Varieties of window lintels

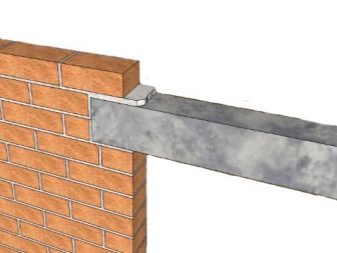

The lintel is a rectangular structure made primarily of reinforced concrete. It is mounted above the window and door openings, as well as above the openings where the door is not provided. This construction serves to strengthen the nodes and evenly distribute the load on the wall. There are also jumpers made of wood and metal.

In buildings made of brick, as well as in the projects "monolith - brick", the presence of a jumper is obligatory according to SniP. In panel structures a jumper is already in the structure itself.

Reinforced Concrete Lintels

The jumper is needed to strengthen the structural components (door, window openings, openings without a purpose) and uniform load distribution, which is created by the wall itself or floors. The bottom line is that the load is distributed along the edges of the reinforced concrete lintel. There are many ready-made options for products in size, brand of concrete and other parameters, but you can make it yourself.

Making a reinforced concrete lintel do it yourself

For the manufacture of jumpers will require a certain tool and material, without which it can not be done.

- Formwork These are sheets of durable material (particle board, fiberboard), which serve as a form for pouring concrete. Also for the formwork, spacers are needed to contain the sheets themselves, because simply knocking them to a friend will not work - the concrete will squeeze out the formwork and have to be dismantled. Formwork is set under the level, you can also use a plumb line, and if there is a level, then the level will be extremely accurate, which is very important.

- Fittings. Represents metal rods with stiffening ribs. Required to impart stiffness and elasticity reinforced concrete lintel.The reinforcement is mounted after installation of the formwork, communicates with each other, creating a reinforcing mesh. It is advisable to weld the extreme ends of the reinforcement to the wall (more precisely, grab it) so that the reinforcement does not float when casting.

- Concrete. The main component of all concrete products. It has many brands and classes. Concrete class B15 will be suitable for the lintel, as well as the M200 brand, but in cases of high-floor construction (from five floors) it is advisable to take the M250 mark.

If you make concrete with your own hands, you need a concrete mixer. If not, then the process of making concrete will be extremely long and inconvenient. In this case, you will need a bath or other design, which will allow you to mix the cooking mixture.

Concrete consists of sand, water, cement and filler (gravel, crushed stone). Depending on the concrete you want to get, the proportions of the ingredients will vary. But there is one caveat: with this method of manufacturing, the building should not be higher than two floors and not have a summer house type, since the concrete will be ordinary and not vibrated, which is not so good for the structure itself.

After 28 days, the concrete sets and you can dismantle the formwork.This is done with scrap, hammer. Before this period, you should not break the formwork due to the fact that the design can swim a little. It would seem that this is insignificant, but even going to the floor a centimeter can seriously affect the structure, leading it to an unsatisfactory technical condition.

Also, when checked by technical supervision, this violation may lead to the suspension of work until the malfunction is rectified. Since, according to SniP, concrete sets in 28 days, it is recommended to perform work on concrete after this period, and technical supervision will not see any violation in this. This applies to all buildings and structures, including houses on individual projects (private houses).

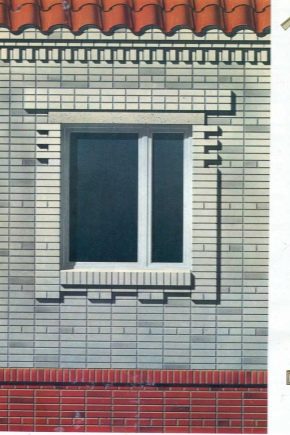

Important: the jumper should go flush with the brickwork. It should not stick out in any direction either on the front or on the reverse side.

- If it bulges, although it was set on a level or level, then this means that the formwork was poorly fixed and floated. In this case, you need to re-check the level (even with the level) and make sure that the jumper did not break its geometry and did not lose its true, calculated dimensions.If all is well, then a small protrusion can either hide the insulation, or beat off with a jackhammer (as an option - grind a grinder with a disc on the concrete).

- If the ridge protrusion exceeds the tolerances, then it is better to dismantle such a jumper, otherwise this object may not be accepted until the violations are corrected. And the dismantling of the lintel in the finished structure, and its dismantling almost immediately after its installation has a different complexity of repair and restoration work.

Also jumpers can be used in the construction of third-party structures: gazebos, pavilions, tents, stairs (small), garages. The principle of their installation is almost no different from the installation of jumpers in residential buildings, except for the size of the structure. The main use of products from reinforced concrete (in particular - lintels) is buildings and buildings made of brick, stone, foam block, cinder block, aerated concrete and other materials with a stone base.

There is a type of brick jumper in brick structures, as well as in block structures. He is a construction with steel guides, in which a brick is laid according to all standards and technologies. In the absence of finished products, this type is the fastest and most inexpensive way to install a jumper.

Previously, the type of jumpers made of wood was used, but only when building a house made of wood entirely. The carrying capacity was not too large, but it was sufficient for two-storey and three-storey houses. It was mandatory fixed on the nails.

