Window openings: device according to GOST

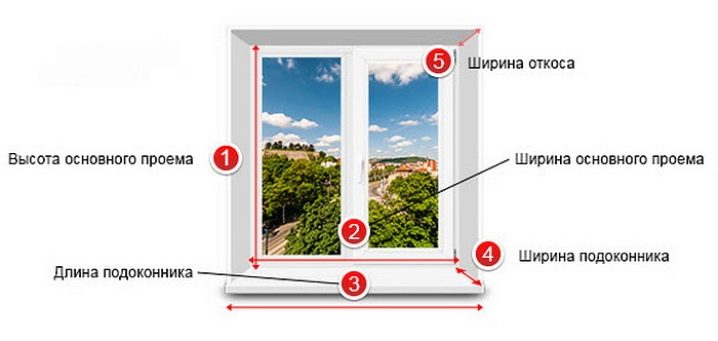

An opening in the wall is needed for mounting one or more window units. The design of the opening should also include the installation of seals, slopes, window sills and drains. General technical conditions for window blocks are prescribed in GOST. However, this is purely professional documentation that is difficult for an ordinary user to understand.

Let us examine in more detail the features and device of the window block in this article.

Special features

Features of window units largely determine the purpose of the premises inside the building. Through the window openings not only the rays of the sun get inside, but along with them the cold temperature and humidity. Therefore, if improper installation inside the house will settle mold and dampness.

In the manufacture of window openings great importance is given to the material manufacturing walls.

The window opening in a brick or concrete wall is made according to the same parameters, and in a log house it must meet completely different standards.

Established standards and restrictions on window openings are in little demand in housing, especially in private construction. Owners of private housing under construction often choose their shape and size according to personal preferences.

Focusing on your own taste leads to the fact that the finished windows are too small or too large. Sometimes they are installed in the wrong places. Such an approach causes the frames to skew, the valves do not fit tightly, and condensation forms. It sometimes rains inside the window, and dew appears even on the walls of the apartment.

According to the rules, a window opening should appear in the wall during construction. These blocks are very rarely made in solid masonry.

The window opening must provide:

- correct installation of frames;

- reliability of fastening the window construction;

- sealing;

- moisture output;

- heat and noise insulation;

- decorative main part of the exterior and interior of housing.

The window frame should easily fit the window frame.Internal and external window sills should not be fixed on the thick solution. There should be a niche for facing.

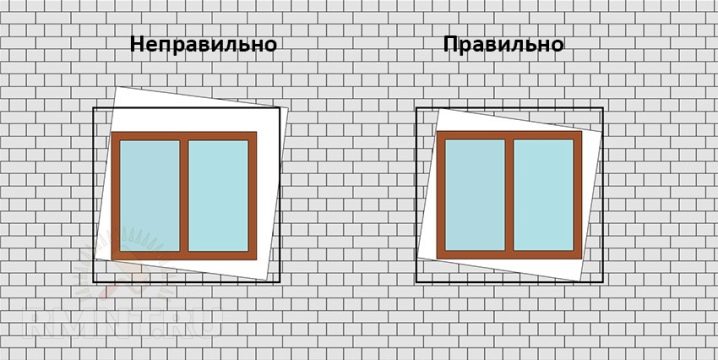

Horizontal and vertical structures must be precisely measured. The top plate should not bend under the weight of wall material. The type and location of windows must be chosen according to the standards.

To make the right choice, it is enough to study the typical parameters for window openings mounted in residential or utility rooms.

In modern construction, pre-made PVC windows are mainly used. It turns out that it is initially wiser to choose products of standard sizes. Openings under the standard design fit easier, cheaper.

Individual manufacturing of structures to existing openings is always an expensive pleasure. Ready-made windows and PVC at the production facilities are manufactured according to the state standard, since the builders at the construction site of multi-storey buildings perform openings according to the same state standard.

