Recommendations for the selection and installation of window drips

As soon as the owner of an apartment or house comes up with the idea to install new windows, he should immediately think about such constructive elements as ebb. They are a kind of exterior window sills that solve the problem of excess moisture that can damage the window and even the facade. Such designs give the window area a complete and aesthetic appearance.

Special features

Window drips are designed to drain water from window panes. In addition, they prevent moisture from falling on the frame and windowsill and prevent the destruction of building materials, and therefore protect the walls from high humidity.Otherwise, after each rain, plaster would fall off, and the wooden frames would gradually become useless. In addition to protective functions, drainage systems also have an aesthetic function - they make the window look complete and adorn the facade.

You can install products at any time: both at the stage of construction of the building itself, and after the start of operation. In the first case, it is much easier and cheaper to carry out installation work - there is an opportunity to seal all seams and joints with minimal loss of time and money.

Deciding to mount the ebb after the start of operation, the customer will face a few sophisticated technologies. However, such a decision will not cause much damage to the wallet, and the work will still be done qualitatively.

Technical requirements

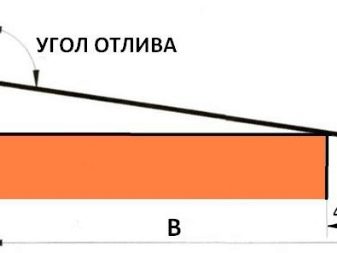

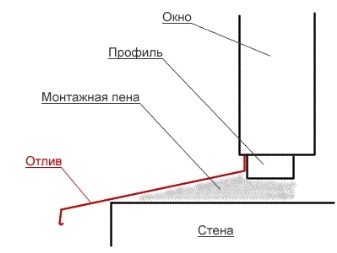

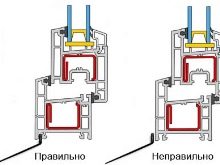

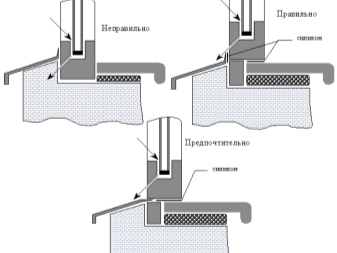

According to GOST, when mounting ebbs, the lower edge of the window box should not be lower than the outer edge of the opening. This feature is due to the need to prevent the overlap of special drainage holes, which are placed on the outside of the window box. The overhang of the structure should be 3-4 cm.

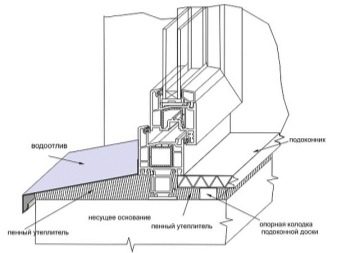

In addition, experts advise not to ignore eventsprevent the ingress of moisture into the assembly seam, and laying the gaskets under the drains, they are dampers, which will reduce the noise impact of raindrops.

