How to choose a window profile?

When installing the window unit select the profile system. Although the profile takes up no more than 20% of the product area, this is the main component on which the reliability and durability of windows depends. Outwardly, all profiles are not very different from each other, but the difference is hidden in the structure of the structure and material of manufacture.

Special features

The design of the window includes 3 parts - profile, glass and fittings. The window profile is a stable support that keeps the glass unit. Frames and casements are made from it, which bear the load of the whole structure.

The profile has the following characteristics:

- The material of manufacture must be with a low coefficient of thermal conductivity so that the frame does not freeze.

- The level of thermal expansion must correspond to the coefficient of thermal linear expansion of glass. It is 0.000009 m / m ° C. The difference in the expansion of the profile and glass should be minimal so that there is no load when the materials are stretched. This leads to premature wear of the seal.

- High modulus of elasticity. Different weather conditions can lead to deformation of the structure. The higher the elasticity of the profile, the greater the force of stress that the material can withstand.

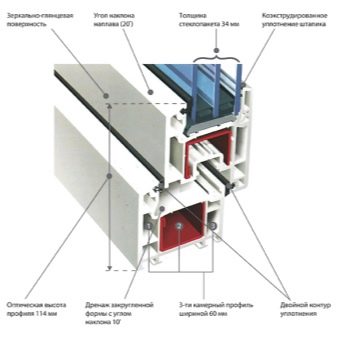

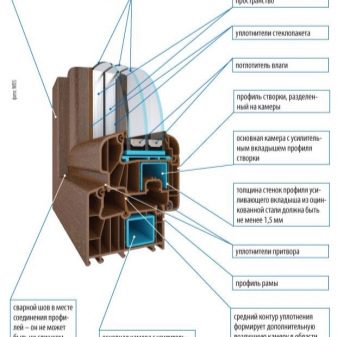

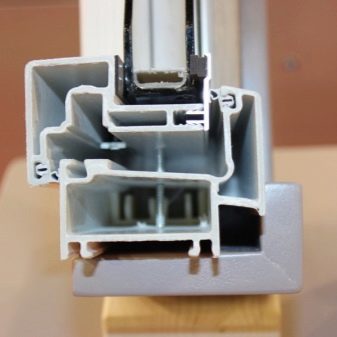

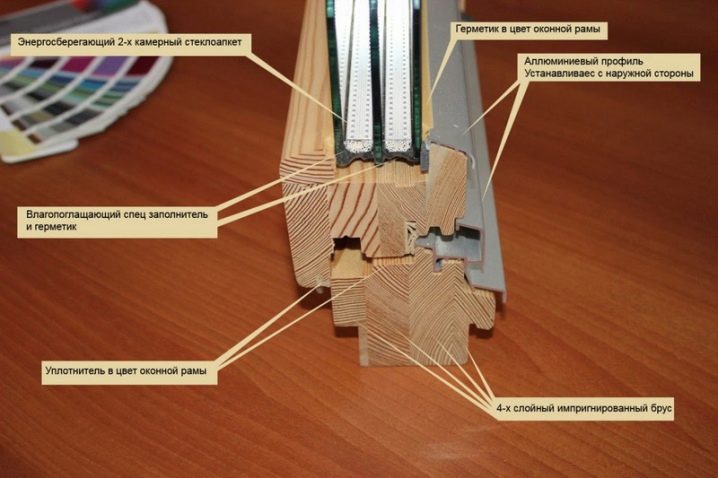

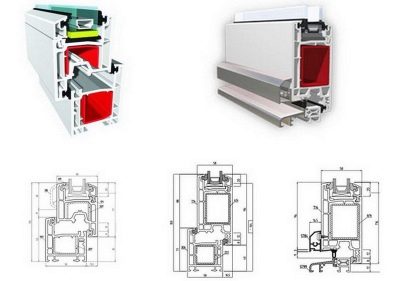

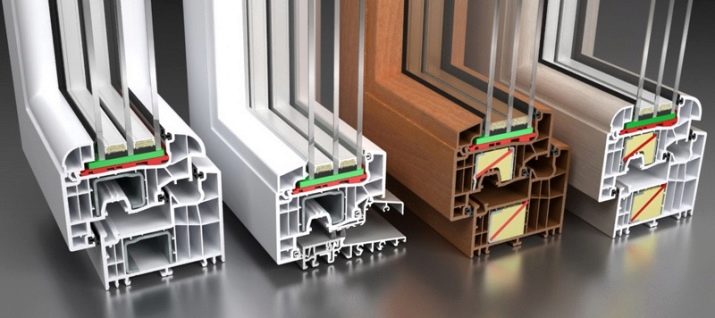

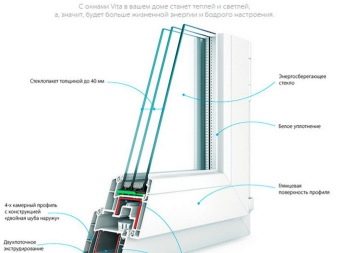

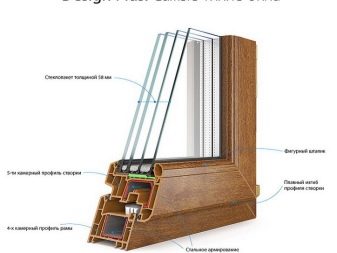

Profile designs are made of various structures. Profiles can be corpulent and hollow. Full-bodied produce from an array of material, usually wood. The hollow structures are separated by partitions, forming chambers. The bridges between the chambers serve as stiffening ribs, increasing the strength of the profile.

