GVL lists: types and scope of application

Gypsum plasterboard firmly entered our life. The scope of their application is extremely wide - they are indispensable in the decoration of walls and the erection of designer structures in the interior - arches, niches, multi-level ceiling. At the same time, the material has a significant drawback - it does not withstand heavy objects, therefore, in order to fix on it an element of decor of great weight, it is required to mount special mounts.

Few people know, but this problem is very easy to solve. Plasterboard has an analogue that can withstand gravity - this is a gypsum plasterboard, or a gypsum-fiber sheet.

Special features

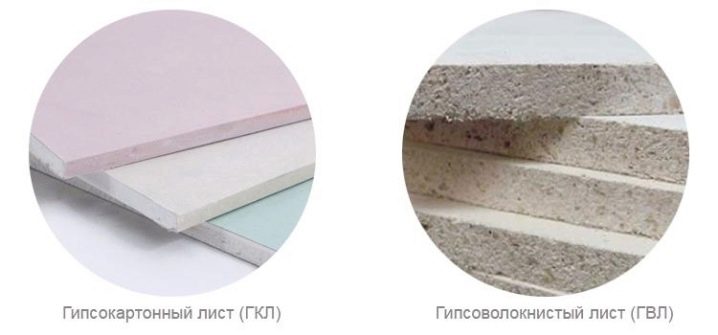

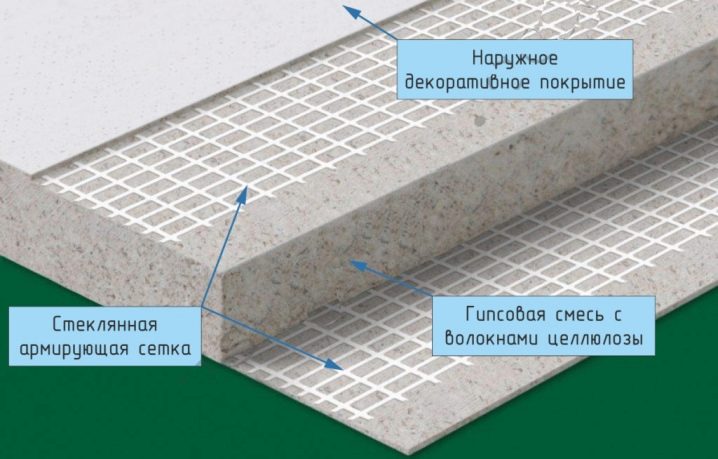

Gypsum fiber sheets are a finishing material made from gypsum with the addition of cellulose, which is necessary for stronger binding of gypsum particles.Visually, it is similar to GCR, but has a higher strength.

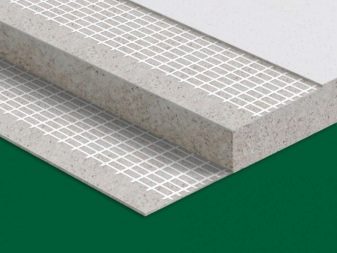

Gypsum in the composition of gypsum fiber board occupies about 80%, the share of cellulose accounts for 20%. The raw material is stirred and pressed, and as a result of such processing a standard gypsum fiber sheet is obtained. It is a homogeneous in structure plate without a paper shell.

By the way, gypsum fiber is an environmentally safe material, and the cellulose used for its production is obtained from recycled materials, which makes it possible not only to take care of a clean environment, but also significantly reduces the cost of plate production, and therefore makes the cost of products affordable for Russians.

In addition to uniformity and hardness, the specific parameter of gypsum fiber is the ability to maintain the level of moisture. With an increased rate, the plate absorbs excess moisture, and when the air is dry, on the contrary, it emits it.

By the way, produce GVLV-plates, resistant to moisture, which are a type of GFL.

Due to its high strength, material viscosity is optimized. The slab is quite plastic, but does not crumble, which distinguishes the material from drywall.So, if in GVL to hammer in a nail, then the sheet will hold it like wood.

Advantages and disadvantages

Like any building materials, gypsum fiber has its advantages and disadvantages.

GVL has a number of advantages that allow it to be used in virtually any finishing work.

