Installation of windows with hydraulic and vapor insulation in accordance with GOST

First of all, it’s necessary to say why it is necessary to install windows with hydro and vapor insulation according to GOST. The problem is that when joining a glass unit and a window opening, moisture can pass into the dwelling. As a result, you will not have either warm comfort or quiet calm.

Waterproofing

Waterproofing - the defense of objects, structures, various constructions from aggressive fluid (washing, filtering). With the help of waterproofing operation of buildings, structures and equipment becomes more reliable and durable.

Materials

Materials should provide full provision of reliable protection of structures under any environmental conditions. In order to properly purchase waterproofing materials, it is necessary to become familiar with their use.

Waterproofing includes the following materials:

- metal sheets;

- roll and sheet materials (geosynthetics or PVC membranes, films);

- liquid deposition materials (liquid rubber, spray cork coating);

- mineral binders;

- dry mortar penetrating (penetrating insulation).

There are several types of waterproofing.

- Anti-filtration - protects against ingress of water in buildings under the ground and under water. It also serves as a defense of the flow of technical and waste fluids.

- Anticorrosive - protects materials from chemically hazardous liquid substances and water, from the attack of the environment, from electrical corrosion, which occurs when stray underground currents.

- Painting - used in the form of ultra-thin (up to 2 mm) cover, which has many layers: they are in the form of bituminous and copolymer varnishes, watercolors. Used as an anti-capillary and anti-corrosion protection, it protects reinforced concrete and metal structures.

- Plastering - looks like a multi-layer (up to 2 cm) special coating, which is often used for reinforced concrete structures.Refers to facilities such as: cement gunning, cool and hot asphalt plaster solutions and resins.

- Pasty - made from characteristic labels of rolled materials that look like multi-layer (3-4 layers) coatings, protects external screeds and partitions. Unlike other insulations, it is more crack resistant.

- Cast - used as a particularly safe waterproofing. The installation consists of hot asphalt mastics, hydraulic solutions spilling them over a surface located horizontally (in 2-3 layers, 20-25 mm thick) and pouring behind the partition or formwork on the sides (thickness 30-50 mm).

- Filling in - acts as a filling in waterproof layers and macro-cavities with loose waterproofing materials. It is similar to the cast waterproofing, but is also used as a thermal insulation.

- Impregnating - this is the impregnation of building products from porous materials. More applicable to elements that are subject to intense mechanical influences.

- Injection - works under the action of forcing a binder material into the seams and cracks of building additions.

- Mounted - it is made of exclusive fabricated elements connected by assembly links to the main structure.

- Surface - it is pressed with the help of water pressure to the insulated surface, which carries the structure.

- Penetrating - dry mixes of cement, quartz sand of a certain chemical and granulometric composition of chemically active additives are used.

- Poured - eliminates the ingress of water in roofs, foundations, ponds, basements and underground huts. The coating is applied to the finished plane by cold spraying, after spraying hardens, it turns into a solid membrane.

Vapor barrier

Vapor barrier is a collection of different from each other variants of protection, thermal insulation materials and construction devices. They help to cope with hit of steam, and also with loss and absorption of dew.

Materials

Vapor barrier materials may not be responsible for the full vapor and water permeability. In the shops you can buy a vapor barrier various materials, but should, above all, read the reviews.

In the role of vapor barrier act such materials as:

- polymeric varnishes;

- roll and sheet materials;

- vapor barrier films.

Application

Despite the fact that the air in the room seems to be dry, it contains a sufficient amount of moisture vapor. Often, vapor barrier waterproofing is used in the construction of wooden houses.

Before using staples to insulate a building vapor barrier, it is nailed to a wooden structure with a special skozabivitel. Lay the material so that it fits snugly, then tape the seams with adhesive tape.

In well-heated premises, vapor barrier is installed inside, and outside it is made two layers of vapor barrier: at the inner and outer surfaces. This is done due to the fact that in summer the temperature on the street is higher than in the building and the steam, on the contrary, goes outside to the inside, that is, to the room.

Installation of windows

Cooking window opening

Preparation includes the following steps:

- dismantling of old windows;

- trimming seals and insulation;

- tidy building material;

- smoothing the walls of the opening.

Installation of plastic windows according to GOST can be performed only when they correspond to the pre-made measurements.

Work begins with the elimination of the old window with sashes.If the window frame is rotten, then you should first carefully pull the glass out of the frame. At removal of a frame the circular saw is applied then to take a frame in pieces. In new buildings, the stage of dismantling is excluded.

Holes freed from the frame are cleaned of dirt and sealant residue. If the walls of the window opening are damaged: there are cracks, gouges, then they are sealed with plaster and putty mortar. They dry out for a long time (5-8 days). To speed up the process, plaster or polymer blends are used.

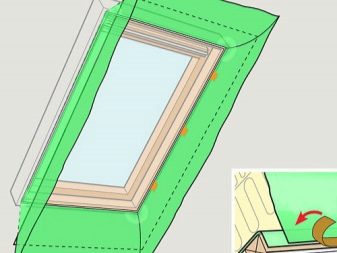

For facade structures and roof windows in a house under construction, it is necessary to cut the material around the lintels correctly.

