The details of the manufacture of wooden windows

Despite the fact that plastic windows are firmly in vogue, the number of fans of wooden windows is not reduced. This is due to the low cost and wide availability of the material, as well as the ability to make a window frame with your own hands. In addition, wood is environmentally friendly, and the frames from it look very stylish and can rightly be considered as a decoration of any interior.

Special features

By and large, the tree was and still remains the best material for the manufacture of window frames and sashes. Like any other material, it has its pros and cons. Let us dwell on them in more detail.

Windows made of wood are inferior to metal in cost and flammabilityBut plastic they lose only in price. But in all other respects, this effective window material is in absolute gain.

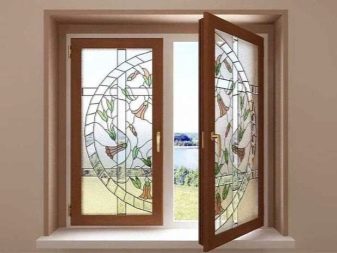

This is largely due to the possibilities of creating frames of any configuration: they can be oval, semicircular, triangular and, of course, square. If desired, you can even make a round window. By the way, the most usual rectangular window openings are quite often covered with glasses in a wooden frame - this is not only beautiful, but rather prestigious.

It is explained simply. In recent years, the fashion for natural materials and, in particular, for wood is rapidly returning. Naturally, a modern wooden window can not be compared with the windows of 70-90s of the last century. Today they look more aesthetically pleasing, and the physical and technical characteristics of such structures are much more efficient. Modern industry offers window frames made of wood, which have not lost their attractive appearance over the years. They are not deformed and do not crack under the influence of adverse weather conditions, and varnishes and paints with which they are coated, retain their original color even under the influence of direct sunlight.

The production technology today completely eliminates any heterogeneity of the wood structure, because most often for the manufacture of frames and sashes uses defect-free glued laminated timber, which is 40% harder and 80% stronger than solid wood raw materials.

In contrast to PVC, the structure of the tree implies an effective air exchange, due to which a favorable microclimate is established in the room, and the risk of mold and reproduction of fungal microorganisms is reduced.

Wood is the only material that allows windows to "breathe", such surfaces are characterized by the ability to absorb excess moisture in the room, and in dry air to return it back. That is why in homes where wooden windows are installed, there is always a healthy microclimate.

For comparison, windows made of plastic or metal tend to condense on windowsills and nearby surfaces.

The wood in the process of use does not emit toxic substances, and the paints and varnishes with which it is covered are absolutely safe.

Wood is far superior to plastic in the degree of thermal protectionbesides, wood products do not accumulate static electricity and resist the accumulation of dust on their surface.

Wood has more pronounced physical characteristics for windows, since this material is both strong and ductile, that is, it can withstand high tensile and compression loads.

From a technical point of view, any window is the same wall, just a little transparent. That is why, as well as the facade of the house, the window should certainly have good heat and moisture protection properties, that is, should protect the living space from cold, water, extraneous noise and dust, but still perform the tasks of insolation of rooms and provide the necessary ventilation.

We will see if wood can become such a protector. After all, if everything is clear with a double-glazed window, then everything is much more complicated with the basic material used to create window frames - even the most durable glass cannot help if the frame is useless.

That is why, giving preference to a window made of wood, you first of all pay tribute to its high performance, exceptional strength and durability.

The advantages of wooden windows include:

- environmental friendliness;

- low thermal conductivity;

- good sound insulation;

- resistance to low temperatures;

- strength;

- ease of processing;

- good maintainability.

Wooden frames are distinguished by high aesthetics, wood texture is clearly visible on them. Such windows can harmoniously fit into any interior and make a stylish ensemble with wooden furniture and doors.

Wooden windows are durable, despite the fact that wood is considered a rather vulnerable material., thanks to the introduction of modern impregnations into the structure, its qualitative characteristics are significantly improved. Therefore, the frames and sashes do not lose their presentability even after a couple of decades, while the lifespan of, for example, plastic frames does not exceed 10 years.

Wood has many advantages over plastic and metal, but we should not forget that this is not about "natural" material, but about a specially treated. If the wood is not treated, it simply rots and deforms, and in addition, the lack of a protective coating reduces the heat-shielding properties of the material by 20%. Therefore, all wooden elements of window frames must necessarily be treated with compounds that increase their resistance to adverse weather conditions.

Windows made of wood are often put in the country, as well as in the bath, such solutions are very popular in eco-houses and buildings decorated in country style.