Adjacent to the street, the chamber serves as a drain for condensate resulting from temperature changes. The central large cavity carries the main load on the body. The camera, adjacent to the room, is designed to install window fittings. Each chamber, filled with air or other heat-insulating material, performs heat-insulating functions.

Additional cameras are needed to improve sound and thermal insulation characteristics.

Kinds

The window profile differs in the type of material from which it is made. There are profile systems of the following types:

- wooden;

- aluminum;

- fiberglass;

- polyvinyl chloride.

Different tree species are classic proven material for making window frames. For the assembly of profiles take glued timber from cedar, pine, larch, oak, alder. The tree answers all characteristics shown to a window profile. The coefficient of thermal conductivity on average is 0.2 W / m * K, the modulus of elasticity is 9-10 GPa. When heated, it does not expand, but under the influence of high temperatures it can ignite.

When installing wooden profiles, you can highlight the following advantages:

- comfortable indoor climate due to natural air exchange up to 2.7 m3 per day;

- wood does not attract dust, as there is no electrostatics;

- aesthetic appeal;

- strength of the structure determines the density of the tree - 0.5-0.6 t / m3;

- the ability to repair defects on the surface;

- depending on the type of wood, the service life is from 30 to 90 years.

Wood constructions hold heat well and are environmentally friendly.

To get a quality product, you need to take into account the features when working with the material. Additional drying, treatment with antiseptic and flame retardant primers leads to higher prices for wooden windows. The negative side is its swelling at high humidity. When changing the temperature and humidity environment in the room may cause condensation. The accumulation of moisture leads to stains on the tree.

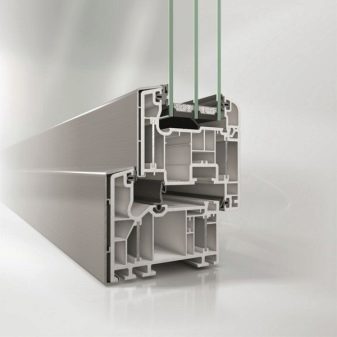

Aluminum profiles are light and durable, consisting of two or three chambers. The main advantage of their use is fire safety. The metal window has a high thermal conductivity - 140-190 W / m * K, which makes it unsuitable for use in the harsh northern conditions.

