How to choose plastic trim on the windows?

Platbands allow you to remove the cracks with gaps between the wall and the window frame, which remain after the installation work. And also this element gives the building an original and attractive look. Every home owner should know how to pick up plastic trim on the windows to improve their home.

Special features

Platbands are design products that are used to finish windows. With their help, you can hide mounting gaps, protecting the insulation layer from the effects of external factors. And also this element is responsible for the decorative component of the windows. Plinth can be used for interior and exterior window opening.

First of all, the trim is installed on the windows in order to close the gap, which is located between the walls and the window frame.

The element acts as an auxiliary protection against the effects of precipitation, dust and noise. And also increases the insulating quality of the window.

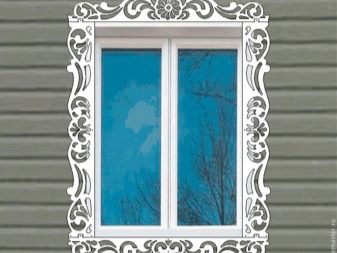

Platbands are able to perform decorative function, giving the building design a touch of individuality. On sale there are different variations of products that will be in harmony with any style. Previously, windows were framed with wooden platbands, but currently manufacturers offer modern plastic products that are of high quality and a wide variety of designs.

The following tasks are assigned to plastic platbands:

- combining conjugated surfaces;

- they give the window construction a finished image;

- security of the connecting seam, which is located between the window block and the wall.

Despite the fact that the frames are considered a small design, they have numerous functions. Competent installation and the right choice of design can complement the building and create maximum harmony between the wall, casing and walls.

The decorative component is an important quality, as with the help of the platbands, the facade of the building acquires a complete and neat appearance. But also such components prolong the service life of windows, thanks to the concealment of connecting seams, which are susceptible to negative external factors.

Despite the fact that the market offers a wide selection of plastic platbands, all the technical characteristics and dimensions of products are tied to the requirements put forward by GOST and TU.

Platbands have many positive qualities.

- Resistance to adverse weather conditions. Plastic is not afraid of sunlight, moisture.

- Affordable price category. The cost of plastic products is lower compared to wooden patch slats.

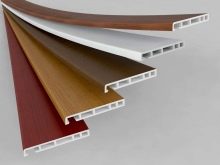

- A variety of colors. White and brown colors are most commonly used, however, manufacturers offer other shades that match the design of the facade of the building. With the help of well-chosen colors you can give the building a catchy and exclusive look.

- Plastic casing does not undergo deformation after prolonged contact with moisture and temperature changes.

- Plastic platbands are easy to install. Overhead strips are fixed with glue directly onto the window profile. But it is also allowed to use special removable parts.

- Plastic does not require special care, unlike wood. A sponge is enough to remove dirt.

- The material can imitate natural wood, so it can be used for framing wooden windows.

- A small mass of products simplifies the installation process. When framing small window openings, double-sided tape is used.

- Many manufacturers offer plastic frames with a cable channel, thanks to which you can hide wires around a window without losing attractiveness.

- In the construction market there are products designed for structures that are sheathed with metal or PVC siding. Such strips have a special installation system.

- Plastic is not afraid of contact with insects and other pests. And also on it the mold, a fungus is not formed.

- Products differ in long service life.

But there are also disadvantages.

- Limited color range, mostly white and shades of brown,as well as a small selection of models and styles. However, the modern market has recently become more and more diverse in this category.

- Still - this is artificial material. Plastic platbands will look ridiculous on a wooden house. The problem can be solved using the casing under the tree.

Despite the shortcomings, the listed features make plastic platbands popular in its segment. Pleasant value for money influence the choice of many buyers.

Kinds

Despite the fact that plastic acts as a basis for plastic platbands, the products are divided into several types.

Flat

They are made of plastic sheet. Typically, this material is used in the manufacture of flat casing. There are monolithic variations, as well as products with a heterogeneous internal part. Sheet material has a low coefficient of stretching, so the slats are not deformed when temperature drops. Therefore, the installation does not need to create large thermal gaps. Since plastic does not absorb moisture, it does not change from swelling.

Flat plastic frames are the most common option, as they are easy to manufacture and install. This option is used in the case when for the framing of the slope does not need delights.

Embossed

PVC casing or polyurethane products are also on sale. Their use allows you to create relief products, which are obtained by pressing or casting. Polyurethane or PVC materials are a versatile element that can be installed outside and indoors. They are immune to UV rays and can withstand different temperatures.

