Features of the choice of primer for liquid wallpaper

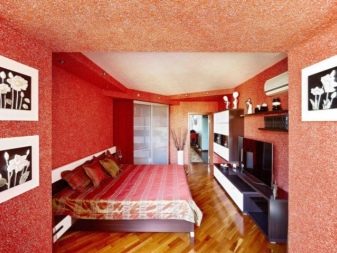

Liquid wallpaper is a popular finishing material in the design of walls and ceilings of different rooms. To keep this finish on the surface for a long time, you need to use a special primer before sticking. In this article we will understand the intricacies of choosing a primer for liquid wallpaper, exploring the recommendations of experts.

Special features

Primer is a means of preparing the base for further finishing. It is produced in the form of a concentrate or a finished composition that does not require adjustment before being applied to the surface. The concentrated type is a powder mixture that must be diluted with room temperature water before processing the surfaces of the walls and ceiling. The amount of water to dilute a particular type of material is indicated on the packaging of the product.The consistency of the finished composition resembles thick milk.

The structure is characterized by viscosity, due to which this material binds microcracks, pores and dust of the treated surfaces. During processing, the primer penetrates into the thickness of the overlap layer to a depth of 1 cm and makes the walls homogeneous. This is especially true for the walls, made in violation of the technology that gives the sand crumbling from them, as well as porous bases.

The primer has a different penetrating ability, however, regardless of the type of material, it strengthens the walls.

The material is sold in plastic buckets and cans. The most demanded volume for surface treatment of walls and ceilings (when pasting the ceiling zone) is the volume of 5 and 10 liters. If the gluing area is small, a volume of 5 liters will suffice for processing. As a rule, the surface is treated twice before sticking with liquid wallpaper. The first time the material will leave more, as often the walls are very absorbent. The second layer of soil will be economical.

A distinctive feature of the primer is a different color and texture. The color of the material can be transparent, white, light gray and pinkish.To strengthen the walls you can not use a colored primer, especially if the color of the selected wallpaper is light. For surface treatment, it is better to use preparatory raw materials of two types: transparent and white.

Immediately apply a transparent primer to the surface. White will allow you to see where the processing took place and even out the tone of the walls, masking the different spots. It is particularly appropriate in the event that the gluing of liquid wallpaper is planned on a dark concrete base. At the same time, the lining material applied by means of a spatula or an airbrush with a large nozzle will not show through the dark tone of the base.

Relevance

To date, the market for construction products primer is represented in a wide range. This material does not relieve the walls from serious problems. The primer is applied to the base only after all the cracks have been smeared over, the bumps have leveled off, and the visually noticeable pits are removed. If you ignore this preparatory process, more liquid wallpaper will go away during the pasting, and their coating layer will be uneven, which can be visually noticeable.

The use of a primer before pasting will not only reliably connect the facing material to the base, this will also simplify the finishing process. It will relieve the overlap of high absorbency, while performing pasting, it will be easier to carry out the adjustment. A lot of liquid wallpaper will not instantly dry out, which will allow it to be distributed over the wall surface in a dense even layer.

The more penetrating the primer, the better.

The use of a primer before pasting surfaces of walls with liquid wallpaper reduces the consumption of raw materials. This composition isolates problem areas of the planes, for example, with metal fittings, therefore rust spots will not appear on the surface of the finished lining over time. The layer of the film formed after the walls are treated with soil will allow keeping fairly heavy types of liquid wallpaper on the surface. Three times applying a primer on the wall will allow you to mask and isolate the spotty base.

Kinds

From the mass of species can be distinguished Three categories of primer, which can be purchased for processing walls before they are covered with liquid wallpaper:

- acrylic;

- universal;

- special (as concrete contact).

A good primer is capable of leveling minor flaws in the walls for finishing. Acrylic variety is quite popular. This primer is distinguished by good viscosity, the film formed on the surface after drying is strong enough. This soil dries optimally quickly, in the process it does not emit an unpleasant odor, it is suitable for interior work. When dried, it forms on the surface of a polymer crystal lattice, providing a sufficient level of adhesion.

The universal analogue is remarkable in that it took a little from each variety. Therefore, this primer has penetrating, strengthening and leveling abilities. However, its effect is not as pronounced as in individual categories. Its penetrating power is less: this kind of soil penetrates into the basement by no more than 0.5 cm.