To increase the heat capacity in the design of aluminum profiles include a polyamide thermal insert, which leads to massiveness and increase in the cost of the product. The high coefficient of elasticity (up to 70 GPa) allows its use when glazing commercial premises, public buildings, and balconies.

Fiberglass profile is made of PVC and fiberglass, which gives a special structural strength, corrosion resistance and chemical inertness. Fiberglass composite with a thermal conductivity of 0.3 W / m * K has a coefficient of thermal expansion of 5-14 * 10-6 m / m * C, which corresponds to the level of glass. A coefficient of elasticity of 20–40 GPa makes it possible to resist stress well during deformation of the profile structure.

The fiberglass profile did not receive wide distribution because of high cost. It is one third higher than the popular plastic counterparts. Also, the production of glass composite windows is complex. The lack of flexibility of the material does not allow its use for the manufacture of solid arched elements.

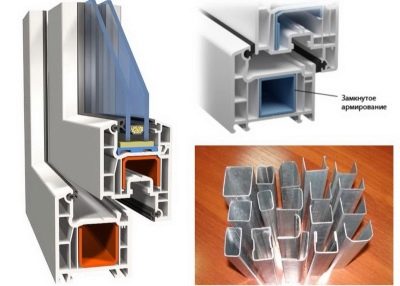

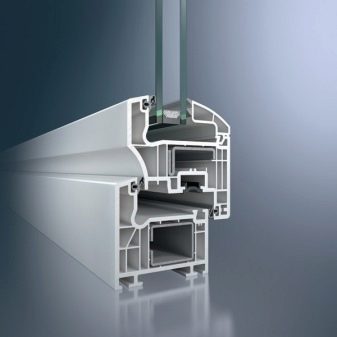

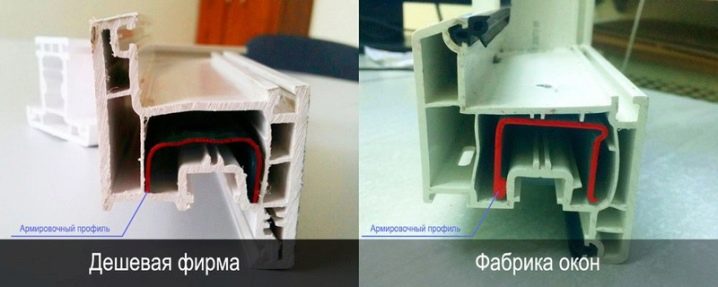

PVC profiles can be completely made of polyvinyl chloride or reinforced with a metal liner. Often, reinforcement profiles are called metal-plastic. Galvanized steel 1.5-2 mm thick is used for the insert. The metal gives strength to the profile construction, levels the expansion of polyvinyl chloride when heated, increases elasticity and resistance to stress and strain.

The type of reinforcement is determined by the size and weight of the entire window. Structures with a profile length of less than two meters can be equipped with an insert with an open loop, where two or three walls are reinforced.For a massive window install metal insert a closed loop. There is no reinforcement for profiles smaller than 60-70 cm.

PVC profiles have the following technical characteristics:

- Low rates of thermal conductivity of 0.15-0.16 W / m * K allow you to be a leader among all materials.

- Density is more than 2 times higher than wood - 1.4 t / m3.

- The high coefficient of linear expansion of 60-70 10-6 m / m * C and a low elastic modulus of 2.8 GPa is compensated by the reinforcement of the profile.

- Chemical resistance to alkalis and fats. Relative resistance to solvents and acids.

- The number of chambers is from 3 to 8. The chamber affects heat-insulating and noise-absorbing qualities, strength and rigidity of the structure.

- Filling width determines the type of installed glazing. The depth of the seat of 15 mm inside allows you not to mist and freeze through the glass.

- Operating temperature - from -60 to +75 degrees.

- The flexibility of the material allows you to give any geometric shape, even a circle.

