Putty walls under the wallpaper

Rarely repairs in an apartment or office space do without work with the walls. The final stage before the wallpapering on the walls is the putty of the walls.

What it is?

This is a mandatory type of work during the repair, which involves working with the wall, after which glue and wallpaper are already applied to the wall. The advantage of the method is that the alignment of the walls is fast, and if necessary, putty can be fixed.

There are people who believe that the stage of filling the walls is absolutely superfluous during repairs. It seems to them that the walls are processed perfectly without it. But this opinion is erroneous. It is fraught with the fact that after pasting wallpaper, the defects that had a surface will become obvious, and it will be impossible to hide them, since the wallpaper has already been glued.We'll have to start the repair, if not from the beginning, then from the middle. After all, you have to rip off the wallpaper, putty the wall and re-glue them. This is a great effort, a waste of money and time wasted. That is why it is necessary to caulk the wall.

Putty allows you to make the surface as smooth, smooth and even glossy. This allows you to make the repair of wall surface ideal.

Why do you need?

Mandatory puttying before sticking wallpaper is a requirement that must be strictly followed.

Filling is intended to eliminate and conceal not only large and medium defects, but also tiny, barely visible or completely invisible microscopic defects that are present on the surface. This contributes to the grain structure of the mass. It is important to note that the level of filler filler is several dozen times less than that of various compositions, which are used when plastering walls.

Putty is a repair material that is able to level the surface so that it becomes a perfectly smooth wall. As a result, it will be much easier for the master to stick the wallpaper. Much easier than plaster wall.At the same time through the structure of the finishing material will not manifest minor defects.

We should also mention the apartments where the walls are sheathed with plasterboard sheets. Of course, this surface must be trimmed by pasting wallpaper on it. In this case, the application of such a material as putty is extremely necessary.

Some people think that one can do without this, because it seems that the surface without this is quite even. But the reason is that if sticking wallpaper directly onto drywall faces problems in the future. For example, when the next repair will require the removal of wallpaper, the finishing material is very likely removed with a layer of cardboard. This threatens to require more serious repairs to the wall than simple and quick filling.

As a rule, specialists can conditionally divide the process of preparing a wall using putty for subsequent gluing of wallpaper into two stages:

-

Applying a starting layer of rough putty. It will allow to fill all defects and microcracks on the surface of the wall, as well as to level small surface irregularities.This layer, according to experienced craftsmen, should be about 3-5 millimeters thick.

-

The second layer is the final composition of the putty. Its application will make the wall incredibly smooth, one might even say perfect. The thickness of the finishing layer, as a rule, can be in the range of 1.5-2 millimeters.

It’s not so important how much experience a person has when he putty walls. It is important to follow the instructions and carefully select the type of mass that will be applied to the wall. To do this, you need to take into account many parameters: humidity, which will be in the room, possible thermal effects, as well as what type of wallpaper you plan to glue over a layer of putty.

You can’t be afraid of doing work, even a newbie will succeed if he follows the instructions clearly and doesn’t worry if something is not going according to plan.

Virtually all the flaws can be immediately corrected, without waiting for the mass to harden. When the composition has already been applied to the wall and began to dry out, and defects were suddenly found, they should be fixed as soon as possible.

Kinds

Extremely responsible it is necessary to approach the selection of coatings that are planned to be applied to the walls.It is necessary to choose only quality material. Such mixtures are considered to be the key to successful work. Material options weight.

The market offers powder, which still needs to be prepared, or ready-made pasty, which does not require time for preparation. On sale you can find plaster, cement, polymer, initial (starting) and finishing putty.

It is noticed that the ready-made mixture is more popular with buyers in stores of building products.

Regardless of the type, any putty effectively removes flaws that are present on the surface. The mixture is the basis for further processing and copes with this task.

To choose the right weight for filler, you need to take into account the characteristics of the walls, the purpose and type of coating. It is important to know what types of filler bases are, and also what are the areas of their application.

Cement

Cement base for putty is recognized by the masters-finishers universal material by which the alignment of the outer and inner walls. This material has excellent resistance to high humidity and frequent temperature changes.Due to this property, it is often used for application in the bathroom or toilet, basement, shower, cellar.

