How to choose screws for drywall?

Drywall (GVL) - the most popular building material. One of the main elements of GVL-constructions is fasteners, on the quality of which the strength and durability of the entire assembly is directly dependent. So fasteners are screws - a kind of hybrid drill and screw.

Special features

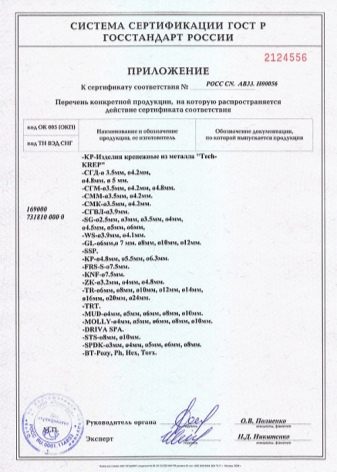

The self-tapping screw - the special fastener which is capable to cut threads simultaneously in the course of production of fixture. Functionally, it is a type of screw, but it has a thinner rod and a greater height of the thread. The safety of people depends on the quality of fasteners along with the strength of the design.Therefore, when purchasing these products, it is recommended to require a certificate of conformity, which each manufacturer is obliged to receive at specially accredited certification centers.

For fixing sheets of drywall used screws, anchors and screws. The most common type of fasteners are self-tapping screws, which is determined by simplicity, versatility and reliability (with proper execution), especially if there is a screwdriver at hand.

Installation, as a rule, implies the presence of metal or wooden frames, to which the sheets of drywall and fasten. It is the frame material that determines the type of fasteners to be used for installation. Wood screws are made with a rarer thread pitch than metal screws.

The main materials for the manufacture of screws are steel and brass. The first have high strength, but are susceptible to corrosion. Therefore, they are coated with an anti-corrosion protective layer, oxidized or phosphated, which gives them a black color.

Brass fasteners - yellow. It is resistant to moisture, but has low strength.

The dimensions (length and diameter) of fasteners largely determine its scope.In practice, depending on the purpose, fasteners are used with a length of 10-15 mm and a diameter of 3.5-5 mm. Such a wide variation in the parameters of the product determines the variety of types of models, their purpose, and hence the importance of the correct choice of fasteners for each individual case.

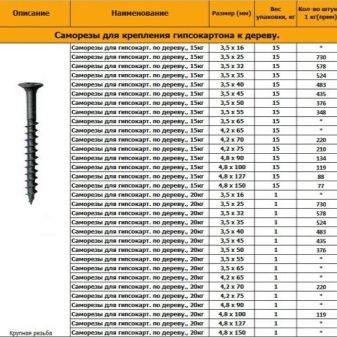

When working on drywall for the selection of screws use special size tables. It indicates the nominal diameters of products, their length, including the cap, and width.

An important issue in working with drywall is also the question of how much fastener goes for 1 square meter of the product. This parameter should be optimal: on the one hand, to ensure adequate structural strength, and on the other - to provide savings in material resources spent on the work.

Kinds

Self-tapping screws differ in many parameters:

Material

- high carbon steel;

- resistant steel to chemicals and water (stainless or alloyed steel).

By types of thread

- frequent

- rare

Coating

- phosphate;

- oxidized;

- without cover.

- galvanized.

By tip type

- sharp;

- sverlopodobnye.

Purpose

- For mounting plasterboard;

- for roofing work;

- woodwork;

- work with windows;

- metal works;

- work with concrete and bricks.

In more detail fasteners are divided into products with a universal thread, with a rare thread pitch and frequent. Fasteners with frequent threads are used to work with metal.

The fact that the self-tapping screw has a drill at the end eliminates the need to pre-drill the material, which speeds up the installation work.

Types of fasteners with infrequent threads are designed to work with soft textures: plastic, plaster, asbestos, wood and other species. Universal fasteners are suitable for almost any texture.

The caps of the screws are functional. They are produced in secret, hemispherical, with large and small press washers, six-sided, funnel-shaped under the hexagon.

Self-tapping screws for each type of work have various parameters and design features. For this reason, buying a product, it is important to clearly imagine what types of work will be performed and what textures to deal with.

To work with drywall, there is also a special combination: a self-tapping screw and a dowel-butterfly.

What to choose?

Choosing the type of fasteners for GK is important to know:

- frame material (wood, metal, other);

- what exactly fasteners are used for;

- how many layers will laying gypsum board;

- conditions of operation of the structure (indoors, in the air, humidity level, etc.).

If you have to work in the system "GKL-metal", then fasteners are selected for work on metal - with a "thick" thread. In the case of a wooden frame, the fastener should have a wider thread pitch.

If you just need to fix the shelf on the drywall, then you can use a self-tapping screw with a dowel "butterfly", equipped with a drop-down device on the reverse side and capable of withstanding high loads.

For laying sheets of gypsum boards in 1 layer the length of the fastener is 25 mm, in 2 layers - 35 mm. The thickness of the thread in both cases - 3.5 mm.

If the product of GKLV is to function at an elevated level of humidity, it is necessary to use moisture-resistant fasteners: doped or galvanized.

For work may be useful in the so-called "bugs" - short screws with a drill, used for mounting profile. Fixing the profile directly to the wall or ceiling is made with anchor screws with dowels.

Consumption fasteners directly depends on the quality of screws, which is important to consider when choosing them:

- In appearance, the self-tapping screws should be of the same size, with a uniform thread, not have any bulges and bends, which reduces its strength.

- Slotted hole should be clear and located strictly in the center of the screw head. Various types of sagging, bulges are technological defects. Non-technological slot affects the quality of installation, can deform the nozzle screwdriver.