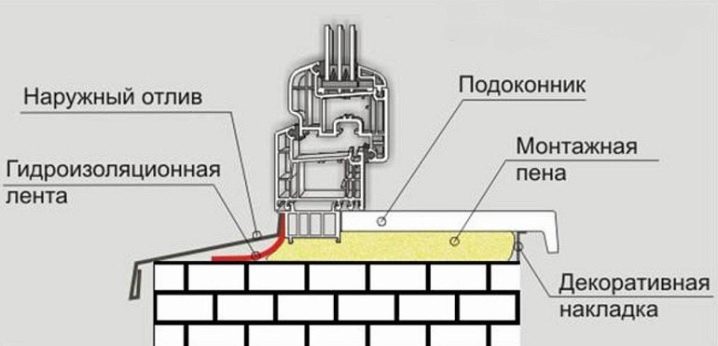

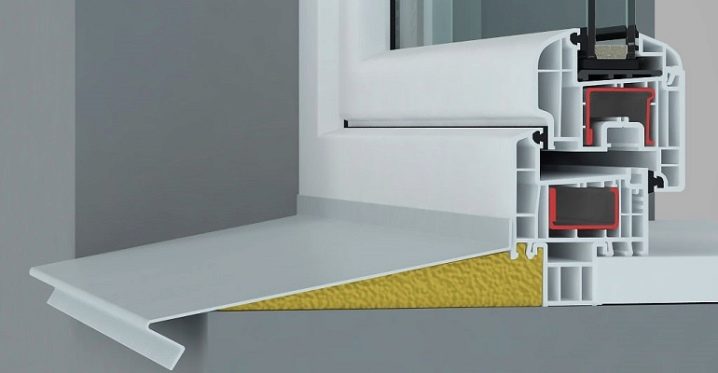

GOST indicates that before installing the drainage system, waterproofing of the external slope of the wall should be carried out with a special tape. Its edges come on the wall under the window and on the vertical gaps. This gap comes with a rounding, that is, without corners, and should be 50 mm. The tape is mounted using mounting foam - it will help the evaporation of moisture from the seam and protection against wall precipitation. The outer product is mounted on the screws, and for noise insulation in the case of a metallic cast, a mounting foam is used.

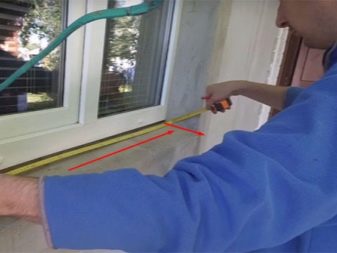

Also, the minimum width of the pouring is 90 mm, and to measure the length, measure the distance between the edges of the window opening from the outside. To the obtained measurements are added 3-4 cm on each side. The finished product should be greater than the distance between the edges on the outside of the window opening by 6-8 cm.

In the process of assembling products, SNiP largely regulates the conduct of the procedure itself: compliance with safety in construction, hygienic requirements and fire safety.

Kinds

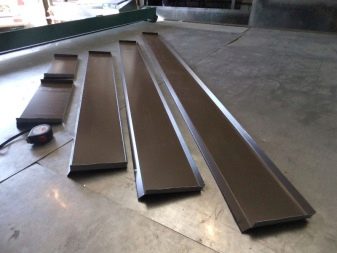

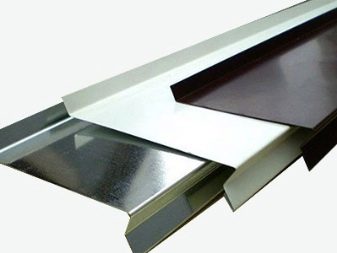

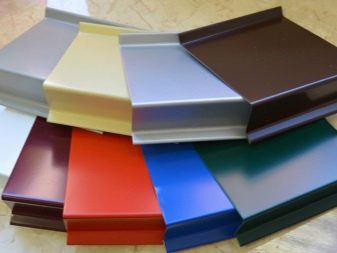

Varieties of external window gutters differ in the materials used. For example, structures are created from sheet steel. The galvanized steel sheet is considered the cheapest, and the most expensive is with a zinc coating and is additionally painted with paints based on polymers. Thanks to an extensive range of colors, you can choose the ebb, which will be in perfect harmony with any facade.

Metal drainage systems are installed on both plastic and wooden windows in brick, block and wooden houses. The installation process is the simplest - if desired, such products are installed by hand.

Metal ebbs can last up to 50 years, which is a pretty decent time.

Sheet non-galvanized steel has recently been used very rarely, due to the fact that under the influence of precipitation corrosion occurs rather quickly, especially in urban environments. To prevent the destruction of the material, the sheet is covered with special paint., but in the future you will still have to clean it of rust and carry out restoration work.

If the coating is made of polymers, the lifetime is extended,while the sounds of precipitation will be much quieter. There is also resistance to the effects of acids and the necessary strength. With proper care, such products can last up to 25 years, but you should protect them from scratches. Metal shells are usually mounted in 20 mm increments.