- Environmental Safety. Since gypsum and pulp predominate in gypsum fibers without adding synthetic components, this material is environmentally friendly, does not emit harmful and toxic substances, so it can be used safely in children's rooms, as well as in health centers. Does not cause allergies.

- Maintain a healthy indoor climate. The gypsum-fiber sheet has a microporous structure, which leads to the fact that the plate “breathes”, air penetrates freely through it, preventing the appearance of fungus and reproduction of dangerous mold.

GVL is characterized by good hygroscopicity and resistance to temperature fluctuations, therefore it can be installed in rooms with high or low humidity, as well as in cold, low-heat houses.

- Durability and wear resistance.Gypsum fiber is highly durable, can withstand considerable weight, which is why its use is justified when creating the most varied interior designs - niches, podiums, etc. screw in the screw, as is done with wood surfaces.

- Wear-resistant material It is not deformed upon impact, therefore it is often used for mounting a floor screed or as a substrate for floors.

- High viscosity allows you to cut gypsum fiber without waste and screw screws into it.

- The special structure of the material makes it practical and durable - technical characteristics remain unchanged for many years of service. This, by the way, distinguishes GVL from drywall, which can break down over time and release dust with particles of gypsum into the air. Often, such destruction causes allergies and diseases of the pulmonary system of adults and children.

- The material has a low thermal conductivity, so it is used for thermal insulation of premises.

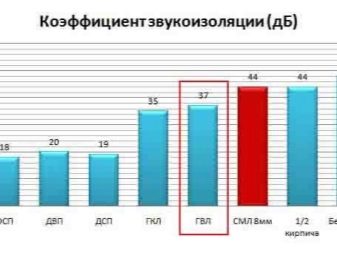

- Installing GVL can significantly reduce the noise level. Depending on the size of the sheet GVL, this figure can be reduced by 35-40 dB, therefore, gypsum fiber is optimal for finishing rooms and bedrooms.

- Low weight. GVL by weight is more than a sheet of gypsum board, however, special mechanisms are not required for its transportation - it can be easily transferred alone, lifted and held in the desired position during installation.

- Frost resistance. Another advantage of GVL is resistance to temperature extremes. It is proved that the material does not form cracks even after 10-fold freezing followed by defrosting. This is what makes the use of gypsum fiber relevant for finishing works in rooms with low temperature, which are rarely and insufficiently heated.

With all the advantages of the material, it has several disadvantages.

High strength gives and minus - GVL is difficult to bend, therefore, in the manufacture of interior structures with curved shapes, preference should be given to drywall.

Gypsum fiber is harder to cut: if the GCL is incised and then broken up, then the plates from the GVL must be cut through from beginning to end.If you violate this rule, the likelihood of breakage during installation and further deformations increases.

The high cost of the sheet is also a significant disadvantage - sheet GVL significantly more expensive than a plate of plasterboard. Today, the price of GVL is higher than the price of the same size of plywood, DSV and OSB-plates, so its use is impossible in conditions of a limited budget for repairs.

As they say reviews, sheets of gypsum fiber domestic producers a little dust. However, foreign analogues are deprived of this disadvantage.

Here, perhaps, and all the shortcomings gypsum-fiber plates. Of course, they are insignificant in comparison with the advantages of the material. However, they must be taken into account when planning repairs.

GVL and GKL: what is the difference?

It is obvious that drywall and gypsum fiber have many similarities and differences. The right choice depends on the conditions and parameters of the premises where the finishing will take place. So, GVL is optimal for retail, industrial and warehouse space. For the manufacture of columns and arches in houses and apartments, experts recommend to give preference to plates made of plasterboard.

Let us see what the main differences between the two materials on the basis of gypsum are.

To begin with, the production technology of GFL and GCR is different. By production of gypsum cardboard are based on the principle of a sandwich (two layers of a dense cardboard and a dense layer from plaster between them). In GVL, cellulosic fragments are initially introduced into the gypsum mixture and repeatedly pressed, leading to the strength and fire resistance of GVL.