PVC profile can be painted in different colors. Standard is monochromatic painting in white color in the mass. Also, the color change is possible when laminating films of different shades.More firmly the color will stay on the surface when applying a color film by co-extrusion method.

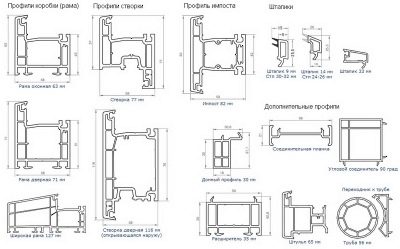

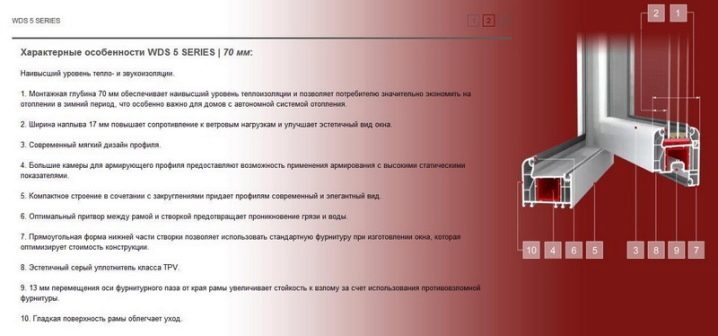

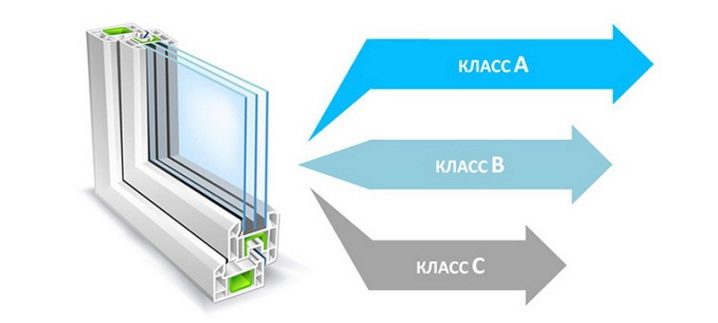

According to GOST 30674-99, for window blocks of PVC profiles, the thickness of the inner and outer walls differs in classes:

- Class A with external walls - more than 2.8 mm, thickness of internal walls - more than 2.5 mm ;.

- Class B has a wall thickness of more than 2.5 mm and 2.0 mm, respectively;

- Class C does not have strict standards for the thickness of the shell.

The outer walls form the profile hull, they are visible from the side of the room and the street. One inner wall is adjacent to the mounting wall, the other is located inside the structure and serves as a base for the glass unit.

Plastic profiles stand out for their positive qualities:

- resistance to high humidity;

- anti-corrosion properties of the material;

- do not burn out from sunshine;

- ecologically safe, do not emit harmful substances to human health;

- service life up to 40 years;

- easy to care for and wash.

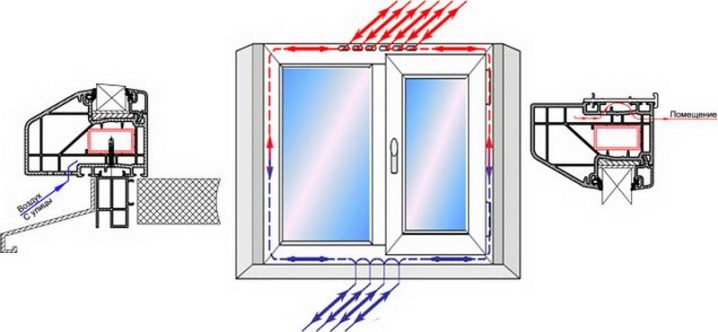

Among the negative sides there is a complete airtightness of the structure, which prevents air circulation in the room and contributes to the formation of condensate on the double-glazed windows.

Removing the drawback will help frequent airing of the room, if not installed additional ventilation. Also, the plastic can not be repaired, scratches can not be disguised.