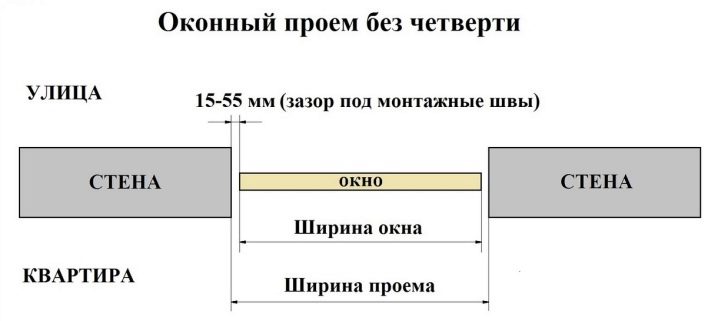

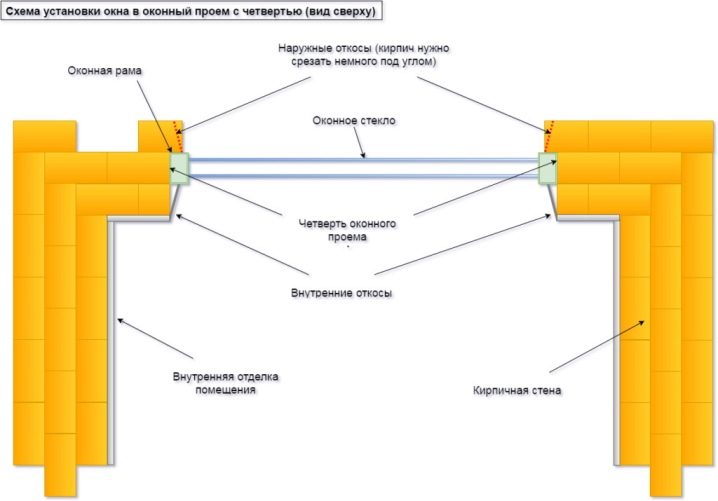

A generic concept for modern guests - required quarters for openings. These are ledges from the outer part of the wall, which should be of a certain size.

The presence of quarters will close the gap outside between the window frame and the wall. This will hide the mounting seal. Windows will get the best protection from blowing and moisture, the whole construction looks prettier.

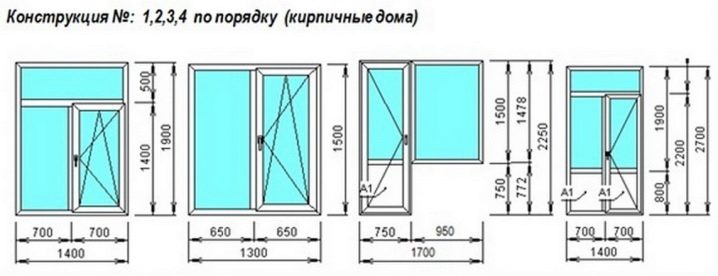

The position of the windows in a brick house is calculated taking into account the size of the brick used.

A quarter is a corner of facing brick, which protrudes to the fourth part of its own size. Usually mounted inside the opening. A larger ledge will interfere with the design of the side slopes. Smaller size of the corner will not guarantee the loss of frames. Building standards assume accuracy of match to one centimeter..

Let us consider in more detail the parameters of window openings for walls of different materials.

Standards

Updating the housing stock is not as fast as we would like. Standards of "Stalinok", "Khrushchev" and "Brezhnev" are generally accepted today. These houses were built thoroughly. Many of these objects have thick brick walls, high ceilings and rooms with large footage.

Standards for window openings with quarters have the following dimensions:

- single window: 85 * 115 cm, 115 * 190 cm;

- double window: 130 * 220 cm, 115 * 190 cm, 15- * 190 cm;

- three-leaved window: 240 * 210 cm.

The conceptual style of the project should not be broken by inappropriate size and incorrect number of window openings. Experts take into account the height of the ceilings, the total number of floors, the area of each room, other architectural features.

The appearance of the facade of the building is largely dependent on the exterior and shape of the windows. Exterior decoration can be made of any materials - at least remember the exquisite facades of prefabricated houses in classical ceramics.

If we recall the stages of construction, the period from 1930 to 1960 is the time of beautiful houses, decorated with red brick, stucco facades with monumental sculptures. In the period 1950-1985, a panel structure came to replace the brick building. The overlap of the walls is often made of frame. Drywall was widely used in the panel house..

The rooms in this house were made small, and the ceilings were low. The standard window opening also changed its dimensions, which depended on which wall (made of brick or panels) this opening would be mounted on.