Drywall has a heterogeneous structure, so it is difficult to cut it - when sawing, chips are formed and it crumbles. Experts advise to use the sheet in whole pieces, while gypsum fiber freely lends itself to any cutting and fitting to the required shapes and sizes.

The advantage of drywall is the fact that when wetted, it becomes flexible, and as it dries, it restores the fortress.

If the plate will be later covered with wallpaper, the GCR will be the best choice.

GKL slabs are not as durable as GKL, not so suitable for interior decorating. But the cold resistance performance of gypsum fiber is higher than that of gypsum board. Defects on the first occur only after 15 freezes, but on the GCR - after the 4th.

The fire resistance of gypsum fibers is higher, the material is difficult to ignite and does not support combustion.

Different performance characteristics of the two types of plates cause differences in the areas of use. So, for ceilings better to get drywall - this is a lightweight material. Its weight makes installation work convenient, and if the construction collapses in the future when force majeure situations occur, it will not cause significant damage to the health and property of apartment dwellers.

When installing interior partitions on the choice of plates will affect the intended form of construction. It is desirable to form rectangular openings from GVL, they will create the required rigidity and sound insulation. Here for the installation of arches rounded decor it is better to give preference to plasterboard compositions.

In rooms with high levels of humidity - bath, kitchen, shower, gypsum fiber is suitable due to the high hygroscopicity. Drywall has no such properties, so it should be left to handle the bedrooms and guest rooms.

Both materials have good environmental friendliness., demonstrate good thermal insulation and sound absorption.In their composition there are no toxic substances, they do not emit odor and do not conduct current. Therefore, both GVL and GKL can be successfully used in wooden and brick house-building.

Types and characteristics

In the free market there are two types of gypsum-fiber materials:

- standard;

- moisture resistant.

Moisture resistant gypsum fiber recommended for installation in kitchens, canteens and other rooms with high humidity. The material is coated with a special hydrophobic impregnation that prevents water from getting inside the slabs, so the gypsum structure is preserved in its original form. This is very important, given the high ability of gypsum to absorb water. This type of GVL can also be used in ordinary premises, especially since the prices for it do not greatly exceed the cost of a standard GVL sheet.

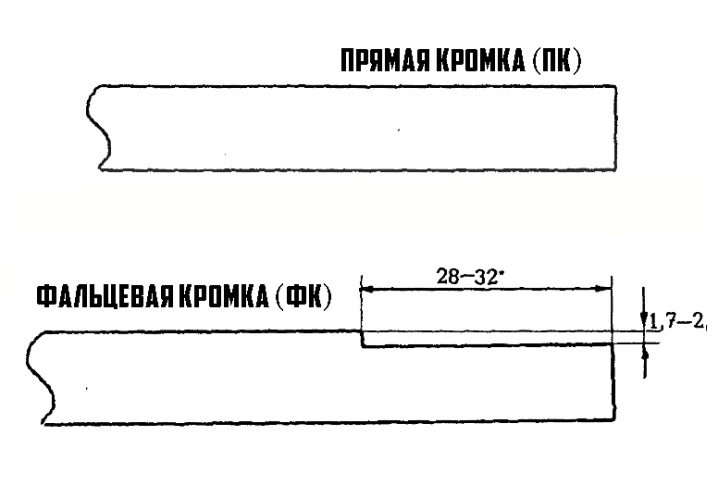

Gypsum sheets are also divided by type of edge:

- straight-edged used for mounting dry screed;

- with a falsetto edge - it is optimum for installation of partitions, walls and niches.

According to the degree of finishing plates GVL is divided into:

- ground;

- unpolished.

The size of the plates for most manufacturers is traditional: the thickness is 10 and 12 mm, the length is 2500 mm, and the width is 1200 mm. Sheets with a thickness of 1 cm are suitable for walls, and 2 cm for floors.Other manufacturers may have other sizes: the length can be 2.5, 2.7 m and 3 m, and the width - 0.5 m and 1 m. The weight of the sheet is 17 kg.

To assess the quality of gypsum fiber, it is worth getting acquainted with its physical parameters.