The thickness of the castings made of galvanized sheets is slightly more than 0.5 mm. This parameter allows the design to have the necessary rigidity and dampen vibrations, which are a natural manifestation of precipitation. These products are much cheaper, but, unfortunately, are exposed to an acidic environment.

Also gaining popularity of PVC designs. Most often, this ebb serves as a supplement to a plastic window. Structures are made of a material resistant to ultraviolet radiation, but despite this, destruction still occurs. The material relatively quickly loses its plasticity and durability, microcracks are formed on it, in which dust accumulates, and biological species settle. Therefore, drainage from plastic can not serve more than 30 years.

Comparing the two types of ebb, we can concludethat the plastic versions withstand large static loads, but quickly fail, and the metal ones last a long time, but have low mechanical strength and heat up in the summer months. In addition, plastic materials are responsible for sound insulation during rain, and in the case of metal, additional measures will be required to protect against noise. At cost, metal reflux is cheaper.

Sometimes non-conventional materials, such as titanium and copper, are used for the ebb. Naturally, in these cases the cost of the construction itself and the installation work will be much higher. Copper drainage systems are considered the most durable and high quality. For them, ordinary copper, patinated malachite or oxidized black is used.

All varieties of copper flashings are not subject to corrosion. A special "highlight" of these structures is the fact that they are installed on any shape, even on round windows. This is due to the fact that several segments are created, which are subsequently joined into a single circle.

Titanium castings have increased strength and wear resistance, but are more expensive than the above options.Make and drainage of aluminum, often with their own hands. For this, strips with a thickness of 1 mm are bent and painted in the desired color. Their strength is better than metal, and hence the shelf life is higher.

Aluminum products are made in white or brown up to 35 cm wide. During transportation, the surface of such structures is necessarily covered with a protective film, which is removed on arrival at the destination.

The ebb can even be made of heavy-duty epoxy., which includes fiberglass. This material is not afraid of corrosion, reduces noise and is made in black, brown or white. Often, one additional polyester element is installed on galvanized castings. This pad increases strength and acid resistance. In addition, it can be painted in different colors.

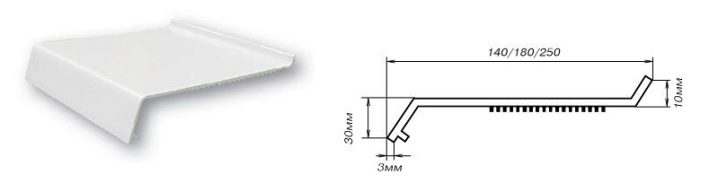

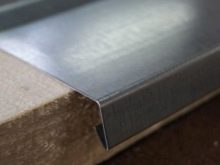

All ebb have a bend for fasteners to the window and side and bottom bends designed to ensure the runoff of water. From the wall they are set at 3-5 cm. There is a drip at the lower bend.

The cost of the ebb depends on the following factors:

- the country in which it is produced;

- the material from which it is made;

- from the available sizes.

We should also consider the dormer windows. They do not have window sills and ebbs, and the opening system is most often different from ordinary window systems. Instead, it is protected from moisture by 2-3 rubber loops between the frame and the pivoting flap.

Plays its role and tight installation, connecting with roofing material. You can install a window with enhanced leakage protection or install a cable heating system around the perimeter of the frame. This "warm" mechanism is designed to melt the snow and direct the water, which is quite convenient. After heavy snowfall, the windows are always thoroughly cleaned.

Dimensions

Ebbs come in various sizes. They are often sold in finished form to the standard dimensions of a window opening, but sometimes buyers choose products according to unique individual sizes.

It is very important to correctly measure the dimensions of the base of the reflux, both in the case of the purchase of the finished product, and in the case of drawing up a drawing and selling your own. However, this is not a particular difficulty, since the accuracy of removal can vary by several millimeters, and it is quite simple to carry out such calculations.

First of all, it is necessary to calculate the small leg of the first corner with the help of a square, then do the same with the second one. The sum of legs is added to the length of the ebb and frame of the window - the total length of the ebb is obtained.