A bit improved layout differed "Brezhnevka". The houses were mostly nine-storeyed, with warm apartments, an elevator and a garbage chute.The dimensions of the windows in the houses were determined by the state standards of the series. The largest window openings were made in houses of the 600 series..

The standard dimensions of windows in modern new buildings are regulated by state standards, however, the width and height of the openings are significantly different. Modern state standards also take into account the floor space. That is, the required level of illumination is obtained due to the difference in the openings.

Window openings of apartments in high-rise buildings - part of the bearing walls of the building. To change the design in such a house is strictly prohibited.

At the same time, manufacturers of plastic windows are not limited to standard sizes and shapes, since non-standard window openings may be present in frame housing, in aerated concrete houses. The nuances are associated with the design capabilities of the profile, as well as the weight of the glass.

Arrangement of plastic windows is a large-scale phenomenon that is observed everywhere. A standard plastic block is only approximately suitable for existing openings in the house, so the replacement of the structure usually begins with the departure of the measurer. The dimensions of window openings of private houses are completely different from the state standards adopted for residential buildings.

The requirements of GOST need to know anyway, they will serve as a guarantee of security in the apartment. In addition, any deviation from the standards leads to an inevitable increase in the cost of the product. Typical models, perhaps, will not make the apartment warmer, but will cost less.

Device

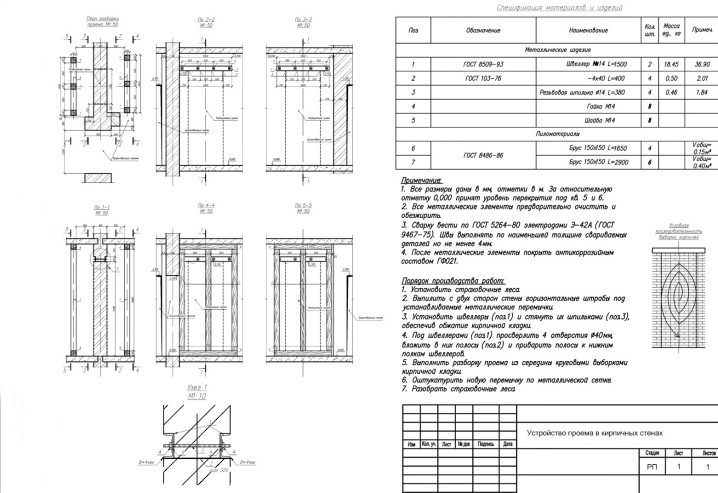

The device of openings begins with the creation of the project design for the whole house. In the architectural office will help calculate the correct position of the openings. According to the rules, the base for the opening should include 10 rows of ordinary brickwork.. This approach will provide the best rigidity and strength of the opening.

At the end of the device must be made a kind of plane. Bricks are laid out for it perpendicular to the axis of the wall with a protrusion out.

The sides of the opening are completed with whole bricks that fit around the perimeter. At the same time, heat insulation is installed, which should cover the gap in the wall and slats.

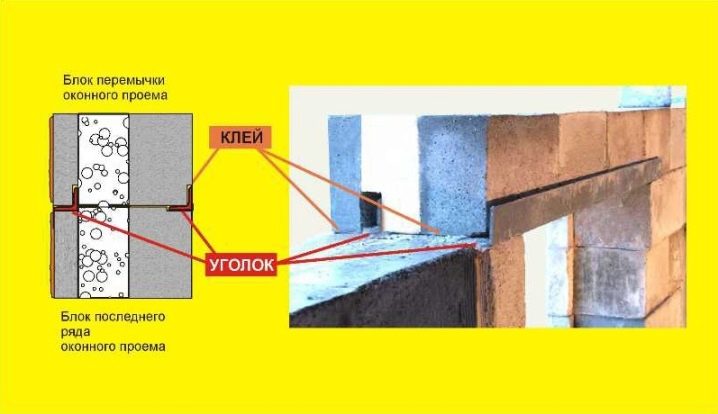

As an overlap for the aperture, a corner is often used, which fits into the distance of masonry material dimensions. The outer corner needs to be slightly drowned in the wall. When you make the facade it must be hidden under a layer of veneer material.

Before facing on the edge of the opening, you must first make a pillow of concrete. The reinforcing mesh is installed on this pillow.

In addition to the metal corner, the builders use such types of floors as:

- double tee;

- concrete block;

- brick lintels.