As already mentioned, GVL is 80% composed of plaster and 20% cellulose. This percentage may vary by +/- 5%. The strength parameter is 1.2-1.25 tons / cm3. By the way, this indicator is equivalent to the density of expanded clay concrete and is twice as high as the corresponding level of a red brick. Density is inversely proportional to the thickness of the sheet: for GVL 10 or 12 mm, it is equal to 1.2tng / cm3, and with a thickness of 14 and 19 mm, the parameter is 1.25tn / cm3.

The calculated tensile strength is also noted at a fairly high level: at a bend it is 0.053 t / cm2, and under compression it is 0.1 t / cm2. For comparison - with a similar value, even a strong pressing of a sharp stiletto heel will not be able to damage the surface of the sheet.

Heat conductivity - up to 0.36 W mK. Swelling in the liquid reaches 1.5% after a day. GVL is resistant to burning. This is a flame-retardant composition that does not ignite spontaneously and does not spread fires over the surface.

Such exceptional performance characteristics are attributed to the special latex impregnation treatment that is carried out at the factory.

The material shows good sound absorption - 40 dB.

For comparison, a similar indicator of other finishing materials is:

- OSB of plates - 18 DB;

- DSP - 9 dB;

- MDF - 20 dB;

- Drywall - 35Db;

- The wall is in a half brick- 44 dB;

- Concrete partition (16 cm) - 48 dB.

Which to choose?

A wide choice of materials from GVL makes it possible to choose the most advantageous finishing option in specific conditions, as well as significantly save on the absence of those consumer properties that are not necessary.

As already noted, GVL is standard and moisture resistant. For finishing the kitchen, dining room, shower rooms and sanitary-technical zones, moisture-proof sheets are used. For standard rooms, they prefer ordinary plates, they are more versatile and optimal for installation in rooms with standard indicators of humidity and air temperature.

Scope of use GVL wide. Gypsum fiber has been used in the decoration of residential premises, as well as production plants, shopping centers, warehouses, hangars, etc.

The material is widely used to install stylish walls and partitions.With the use of fiber, the operational characteristics of surfaces in storerooms, in attics and penthouses are improved. Plates are often mounted in basements as a base on the floor and walls, as well as the base for a cupboard.

Antiallergenicity and environmental friendliness of GVL allowed the use of plates in children's educational institutions and centers of additional education for children and adolescents. And this is justified - the natural irradiation of the coating is three times lower than that of the red brick!

The high stiffness rate allowed the use of gypsum fiber where there are strict requirements for structural stability (on tennis courts, in gyms, etc.).

High fire resistance has led to the popularity of slabs in elevator mines, escape routes, electrical substations. However, for the repair of the walls of the boiler, switchboard distribution and other structures, it is advisable to purchase a GKLVO.

The use of gypsum fiber on the floor is very popular. To do this, take the panel that can withstand high humidity. Due to the low expansion coefficient, all joints remain tight. GVL is equally effectively mounted on wooden and metal frames and creates a perfectly flat surface, which is further trimmed with tiles or painted.

Gypsum fiber is often used for doors and windows in the arrangement of slopes.

Tools and additional materials

To install gypsum fiber properly, you should follow simple rules. Before applying putty you should not remove the chamfer. In the work you need to use special screws for GVL.

To prepare the plates, they should be marked and cut. This is done with a jigsaw or electric saw, and the edge is processed using a peeling planer.

For quality work requires certain materials.

Plates:

- standard GVL;

- moisture resistant GVL.

There are three types of profiles for the starting frame device:

- connecting;

- rack-mount;

- wall mounted.

Bars are used to fix some elements of the structure or as an alternative to the profile. Fasteners - screws, dowels, anchors, brackets and other devices needed to install the metal profiles to the walls.

For the preliminary preparation of the walls are required:

- universal primer;

- putty for interior work;

- serpyanka tape;

- special linings.

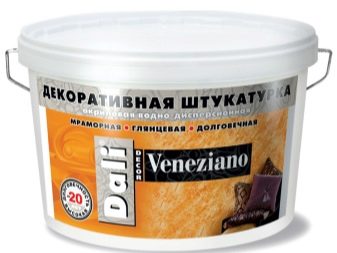

For decorative trim purchase:

- interior paint;

- non-woven, vinyl or paper wallpaper;

- decorative plaster;

- tile, etc.