Complex forms are made in the same way as the metal-plastic profile using the extrusion method. By pushing the molten material through the calibration frame, products of any shape are obtained. With this method, we create platbands equipped with a cable channel.

The patch plate may have a different design and color scheme. On sale there are white, color, patterned variations. Demand products that mimic natural materials.

The profiled patch plate has a convex surface.The profile can be symmetric and asymmetrical with different angles. The most commonly used frames are 50, 80 mm wide. Some users choose a self-adhesive casing, which is used for interior work. Delivery of such products is carried out in rolls. The most commonly used width: 30, 40, 50, 60, 70 mm.

The structure of the trim can be overhead or telescopic. The latter version is a special design in the style of "Lego", where all the details are connected with locks. Usually in the configuration there are dobory. Acquisition of plastic strips with dobor allows simplifying the process of framing colored or wood-styled windows.

Installation

Installation of plastic slats can be done in several ways.

- With the help of mounting components. This option is considered the most common. Fixing products made directly on the wall or window unit.

- Fastening with mounting clips. Fasteners are mounted on the window frame, on top of which the casing is laid, its fixation is performed until a characteristic click is formed.

- Use double sided tape.This method is not very reliable, so it is rarely used. A strong wind can snatch the slats from the windows.

If you need to install plastic frames with fasteners, you should follow the sequence of actions.

- The first step is to take measurements from the window frame. You will need a height value from top to bottom. To the value obtained, add the width of the plank, if there is a tide at the bottom, or two widths (when installing along the entire perimeter of the window).

- After the calculations are made, you can start cutting products. You will need to cut pieces that will be used for the horizontal and vertical parts of the casing.

- On each platband need to make a cut, the angle of which is 45 degrees. This action allows you to join all the details around the perimeter of the window opening. For a competent and quick cut of the desired angle, you can use a special mounting corner. This tool has the necessary markup, which eliminates errors.

The following requirements are put forward for cuts:

- on the horizontal patch plate there should be two cuts;

- on the vertical parts, sections should also be present on both sides (if a closed connection is planned), or only on one side (for windows with reflux).

When the trim will be ready for installation, you can proceed to fixing the upper part. To do this, you will need to create a mark on the wall to which you will mount. Then you need to create with the hole punch. Dowels are inserted into the received deepenings. You can use plastic or nylon fasteners. On the casing marks are made under the holes. Fixing of elements is accomplished with the help of screws. Installation of other overhead slats is done in the same way.

Make sure the joints are tight. The design should have a neat look.

In the next video you will clearly see the installation of PVC platbands.

How to choose the right size?

The correct calculation of the dimensions for the casing is a crucial step, which must be taken seriously. Otherwise, you may be confronted with the fact that at the final stage of work it will be found that there is not enough several millimeters to match the window opening.The right choice of sizes ensures a perfect match of the planks in the corners.

Calculations of the required dimensions are made in a certain way.

- It is necessary to measure the height and width of the window opening. The data obtained will mean the inner perimeter of the invoice plate.

- From the opening you need to measure the width of the casing, to understand how it closes the wall. This step is important when the window unit is located in a single plane with the walls.

- The height of the overlay slats should coincide with the height of the window opening, in which the two widths of the trim panel are added. Such calculations are necessary if all the slats, which are located vertically and horizontally, have the same width.

- If the horizontal panel is wider, the vertical height is calculated using the following formula: the height of the opening, to which the width of the upper and lower planks is added.

Knowing the features of choosing the right size, you can avoid the cost of re-purchasing materials and minimize time costs.

Tips

To make the right choice, you should study the recommendations of specialists.

- When buying patch slats of plastic, you need to consider the appearance of products.They should harmoniously look with the overall style of the house and complete the image.

- For the street is best suited profiled products made of polyurethane or PVC. They withstand precipitation and negative weather conditions.

- If the installation is chosen using latches, it is recommended to check the condition of the mechanism. It should not be defects and signs of deformation.

- For a frame of houses from a bar the platbands imitating wood are issued. Products are harmoniously combined with the style of construction and reliably protect windows from drafts and moisture.

Despite the fact that the plastic does not require special care, you need to know some of the features.

- To remove dirt and dust deposits, the outer and inner strips are wiped with a damp cloth or sponge.

- The use of abrasive components and other means with the content of aggressive ingredients is not allowed. To remove strong pollution, it is enough soap solution, which is actively rubbed contaminated area.

- The use of brushes with coarse fibers is not recommended, as they may damage the plastic.

Knowing the features of care, you can extend the life and attractive appearance of plastic products.