Dimensions

The width of the profile system, called the installation depth, can vary from 58 to 124 mm.

The following profile sizes are distinguished:

- 58 mm - the classic version that meets the standards;

- 70-80 mm - extended version for high-rise glazing with improved thermal insulation characteristics;

- 90 mm - energy-saving profile with 5-6 cameras and the ability to install double-glazed windows up to 5 cm.

In a three-chamber profile, the width is 58-60 mm. For more cameras, a frame thickness of more than 70 mm is required. With a narrow profile, the size of an installed double-glazed window can not be more than 32 mm. With an increase in the installation depth, the thickness of the glazing expands, increasing the thermal insulation of the window.

Not always the large width of the profile corresponds to the multi-chamber. Capacity design with 3-4 cameras retains heat better, because the air volume is larger.

How to choose?

When choosing a window profile, you first need to decide on the material of manufacture.If an aesthetically attractive appearance and high standards of environmental safety are important, then it is better not to pick up a wooden profile. Modern fiberglass and aluminum windows are suitable for a progressive interior design. A suitable solution may be a PVC profile system.

The selection is made according to the following criteria:

- Profile size. It is characterized by the mounting width and is determined by the installation location and conditions during operation.

- Available budget.

- The number of cameras.

- The presence of a certificate for products.

- Depth and width of a seat of a double-glazed window, class of a profile.

- The presence of reinforcement.

- Appearance and color.

The most important indicator for preserving heat in the house is the width of the profile.

It depends on the atmospheric conditions of the local climate. In the southern regions, you can put a narrow profile with a depth of 58-60 mm. In temperate climates, systems with a width of 70-84 mm are suitable. In the harsh northern conditions, it is preferable to install an energy-saving profile 90 mm wide or more.

You also need to consider the location of the profile system. For an unheated balcony or loggia, a narrow profile of 58 mm or less is suitable. On high floors set the profile in 70 mm.For public and commercial buildings, a profile with a depth of 58-70 mm is suitable. For country individual construction used 70-90-mm systems.

For many consumers, the main criterion for choosing a window profile is its price. Therefore, when choosing well-known brands of profile produced abroad, the cost may not coincide with the planned budget. In such a situation, the best solution would be a profile that matches all the characteristics produced in Russia.

Depending on the price category, there are several classes of profiles:

- economy;

- standard;

- exclusive;

- elite.

Economy-class profile structures are the most budget with low quality and thermal insulation characteristics, with a width of not more than 58 mm and a wall thickness of class B or C. Class Standard corresponds to GOST and European standards, three-chamber, with a width of 58-60 mm. The most correct decision on quality and price.

Elite profiles with an installation depth of 70-80 mm make it possible to mark glass of 40 mm, class A walls, 5 chambers. Thermal insulation is 15-20% higher than that of Standard profiles. The exclusive profile system is 2 times warmer than the elite. The most expensive choice, emphasizing the status of the owner. Width is 86-90 mm, 6-7 chambers and a double-glazed window to 5 cm.The number of cameras corresponds to the width of the profile. 58 mm profile can not contain more than three cameras. Depth of 70 mm allows to contain from 3 to 5 air chambers. Profile 90 mm has 6-7 cameras. The same width of the profile, containing a different number of chambers, slightly affects the thermal insulation characteristics of the entire unit.

Quality window profiles are RAL certified. A certified product is the key to long life and compliance with all production cycles. Plants where products are manufactured also receive an ISO9001: 2000 quality management certificate. The thickness of the glazing unit is associated with the dimensions of the profile, which is installed in the seat. Its depth should be more than 1.8 cm, with increasing depth increases. The most optimal in terms of performance is a double glazing.

The durability of the profile construction depends on the class of the wall thickness. Class A profiles provide strong welding seams and a strong structure. Class B is able to provide the necessary reliability for small window units. Although class C is massively used for budget construction, its strength is low, the corner joints are thin,and the tendency to distortion and distortions reduces the lifetime.

