How does the window unit?

More recently, window openings covered simple wooden frames with glass inserted into them. Today, this important function is performed by so-called window units, which are made of various types of materials.

Special features

In accordance with the accepted rules, the window unit is a design that transmits light. It is designed for natural light and fresh air supply.

Structural elements of the block

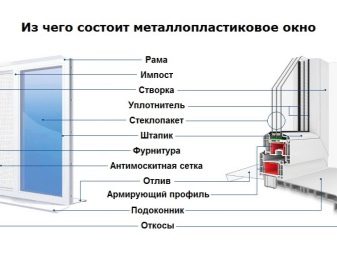

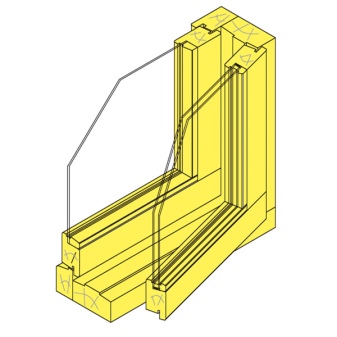

- Frame. Frame profiles surround the entire object and perform the function of a kind of frameworks.

- Sash. The frame contains one or more sashes, depending on the window models.

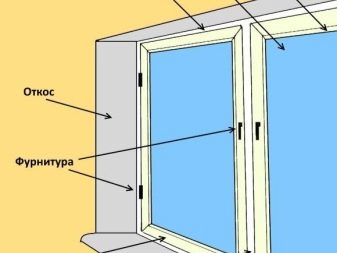

- Fittings. This term refers to a hinged connection or a handle-like lock handle, which is contained in the set of each leaf.Such improvements allow the function of airing the premises. If we are talking about installing sliding glass, the elements of accessories will be different from the windows that open in the usual way. Often, if there are young children in the family, it is necessary to take into account the danger that a child can easily fall out of an open window. Therefore, it is recommended to install additional window locks made of a cable with a locking device, which can prevent unauthorized opening of the valves, but at the same time do not interfere with the use of free ventilation modes of the room.

- Imposts Impost is an internal vertical jumper that enhances the resistance of the window frame to the pressure acting on them from top to bottom. Imposts also support window frames when the doors are open.

- Glasses. Glass is the main insulator that separates the room from the external environment, but does not prevent the penetration of sunlight into the room and the external view. The thickness of the glass paintings themselves also plays an important role.

- Shtapiki. Shtapikami called strips holding glass in the frame.

Slope and window plates could be added to this classification, although they are only optional and optional components.

Documents

Here we consider the terms that are described in documents such as SNiP and GOST. Specialized documentation provides an opportunity to get acquainted with the most detailed information about which locks and hardware are used in the creation of window blocks, on methods for determining sound insulation and determining the overall coefficient of light transmission.

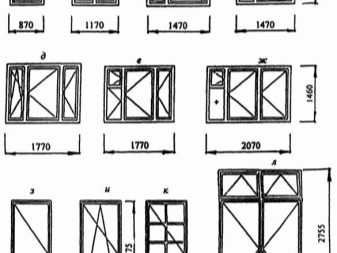

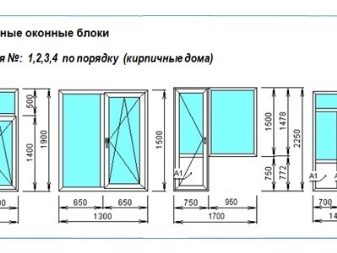

It is also possible to find out information about standard sizes:

- in an aperture of 500x500 mm a block with dimensions of 470x470 mm is installed;

- in the opening 900x600 mm a block with dimensions of 870x770 mm is installed;

- in the opening of 1500x900 mm a block with dimensions of 1470x870 mm is installed.

Kinds

It should be said that today there is a huge number of diverse variations that have different technological features.

By differences they are formed into subsections.

Number of leaves

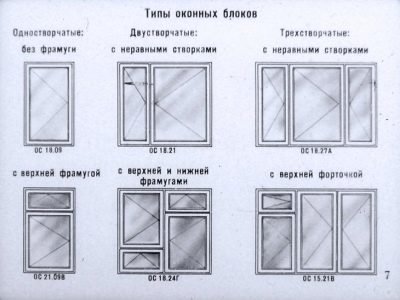

Options for the number of valves can be different, which, in turn, can be divided into some groups.

- Single door block. Such a window is usually small in size, since it does not have reinforcing imposts.These windows are most suitable for auxiliary non-residential premises, since they are not very convenient to use and do not allow a large amount of sunlight to pass through. These are just small single-pane windows.

