Milling drywall: features of the process

Milling drywall - this is one of the methods of changing the texture of the sheet in order to give it various forms. Such processing allows you to create various figured designs, without resorting to the use of frames. Thanks to milling, a gypsum board can change its shape by being bent at different angles, while there are practically no restrictions on the size and shape of the shape being created. It is possible to apply various relief patterns on the surface of the sheet, in addition, the technique is easy to learn and is economical both in terms of resources and in time.

Special features

The advantages of milling GKL include a number of features:

- Save time. The construction of boxes and other figures with the use of milling several times reduces the time required in comparison with the frame method.

- Simplicity. This method is characterized by ease of manufacture of figures, and strict adherence to the rules leads to the almost complete absence of marriage.

- Flexibility. In addition to other positive qualities, this method allows you to give almost any form of drywall, thereby expanding the range of design solutions. Accuracy and accuracy - the only requirements when creating complex shapes.

- Saving materials. Corner joints, which supposedly will not be under serious pressure, can not be reinforced with metal corners. The design by default has an adequate margin of safety to last for a long time without losing the shape.

- Reducing the amount of work. Since during the milling the corner of the room remains covered with a sheet of plasterboard, it is possible not to trim it with a corner for putty to cover the open end. In this way, a significant amount of building materials is saved.

Types of milling machines

There are two main types of milling machines used for milling GKL - disk and shaped.

Disk is used for cutting out plasterboard sheets, mainly - long sizes.

This method is different:

- high processing speed;

- neat cut line without chipping and chipping;

- limited work on straight lines.

Shaped milling machine is used for the main scope of work, the distinctive features of its use include:

- the ability to cut complex intricate shapes;

- the ability to drill holes of different depths and shapes, for example, oval or round;

- convenience of applying a relief pattern to the surface;

- relatively low speed linear cutting, the chance of damage to the sheet is also higher.

Types of cutters

There are different types of cutters, each of which has a special shape and is designed to perform certain tasks.

Among the many we can distinguish the following:

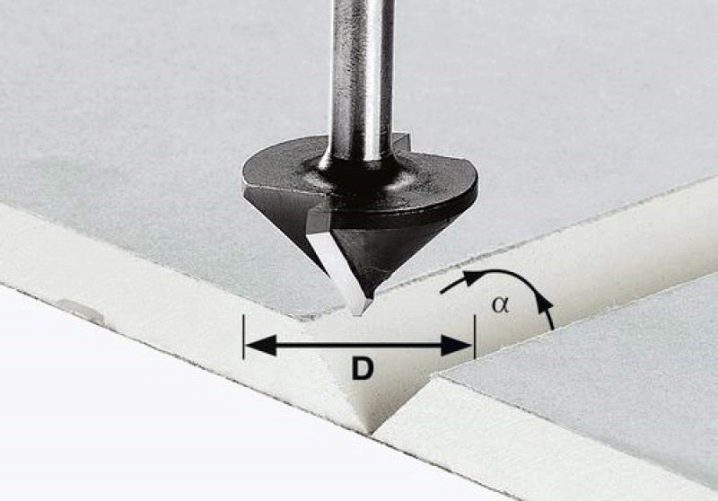

- fillet-grooving V-shaped cutter - used to create right angles, this is the most common form when working with plasterboard sheets, since most of the collected objects are rectangular boxes;

- A straight cut milling cutter is used to cut holes that are perpendicular (at a 90 ° angle) to the sheet plane;

- the cutter for T-shaped grooves is similar to a straight cut, however, the holes obtained by its use can be of much larger diameter;

- the milling cutter for U-shaped grooves is distinguished by drilled holes with a rounded bottom;

- Edge milling is used to chamfer the edges of the sheet.

Recommendations for the choice of cutters

When choosing a cutter in the first place you should pay attention to the manufacturer. A high-quality European-made product is an order of magnitude higher than its Chinese counterparts, which is offset by higher quality products. Nevertheless, there are samples of Chinese-made fairly good quality, when choosing them, it is worth asking the advice of knowledgeable people or to look for reviews on the Internet.

When choosing a mill, first of all check the diameter of the shank for compliance with the available tools.