Each tool can cope with gypsum fiber, its rigidity and strength require special devices:

- perforator;

- screwdriver;

- scissors for metal;

- saw on GVL;

- a set of standard tools;

- devices for finishing work.

Properly selected and smoothly working tools will allow you to carry out all the work at the highest level and to avoid deformation and breaking gypsum fiber.

Technology work

Very often the masters who carry out the installation of drywall on their own believe that the work with the gypsum plasterboard is conducted in the same way. And this is a big mistake - gypsum fiber is more durable and at the same time more fragile at break. The material is easily broken and not bend, so its processing requires more skill and technical training than the processing of drywall.

GVL cutting tools.

- Construction knife at least 12 mm thick. Take care of a replaceable set of blades. In the process of work, they will often become blunt and will need to be periodically changed.

- GVL special hacksaw allows you to saw off the plate without the formation of dust.

- Circulation saw - the most rapid way of cutting gypsum fiber, but at the same time the most dusty.The use of grinders is allowed only in well-ventilated areas with the use of protection for the eyes and respiratory tract.

- Jigsaw with built-in vacuum cleaner is another effective option. However, as well as the previous one, it requires the use of construction glasses and a respirator.

Be sure to take care of safety at work.

Should act as follows:

- first you should mark the sheet GVL - marking line is necessary in order to be able to exactly attach the ruler;

- with a knife, with an effort to mark the marking several times until the size of the furrow is 2⁄3 of the total thickness of the sheet;

- put a special rail under the slot;

- with a quick movement of your hands to break the material.

As a rule, when cutting GVL, smooth edges are formed and there are no problems with the layout. In the event that a small adjustment is nevertheless necessary, you can use the most common peeling plane.

For a standard rebate, the use of a shoe cutter is optimal.

With a significant amount of work is to give preference to the router. - use of mills with a step of 2-4 mm allows you to perform the necessary work for a couple of approaches. After the incision, do not turn or lift the sheet, otherwise it may burst.

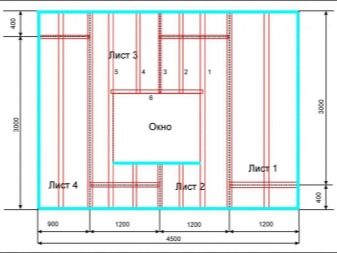

Frame

Installation of gypsum-fiber boards can be done in two main ways - frame and frameless. In the first case, a framework is pre-constructed on which the plates are subsequently fixed. In the second plate are glued directly to the surface of the wall with a special glue.

The best material for creating a false-wall framework will be metal profile.

Works are carried out in the following sequence:

- Room marking - with the help of special tools marks are applied on the surface, on which the frame will be mounted.

- Installation of the starting profile provides for the installation of the frame around the perimeter of the room. To do this, use an anchor with sleeves made of plastic or metal. They are screwed into pre-drilled holes with a depth of 40 mm. In the sections of the profile to the main structures superimposed seal.

- The installation of the rack opening begins with the door opening, its edges are mounted from two-post elements that are embedded exactly into each other. All necessary parts are certainly fixed with wooden bars. The jumper is made of a profile for racks bent U-shaped.

- The formation of vertical racks - they are inserted into the starting profile from the top and bottom, the pitch is calculated so that the edges of the gypsum-fiber plate during the plating fall exactly on the center of the guide. The main thing is that on both sides of the formed partition GVL-sheets were placed with a small offset joints.

When installing the frame, do not forget to think over the communications; for this purpose, special holes for cables and electrical wires are made in the racks.

Covering the frame panels - the work is quite time-consuming, requiring time and effort:

- GVL sheet is trimmed so that when joining the plates there remains a gap of at least 5 mm. If this rule is not followed, deformations may occur in the future.

- A cropped sheet of gypsum fiber is applied to the core and leveled. In case its edge “sags”, an additional metal bridge is inserted into the design.

- Using self-tapping screws, the plate is fixed, screws should be taken 4 cm long and twisted in 30 cm increments.

Sheathing is performed first on the inner side of the partition, then communications are laid, and only after this stage of work is completed, the outer side of the unit is sheathed with plates.

