Types of seals for plastic windows

Plastic windows - reliable and modern designs. But even such attractive products need support and protection of the joints. For this there is a special seal.

Special features

To install a new window every time, as soon as the sealant of plastic windows made of PVC, installed by the installers, is worn out, is completely unprofitable. The solution is to replace the sealing product with its counterpart. Of course, it should be selected as carefully as possible. Ideally, the old sealing layer should be changed to exactly the same, just acquired again. On the strength of the seal should be the same as rubberequally important resistance to temperature effects and resistance under the action of water; modern products are sustainable even with winds up to 100 km / h.

Reasons for replacement

There are a number of points that indicate that it's time to replace the brand insert:

- blowing out of the window;

- it freezes and is covered with frost inside;

- condensate detected;

- drafts have become too frequent;

- torn and cut places, cracks were noticed;

- the seal partially fell out or went beyond the grooves;

- in winter, it suddenly became noticeably colder than in previous years, although the heating works normally, the house is insulated and the weather is not worse;

- in the summer months on the window sill, even if the window is locked, dust constantly sits;

- the window was at least a little covered with mold or another fungus.

But since the matter is quite serious, it is worthwhile to check in advance whether the inserts are really to blame.

In the absence of obvious deformations and external integrity, it is better to adjust the plastic window. Repeatedly, employees of repair organizations faced precisely such a situation, when setting failures worsened sealing.In this case, of course, the addition of a new seal will only bring additional costs. The problem will not be solved.

Kinds

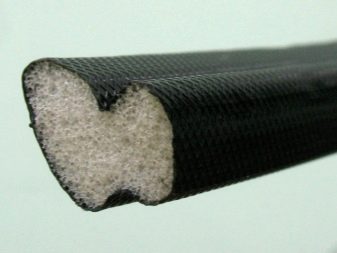

Among the types of window seals for PVC a prominent place belongs to rubber structures. The role of the seal is to close the outer and inner contours to be protected. With this material, the room is isolated from dust and dirt particles, from the penetration of the ubiquitous noise. Therefore, it is becoming more comfortable to operate compacted double-glazed windows. The use of rubber, which is made on the basis of vulcanized rubber, helps to improve the tightness of the window and in addition reduces the cost to consumers.

With a sharp temperature jerk (strong frost or heat), the rubber manifests itself badly. It sometimes shrinks and becomes covered with cracks, it can be damaged by mechanical impact, which it usually does not notice. Moreover, deformations accumulate gradually, and the effect of negative factors, if it does not appear immediately, then in any case will shorten the life of the products. If we focus on cost, it is useful to pay attention to the EPDM rubber sealing structures. This material is distinguished favorably by softness and plasticity, it has no particular drawbacks.

The advantage of silicone pads is the variety of the range. But their popularity is strongly limited to high prices. Such compositions are recommended for windows, which will be subjected periodically to either low or high temperatures. The weakness of silicone is also in its insufficient strength, the seal will quickly tear. For maintenance of aluminum double-glazed windows it is often recommended to use a polyurethane sealant.

It manifests itself well in protection against negative factors of a meteorological nature, as well as against street noise. Modern products based on polyurethane are designed so that they do not damage the surface, even in the case of dismantling. Thermoplastic materials, that is, modified polyvinyl chloride, are widely used in factory sets of plastic windows. It has good springing qualities, but it is not designed for a sharp drop in temperature. This disadvantage of thermoplastic polymers substantially pays off by introducing polyethylene and rubber into the composition of specific products; sometimes even self-adhesive sealing material is used.

EPDM, if the choice is stopped on it, can be represented by two different subspecies. Sulfuric acid is undesirable when using PVC windows in white. It cannot be excluded that yellow traces will remain as a result of a chemical reaction. But the pyroxide variety, despite its high cost, turns out to be much better. For vulcanization it is used organic peroxide, which further increases the service life and increases reliability.

A fundamental disadvantage of EPDM is its unsuitability for welding. The only way to install is to use glue. The cost of a color sealant of this type is noticeably higher than when using black mass. But resistance to adverse factors is quite large. Returning to the thermoplastic compactor, it is worth noting that it does not burn and allows welding, and not just gluing.

This material has an excellent spring effect. Summing up, we can conclude that with some caution it should be used in warm places with a relatively low intensity of operation of windows. If they are used too actively, wear will be excessively fast.

Self-adhesive seals should be mounted at a temperature of +1 to +40 degrees. Before replacing the gasket is to adjust the window accessories. With the help of a key and a marker, the initial position of the heads is marked. So it will be easier in case of an error to immediately return to the original settings. The removal of window leaves occurs after the removal of decorative caps covering the hinges.

How to choose?

Even a simple listing of information about seals shows how important it is to select their appropriate version. Differences for the consumer begin with the installation methods.