Kinds

Wooden windows vary in material performance. The most commonly used are ash, oak, beech, elm or meranti.

Wood of coniferous varieties of wood for the production of frames does not apply, because it contains a large percentage of resinous substances - on hot summer days, the resins protrude and form ugly stains on the frames.

The design of wooden windows may vary depending on the overall style of the structure, family traditions and personal preferences of the building owner.

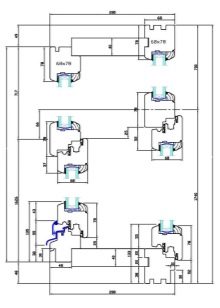

Multiple windows are very popular. Most often they are represented by double and tricuspid species, their leaves open with a simple turn.

Windows with combined casements differ in high demand, in which aluminum and wooden profiles are combined with each other so that aluminum elements are outside, protecting the window from adverse natural factors, and wood - inside.

The main trend in recent years is the rejection of double sash and care in the direction of single. It is not surprising - it is not necessary to combine and add doors, when you can simply purchase a glass unit with several cameras, and make the door itself a little thicker. Note that blind windows are mounted only next to the opening window or balcony door. However, when drafting a blind window, it should be borne in mind that such a shutter will be somewhat narrower.

In recent years, sliding windows are in great demand.

Drawings and projects

Depending on their design parameters, wooden window projects can be:

- German;

- Russians;

- Finnish.

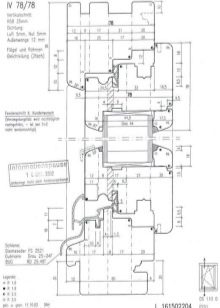

The first option is distinguished by the presence of a single separable wooden part. This model consists of a large box and two wings, each of which is glazed. As a rule, for the manufacture of wooden parts is taken solid pine.

The main disadvantage of such constructions is the tendency to deformities; moreover, it does not allow to achieve the most complete connection of the sash directly to the window, therefore, in case of rain, external moisture can get on the windowsill. Such windows are usually staffed with unregulated handles and hinges, so they do not provide for a ventilation mode.

German windows are often called European, because all the accessories are made in the countries of the Old World. This design allows you to effectively adjust the location and angle of the valves, and in addition, provides for the presence of locking mechanisms and air ventilation options.

Such windows usually have a box and a two-chamber casement. Eurowindow includes a window box and sash. Such products are easy to use, they are lightweight and characterized by high heat protection. The service life of eurowindows exceeds 60 years - such durability is due to the high strength properties of a three-layer glued laminated timber used in the manufacture of German windows.

Drawings of Finnish windows have a wide box and two doors with a stepped opening method, while the outer door is designed from simple glass, and the inner one from a single-chamber double-glazed window.

The raw material for the production of such windows is wood, rather than timber, thanks to which the window looks very stylish and aesthetically pleasing, however, it slightly loses in German in quality and durability.

How to make?

Wooden windows can be made on their own, but this requires at least a minimum skill in working with wood and a set of necessary tools.

For work you will need:

- glass cutter;

- drill;

- jigsaw or frezer;

- hammer;

- roulette;

- chisel;

- plane.

- Naturally, you will need materials:

- glued laminated timber;

- glue for wood;

- self-tapping screws;

- dowels;

- beadings;

- sealant.

Works are performed in a specific order.

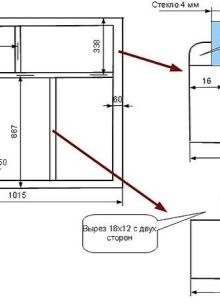

At the first stage it is necessary to build a wooden box. Depending on the size of the window, it can be large or small.