- Double wing block. This is undoubtedly the most common types of window block, which are found in the vast majority of residential premises. It can be said that the bivalve block is a classic version.

- Multiple block. The most graphic example of such a block, without a doubt, is a plastic balcony door combined with a window in a regular apartment built in the Soviet period or later. In other words, one door in the construction process was simply expanded and turned into a door leading to the balcony. Window and balcony blocks are not with the number of shutters less than three. In this case, a large window block has several wings and more than one impost, which serves as a support for the upper frame profile, which gives the prospect of being able to withstand the increased pressure on the window openings.

Device

Sash design

The leaf can have the most various designs and fastenings.

- Single It is an ordinary single-leaf profile with glass. No frills in this design is not observed.

- Coupled. Here you can observe the inner and outer sash, connected in a whole and fairly well tolerated mechanical action structure. One of the wings is usually provided with hinged joints that allow you to open the window.

- Separate. You can also observe both doors here, but the peculiarity is that they do not connect with each other, and each has its own fittings. Thus, they have the possibility of opening in both directions.

- Separately coupled. This design is a combination of the above types: twin sets are installed inside, and single - from the outside. A feature of this unit is a very high rigidity, as well as ease of use. The price of this design is quite high.

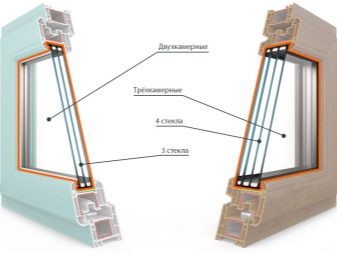

Number of glasses

Another classification method can be applied when referring to the number of glasses in a glass pane frame. The number of air pockets formed between each pair of glass sheets increases thermal insulation.Accordingly, a direct proportionality is formed: the more glass panels will be in the glass unit, the room will be warmer, and the insulation - the better.

It is necessary to take into account that the double-glazed windows will have a higher cost.

- Unary layer of glasses. This window can only be used for rooms without heating, where people do not live. The cost of such double-glazed windows is the lowest.

- Double layer glasses. Most often, the most obvious example of such a design is an old window with a wooden frame. Today, these windows are also used, and this type of glass unit is called single-chamber.

- Triple layer of glass. In this case, two unique air-filled pockets form inside the glass unit, which guarantees a high level of noise insulation, as well as excellent thermal insulation.

- Four layers of glass. As a result of the installation of four glass webs parallel to each other, the effect of a three-chamber window block is achieved. This provides an excellent degree of insulation and sound insulation, although the cost of this design is very high.

Sash opening direction

The most familiar to our eyes are windows equipped with swing mechanisms, although in reality a much greater variety of options is offered.

- Turn on yourself. This is the most popular type of opening the inner flap - its hinged joints are the simplest and most reliable in handling.

- Turn away from yourself. This mechanism is mainly used when dealing with external flaps.

- Double-sided rotation. Its use is possible with single-leaf window blocks, however, this type of mechanism wears heavily during operation.

- Suspension. Quite a specific and not very common mechanism of operation of the structure. The window of this variety is mainly installed in the attic - where it is not very comfortable to open the window to the side, since the roof surface is tilted.

- Folding As a rule, it is implemented for use with vents. Samples of its accessories are made of aluminum alloy or stainless steel.

- Swing-out. This design has long been in use for a long time because of its popularity and prevalence.To completely open the window, you must rotate the handle at a right angle and install it horizontally. If you need to open the window, then you need to rotate the handle 180 degrees.

- Sliding. This option is quite popular for houses in the country. It replaced the loop on the roller. The main advantage of this type is the freeing up of free space that would otherwise be occupied by the opening flap. In this design, the sash "moves off" to the left or right, and not into the room. But such an economy of space can easily be nullified, since it is worth breaking the geometry of the double-glazed windows just a bit - it will be absolutely impossible to move the sash.

- Lifting. This option is almost similar to the previous one with the only difference - the leaf does not go to the right or left side, but rises vertically.

- Deaf. In this version, it is impossible to see any loops, or rollers, or pens. It will not be possible to ventilate rooms through a window equipped with such a mechanism, but nothing can be broken here, since there are no seams through which heat can escape. It can be said that such a window design will enjoy a high degree of simplicity and reliability, even despite serious limitations during operation.

Airing function

Airing of rooms with the help of window blocks can also be organized in different ways, and this depends on their equipment.

- Vents. This is a fairly common part of the window that can be opened.