Reinforcement increases the strength characteristics and the load on the profile. This is especially important for massive heavy construction. Be sure to make sure that the profile is reinforced.

In appearance it is possible to characterize the quality of plastic. To the touch it is smooth, without chips and scratches. It should be visible stains, there is a uniform color. The choice of color depends on the interior space. Many manufacturers offer a variety of colors.

Manufacturers and reviews

The leading position in the market of plastic windows is occupied by imported brands of the profile system. This number includes German brands Rehau, Schuco, Salamander, KVE, Veka, Korean LG, Belgian brand Deceuninck. Russian manufacturers are incomparably smaller, but they benefit from lower pricing. Presented profiles Novotex, Montblanc, Proplex, Exprof.

Known company Rehau since 1948 it has been creating polymer constructions. The brand has established itself as the production of high-quality profile window systems focused on different market segments. The company controls the quality of certified products by selling profiles to equipped enterprises for assembling windows.

- The system is available for different consumers. "Blitz New" with a width of 60 mm and three cameras. It is widely used in object and individual construction. With decorative lamination and similar characteristics, the Euro-Design profile is produced.

- Insulated window block "Sib-Design" created specifically for harsh climatic conditions. Mounting depth of 70 mm allows installation of glass pack up to 41 mm. Three expanded chambers increase thermal insulation properties. Five-chamber profile with a width of 70 mm in the system "Delight Design". A distinctive feature is narrower dimensions, which allow to increase the flow of light by 10%.

- Premium class profile system "Brilliant-Design" with a depth of 70-80 mm has 5-6 chambers. The high sound insulation qualities of the Intelio profile provide 6 cameras and an installation width of 80-86 mm. The Geneo window system with a depth of 86 mm has especially strong characteristics. Maximum sound insulation and full reinforcement allows their use in high-rise construction.

High quality and global production experience is available from the German company KBE. It produces environmentally friendly products with calcium-zinc compounds with a service life of up to 50 years, recommended for installation in children's and medical centers.Profile systems with an assembly width of 58 mm and three cameras are manufactured by the “KBE Etalon”, “KBE Engine”, and “KBE Gut” series. Under "KBE Bau", "KBE Master", "KBE Energy", "KBE Expert" profiles with an installation depth of 70 mm are produced. From 3 to 5 chambers and the size of a double-glazed window up to 42 mm make it possible to improve thermal insulation by 20%. The fitting groove of 13 mm provides protection against breaking.

The best sound and heat insulation qualities are provided by a 76 mm wide profile with two and three sealing contours. Energy efficient indicators have a seven-chamber system "KBE 88". It is 2 times warmer than standard blocks 58 mm wide.

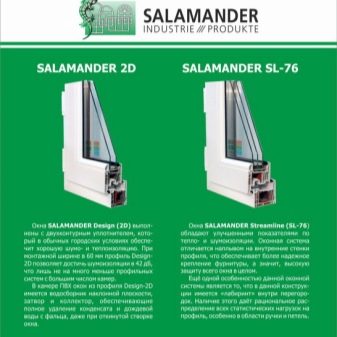

The Salamander brand is famous for its production in Germany and high European quality. It produces profile blocks from 60 to 76 mm depth. Inflated prices do not add popularity in the Russian market.

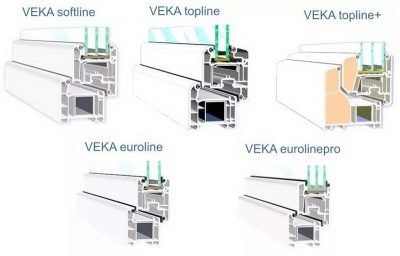

The class A profile is produced by the world leader in the production of core systems, the Veka company. A subsidiary company has been opened in Russia with its own production facilities. Large range allows you to choose the appropriate profile for any needs. For glazing of balconies and loggias there is a 58 mm wide “Sunline” system with three cameras. Available modification is the profile block "Euroline", which belongs to the economy class.

