Varieties of film from the sun for windows

To give the room more comfort allows the use of protective films on the windows. Almost all of them serve to protect the rooms from sunlight and heat. Some species have a mirror effect, are characterized by increased resistance to impact or are used for interior and exterior decoration.

Special features

The film on the windows is an inexpensive and effective material that serves primarily to protect the interior of the room from the effects of UV rays and overheating. Most films hold up to 99% of the sun's rays and up to 80% of the infrared radiation. These indicators are more than enough to provide a pleasant coolness in rooms on a hot summer day.

The basis of the film - polyester, characterized by high light transmission qualities, low weight, environmental friendliness. In addition, it does not emit toxins during the heating process and is fire resistant.

There are also multi-layered options, with a colored layer or laminated film. Such products have a fine metallized layer, which prevents the fast burnout of the colored layer.

This film allows you to reduce the amount of sunlight penetrating into the room. It becomes a real salvation for those who live or work on the upper floors of high-rise buildings or those whose windows face the sunny side.

In contrast to curtains and thick curtains, films are cheaper, and in addition, there is no need to think through how to fit them into an already existing interior.

The film with a mirror effect is usually in demand among residents of the first floors, office and shop owners., because it hides the inside of the room from prying eyes.

When using special energy-saving films, you can reduce heating costs, since this coating sends back heat energy from the room,preventing heat loss through the windows (of course, provided sealed windows).

Finally, products have a reinforcing effect, strengthening the glass. Even if the latter is broken, it is not showered by a hail of sharp fragments, but remains on the film.

In most cases, the installation of the film does not cause difficulties, although it requires skill. It is important to choose quality products and comply with the technology of pasting.

During storage, operation and operation of the film requires careful handling. Since, being thin and fragile, it is easily damaged, which naturally leads to the loss of its technical properties.

The disadvantage is that on a rainy overcast day indoors, on the glass of which the film is pasted, it will be dark and gray. In addition, unlike curtains or blinds, the film can not be moved. Although, unlike the above remedies, the film does not collect dust.

If necessary, the film is easily dismantled, leaving no traces. Used film can not be re-pasted.

Kinds

Depending on the functions performed, there are several types of films.

Tinted

The tinting self-adhesive film absorbs the sun's rays, thereby saving the room from overheating and overly bright sun.The light absorbing ability of a quality product is 99%.

Mirror

In its functions, it is similar to tinting - protection from ultraviolet exposure. However, unlike a tinted film, the mirror does not absorb sunlight, but reflects it.

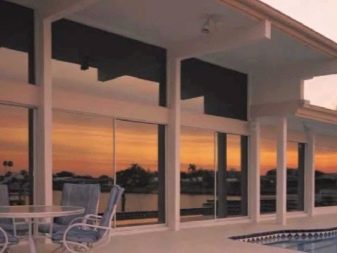

In addition, the sun-repellent surface makes the glass opaque, mirrored, protecting the room from prying eyes. Glued surfaces look like mirrors, so that the exterior of the building takes on a special look and respectability. Overview of the inside is unlimited, reflective film can be fastened both from the inside and outside of the glass. Another advantage is that windows equipped with such a film are not prone to fogging.

Available for both outdoor and indoor installation.

Protective

It also protects the room from the aggressive effects of the sun, and in addition, acts as a kind of reinforcing element, strengthening the glass. This characteristic has led to another name of the protective film - “shockproof”.

It is recommended for sticking to the windows of the first floors, because it has a large polymer thickness (115-600 microns), it is not easy to break. That is, the product acts as an additional means against hacking.

Even in case of damage to the glass, it will not crumble, and access to the room will be protected by the film itself. They are placed in the apartment, where there are small children. If the glass is damaged, the baby will not be injured.

Separate types allow to minimize the effects of an explosion. They are usually used in crowded places. Such a light-shielding film, also for a short time, is capable of restraining the spread of smoke and fire.

Energy saving

Its main purpose is the preservation of heat in the room during the cold season. This is achieved thanks to the ability of the coating to reflect up to 97% of thermal energy.

It is worth noting that in the summer, the product ensures the preservation of pleasant coolness in the room.

Metallized

Provides a tinted and light mirror effect, has a pleasant metallic luster and shade (silver, green, purple, smoky, and so on). There are products for internal use, which are glued into the glass pane in the factory and on the glass from the inside. And also produced analogues for fixing the outside of the glass.

Such a reflective surface has an additional protective layer that protects the film from negative atmospheric exposure. The color range of exterior metallic materials includes only 2 shades - light and dark metallic.

Decorative

Serves for the embodiment of a design solution. It is carried out in various shades and dimensions, can have drawings, patterns. The main purpose is to decorate and give originality to windows from inside and outside. It may have a matte (almost opaque) or clear surface.

A kind of decorative film is considered architectural, which is glued to the outside of the windows. Serves to obtain a specific stylistic effect.

The main difference between decorative films from architectural ones is that the first ones serve to decorate the room from the inside, and the second ones - to decorate the exterior. The first ones are mounted from the inside, while the second ones are glued to the outer surface of the glass. Finally, the architectural film, like any analogs pasted on the outside, has a protective coating.

Athermal

The transparent film which is not having blackoutbut also brilliantly coping with the protection of the room from exposure to UV rays and heat. It is invisible on the glass, glued from the inside or outside.