- Swivel flaps. This is a structural solution that is implemented on most variants of opening glass packs and is the most functional of all used windows made of metal-plastic.

- Framugi. It can be said that a transom is a window leaf, which occupies a large (usually upper) section of double-glazed windows.

- Ventilation valves. Allow to carry out airing of a moderate degree of intensity, even if the flaps are in the closed position. Also this option is good for double-glazed windows, which structurally do not have the ability to open.

Materials

Today, only two main materials can be considered.

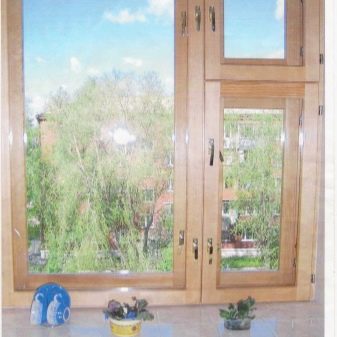

- Polyvinyl chloride (PVC) or, as it is also called, metal-plastic. It is quite reliable and has an inexpensive price. Its disadvantage is that it “does not breathe,” and as a result, some owners return to windows made of wood.

- Tree. It is a natural material, it "breathes", has a small weight and aesthetic appearance. But there is such a material and known disadvantages: high price and a tendency to deform when used for a long period of time.

Manufacturing and repair

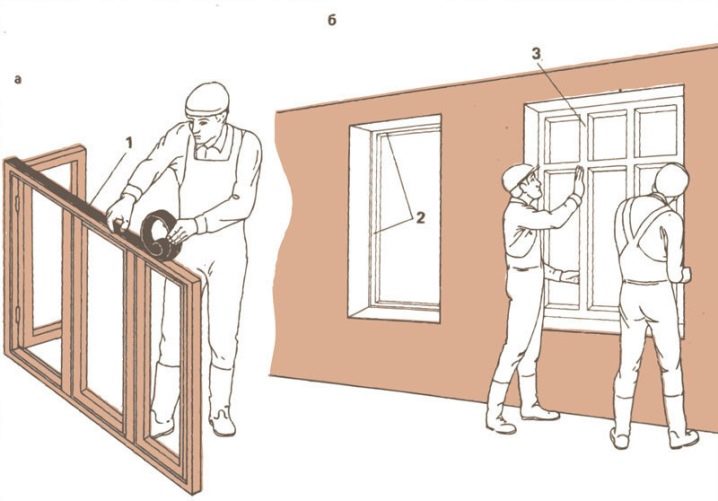

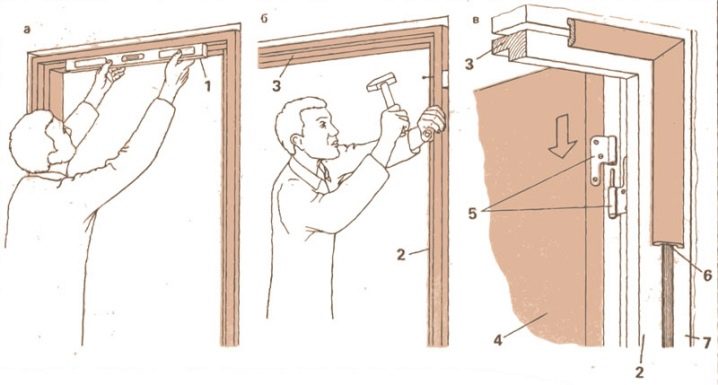

Installation of PVC windows is best left to professionals who already have the necessary skills.

If necessary, a person who has the tools will be able to strengthen the unit independently.

- First of all, you need to find a drawing - it is available on the Internet.

- In accordance with the schemes, corner profiles are cut out and machined on a milling machine.

- After that, the locking system is glued according to the thorn-groove scheme, and all the elements are connected into a whole structure, and each corner must be controlled properly.

- Then insert the glass and fix them with glass beads.

- The next step is to install the unit. Here you need to understand that the old window will have to be dismantled. In the process, you should try to avoid damage to the wall and window opening.

- It is desirable to process the frame with antiseptic agents and insert it into the opening with wedges and linings.

- The sash should be hung only after the final fixation of the frame in the absence of any distortions.

Tips

Experts recommend using the following tips when installing window units:

- if there is a small child in the family, it is recommended that the window blocks be immediately equipped with special metal or plastic locks, which he will not be able to unlock, as falling from a window even from the height of the first floor can cause a small child severe injuries;

- when installing window units on windows facing south, it is worthwhile to analyze the possibility of using a dark tinting film.

How to make a window block with your own hands, see the next video.