Taking into account our advice, you will be able to independently calculate all the necessary parameters of the products and set them accordingly to GOST. If you have a concrete or aerated concrete window, then it will be most practical to install plastic models of the corner.

Reinforcement must be at least 1000 mm.

First of all, it is necessary to fill the structure in an angular way, and then drill and install jumpers. It will be the best solution.

Jumper Types

Lintels are divided according to several criteria: by material, by purpose, by method of manufacture, by heat resistance and cold resistance.

According to the method of manufacturing jumpers are finished products supplied from the factory and filler (manufactured by the method described above). All finished products have special reinforcing loops or technological openings intended for their transportation and ease of installation.This also applies to the rest of the finished products of reinforced concrete.

To destination distinguish such products as:

- squared (width up to 25 cm);

- slab (width from 25 cm);

- beam;

- front.

The most popular for installation in residential buildings are lintels bar-type. They have a square cross-section of up to 25 cm. As jumpers, they are used both in residential, private construction, and in special construction of auxiliary facilities, even when building non-metal fences. Regarding the characteristics of these jumpers, it is worth noting that they are not afraid of either temperature or moisture. This is, above all, the dignity of concrete. Bridged lintels are used in buildings and structures of all types: brick, stone, blocks and wooden. The exceptions are metal structures, but there the jumpers are completely differently executed and calculated.

Plate lintels are designed for the same types of structures as squared ones. Often they are used in monolithic structures, since they have greater flexibility, which is necessary in such structures. The width of such jumpers starts from 25 cm.The peculiarity is that one part has a special selection for laying additional floors, visually it is a quarter. Unlike bar lintels, it is also used in large industrial buildings with increased load on the load-bearing walls.

Beamed products are used to overlap openings, the main difference from bar lintels is that there is a special recess at both ends for supporting the floor slabs and floor slabs. In view of this factor, it is necessary for structures in which the windows go below the level of the upper floor slab. Also beam jumper has a high frost resistance coefficient F100.

There are facade lintels that cover the openings of the facade walls when the masonry protrudes more than 25 cm. Due to the development of building technologies and the variety of squared lintels, the façade is almost never used.

Installation of reinforced concrete lintels

Ready-made lintels are mounted using the building level, mortar for mortar and crane. In the opening there should be a notch under the lintel where the mortar is applied and the lintel is laid.Also, after its installation, it is usually set at a level and left until the mortar sets. Already after this, a brick or block is placed on the lintel. The exception is made of beam plates, which themselves have a notch below the level of the floor slab, they must be set to the maximum level and the loops must be cut immediately, otherwise this may prevent further installation of the floor slab.

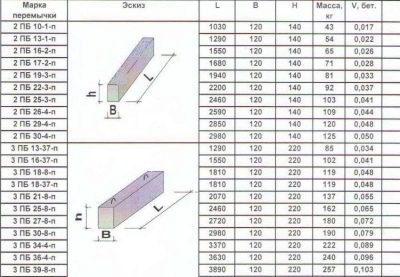

Marking and specifications

Marking is an abbreviated information plate with the characteristics of any product. The concrete grade is indicated by the “M” index, the reinforcement class is “A”, and the frost resistance is “F”. The jumpers themselves are indicated by the abbreviation:

- Bar lintels are designated as "PB";

- slab - "PP";

- "PG" is a beam;

- "PF" is a jumper front.

After these abbreviations follow numerical values, where the number of the cross section is indicated first, and the letter indices indicate the type behind it. Behind it is a number that indicates the approximate length in dm. Then a hyphen is written, followed by a number that indicates the bearing capacity in kN / m.

Also there is a small letter "p", indicating the presence of mounting hinges, indicated and releases of reinforcement, denoted by the small letter "a".

There are also special reinforced concrete structures that withstand the loads of seismic activity, withstand the ingress of highly toxic and chemical substances, as well as radiation. Therefore, it is necessary to select the jumper, based on both the technical task and many other factors that are usually prescribed in the project.

Price of reinforced concrete products

In addition to the type of products made of reinforced concrete, the cost affects the size. Before you buy a jumper for openings (both window and door) of any brands, sizes, characteristics, you should pay attention to their technical condition. Large chips, cracks, visible deformations are critical.

There are maximum permissible deviations, according to SniP, but often, it is rejected at the plant’s release stage and non-marketable items are sold at large discounts. If one supplier offers a price that is noticeably lower than that of competitors, then the inspection and inspection of the product must be very thorough, as this may be a fraudster who has bought defective products and is trying to sell them.

After purchase, reinforced concrete products are shipped to storage sites, usually to a construction site. The rules for storing jumpers provide for the height of the stored products up to 2 meters. Between the rows it is also necessary to put a gasket that will not allow chipping and other damage.

Conclusion

Installation of reinforced concrete lintels is, in accordance with applicable building codes, safety regulations, observing and additional requirements. Remember that the load from the walls, especially bearing, is very high and if you break the technology, it can lead to tragic and lethal consequences.

Technology installation window jumpers when building a house, see the following video.