Buying cutters for the first time, you should not spend money on an expensive option with a wide range of applications. A set of several basic cutters at a reasonable price at the start will allow you to try the tool without fear of spoiling it.

Further, the kit can be supplemented with the necessary types of cutters based on experience and working needs.

The use of any cutting tool requires special care. First of all, you should familiarize yourself with the instructions, even if you have already used a similar tool.Each model has its own differences and its own security technology.

Preparation of the tool and workplace

Before you start cutting sheets, you should prepare everything you need:

- Any milling machine with a capacity from 1 kW to 1.5 kW is suitable for cutting drywall. It will be difficult to work with a more powerful machine, and the chance to spoil the material will increase.

- If the milling machine does not have a device for collecting dust, you need to attach it yourself, and connect a vacuum cleaner to it. Otherwise, when cutting a cloud of dust will rise, which will spoil the visibility and complicate cutting, as well as complicate breathing.

- For comfortable and high-quality work necessary means of protection. These are at least safety glasses, but it is also advisable to wear a simple petal respirator.

The workplace should be organized as follows:

- need a smooth flat surface, such as a table;

- an emphasis is placed on one of the edges of the table, which can be made from several boards - fixing the material will ensure the accuracy of dimensions;

- a suitable milling cutter is selected - the most common type is V-shaped, which allows to get a smooth edge of regular shape.

Phased plasterboard cutting

To obtain a quality result, you should follow a certain procedure. After all the preparatory work, you can proceed to direct cutting.

There are various methods of cutting plasterboard sheets, which, in essence, are as follows:

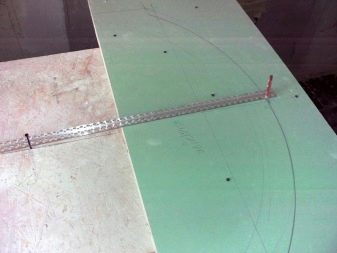

- Layout material. First you need to put on the blank outlines all the details that will be cut. For these purposes, useful pencil and ruler. Sometimes with the first markup, it seems that the material is not enough, in this case it is worthwhile to estimate the cutting option again - it may be possible to reduce the costs and put everything on the existing sheet. However, it is not necessary to place the parts too close to each other when marking, because drywall crumbles easily, and accidental cleavage can spoil the plan.

- Pre-processing of blanks. Before cutting to the exact sizes and relief processing the whole sheets can be divided into preliminary preparations with draft sizes. Cut sheets can be with a knife or other tool.

- Preparing for cutting. The workpiece is located in the clamps or rests on the manufactured retainer.Wear protective equipment. The equipment connects to the network.

- Begin processing. With the motor turned off, the machine is applied to the sheet of drywall so that the rounded part is touching the fixing stop. With the inclusion of the cutter begins a uniform movement of the machine from itself to the opposite edge of the clamp. So the resulting seam will be smooth and forms the desired angle when bent.

- Bilateral processing. In cases where sheet processing is expected from both sides, and furrows have already been applied on one of them, the gypsum turning must be turned over very carefully, since its strength at the places of processing is significantly reduced and breaking off is possible.

- After all the manipulations with the machine, the cut through blank is folded along the seams. For fixation, various substances can be used, for example, assembly foam, a certain amount of which is blown onto the treated furrow. In a tightly folded position, the part must be fixed for a few minutes until the foam hardens, after which its surplus is removed.

Observing the technical rules of the process, in just a couple of tens of minutes with the help of a milling machine, you can give the necessary form of gypsum board without a carcass construction.This approach primarily saves time and money, in addition, the angles and transitions of such an object are of high quality and reliability.

Create a right angle

Rectangular boxes, for example, under the lighting equipment - one of the most common objects of drywall.

The most convenient method of creating them is to use a V-shaped cutter.

For such works 2 features are important:

- when cutting drywall, the underside must remain intact - it will keep an angle on it;

- the cutter used for cutting the sheet should go deep into the gypsum board to a depth equal to the thickness of the sheet minus 2 millimeters - this way the safety of the back side will be ensured.

Milling cutter on a tree practically does not differ from a milling cutter on GCR. If we mill independently at home, then any attachment will do.

You can see a master class in drywall milling in the next video.