It is great for applying to external walls. The cement base is perfectly placed on the concrete and brick surface, but because of its rough texture, which is difficult to grind so that it is perfectly smooth, rather hard decorative coatings such as tiles, tile, chipboard are often applied to the base.

Gypsum

Usually this type of putty is used only for interior decoration. The reason is that gypsum plaster is the most plastic. Masters recognize that it is convenient to use and allows you to make the walls much lighter. Another property they get is haze. Master finishers advise to use two types of mixture at the same time: starting and finishing. Starter is used to fully align the surface of the wall, which differs markedly in structure.

This mixture can perfectly fill cracks and pits on the surface. The second layer of the mixture will allow you to create and polish a smooth base under the wallpaper covering.

Polymer

The mass based on the polymer is an innovative material. It is noted that he has the highest level of smoothness. Polymer putty is divided into two types: acrylic and latex. The first option is used to create any kind of coverage indoors and outdoors. As a rule, it is used as a roughing basis at the beginning of puttying, as well as as a leveling finishing layer.

Specialists, decorators believe that the polymer putty on the wall is easy to apply. This can be done in almost any room. In this case, the amount of material spent will be small. Usually latex material is used as a finish. As a finishing it is perfect.

This mass is very good at covering the walls. Often used on ceilings before painting them. Latex material allows you to create on the surface smooth, glossy, almost oily surfaces, on which there will not be the slightest flaw.

It is important to note that unlike other materials, this one is the most expensive. This is due to the fact that despite the huge number of advantages, in Russia it is not yet very popular.But experts still appreciated the quality of the putty and the result it gives.

Water dispersion

There is another kind of putty. Buyers became interested in this variety not so long ago, as it appeared very recently in hardware stores. Since the water-dispersion putty has very high performance, it is preferred to acquire professional builders. Finishers point out that it can be applied without difficulty on all surfaces, even concrete or fiberboard. They are also applied to brick or wood surfaces effectively.

This putty paste has an acrylic base. The composition also has adhesion, shrinkage. The mixture has a high moisture resistance, flame retardant. At the same time it does not contain all sorts of organic compounds. The cost of the mixture is within the affordable price range. If suddenly the mass becomes too thick, then it will not be difficult to fix it. You just need to dilute it with water. It dries quickly after application. Since a certain number of different resins are added to it, all its properties are improved compared to the mass in which there is no such addition.

Due to the fact that there are resins in the composition, the putty dries much faster than all the others, so it is very convenient to use it in cases where repairs need to be done as soon as possible.

Instruments

To perform the work on the putty, we need not only materials, but also tools.

For quality work with putty you may need:

-

Drill with mixer nozzle. Often, the putty mix is made as a dry powder. To be able to put it on the wall, you need to dilute it with water, and then bring to the desired consistency. To get the putty without lumps, it is best to use a drill with just such a nozzle.

If there is no possibility to mix the mixture, it is better to choose a putty in another form, because mixing it without a mixer is almost impossible, and putting the mixture with lumps on the wall means starting up a repair under the slope.

- Several spatulas of different sizes. They will be useful in a variety of situations in the repair. So, for example, in the case of processing corners or other difficult surface areas, a small spatula is perfect. But for the rest of the useful spatula, the size of which will be in the range of from forty to fifty centimeters.

- Many brushes and foam rollers of different diameters. Such tools contribute to the quality of the primer of various walls. They are very easy to apply the thinnest layer of primer material. It is this thin layer that provides excellent adhesion between the wall and the wallpaper layer.

- If the walls are very uneven, then you will need tool with an interesting name "rule"which is derived from the word "correct." Such a tool is required when working with walls that have irregularities. Putty in such cases should be applied quite thick. Because of this, there is a risk of uneven distribution of mass over the surface. To avoid this, you need a rule.

- Sandpaper. It is used when you need to grind walls. These works are performed after the puttying process, in order to improve the transitions between different layers. In addition, microscopic tubercles and depressions that appear after applying the solution are eliminated. To get rid of them, apply paper, in which the grains are small. You can also take to facilitate sanding hand skin.

There are several types of primer solutions that are used in repair work as professional builders,so and amateur finishers:

-

Acrylic blends used for application to a wide variety of surfaces. They will be equally good on concrete, cement, wood, brick, plywood and plastered wall surfaces. Masters appreciate the fact that this material is not inherent in all sorts of specific odors that some extremely dislike. Among the positive qualities note that the composition can dry for five hours. Sometimes it happens even earlier.