Standard windows with high thermal insulation are created using the “Proline” profile with a width of 70 mm and a four-chamber design. The five-chamber “Softline” system is made with improved noise insulation and an installation depth of 70 mm. The premium Artline profile has been designed with a special design for greater light transmission. The width of 82 mm and six cameras retain heat and protect from noise.

German oldest manufacturer supplies Trocal eco-friendly profile systemsproduced in the Russian territory. All blocks can be equipped with color lamination and aluminum lining. The range includes series for different budgets. “Trocal Balance” and “Trocal InnoWave” with 5 cameras and 70 mm wide, five-chamber “Trocal InnoNova” with a depth of 70 mm and a double-glazed window width from 40 to 58 mm.

The production of elite metal-plastic and aluminum profiles is engaged in the German company Schuco. High prices are justified by high quality characteristics of products.

- Three-chamber profiles are intended for object construction. "Schuco Corona AS 60".

- With an assembly width of 70 mm and a different design, brand profiles are produced "Schuco Corona CT 70".

- High-quality energy-saving profiles "Schuco Corona SI 82" with six cameras and a width of 82 mm have anti-burglary protection. Durable reinforced frame reduces the area by 30%, letting in more light than standard windows.

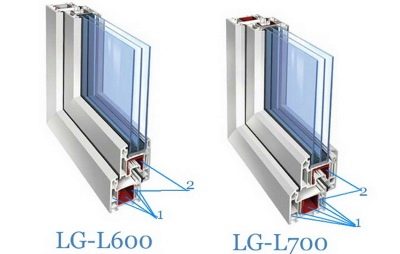

LG supplies four types of plastic profiles to the Russian market, specially adapted to our climate. Standard features of the LG L-600, manufactured in a width of 60 mm with 3-4 cameras. Improved protection from the cold and sounds of the system LG L-700. Mounting depth is 70 mm, it is possible to design with three and five chambers.

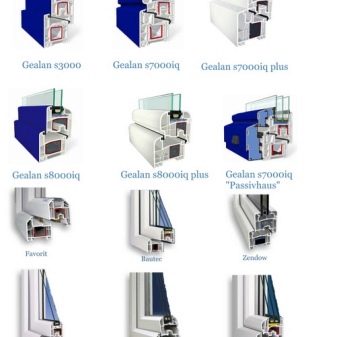

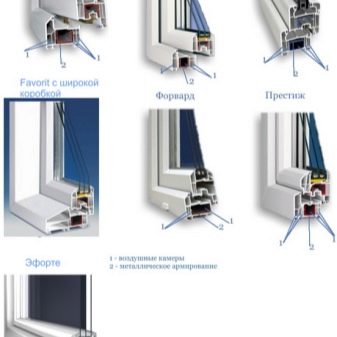

The Deceuninck group of companies with an office in Belgium founded production in the Moscow region. Produces profile systems "Forward", "Favorite", "Eforte". The “Forward” block, narrow (60 mm wide) and three chambers, belongs to class B. The width is 71 mm and 5 air chambers at the “Favorit” provide for the possibility of installing glass packs up to 47 mm. The Eforte profile has a depth of 84 mm and 6 chambers, which allow for a decent level of insulation.

Since 1999, the large Russian manufacturer Proplex has been producing profile blocks of four modifications.

- The two-chamber profile "Proplex Outline" with a width of 46 mm is intended for use in industrial and non-residential buildings, non-insulated loggias and balconies.

- The budget option - "Proplex Optima" with a depth of 58 mm.

- With a width of 70 mm "Proplex Comfort" with 4 cameras, warmer, it is possible to install a double-glazed window of 12-42 mm into it.

- "Proplex Premium" is suitable for operation in a harsh climate, consists of 5 chambers with a width of 70 mm.

- The depth of 127 mm in “Proplex Lux” allows you to increase the heat-shielding characteristics.