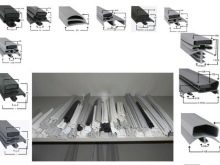

There are three main options:

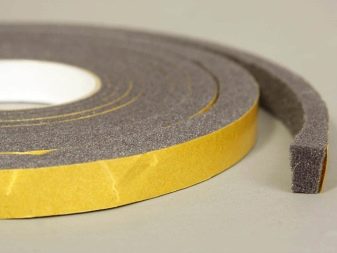

- attached to the adhesive mixture materials;

- self-adhesive (practicality for independent work is ensured by applying initially glue to the element under the protective surface);

- placement of rubber blocks in pre-prepared slots (mainly this approach is used on wooden windows).

As for self-adhesive tapes, in the process of their production can be applied:

- rubber;

- silicone;

- thermoplastic;

- rubber;

- polyurethane foam.

Ethylene-propylene rubber sealing structures, despite their resistance to destructive external influences, are almost always painted in black tones.This significantly limits their stylistic compatibility in the interior. Polyurethane foam sealing strips that have recently entered the market are made in Germany. Therefore, these products, equipped with a sheath of polyethylene, are considered to be quite an effective solution to the problem.

Judging by the reviews, foam seal:

- tolerates ozone and ultraviolet radiation;

- serves for a long time and recovers after an unfavorable period;

- differs in a variety of coloring;

- stably keeps the color of the production;

- frees consumers from lubrication and other services.

But such an element has weaknesses. For example, it is worth only slightly deform the shell so that the foam quickly lost its valuable qualities. The compactor has an increased effect on fittings, it is quite expensive. Installing it also entails significant costs. As for manufacturers, experts recommend giving preference to products for a long time by firms present in the market.

In addition to the German Rehau, KBE, you should pay attention to Novotec. It should be remembered that a quality seal can not cost less than 30 rubles for 1 rm. mChinese products, with very few exceptions, have not yet become as high-quality and visually appealing as a Western European product. An additional selection criterion is the geometry of the gaskets. It is recommended to focus on the product of the same company that manufactured the window profile, or on the "platform". Most of the profiles made at Russian plants are thought out in accordance with the Veka standard.

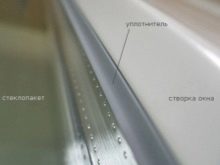

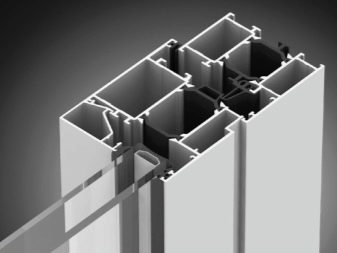

You can seal the glass unit itself with gaskets that occupy the gap between the glass and the frame, or glass and bead. But the porch is compacted with frame and sash designs. This directly affects the geometry of the corresponding blocks. It should be remembered that the initial color of the thermoplastic composition of TPE is gray; You can safely buy it in any color, because the pigments will not affect the quality. EPDM, and also rubber initially black; their staining is possible, but the replacement of soot by other substances significantly reduces the elasticity of the product.

It is easy to understand that black seals will invariably correspond to the stated parameters, and gray ones are durable only when using TPE.Polyurethane foam tape can be of any kind. Black coloring immediately highlights the contour of the window, but to many people it seems a dubious decision to have a strong contrast with white PVC. In such cases, you need to choose gray or white materials, they are almost unlimited to merge with the window structure.

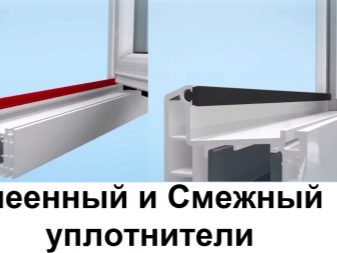

Sometimes in the special literature and even in the accompanying documentation from manufacturers one may come across references to classes of seals. Here, too, everything is quite simple, you only need to take into account the principle of differences in order to understand what is at stake. Thus, the first group includes only substances that can be used without consequences in the temperature range from 0 to 45 degrees. From the window seals only co-extruded composition used in single systems falls into this category. The second class includes seals made from polyvinyl chloride grades PVC, NRB, as well as rubber TPE S.

Such materials are widely used in window systems, but they are acceptable only in areas with a mild climate. Therefore, residents of even the middle band should discard the very idea of buying such a product.The 3rd class includes constructions formed by thermoplastic rubbers and classic vulcanized rubber. They are designed to restore and adjust the sealing blocks, to change worn material in aluminum glazing, too, will be useful. In the 4th group, seals are detected, in the manufacture of which EPDM is used. A more advanced cured material does not exist at the end of the 2010s.