It is the acrylic blend most often bought by professionals to prepare the wall for further sticking a different type of wallpaper.

- Alkyd putty purchased for finishing wooden walls. As a rule, for country houses such a mixture is the most popular and relevant. Unlike the previous species, its drying time is much longer. But at the same time the masters note that the mixture does not dry out for more than fifteen hours, as a rule, the drying process is completed earlier.

- If you need to finish wood or metal surfaces, and the humidity in the room is quite low, you can buy glyphthalic putty mixtures. A distinctive feature of these mixtures is that they dry out during the day, which is much longer than in previous species.

- Perchlorvinyl filler can be purchased if the wall is concrete, metal, brick or plastered. It differs almost instant drying, it will take no more than an hour. It is important to note that this applies only to those cases where the puttying is carried out at room temperature.

Brands

The choice of materials for repair is a responsible event. After all, it depends on how high quality they are, how the interior will be after the completion of work. Before going to the hardware store, you need to carefully read what brands and brands that produce mortars exist to find what you need in a particular situation.

Often professionals buy one of the cheapest branded mixes on the market. "Vetonit". Despite the low price, it is good because it has a relatively minimal consumption, easy application on almost any surface. With its help, it is possible to correct almost any defects of the wall, regardless of the extent to which they are presented on the surface.

But even such a great mixture is not without flaws.Among the minuses can be noted that it has a low level of strength. It in no case should not be used in high humidity. In addition, after drying it has a rather large shrinkage.

German brand Knauf celebrated by professional finishers as a manufacturer of high quality finishing materials. Due to this, the company rightly somewhat overstated the cost of its products relative to other materials. Usually masters use this putty in order to putty plastered walls. In addition, it is excellent for plasterboard surfaces, which will later be covered with a layer of decorative paint or wallpaper, whether paper, fiberglass or non-woven, will be glued.

Knauf HP for draft works is very popular. It is purchased both for work inside the dwelling, and for all kinds of premises that are not intended for living. When working with this mixture, it is important that the room is maintained at normal humidity. Experts believe that the mass should be applied in a layer whose thickness will be at least 4, but not more than 5 millimeters.It is in this range that it works best. A package of such a mixture weighs 30 kg. Other packaging is not provided. Masters point out that they didn’t reveal any deficiencies in this mass, therefore, they recommend it to all their colleagues and beginners.

Finish line Knauf HP also proved itself on the positive side. It is used to prepare the surface for painting or sticking wallpaper. It is not suitable for premises. where high humidity. Masters recommend that when applying not to make the layer thicker than 4 millimeters, otherwise the work will be of poor quality. The mass should be applied in 15 minutes, and after that it becomes unusable. Unfortunately, according to the otdlochnikov, large particles of different diameters are often found in the mixture, and this significantly complicates the filling process.

Very white putty Unis "Kron" it is used in heated rooms where it is rather dry. Non-professional finishers do not like this material because it is difficult to cope with it. For lovers, it is not suitable, because it is difficult to smooth, and the mixture consumption is very high. It is better to pick something else, if the work will be carried out by a beginner.

Cement based putty for concrete walls - Kreisel 662. She has a fine grain. You can apply the mixture on an unprepared surface. Its peculiarity is that the application implies only a thin layer. Masters familiar with this material note that she has a very large shrinkage. If you decide to purchase this particular mixture, then you need to consider that it is packaged in 25 kg bags. There are no other packaging offers on the market.

Expensive but high quality mix Ceresit It happens both starting and finishing. Ceresit CT 29 belongs to the first category, Ceresit CT 225 belongs to the second category. Both species are based on gypsum. If we talk about the starting mixture, then it is perfect for both internal and external decoration, the difference in the quality of work will not be. In addition, it can be used to cover up defects of a different nature. But it is important to bear in mind that for wet rooms it will not work. A distinctive feature of this mixture is that the composition contains special microfibers. Thanks to them, a very strong setting occurs. For this mixture is appreciated by professionals.