- The color of the entire batch of screws should be of a uniform dark or grayish-black hue, which indicates good quality when phosphating or oxidizing products. Otherwise, the increase in humidity leads to the appearance of rusty streaks, for example, under wallpaper, the elimination of which is extremely difficult.

A reliable manufacturer, as a rule, marks products not only on packaging, but also on the product itself. For example, the letters X, T, W, G, Z on the cap of the screw. So, the letter X designates OMAX, being one of the most reliable producers of fixture.

To work on aerated concrete, a special group of self-tapping screws is produced, which takes into account its porosity and brittleness, which is called the Nogli - universal types of fasteners, its “Christmas tree” varieties.

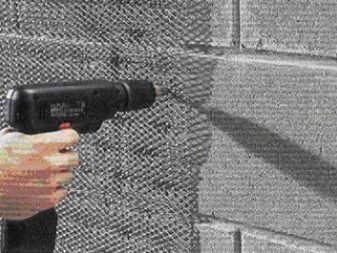

Without dowels, fasteners for aerated concrete are practically not used because of its special structure and are usually used for fastening structures of low weight. For example, for equipment of a reinforced network on an aerated concrete wall before its plastering, fixture with a wide thread pitch and a length of at least 100 mm is usually used.

To fix the roof to the crate, galvanized self-tapping screws with a 6-sided head of the following sizes are needed: 4.8 × 16 mm and 4.8 × 19 mm.

Installation

To perform large volumes of fasteners The tools needed for the installation of the gypsum tools include:

- perforator or hammer drill;

- screwdriver with which you can conveniently and quickly fasten fasteners;

- level;

- special knife for cutting sheets;

- roulette;

- needle roller for bending HL;

- peeling plane for processing the edge of the plasterboard;

- Bulgarian and special scissors for cutting profile;

- special tongs in order to fasten the profile (with their help it is easy to connect the profile to each other in the same way as a rivet system);

- gas gun for mounting plasterboard;

- a tape screwdriver reduces installation time, as self-tapping screws are fed automatically thanks to a special tape;

- special crowns for cutting holes for sockets, lamps or junction boxes;

- disk cutter for cutting even material strips;

- punch for the production of holes in the profile;

- a set of self-tapping screws of various lengths, with frequent and rare threads, with serifs on the reverse side, and other types of fasteners.

Complete with professional tools there is usually a whole range of different devices that significantly speed up the installation process of the gypsum board and profile.

To perform one-off work for the house, it makes no sense to purchase expensive equipment (perforators, pistols, etc.), since it is not difficult to always find some alternative and more economical option. However, when hiring installers need to pay attention to their professional equipment.

Proper installation GKL requires the observance of several rules:

- Preliminary and accurate marking of the location of the holes for the connection of drywall and the profile among themselves not only allows to improve the aesthetics of the product, but also to increase its strength.

- The approximate consumption of fasteners for one sheet of gypsum board of standard sizes is not more than 70 pieces (with a common fastener spacing between the holes - 300-350mm).

- It is more practical and more efficient to assemble the gypsum board with the help of a screwdriver, using different nozzles (bits) for different splines of self-tapping screws.

- During the fastening, the first half of the screw must be screwed in with the maximum speed, the second one must be screwed on at the minimum speed in order to fully control the degree of immersion of the screw in the drywall sheet.

- Drywall is a fragile material, and therefore accuracy and accuracy are important when working with self-tapping screws. If during the fastening process the sheet was deformed, it is necessary to unscrew the screw, putty on the deformed hole and screw the new one at a distance of about 50 mm from the old hole.

- The head of the screwed screw should go no deeper than 1 mm into the material, and its location should be strictly perpendicular to the surface of the sheet.

- At the end of the work it is important to check how correctly and accurately all the screws are screwed.

For fastening of 2 wooden elements it is recommended to use black screws with a rare thread. In this case, preliminary drilling is not performed. For fixing other elements to the tree apply yellow or white screws.Silver self-tapping screws are used for more durable fastening of sheet material.

Tips and tricks

The consumption of self-tapping screws per 1 m2 of GCR sheet depends on the optimal size of its pitch, which is selected on the basis of the following features:

- practice shows that the average strength design has a pitch norm of 300-350 mm (distance between the holes);

- to enhance the plasterboard construction, the distance between the holes can be somewhat reduced, sometimes to 100 mm;

- To bring the screw to the edge of the sheet less than 10mm should not be in order to avoid chipping.

In work with a reinforced profile (for example, 2 mm thick), it is necessary to use self-tapping screws with a drill, which will relieve from an additional operation — pre-drilling — and significantly shorten the operating time.

For hanging various elements of the interior, it is better to use the "dowel" butterfly, which, after installation, opens and forms a reliable support. Installation of such a dowel is made as follows: a hole is drilled in the wall with a diameter equal to the diameter of the dowel, 5 mm longer than the fixture. After cleaning the hole, the dowel is inserted, and then the fastener is installed.One such "butterfly" can withstand up to twenty-five kilograms of weight.

For working with wood, self-tapping screws are used, usually 24 mm in length. For a metal frame, experts recommend the use of screws with a small cap, since they are more convenient to hide under the trim.

After the marking, it is advised to pre-drill the hole with a thin drill with a depth of not more than 3 mm. In the future, it provides high-quality and reliable fastening.

It is recommended to install the gypsum board to the ceiling profile using a special attachment that limits the drilling depth to a fixed size. The cap of the finally self-tapping screw must be flush with the surface of the sheet.

When a multi-layer structure to increase its rigidity, elongated screws are used, which are installed more often - with a pitch of 200-400 mm.

On how to properly tighten the screws in the drywall, you can learn from the video below.