The merits of such a decision are evidenced by the fact that it is used by the world's leading manufacturers of plastic windows. Grade 4 quite adequately manifests itself in areas characterized by a long and harsh winter. Grade 5 covers all TPE V thermoplastic materials. Attractive features are largely impaired by high costs. Silicone seals are usually assigned to the 6th category, designed to work at temperatures up to 200 degrees. They are used quite rarely, and at home they are not needed at all.

When selecting a self-adhesive sealant, it is necessary to carefully check whether the expiration date has not expired. After it is exhausted, the element may not stick at all or it may not be held tightly enough.Solid material is relatively cheap and is used for mass glazing. It should be borne in mind that during temperature jerks the structure of the material may deteriorate sharply. Petal gasket is widely used and very convenient, it guarantees excellent insulation.

How to install and change your own hands?

But whatever seal is chosen, you need to know exactly how it should be put. This is useful even when referring to professional performers in order to control the literacy of their actions and not give up their money for bad work. However, it is also possible to perform the necessary repairs yourself. It should be noted that in addition to the replacement, it will be necessary to apply a lubricant on the surface of the used material. It allows you to extend the life of the material and reduce the intensity of wear.

It is cheaper to lubricate the seals with glycerin. Such a drug is sold in any pharmacy, no coloring has not. But wide availability and low cost are overshadowed by the lack of waterproofing qualities. Vaseline is considered a more practical solution, also forms a transparent surface.But it can be applied only on rubber, which as a result loses excess rigidity.

Petroleum jelly has excellent hydrophobic characteristics, but is unsuitable for temperatures below -25 and above +28 degrees. Since the majority of Russian regions differ in climate that does not fit into this corridor, it is rash to use such a substance for processing. The output in some cases is the use of a mixture of WD-40. The quality of such a lubricant is already indicated at least by its worldwide recognition and use in various countries. WD-40 is supplied in the form of spray cylinders, which makes the use of the composition as convenient and practical for non-professionals.

Reliability meets the most stringent requirements. Suffice it to say that this particular drug has found application in the protection of spacecraft bodies from corrosion. Silicone grease helps protect the window seal from the cold at 50 degrees and from the heat at 230 degrees to the same degree. Many experts recommend purchasing professional-grade protective kits, which, although costing significantly more simple solutions,but provide the highest stability of the seal and its properties.

Having found out the details about the additional protection of the sealing material, you can already change it. After buying the tape take a special adhesive and scissors for cutting rubber. Worn material is removed, simply removing from the grooves. The exposed surface should always be prepared for work, since its condition will definitely be far from ideal.

It is recommended not only to remove dust and dirt, but also to degrease the substrate using:

- solvent;

- white spirit;

- alcohol;

- other similar substances.

Important: it is necessary to find out in advance which substance can be used, and which can be destructive for products. When cleaning is complete, the perimeter of the frame is smeared with a uniform adhesive layer. Next, the seal must be entered immediately and completely. It is better to practice doing it without glue, because mistakes can lead to very unpleasant consequences. It is unacceptable to excessively tap on the tape or attempt to stretch it.

But to replace the seal - it does not mean just to put it in place. All excess areas must be cut.The points of the joints are immediately coated with a protective mixture. Processing is repeated regularly. Only in this way is it possible to maintain a proper microclimate in the home or in the office.

Self-adhesive types of tape set, placing the sash on a flat surface. Then from the surface of the seal remove the insulating tape. During installation, they work with a protrusion, which is intended for fastening into a groove located along the perimeter of the sash and the frame itself. Holding the ribbon a little, they transfer the flap to the initial position.

Removing the sash is easier if you remove the stud with a chisel. When replacing, only an unbreakable cord should be used. The use of separate segments does not give any result. The ends, after the excess is cut, you need to fix the glue.

When checking the quality of work find out:

- whether the opening is not complicated;

- whether it is blown in the closed state;

- Does the sealing block leave the recessed recesses after several cycles of use?

If everything is immediately in order or the defects originally found are eliminated, the sealant should be lubricated with the recommended composition. Careful adherence to these recommendations ensures long-term operation of the window unit as a whole. Before replacing it is useful to take a picture of the frame.With it, you can then compare the progress of work to assess whether a particular action is being done correctly. It is possible to remove the flap blocks from the hinge elements only in a locked form, bearing in mind a considerable mass.

New areas of the seal should be slightly longer than before - because any material is compressed over time. The same principle applies to the insulation of plastic windows around the hinges. The sash is returned to its place with its lifting 2-3 cm above the sill, after which the product is put on the bottom loop. Axis driven in using a hammer.

In modern windows, two or even three profiles are most often used for sealing. They must be replaced strictly at the same time, even if the wear of a particular contour is not very large at first. In the absence of the necessary experience and training, it is not worth risky experiments. Appealing for help to specialists is then the most profitable and justified decision. It is only necessary to choose qualified and bona fide performers.