No less high quality and finish mixture. To perform the work it is necessary to apply it on a surface that has already dried and grounded.Before this, a starting layer must be applied. Both types of putty are packed in bags of 25 kg and are much more expensive than similar putty mixtures. That high price can be considered the main and, perhaps, the only drawback.

If the work on the putty of the walls is coming for the first time, then on the advice of experts it is recommended to take the already prepared mixture, which is based on water and polymers. Its convenience is that a suitable optimum consistency has already been achieved, and it is very easy to apply. Such mixtures are sold in very convenient plastic packages.

No need to doubt whether the best putty has been purchased or not. In addition to a small overview of the types of putty materials, which is given in this article, consultants can help a novice in choosing a store. They know perfectly well what to advise a non-professional. Do not hesitate to seek help from professional craftsmen. If this is neglected, then the work can be done very poorly and they still have to be redone, attracting professionals. And this is an additional cost.

Calculate the amount

Before you begin to putty on the walls, you need to be familiar withWhat is the material consumption. Know this is necessary, because before buying the material you need to calculate the right amount. Consumption depends on many indicators. They must be taken into account even then. when a team of craftsmen is working on repairs, and not the apartment owner himself.

The required amount of the mixture depends on how initially the walls are curved, what is its size and the area to be processed. The average consumption rates are as follows: if you make a layer of putty with a thickness of 2 to 5 millimeters, it will take 1-3 kg per square meter. If the surface is extremely uneven, flaws are noticeable, then the layer thickness increases from 7 to 10 millimeters. This, respectively, affects the consumption, which increases to five to six kilograms per square meter.

We should also highlight the final coverage. As a rule, the finishing putty is applied with a very thin layer, the thickness of which does not exceed 1 mm. Its expense, naturally, is much less. It ranges from 0.5 to 1.5 kg per square meter.

Technology

Having studied the technology of application, any newcomer will be able to easily wipe the joints, level the corners, properly putty with his own hands without any experience a wall made of drywall or plywood, OSB-slab. He will not be difficult to putty concrete and plastered walls, wood, chipboard.He will succumb to panel walls, hardboard, painted walls and even very curves. Works on plaster will bring pleasure, and putting finishing finishing - exultation from completion of works.

Before you start, you must remove the old wallpaper. When it comes to basic leveling, you need to use clean dishes and pour water into it. Pour some powder into it and then mix everything with a special mixer nozzle on a drill. You can also take a special mixer or perforator with spetsnazadkoy. As you stir, you can add more powder. The result should be a mixture, the thickness of which corresponds to the density of sour cream. The texture can be selected by trial and error.

Certain features involve working with gypsum putty, as it dries very quickly. In this regard, you need to prepare the mixture exactly as much as you plan to use in the next half hour, otherwise it will turn into a plaster figure.

The first smear should be applied with a thin layer. The putty must be liquid, and the application must be done with sharp movements. The spatula must be taken such that the length of its blade is about 60 centimeters.Despite the vigor of movements, it is impossible to press on the spatula, otherwise it will cut off small irregularities. The mixture does not fill the cavities formed in the process, so when everything dries out, new irregularities will appear. They will disappear after the next, thicker layer.

When working in the corners and joints of the walls, the movement of the spatula should be horizontal in the direction from top to bottom, and on all other parts - arc-shaped.

Next, you need to eliminate the remaining noticeable depression. Thick putty perfectly contributes to this. To take for the work you need again the same spatula, the blade of which is 60 centimeters.

Having taken a spatula for the first time, a person can decide that working with him is an impossible task, since considerable efforts are needed. But if you take a spatula with a shorter blade, then it is simply impossible to get a perfect or close to that result.

After the composition is completely hardened, you need to take fine sandpaper and carefully sanded the treated surface. Paper will help eliminate all the flaws. And only after this action should be applied to the wall finishing layer. For this perfect liquid putty.

How many layers to apply?

This issue is resolved strictly individually. as each wall may need a different number of layers. For more even enough starting and finishing. For those where the flaws are visible to the naked eye, three layers are urgently needed, two of which will be rough and one fair and finishing. In addition, it is important to note that some surfaces look so smooth. For them, you can take only the finishing composition, but still apply it in two layers.

