size.

Dimensions non-standard for tiles (150x450, 120x600 and 20x600 mm) make it more fragile than more usual square products, therefore it is made of extremely durable ceramic granite with a thickness of 7-11 mm.

No less important criterion when choosing the thickness of the elements is the maximum permissible load of the floor covering on the base.

The most common types of subfloor, which are laid tile or porcelain, are:

- concrete;

- wooden base;

- plywood;

- dry gypsum fiber screed.

The most durable of them - concrete, it can easily withstand tiles of any thickness. At the same time, it is thanks to its strength that thin elements can be laid on it - concrete will strengthen them and increase the reliability of the foundation. The same effect is achieved when laying the coating on the base, also consisting of ceramic fragments. As for the other materials, here the best option is considered to be elements with a volume of 9-11 mm.

It is not always necessary to increase the strength characteristics of the floor by increasing the thickness of the tiles. In some cases, this can be done by reducing the size of the elements themselves.It is important to remember that bases such as wood and plywood are considered unstable, so when installing tiles on them, you must use elastic grout.

Glue selection

When laying tiles and porcelain tiles, it is necessary to take into account not only the parameters of the tile elements themselves, but also the thickness of the adhesive layer.

The thickness of the tile adhesive can also be different.

Its parameters depend on:

- tile size;

- what tile is used (type of material);

- height differences of the subfloor.

In addition, it may depend on the type of the adhesive composition, which can be used as:

- Cement mortar. This type of bonding composition contains cement, sand and additional modifying components and is considered the most simple and convenient to use.

- Two-component formulations. As a rule, they consist of epoxy resin and a substance that accelerates the hardening of the composition. The use of such a mixture provides effective adhesion of the tile with the base.

- Dispersion glue. It is realized in the form of ready mix. It is based on resins, sometimes supplemented by polymer components. The most popular composition of this group is latex glue.

When using cement to bond the coating to the base, the adhesive layer will be thicker than when using synthetic compounds. It should be borne in mind that the quality of installation, the durability of the coating, as well as the complexity of the installation process depend on the correctness of the choice and application of glue.

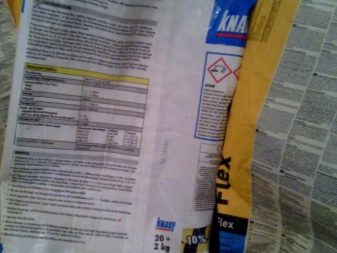

As a rule, recommendations on the application of glue and its thickness are indicated on the package with adhesive composition.

However, if necessary, you can make calculations yourself:

- A large role in the calculations is played by the state of the base of the floor - if the surface is as flat as possible and has no gaps or recesses, then the glue can be applied with a thin layer of 4 mm.

- When laying large items, for example, the size of 6x6 cm (on a flat floor), the volume of the adhesive layer increases to 5-7 mm.

- If the draft floor is uneven, the thickness of the adhesive can be increased to 30 mm.

However, experts do not advise to align the subfloor and hide the cracks with the help of adhesive composition. First, the larger the layer, the longer it will dry. Secondly, when applying too thick a layer of glue will increase the risk of its delamination and, as a consequence, damage to the floor covering.Much faster and more economical will be the implementation of leveling screed on the base.

It is important to remember that when calculating the total height of the floor covering, it is the indicator of the thickness of the tile with glue that is taken to avoid reinstalling or trimming the doors.

How to choose a ceramic tile, see the following video.