Arched drywall: features of the application

Arched drywall - a type of finishing material used in the design of the room. With its help, various arches, semi-archs, multi-level ceiling structures, a variety of curved, curved structures, including oval and rounded walls, partitions and niches, are created. To understand what are the features of the use of an arch drywall, how the device of the opening from the gypsum board is made, whether you can do it yourself, let's examine the characteristics of the material.

Special features

Any finishing building material has its own characteristics. Arched drywall tends to bend, it is endowed with ease. However, it is not necessary to subject it to any treatments.It does not need milling, wetting with liquid, processing with a needle roller.

Of all the types of drywall arch material is the most expensive. This is due to the fact that the structures made of it are multi-layered, therefore, a large amount of material is required to achieve the required thickness.

Features and Benefits

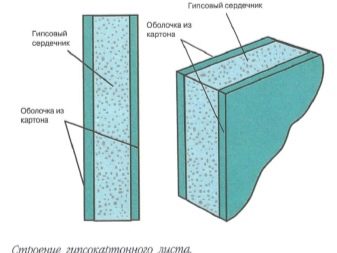

Arched drywall has the appearance of a sandwich. It consists of two cardboard surfaces and a mineral inner layer, impregnated with fiberglass. It is based on gypsum, the amount of which is more than 90%. In addition, the components are cardboard (6%) and auxiliary components (1%).

Among the advantages of GCR is to highlight:

- increased flexibility;

- high strength;

- small thickness;

- high thermal insulation and noise insulation;

- high degree of fire resistance;

- lack of foreign odors;

- ability to regulate indoor humidity.

disadvantages

The disadvantages of arched drywall include:

- inconvenience during work;

- cutting complexity;

- the complexity of screwing fasteners;

- price segment.

Excessive thinness of the sheet increases the amount of material used, and it is financially expensive. The thickness of the commonly encountered arch drywall is 6 mm and 6.6 mm, the length and width depends on the manufacturer, the most common dimensions are 1.2 x 2.5 m, 1.2 x 3 m.

The device opening from gypsum

In order to properly make an interior doorway of drywall with your own hands, you must first prepare the necessary tools and follow strict rules when performing.

Initially you need to prepare:

- arched drywall;

- metal cutting shears;

- serpyanku tape;

- sandpaper;

- roulette wheel;

- perforator;

- screwdriver;

- construction level;

- foam assembly;

- plumb lines for installation of guide profiles;

- cutter;

- pencil.

The device opening from drywall can be divided into two stages:

- frame making;

- installation of a doorway.

To carry out the work correctly, you can take note of the step-by-step instructions for mounting the frame:

- Rack doorway fastened to the ceiling and the floor (to the profiles).

- Install intermediate racks (the distance from each other is 0.5 m).

- Fixed to a horizontal crossbar above the door is an arcuate segment made of plasterboard.

- The connection is made with screws.

- If necessary, additional rigidity, you can insert a wooden bar in the doorway.

Upon completion proceed to the second stage. This is laying drywall, which is performed in compliance with the basic rules:

- The distance from the screw to the edge of the sheet of drywall should be equal to 1 cm.

- The distance between fasteners should not exceed 15 cm.

- GKL, located next to, must be on the same profile.

- The fastening cap is driven into the sheet to a depth of no more than 0.8 mm.

- The suitable size of the screws is 2 cm.

Then perform all the work on sealing joints and cosmetic procedures. So fixed sheets of drywall on the prepared frame look beautiful and aesthetically pleasing, forming an opening.

Application tips

In order not to spoil the repair, exclude additional expenses for finishing and construction materials, need to consider some of the nuances:

- Drywall does not like moisture, from its excess it can fall apart.

- Complete drying of the finishing material takes at least 12 hours.

- To avoid rust spots on the surface over time, it is better to use galvanized screws or stainless steel fasteners for fastening.

- In order not to get enough sleep plaster, it is necessary to screw the screws to a clearly specified depth.

Choose and apply finishing material must be strictly for the purpose. For example, for a multi-level ceiling and curved structures, an arched material is used, which can be given any shape, and for walls more dense wall material with a number of additional advantages is suitable. Sheets must be used within a few days of purchase.

Ways to use to bend drywall, see the video below.