Manufacturers

Compactors are made in a variety of factories and plants. Therefore, one should pay attention not only to their abstract appearance, but also to what brand the purchased product is issued under.Schlegel is a well-deserved German company that began its work in the 1880s. Initially, there were prepared auxiliary parts for horse-drawn passenger carts. But now, for about half a century, they have been making polyurethane for sealing with foam compounds.

Schlegel products comply with industry standards at the international and European level. The company has certified its quality management system in accordance with ISO 9001: 2008, and has repeatedly confirmed compliance with the results of thorough examinations. The level of thermal insulation meets the most stringent requirements, and thanks to ultramodern materials, the doors open and lock very easily. High density of adhesion to the surface provides decent sound insulation.

The manufacturer claims that the supplied sealing material is odorless and stably retains its color over the entire period of use. Elasticity is guaranteed from -70 to +60 degrees. That is, drafts and freezing of the window, which are disturbed by a huge number of people, will cease to cause problems. The surface is designed for impressive abrasion resistance.During factory tests, test samples from each batch are opened and locked 285,000 times.

KBE is another reputable German corporation that supplies products for maximum window protection. Rubber products and EPDM dominate the company's product line. Important: the original product is labeled along its entire length. The 227th material is designed to ensure that the glass unit is pressed as tightly as possible to the profile. Do not use the 228th grade instead. This can lead to the fact that the shutter does not close at all.

Usually, qualified on-site repairmen decide what to use. If someone claims that you can find out all the details on the phone, these are just primitive charlatans. It is recommended to require a certificate from the sellers for compliance with GOST 30778-2001. Perfectly meets the modern standards of production of seals in the company "Sibrteh".

The company has established the production of white and self-adhesive tapes of various sizes:

- 0.5x0.8;

- 0.5x1.6;

- 0.8x0.8 cm

Also in the line of the Russian manufacturer there was a place for the product for windows with adhesive tape. There are profiles:

- E;

- D;

- P.

Marking of sealing substances and structures can be quite different: so, Rehau is equipped with a pair of single, slightly bent teeth. The clove, which is located near the center of the cushion assembly, is slightly larger than the other two. KBE (without modification) is equipped with a single prong. The modified material is equipped with a stiffener. Sealing solutions from this manufacturer roll inside the groove with a specialized tool. Veka products are easy to recognize by a right angle, which is not bent on production.

Products from Rehau guarantee a stable clamp around the perimeter, and the geometry of the window and even its magnitude do not matter. The company's engineers were able to create materials that can withstand frost at -55 and heat at +60 degrees. From domestic counterparts, we can recommend products from Obninskgazpolymer or Standard Prof. According to practical characteristics, it is not inferior to imported samples. But we must remember that the geometry may be incompatible with a particular profile.

Tips and tricks

To reduce the need to replace the seals and stretch their life, you need to follow the simplest recommendations. To maximize the insulation parameters, you can use beadings that seal the middle of the profile.Seamstress is sealed with an elastic cord fastened to the flap along the entire length. To make the seals work as best and as long as possible, the window blocks should be washed regularly. The material itself is ground with a slightly wet cloth.

It is recommended to avoid fogging and freezing. Caring for the state of the surface of a gray or black substance implies a cover from fat, acids and other harmful substances. Accessories special service does not require, but be sure to lubricate it. It is also desirable to regulate the force pressing the sash, weakening it in the summer and increasing at the approach of cold weather. It is still useful to handle the compactor regulated substances.

Washing seals involves the use of wet matter. In addition to plain water, you can use a solution of LOC. How often to wash the sealing gasket depends on its material. Silicone is washed relatively rarely (once in 3 months), and other materials will have to be processed more often. Sometimes they use the Edelweiss set, by default everything that is needed for a full service is included.

Do not use for lubrication:

- glycerol blends;

- cream, machine and vegetable oils;

- vaseline (all these substances can have a detrimental effect).

Cleaning of dirt and dust under the petals should be carried out only with soft devices. Knives, screwdrivers, chisels, chisels, and so on can, along with the removal of harmful inclusions, damage the material itself. Damage, including even microscopic, is a serious danger and adversely affect the timing of operation. Moreover, the seal must be cleaned a maximum of once every 12-24 months. Exception - windows installed in particularly dirty places; in the absence of experience or confidence, it is better to hire a team of specialists.

When buying a lubricant, especially outside specialized hardware stores, you need to pay attention to compatibility with the material being processed. Observing this condition, you can buy a tool even in a car shop. Important: after removing the sealant, it is washed in warm water with the addition of soap. Regardless of the resistance of the initially applied preparation, the protective layer must be renewed. In case of detection of fragility, when the seal crumbles, it will not be possible to restore its properties, you can only replace the material.

How to change the seal on the windows, see the video below.