The overlap in the wall should be half the height of the structure plus about 15 cm. Under the design of the opening there should be an understatement in the wall. Details of the opening in the wall are provided with a frame. Window decoration should be done after installing frames.

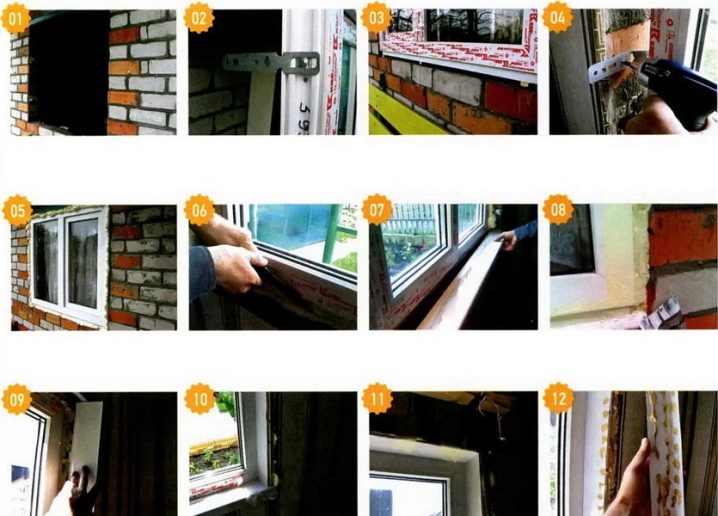

Rules for opening a wooden or metal-plastic window are generally the same.

The width of the opening in the house can be made somewhat wider than the size of the window frame. During installation, both plastic and wooden construction should be installed from inside the house. It should rest against the front of the slope.

The frame should rest against the back of the quarter, thus ensuring the quality of heat and waterproofing of the structure. Rains and cold winds will not be able to get into the gap of the outer slope and the window frame.

After laying the sidewalls on the top row is laid overlap. This is a horizontal jumper,which will take on the load from all other brick rows, as well as from the ceiling beams. The beam is made of concrete, the width of which is 25-30 cm. It can also be a channel made of metal or a steel corner with dimensions of 12 * 12 cm. Sometimes this bridge is replaced by a monolithic reinforced concrete block.

Steel lintels have one drawback - increased thermal conductivity. As a result, cold bridges appear above the windows. This increases the likelihood of low temperatures entering the house. Therefore, the decorative decoration of the house must necessarily be insulating materials.

Note that the length of the jumper must exactly match the parameters of the window opening. It can even go on the sides of the opening about 10 cm on each side.

After laying the jumper, you can verify the size of the opening. Next, proceed to laying the following rows. Window units are usually mounted at the very end of construction. - after the installation of the roof and seal all gaps in all openings.