The structure of gypsum fiber is porous, it often causes inhomogeneous application of paint or glue during the further finishing of the GFL surface. That is why you should carefully putty the surface of the entire area of the plates. To do this, you can use the most common plaster putty. Only after that the wall becomes suitable for all types of finishing materials.

Some tips

When installing the frame, it is advisable to use metal or wooden profile types. If wood slats are used, their minimum allowable cross-section should be 30x50 mm on the ceiling and 25x75 mm on the uprights. Step racks should not be already the width of the sheet GVL.

All slabs must be mounted manually from the center. premises and strictly perpendicular. To insulate the space between the racks should be supplemented with glass wool.

The frame method is used in cases where the walls are old, with irregularities and defects.

GVL mounting in a frameless way is not so common, but for a residential building this option is preferable.

Work on the installation of slabs directly on the walls is performed in a certain sequence:

- If the maximum unevenness of the wall does not exceed 4 mm, then the plates are fastened with a putty - it is applied with a neat layer in the longitudinal direction along the perimeter of the sheet GFB.

- If the irregularities are in the range of 4-20 mm, then it is advisable to use a special glue, it is applied directly to the gypsum-fiber plate in the center and along the perimeter.

- If the irregularities exceed 20 mm, it is better to use the frame method. But if this is not possible, then the work should be carried out in several stages. To begin with, with the help of glue, GVL strips 10 cm wide are attached to the wall and only after that cut the sheets of the desired size using putty to the strips.

Consider that if you plan to fasten furniture or heavy interior items to GVL-slabs, then glue should be applied to the entire surface of the sheet, and not just around the perimeter.

The walls are glued starting from the corner, then - on the edge. When facing wooden surfaces, they additionally resort to fixing sheets with self-tapping screws or roofing nails. Similarly, work is carried out when finishing the balcony with their own hands.

As in the case of frame mounting method, the final stage of laying gypsum fiber should be a decorative finish - puttying of all joints and fixings.The surface should be smooth, it will allow your repair to be aesthetic and durable.

Has its own characteristics in laying gypsum fiber on the floor. First, gently clean the surface, remove all debris, collect dust. All the cracks and cracks cover up. To protect it from moisture, polyethylene film is laid, and along the perimeter it is treated with edge banding. It not only fixes the coating, but also contributes to better sound insulation. Next, insert the beacons and pour a layer of expanded clay. Only after that begin laying sheets of gypsum fiber with high moisture resistance. The first layer is fixed with glue or mastic, a second layer of plates is placed on top of it, screws are used to fix them.

Tips and tricks

The temperature of the room should not fall below 11 degrees Celsius. If work is carried out in the winter, you must first turn on the heating.

GVL sheets before installation should be a couple of days to endure in the room where the installation will take place, so that they are acclimatized.

During the entire period of installation, it is necessary to observe constant temperature and humidity levels. Otherwise, misalignment and installation defects are possible, even if plaster fiber material is used in the work.

If laying of several layers of plates is planned, then it is extremely important to carry out all the work in one day.

Reviews

Reviews about the use of gypsum fiber materials in the decoration of the most contradictory. On the one hand, consumers from competent sources receive information on the advantages of GVL sheets, their advantages, reliability, practicality and durability. At the same time, many people are stopped from buying a high price for a product that significantly exceeds the cost of drywall sheets, plywood and chipboard.

According to users, the use of alternative materials gives no less effect, provides structural strength, thermal insulation and absorption of excessive noise, while requiring much less effort and money.

Buyers note the large weight of the plates, which makes it impossible for one person to finish the work in order to carry and hold the sheet in the right position during fasteners; considerable physical effort is required.

It is doubtful the assertion that gypsum fiber can be used in the bathroom and shower room.

Consumers doubt that gypsum, even if specially processed, can be resistant to moisture. Unfortunately, the material is relatively new and data on the effects of moisture on it in the long term are not available today.

However, consumers, who still purchased gypsum-fiber boards, are satisfied with the quality of this finishing material.

About the features and advantages of moisture-proof GVL-sheets, see the video below.