Then one centimeter is added in the case of a tie-in and two centimeters in the case of bending the edges. So in its pure form, the length of the ebb tide is the distance between the outer cuts of the window opening, plus 60-80 mm for tolerances at the edges. The width of the window sill directly depends on the size of the ledge, that is, the distance between the edge of the wall and the window frame. Additionally, you need to come to this figure 30-40 mm at the visor and take into account the angle of the tide relative to the horizon.

Metal drainage systems are made from 9 to 40 cm wide and up to three meters long. The thickness of steel and stainless, and galvanized is 0.5-1 mm. It should be mentioned that the outflow can be made of any size at the request of the customer.

Design

Since the ebb not only protect the window designs, but also are a decorative element, when choosing, it is worth considering the color factor. The colors with the design of the window itself, the design of the facade, and the appearance of the ebb itself are taken into account. This device should look neat and in soothing colors.

Manufacturers offer an impressive range of colors, but white colors are still the most popular., especially in combination with standard plastic windows. If necessary, the product can be painted using a special technology in any shade according to the RAL catalog. Window ebb is most often chosen to match the window frame. But a creative solution allows you to experiment with designs of a contrasting color - with such a decision, the building will look unusual. Also, the use of embossing and perforation allows you to create unique models that attract close attention to such a construction.

Low tides may also be different configurations and textures. Most of these elements are produced under standard window shapes, and for unusual design ideas, you can always buy an individual outflow to order. Exterior metal window sills are not only in the form of standard curved rectangles - they are shaped into tiers and steps, round or semi-circular, convex or concave. Possible solutions are limited only by the imagination of the master manufacturer.

The configuration, as a rule, is selected depending on the material from which the house is built. For example, the ebb in a frame house or in a house with a ventilated facade will be radically different from the ebb in a classic brick or panel structure.

However, regardless of the shape of the product, they will always consist of three parts: a kind of “shelf” at the top that attaches to the frame, the water drain and the drip pan.

Installation

Proper installation of the ebb is extremely important, since the consequences can be found out later, and it will take too much time and effort to repair. Sometimes you even have to repair the facade coating. Therefore, you should always follow clear instructions.

Self-assembly usually requires:

- scissors for metal;

- polyurethane foam;

- sealant;

- insulation;

- fittings.

A marker with a level to determine the horizontal structure will also be useful.

In order to install a do-it-yourself tide, first of all, it is necessary to decide whether the production will also be independent or it will be a customized item. After that it is necessary to take measurements.

Both options are possible. For example, the choice is made in favor of the purchase of metallic reflux.

- At the first stage, the state of the lower slope is checked. If it does not meet the requirements, then plastering is carried out.

- Before this, the extra assembly foam is removed with a knife, the surface is cleaned of debris and dust.

- Small irregularities are leveled with glue for ceramic tiles, and cement-sand mortar is used when the slope is not prepared at all.

- During operation, observe a slope not exceeding 10 degrees and place the ebb on the windows perpendicular to each other. By following this simple recommendation, you can effectively drain water, snow and condensate.

- Before plastering it is also important not to forget to wet the surfaces of the facade. When the mass leveled by the trowel hardens, the installation of the ebb itself can begin.

- At the stage of ordering a structure, one should not forget that it should exceed the parameters of a slope by a few centimeters. Then, in the first case, the dimensions of the slope are transferred to the ebb, and then the metal surface is bent along the marks, and the places of the bends are cut by a grinder or scissors on the metal.The height of the side limb should be approximately equal to a centimeter, and the edges fit snugly to the side slopes. Then the finished ebb is placed in the mortar mass.

- In the second case, the grinder in plaster cut centimeter grooves at the level where the ebb will be located. The groove in the corner, where the grinder disc is missing, will have to be cut manually. Fastening is carried out as follows: the tide is tightly inserted into one groove, bent and the second end falls into the second groove. The design is aligned, and the grooves are filled with mortar. Do not forget about the waterproofing tape at low tide.