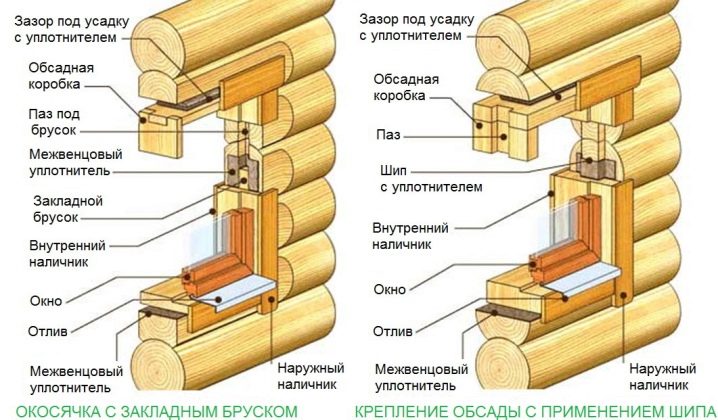

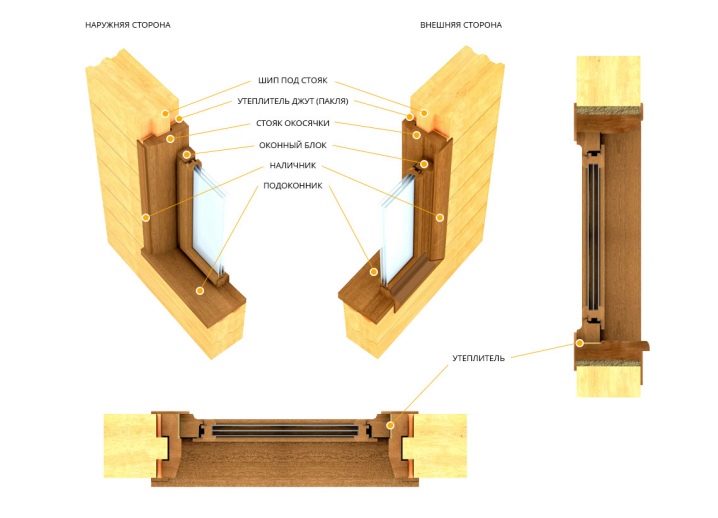

The openings in the walls of the log materials require the installation of an additional element called a siege. Okosyachka is done because wood materials are prone to changes in their size.

The strength of the opening in a wooden wall is small, so a certain pressure is created on the window, as a result of which the glass can simply burst and the frame bend.

Dry wood is selected for the casing, which should be properly harvested. A special connection between the casing and the wall provides a special groove made along the outer perimeter of the frame. He sits on a ledge, which is prepared inside the wall.

Casing construction can be made of:

- array;

- several strips that are connected or glued together using a special technology;

- combined materials.

For example, the combination is popular when the window sill is made of wood, and the sidewalls and the upper crossbar are made of solid wood.

To connect parts of the casing frame, special spikes are more often used, less often glue. Expansion for the installation of the frame is carried out depending on the window design. An extension is not required under cashing in. On the contrary, the entire perimeter is caulked, which will ensure tight sealing.

Window decoration is performed only after shrinking.. Usually it is selected in accordance with the dimensions of the house and the design style.

For example, the window sill can be galvanized or plastic. If necessary, carved platbands and kokoshnik are installed. Plastic frames can be edged with lining of wood. Lining will play the role of additional sealing.

Finding windows of the house with log walls is done from the inside and is usually attached to the casing. This also provides additional sealing of the joints.

Note that the expansion of slopes is possible only if in the future the walls will be finished with plaster and covered with additional decorative materials.

If plastic windows are installed in a wooden house, you can use a finished cashing in from the same plastic.

Plastic cashing will play a role:

- functional sealing;

- noise absorber;

- protection against moldy formations;

- decorative interior decoration.

To fulfill the last point, it is important to choose the color of the cash out. Most often recommended options for wood. In addition, the slats should be of such width that will block all existing gaps.But it is worth considering that the massive trim will be relevant as a design only in a large room. They can also play the role of a specific stylistic dwelling.

We should also mention the stages of the device opening in the house of aerated concrete. Inside the window opening in such a house, it is recommended to install special supports. It can be trimming thick bars or steel pipes. They are mounted on top of a flat board, and then laid out additional blocks that form the top of the window opening.

The resulting opening is reinforced mesh reinforcement. Then the whole structure is poured with liquid concrete.

Installation of PVC windows in aerated concrete houses can begin only after the concrete mix hardens.. This period is sometimes stretched to a month, as it is associated with the brand of concrete, as well as external weather conditions.

How to increase and decrease?

Sometimes it is necessary to install windows in a solid wall.

In this work it is also necessary to comply with certain requirements:

- First, cut a hole in the wall for the ceiling. Next, lay the block or jumper design. It is also allowed to set the reinforcement and fill with concrete.In this way, the reinforcement of the structure is prepared.

- If the opening needs to be warmed, choose materials only with quality certificates.

- The hole in the wall under the window should be equipped with the obligatory presence of the lower support and side quarters.

- The filling of the opening is done from the bottom next to the transverse bricks. Then laid out the sidewall opening.

- The frame in the opening can be installed only after the complete drying of the solution, as well as the initial shrinkage of the structure.

- Expansion, reduction, increase of openings is possible, because even standard sizes according to GOST vary widely.