The best choice for preparing the surface of the walls for sticking with liquid wallpaper is a primer for concrete contact. Its distinguishing feature is the presence in the composition of a mixture of quartz sand, due to which the surface acquires some roughness upon drying.This fact provides maximum adhesion of liquid wallpaper with the treated surface. This feature is explained by the fact that a too smooth base complicates the pasting process (liquid wallpaper is less distributed over the surface and can roll). The presence of roughness on the wall delays the adhesive mass, so it is much easier to lay out the desired pattern of material of different colors.

Subtleties of choice

The type of soil depends on the type of liquid wallpaper used. It is unacceptable to buy the first thing you like on the counter: the choice must be solid. It is important to take into account not only the brand: it makes sense to buy soil with an antiseptic effect. Due to this, the surface will be reliably protected from the formation of the environment for the appearance of fungus and mold.

When buying, pay attention to the mark of "deep penetration": This primer will more thoroughly prepare the surface for the finishing work. It will make the base uniform, reduce porosity and strengthen the walls. Experts recommend processing walls with two types of material - transparent and white. Despite the fact that the primer can be painted with an ordinary color scheme, do not experiment with color, as you will distort the color of the intended lining.

If you plan to glue the walls with white or light liquid wallpaper, in the preparation process, use a white primer twice: it will mask problem areas of the walls with higher quality. Due to the color in the process of working with such material, each treated area is visible. This will allow the surface to be treated with a uniform layer: the film lattice formed after drying should be uniform.

When buying a material, pay attention to the purity of the color, it must be perfectly white or transparent (without admixtures of other shades). Consider the nuance: high-quality primer deep penetration is more expensive than conventional counterparts. When buying, look at the shelf life: after it passes, the material loses its properties. If the repair work is not planned in the near future, and the shelf life of the selected material comes to an end, such material cannot be taken. If an expired primer is used, adhesion will not be sufficient.

If the basis of the problem, you need a primer for surfaces of the porous type. Carefully read the features of the application of primer indicated on the label. Not every primer is suitable for treating dark surfaces.

It is necessary to buy a primer strictly in accordance with the scope and type of treated surfaces. If there is a question of choosing a particular brand, you can pay attention to the products of Ceresit, Knauf, Silk Plaster. Sometimes these materials have a label “for silk decorative plaster” (liquid wallpaper based on silk or paper fibers).

How to use?

So that the process of surface treatment before pasting liquid wallpaper does not cause difficulties, you can use a small instruction. Before the working process, a roller, a flat brush of medium size, gloves, work clothes, and a container for a primer solution are prepared.

The algorithm of work will be as follows:

- The composition is poured into a prepared container, the dry mixture is diluted according to the instructions on the package.

- Take the construction roller, impregnate it in a primer solution, gently squeeze and roll over the surface.

- Priming is necessary, evenly distributing the composition. However, it should not flow along the walls, forming pools on the floor.

- In hard-to-reach places use a flat brush: it will allow you to perform the processing of corners, ceiling joints and walls more accurately, without overspending the solution.

- If the walls do not absorb liquid well, they roll the same section several times with a roller, then proceed to the next one. At the same time for each site add a new portion of the liquid.

- At the end of processing, the tools are thoroughly washed, because if the composition remains, it will become hard, the brush and roller coat will have to be thrown out.

The second layer of primer is applied only after the first one dries. Do not break the process technology and hurry: it can affect the level of adhesion. After applying the second layer, it is worthwhile to wait a day and only after that start to stick the walls with liquid wallpaper. Dry walls do not stick to the touch.

What else to consider?

In order not to doubt which primer to choose for the preparation of walls for pasting with paste-like liquid wallpaper, pay attention to information indicating additional properties of the soil.

Plasterboard walls should be treated with a deep penetration primer.starting from the joints of the sheets. It will not be superfluous to handle connecting fastenings with enamel or acrylic paint.

It is necessary to process wooden surfaces or walls on the basis of pressed wood with primer with waterproofing properties.If the wooden wall under the liquid wallpaper is not processed, use a solution based on shellac: it will not allow resin spots to appear on the surface.

If possible, scrub the paint from the surface of the painted base and treat it with an anti-fungal compound. If the wall has metal fasteners, treat it with an alkyd primer or a material based on phenol or glyptal. For concrete, it is better to use primer for concrete contact.

If the store does not have a primer with quartz sand, which makes the surface rough, you can buy ordinary deep penetration primer and add fine-grained seeded river sand to the composition. It is not necessary to replace this material with a home-made primer created from water-based paint with the addition of PVA glue. The composition of this material differs from that developed by trademarks. The components of the primer are designed in a special way, they balance the necessary components to strengthen the walls from the inside, which is not the case for home-made formulations.

In the next video you will find instructions for preparing the surface for applying liquid wallpaper.