The differences in light-absorbing films are also based on the degree of transparency of the material. The level of light transmission ability can be from 5 to 50%. Silver sun-reflecting films have the lowest transparency (50%). Although using this material, you can choose more transparent products (15-50%).

The transparency of the most popular bronze, smoky, green and purple films ranges from 15-35%.

The greater the level of light absorption, the better protection from bright sunlight it will provide. However, the greater color distortion awaits everyone who looks out the window through such a film.

How to choose?

- If you only need protection from the sun and excessive heating of the room, it is enough to buy a tinting film with a transparency of 5-10%. It will perfectly cope with its functions and will allow to avoid the appearance of glare and reflections on the screen of a working TV or computer monitor.

- If you prefer a mirror film, choose products with double-sided mirror coating.It better reflects the sun's rays and is indispensable in rooms with expensive or antique furniture. In addition, it will preserve the opacity of the glass even with stronger illumination in the room compared to the illumination outside (for example, when the light in the room is turned on late in the evening or at night).

- Matte film has a light transmittance of only 77%therefore, it is not recommended to paste over windows of residential premises, offices, administrative buildings with it. The best way to use it is to glue glass partitions or doors inside the room to reduce their transparency.

- When using metallized film choose material with a coating based on titanium, nickel, aluminum. A variant based on gold and silver is also possible, but such a product has a higher cost.

- Should remember that material characteristics directly depend on its cost. Cheap unnamed products do not cope with the declared functions, spoil the surface of the glass, may be toxic.

- Among the manufacturers of premium films can be identified British company Sun Control. Similarly, high quality are different American films Armolan and Ultra Visio.However, their products are less expensive. The best combination of price and quality is demonstrated by films from the South Korean brand Professional Window Film Film.

How to glue?

There are 3 ways to place coverage on windows:

- inside window construction (the method is only suitable for implementation in the factory);

- outside glass (for this you can only use exterior films equipped with a special protective coating);

- inside the glass.

Windowing should only be done using high-quality film from a reputable manufacturer. Poor-quality products are difficult to install, roll down, in the process of sticking it bubbles and gathers in folds.

The film should be glued at a certain temperature. It should not be lower than 7-10С, but not higher than 23-25С. Humidity level should be 25-80%.

You can glue the product in several stages.

- Thoroughly clean and clean the windows, removing all dirt, dust, grease stains. Their presence significantly reduces the effectiveness of the film and can cause it to peel off.

- In a spray bottle, mix water and a little liquid soap. The solution can not be shaken.

- On a clean surface, unroll the product and carefully remove the protective coating from it. Dust on the sticky side should be avoided.

- Spray the composition of the spray on the surface of the film and glass, making sure that they are high quality and uniformly moistened. This is the key to proper gluing.

- Attach the film with a moisturized side to the glass, align, glue. Work must be done from the top down, smoothing the surface with a soft cloth or silicone spatula from the center to the sides, expelling air bubbles.

- After the film is fixed, it should be left to dry for a period specified by the manufacturer.

- The final stage will be trimming the excess coating to the size of the window.

How to remove?

Each product has its own service life, so sooner or later its surface becomes cloudy, becomes covered with cracks, adhesion of some sections decreases. In this regard, the question of how to remove the protective film from the sun, is very popular.

Removing quality film is usually easy. To do this, use a blade or a construction knife to pick up one of the corners (preferably the top) of the coating, pull it away from the window and peel off the entire film with a sharp movement. After that, it remains only to wash the windows in the usual way.

Sometimes remove the film in this way fails. In this case, you can heat the surface, which softens under the influence of warm air. After that, you should also pull the corner and remove the film. The remaining particles of material and glue can be processed by such means as Fenosol or Cosmofen 10.

Another way to clean the windows from the film is to pick it up and apply Hg Sticker Remover to the entire surface. After waiting a few minutes, you can begin to remove the coating, under the influence of the components of the composition it will become more pliable. If after removing traces of glue on the glass, they are removed by the same means.

It is unacceptable to use cutting objects for removal, to rub the glass with a metal brush. All this will not allow to remove the layer by one layer, the main thing will be the cause of glass damage.

Tips

- For the care, cleaning of the film can not use aggressive and abrasives containing tools, as well as brushes, hard sponges. The best remedy is warm water containing a small amount of liquid soap.

- Reviews allow us to conclude that for washing it is better to use not a sponge, in the pores of which dust remains, but a soft microfiber cloth.

- Use a spatula of maximum thickness for smoothing. With it, it is possible to better deal with bubbles and more convenient to work.

- If a rag is used for smoothing, it should be new, clean and dry. It is important that the rag does not leave fibers on the surface. To avoid this also allows the use of paper towels instead of rags.

- Sunscreen, as already mentioned, may have different transparency. In any case, they "cut off" part of the sunlight. On a hot sunny day, this is good, but on rainy days of the off-season and winter cold, they make the atmosphere in the room uncomfortable, and the room itself is dark. This can be avoided if, in winter, the film is used only on the windows facing the south and east, and choose athermal material or analogue with a shading of 5-15%. On the windows facing north and west, in the winter it is better to abandon the use of coating and use curtains or blinds.

- When gluing it is important to follow the manufacturer's recommendations. Most of the metallized products are mounted with a metal layer to the glass, which provides the best reflection of the sun's rays.Such a coating is later removed more easily than the one whose metal surface was inside the room.

How to stick a film with your own hands, see the next video.