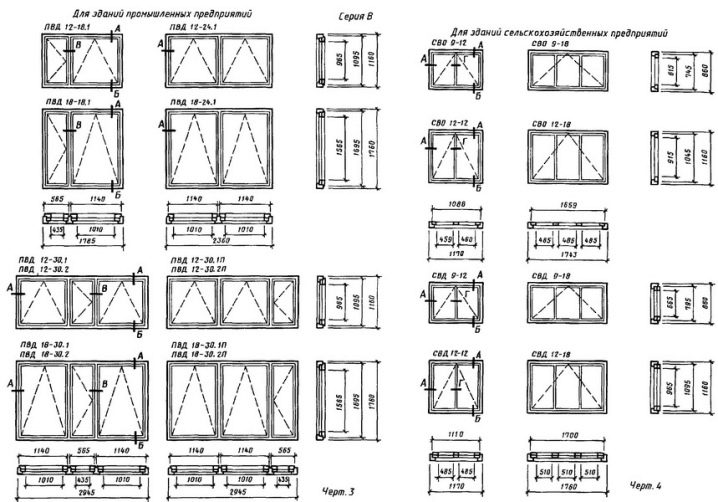

In GOST, up to 17 different dimensions are allowed only for double-wing windows. In the designs there may be windows with one flap, with three flaps. Modern developers are available GOST on more than 40 series. Dimensions are often governed by the area of the room.

Glazing area, in particular, the standardization of window openings of private homes is governed by SNiP P-A862. The standard requires a total light opening area of at least 1/8 of the total area of each individual room of the apartment.

For utility rooms, the total area can be reduced or increased up to 4 times. The area of the window in the bathroom, pantry, boiler room may be about 3 percent of the total area of the room.

Tips

- Choosing technical indicators for a window opening, be guided by the purpose of the room in which it will be located. The objectives of the use of the premises are of no small importance.

- The overall glazing performance of one or more openings in a room should provide sufficient natural light. Sunlight should be enough to not turn on the lamp during the day.

- For a country house, the aesthetic aspect of the issue is of considerable importance. It is important not only to choose the right place for the installation of windows, but also to think over the style of exterior decoration of window openings. They have a significant impact on the appearance of the facade.

- If your region is characterized by cold weather conditions, and the length of daylight hours is short, it is best to make windows on the south or southwest side.

- If the climate in the region is warm, the amount of sun is sufficient, locate the windows from the north or east.

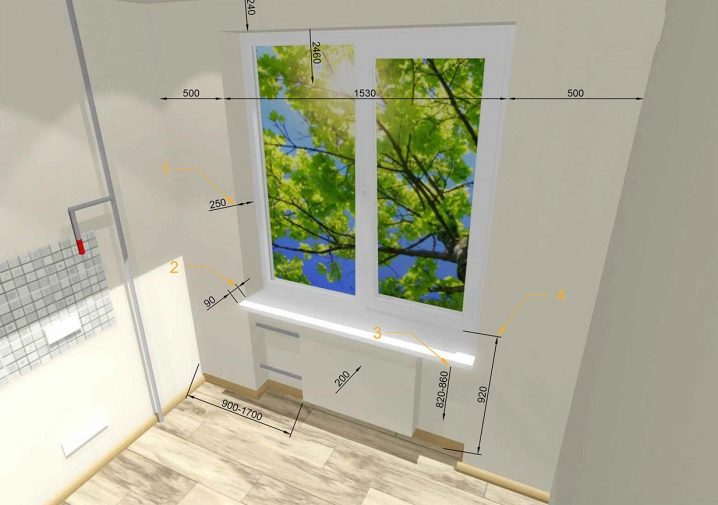

- Convenience of use and functionality of windows under various conditions are often associated with the height of the window sill from the level of the finished floor. Experts recommend focusing on the following values:

- If the room is a living room, bedroom, or children's room, the optimal height of the window sill will be 70-90 cm. If the window is placed at such a distance from the floor, it will provide a good view, as well as maximum transmission of sunlight.

- If it is a kitchen or dining room, it is better to increase the distance from 80 to 120 cm. The dimensions should be primarily determined by the dimensions of the worktop, which is usually taken to be flush with the sink and other kitchen furniture.

- If the room is a bathroom, the height of the window sill should be increased to 160 cm. The window in the toilet and the bathroom is necessary for ventilation, but at the same time the room should not be accessible to unauthorized persons who can observe hygienic procedures.

- From 160 cm and more can be the height of the window sill in the household rooms. Here the window is often a small window.

- If the windows are mounted on a warmed veranda, a balcony or a summer terrace, the window sill can be placed at 70, up to 100 cm.

How installation of windows in accordance with GOST is made, look in the following video.