The company "Narodny Plastic" produces profile systems brand Novotex.

- Four-chamber profile "Novotex Classic" with an assembly width of 58 mm, the height of the seat of the glass unit 20 mm.

- Cheaper three-chamber unit - “Novotex Light”.

- “Novotex Termo” with a width of 70 mm and five chambers has enhanced thermal insulation properties; it allows a double-glazed window to be placed up to 42 mm.

- The three-circuit sealing system, an installation depth of 82 mm and 6 chambers give the Novotex Nordic profile characteristics and premium quality.

- Also in the line there are profile systems of class A - “Ecoline Pro” with a depth of 70 mm and “Ecoline Balance” with a width of 58 mm.

- Under the brand name Techno, the company produces low-profile systems.

Since 2001, the production of profiles under the Montblanc brand has been launched. The product line includes 5 series: “Eco”, “Termo”, “Nord”, “Grand”, “Quadro”. They have different thermal characteristics due to mounting widths from 60 mm to 80 mm. The company also manufactures the Reachmont Goodwin and ECP profile systems.

The company "Exprof" is engaged in the production of profile structures brand Exprof.

- The budget profiles are represented by the “XS358 Prowin” and “S571 Profecta” series with class B walls. The widths are 58 mm and 70 mm, respectively.

- The “S358 Practica” modification belongs to class A with a depth of 58 mm.

- The S670 Experta series is characterized by 6 cameras, 70 mm wide and class A.

- "S570 Suprema" with deepening of a double-glazed window by 25 mm, 5 cameras.

Each series has a profile version with an expanded installation depth of up to 101 mm, in which an air intake system is integrated. This enhances the insulation, is a prevention of condensation and freezing.

Kaleva plant produces 4-5-chamber profiles 70 mm wide in seven modifications - “Vario”, “Space”, “Deco”, “Design Plus”, “Design Standart”. Two models with a depth of 79 mm - "Titan" and "Titan Plus". The Vario series is distinguished by an unusual design thanks to aluminum lining. “Kaleva Space” is remembered for black and white outdoor performance. “Deco” series with 5 chambers and 3 sealing contours.

With enhanced sound insulation profile "Design Plus".

- The low-height Vita model provides increased light transmission.

- The “Standart” series is an energy saving solution for the Russian climate.

- The Titan profile system with aluminum lining improves durability and energy efficiency.

- The package "Titan Plus" includes a glass door with integrated blinds on a mechanical drive.

The most positive reviews have European manufacturers Rehau, Veka KBE. Placing its production facilities in Russia, the products comply with GOST and European quality certificate. The best profile of the company Salamander, produced in Europe.

Comparing profiles of different manufacturers allows you to make a rating:

- Rehau, Veka, KVE, Scohuco.

- Novotech, Trocal, Deceuninck, LG.

- Proplex, Montblanc, Exprof.

Tips

It is experimentally verified that the best in price-quality ratio will be a metal-plastic system. In addition to the selection of quality products, you need to take care of the wizard who installs the window unit, because 70% of successful operation depends on proper installation. An important characteristic is the seal in the profile. For Russian climatic conditions, there should be 2-3 sealing contours, only this way high insulating performance will be maintained during severe frosts.

The rubber seal between the profile and the glass pane will last longer than polyurethane.

To maintain the temperature and humidity microclimate in the room on the profile can be installed ventilation flaps and slots. In the profile, special grooves and grooves are laid, with the help of which the hardware is fastened with screws. Thanks to them, the screw is not displaced during installation, being fixed in the adjacent chamber.

Since reinforcement is a prerequisite for imparting durability to polyvinyl chloride, you need to check its presence during installation. This will help the magnet. If the walls are not magnetized, then there is no metal inside.

Quality certified profile designs are labeled. It can be found on the inside of the profile. The marking contains the name of the manufacturer, date of production and other information. The stamp will help to determine the authenticity of products.

How to choose a window profile, see the following video.