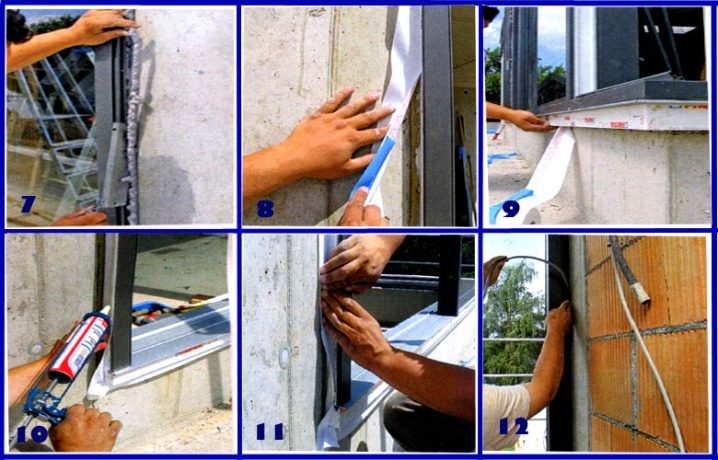

Installation and alignment of the window in the opening

After making the opening, dismantling is continued by installing the frame. We must not forget that the structure is installed on a plumb line, and not at the edges of the opening.

When installing plastic windows according to GOST, it is necessary to follow the instructions, the deviation should be vertically no more than 3 mm. This can be verified by laser or water level construction.

Before zapenivayut seams, it is necessary to check the vertical frame - just open more than half, sash. If it does not close or does not open, you need to adjust the window. Otherwise, the window structure will be damaged, and the air temperature in the room or room will be low.

The frame is fixed with anchors and special mounting plates. Before fixing the frame it is necessary to remove the sash and dismantle the glass. This will align the frame.

From the inside, there are holes with a diameter of 8-10 mm, for anchors - three on vertical walls and two on horizontal ones. Drill a hammerless drill, and for the preparation of openings in the wall material will require a hammer drill. If the wall is made of wood or of cellular concrete, then they work only with a drill.

Fastening occurs as follows: fix the lower anchors on two sides (do not twist to the end), then - the middle and top. Then tighten the anchors, observe moderation.

After the frame has been stuck in, the supporting pads should be urgently moved along the edges of the frame so that the horizontal lower part of the frame makes contact with the vertical center post

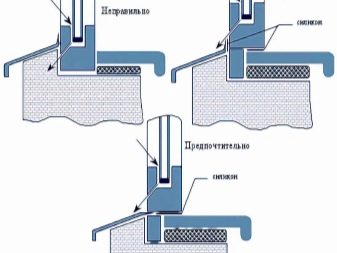

Formation of a three-layer assembly seam

According to GOST, plastic windows should have three-layer seams between the wall and the frame cut. They give:

- heat insulation;

- noise protection;

- vapor permeability;

- waterproofing.

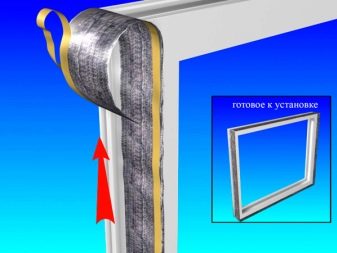

The seam is packaged by the following types of materials: polyurethane foam, PSUL (or STIZ-A sealant), vapor-waterproofing tape, vapor-insulating tape.

The bending of the seam occurs prior to installation, if glued with tape PSUL. It is applied to the perimeter of the frame or the opening by means of a self-adhesive composition, which is pre-applied to the tape twisted into a roller.

This allows you to fix a reliable vapor protection and protect against moisture ingress into the seam, and bypass the extrusion of the mounting foam over the frame cut. The tape goes only with mounting foam. At a temperature of +30 degrees, the ribbon is fully expanded within 30 minutes, and at a temperature of 0, within 48 hours. Therefore, in the fall or winter, a building dryer is used.

Before filling the joint with foam, it is necessary that the surface is slightly damp, then (when the foam has been applied) spray a little water from above. The foam becomes hard, it can be plastered, painted. But elasticity remains.

Formation of the inner layer

The inner seam that is in the room is sealed with the SASILAST 11 (StizV) compound.After drying, it turns into a vapor-proof layer.

Finishing work

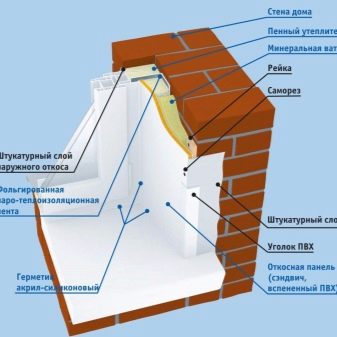

Installation of a window sill

The scale is determined depending on the thickness of the walls. The sill is installed under the frame by two centimeters. Looking at how it is located above the wall, the holes are filled up or filled with mortar. On both sides of the window sill comes down a slope of not less than 2 cm.

From the horizontal towards the floor, the window sill should be tilted within 5-6 cm.

Mounting low tide

Outside, a 3-5 cm ebb is made, receding beyond the surface of the wall, for diverting water pouring over the window. PVC is used for reflux. The ebb down is lowered by 5-8 cm. The ebb is attached to the profile on the lower side of the window. Must go downhill.

Installation of slopes

Slopes on PVC can be different: plasterboard, plastic, plastering. Slopes perform decorative functions.

You will learn more about the window installation process in the following video.