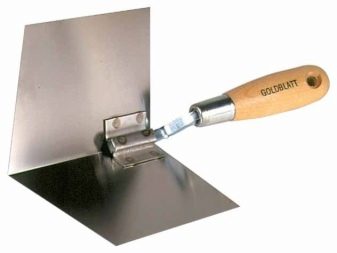

Smooth and precise angles are the most important requirement for rough finishing. It is necessary to ensure that the corners are as even as possible, then the wallpapering will be high quality. Before applying the wallpaper, you need to carefully check that there is not even the slightest flaw, and the corners have a clear shape. It may seem like a very laborious and costly process. For a beginner in finishing work, this is true.

Professional finishers advise you not to remove the excess mixture from the corner surface in order to grout after using it with abrasive material, so the corner will take on the necessary shape.

For this type of work most suitable special angular spatula. This tool is very effective for this job. Its peculiarity is that it functions according to the principle of “reliance on the wall”. If the work is done by a novice and he doesn’t have a lot of tools, you can take a special silicone tube and use it to distribute the volume of putty. Even the most common pastry syringe is great for this. It will allow to distribute the entire putty mass.

Following this action, you need to do the cornering with an abrasive. The slopes are filled in exactly the same way as the corners. The difference between these types of work is only that it will take much more time because of the hard work. If the work is done for the first time, then it will be extremely difficult for a beginner. A rare person, who first took on this work, will cope perfectly well the first time. Professionals use an angular spatula and level the surface abrasive.

Important nuances

Master finishers produce putty for all types of wallpaper using the same technology. It consists of several important stages.It does not matter what wallpaper master took: paper, structural, vinyl or textile.

The very first stage of work involves cleaning the surface from dirt, dust, as well as the old finish, whatever it is. This is very important, otherwise new works may go down the drain, because a new layer on top of the old one will stick badly.

Next you need to prime the cleaned surface. Non-professionals can decide that priming is an unnecessary step that can be abandoned. It is necessary to take the impregnating or strengthening mixture. They will help the dresser prepare the wall surface. In addition, a tight adhesion of the putty and the wall surface will be ensured. It is most important to prime the walls that are made of concrete with a primer. For such work it is best to take a wide roller.

The next step involves applying a layer of leveling putty to the wall. The thickness of the layer is determined individually for each wall, since some surfaces can have only the slightest flaws, while others require long and careful work on them.

Next you need to put the finishing putty mixture.If the surface of the walls have obvious irregularities, then these defects should be corrected with the help of three layers of putty material at once. But if there are no obvious dimples, cracks, mounds on the surface of the wall, then two layers will suffice, one of which will be starting and the other finishing. The most suitable for working relatively flat concrete walls. Specialists-finishers recommend in cases where the concrete surface and so perfectly flat, use only the finishing composition. But at the same time it still needs to be applied in two layers, just both will be made of finishing putty.

Masters are not recommended to use for the work of a mixture of different manufacturers.

This is due to the fact that products of the same brand are perfectly combined with each other. Finishing and starting putty of the same manufacturer complement each other, while the compositions of different brands may conflict with each other. Because of this, cracks and irregularities will appear on the wall. In some cases, it is even possible to shedding the finishing material, which is very dangerous not only for builders performing repairs, but also for future visitors to the premises.

Upon completion of these works should be re-primed surface. This is necessary so that the wallpaper, which will be stuck on top of the primer, held as long as possible and stronger. This final stage prepares the surface for decorating.

For a beginner, it is quite difficult and time-consuming to putty the surface of the wall, especially if the putty is required for the subsequent gluing of wallpaper. To do the job qualitatively, it will take a lot of physical labor, as well as a healthy share of makeovers. Those who can call themselves a pedant may be a little easier, it is easier for them to achieve the ideal result, but at the same time they notice defects better than others, so the work can go on longer than usual.

If you look at the issue of filling the walls in terms of technology, it becomes clear that this is not as difficult as it may seem at first glance, because if there are flaws, they can be easily corrected before the final decoration is carried out.

Thanks to puttying, a novice in finishing works can save money by doing his own work.In addition to the satisfaction of high-quality independent work, he will receive the first skills in finishing work. From now on, the amateur dresser will find it easy to navigate the topic of wall filling and also select materials for certain types of wallpaper. Such knowledge is useful in life.

For information on how to putty the walls under the wallpaper, see the next video.