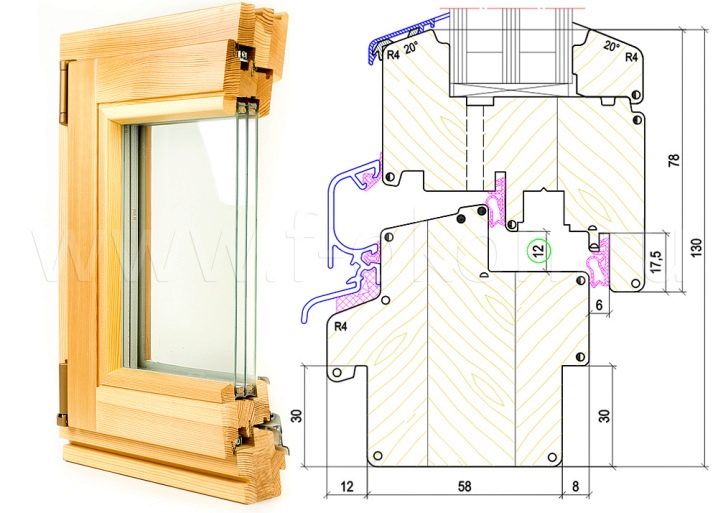

To make a frame, it is necessary to use boards of 15x5 cm. In the blank, you need to make a small l-shaped slot hole to a depth of about 1.5 cm. All basic elements are attached to each other with wood glue, and for greater fixation the joints are reinforced with a rod length up to 3 cm, it is he who will be the main fixer of the remaining structural elements.

Then comes the installation of the box directly into the prepared window opening. To do this, you need to drill holes in the wall, fasten the dowels in them and fix the box with self-tapping screws, after which the joints are processed with sealant.

The second block of works is related to the manufacture of the frame; for this, a 5x7 cm timber is used, however, its thickness may vary depending on the thickness and dimensions of the glass that will be mounted in it. If a single-glare profile is mounted, then only two slot holes will suffice. In case the profile is thicker, the number of holes should be increased.

When all the main parts are made, it is necessary to proceed directly to the assembly of the frame. For this, the boards are sawn at an angle of 45 degrees, and with the help of a profile, a tongue-and-groove joint is formed, it is reinforced with self-tapping screws.

How to install?

After the window opening and frame are completed, you can proceed directly to the installation of the window, which begins with the installation of glass, which has its own nuances and features.

First of all, in order to exclude the possibility of the formation of cold bridges and the formation of condensate, it is necessary to accurately measure the dimensions of the opening in which the glass will be mounted. The minimum allowable error is allowed in the amount of not more than 1 mm.

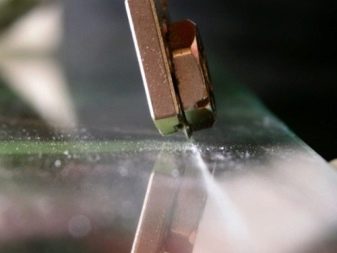

Glass is cut with a screw, and the edges are polished with fine sandpaper.It is very important to observe safety measures when working with glass, you must wear tight gloves and a mask that will protect your eyes from glass dust.

Technically, the step-by-step instruction looks like this:

- a ruler is superimposed on the glass, while leaving a small margin, it draws a line and cut it with a glass cutter;

- if the workpiece does not require correction, then it is inserted into the frame and fixed with screws;

- the joints are treated with sealant;

- the cracks are filled with mounting foam, which is polished after drying.

The windows are ready.

Tips and tricks

In order for the windows to serve you for many years, you need to adhere to several rules of caring for them.

In order to improve the operational characteristics of windows, the wood must be specially treated, for this purpose use:

- impregnations that protect the material from the adverse effects of moisture and prevent the occurrence of cracks and deformations;

- primers and special paints that facilitate the care of the window, and in addition, give it the desired shade.

However, the care does not end there. No matter how qualitative the impregnation may be, it is still necessary to treat wood very carefully and observe “hygiene”.In particular, if you carry out general repairs in the house, then all the finishing works associated with plastering and making concrete screeds should be completed before installing the double-glazed windows, especially if the work is carried out during the cold season. Plaster and other building mixes should not get onto the window surface, which means that all surfaces of the window opening for the period of finishing work should be covered with plastic wrap and fixed with masking tape.

The windows should be cleaned regularly, and this is important not only to increase their aesthetic appeal, but also from the fact that the dirt causes significant damage to the paintwork. Wood frames can be wiped with a regular cloth with a small addition of liquid detergent. Keep in mind that the use of alcohol and abrasives is absolutely unacceptable.

A couple of times a year it makes sense to update the wooden elements with a special polish, and non-wooden fittings with machine oil.

It makes sense to insulate the same windows so that they can better endure the winter, and in the summer you will need a mosquito net that will protect the frame from insects,who are known for their "love" to build homes in the wood.

In the case of deformations, you can easily repair windows using a manual router.

And finally, let's focus on the issue of how to choose the right wooden windows.

The market is full of offers, but there are not so many manufacturers offering really high-quality and high-quality products. To choose a company that will manufacture and install wooden windows for you, you need to be very careful: collect information about it, get acquainted with customer reviews, clarify the level of professionalism of the craftsmen and warranty obligations.

The process of making wooden windows is shown in the following video.