- It is worth mentioning that the second method is not suitable for plastic castings, which need to be butt-fastened and sealed. In this case, special inserts are used for the end caps. Returning to the metal shells, in the next step, the bend is mounted on the screws, attaching to the window frame.

- Ideally, the bends are in the groove. Alternatively, liquid nails can be used instead of screws. In some cases, all the joints and points of contact of the ebb with the wall are covered with mastic, which increases the waterproofing and strengthens the connection. But usually everything ends with the usual sealing of the junction areas.In the case when the production of reflux is carried out independently, a sheet of galvanized steel of a certain size is bought, all parameters are measured taking into account bends, and the final design is cut along marking lines.

- In the case of installation of a metal reflux on a wooden house, a framework of wooden bars will be used instead of the cement mixture. Most often there are a few planks, differing in thickness, which are laid along the aperture and fixed with nails. In order to protect the outflow from the snow and strengthen the mount, an assembly foam is added.

Professionals advise that, upon completion of the main works, also provide anti-damp insulation inside and outside the building. To do this, use vapor barrier film that is glued to the wall and window frame. In the places of junction with the wall, the lateral edges of the reflux are also protected by an elastic tape.

Tips

In order for the ebb to serve smoothly for a long time, it is necessary not only to carefully select the model, but also to carefully carry out the installation process.

- The procedure for sealing the joints should be extremely thorough.Paying special attention to those places where the ebb is adjacent to the side slopes and the window frame. But it is worth being prepared for the fact that sealants are just an addition to the main sealing. They will last only a few years, and then due to weather conditions will begin to flake off and pass water into the cracks. Therefore, it is much more important to use the right building technology.

- Besides, the width of the tide should be greater than the width of the slope. Usually the difference is two centimeters or more. The ebb also has to withstand as flat as possible, otherwise water will accumulate in one place and form spots on the wall, which will not completely decorate the exterior of the building. Proper operation is one in which water drips evenly over the entire length of the outflow.

- Under the tide will need a solid foundation - It is usually made from a mixture of cement and sand. The use of foam is not recommended, although this method will be quick and cheap, but the result will not differ in quality.

- Polyurethane foam is used as follows: the outflow is wedged in several places, and the free space is foamed.However, no foam can withstand the weight of a person who has become ebbing, and in fact such a situation may well occur during window washing.

- The sides of the tide should be located under the trim slopes, and if the slopes of plaster, it is necessary to crash into it to a depth of about a centimeter.

- Installation of ebb is better to produce in good clear weather, as the installation is carried out on the street.

- In cases when the reflux is attached to the PVC construction, a special groove is used. It is manufactured by manufacturers for this very purpose. At installation of otliv below the level of a frame additional profiles with the purpose to increase a waterproofing are used.

- It is recommended to install reflux before finishing the external slopes.by going under them. Thereby it will be guaranteed that the water from the slopes, as well as from the window, will begin to fall on the ebb.

- When installing it is not recommended to block the holes designed to divert water. They are located on the outside of the window frame, so the ebb must fit under them.

- For metal castings, sub-window linings are recommended.designed to provide soundproofed construction.

- When choosing such an element one should also take into account the existing climatic features. For example, if the climate is harsh, then it is important that the material be able to withstand temperature extremes and is characterized by high strength.

- It is important to check whether there is a counter-slope on the sill. Otherwise, water will not be able to flow down, but it will accumulate on the surface.

- Professionals advise using sealantthat can dry out in a short time. The best are silicone samples, which combine well with ribbons made of polyurethane.

- At the time of drying of the mounting foam, the reflux is pressed in order not to change its position.

- Under no circumstances should nailing be done. or fasten with screws.

- Low tides should protrude beyond the window, not only in width but also in length. This rule applies to both balconies and loggias.

- If the ebb is wide and bigthen additional mounts are required. An additional window sill will be mounted on them from the street side.

- While window designs are equipped with special grooves for fixing ebbs, the wooden versions have a special “quarter”.The construction is attached to it on screws and rivets.

For information on how to properly install the ebb window, see the following video.