Plasterboard slopes: the pros and cons of structures

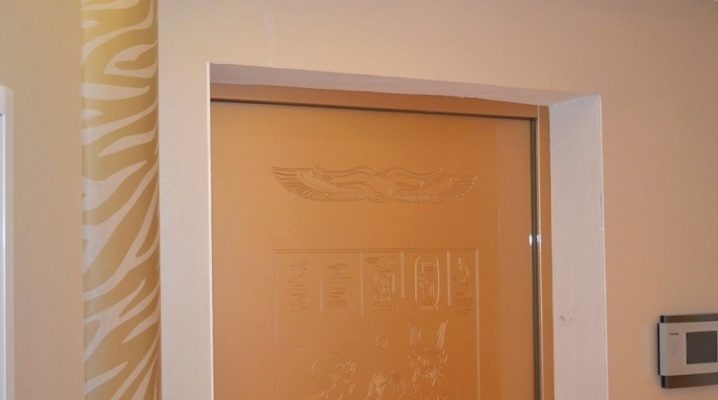

Replacing glass - an important stage in the improvement of the dwelling. Installing new windows will create a stable microclimate in the house without drafts, street noise. It will increase the level of energy saving. Each master can independently determine which type of finish is most acceptable for him: plastic finishing, installation of drywall, plastering.

In order to get a flat surface with clear and correct angles, it is better for home craftsmen to opt for slopes from the gypsum board. We study their advantages and disadvantages.

Special features

Gypsum cardboard - gypsum panel plastered on both sides with a strong cardboard. The unusual device of the panels, the combination of gypsum base and cardboard sheets allows you to create strong and durable partitions, slopes and other types of home interior designs.Affordable price and ease of installation made GCR the most popular, even among beginners.

The construction market offers gypsum panels of various markings that can be used in various fields of use:

- Gray sheets with a length of 2.5 m and a width of 1.2 m are suitable for walls. The gypsum base with a size of 12.5 mm does not contain additional additives and has properties that meet the established standard.

- Light gray panels, similar to sheets for walls, but having a thickness of 9.5 mm, are designed for the ceiling. This can significantly reduce the price of the material and makes it affordable.

This material has additional properties.

Moistureproof (GKLV)

This material is a green panel with a plaster base. They are resistant to moisture, have a special moisture-resistant impregnation and impregnation with antifungal properties. Suitable for installation of rooms with high humidity and in places with possible formation of condensate, has the standard sizes of sheets.

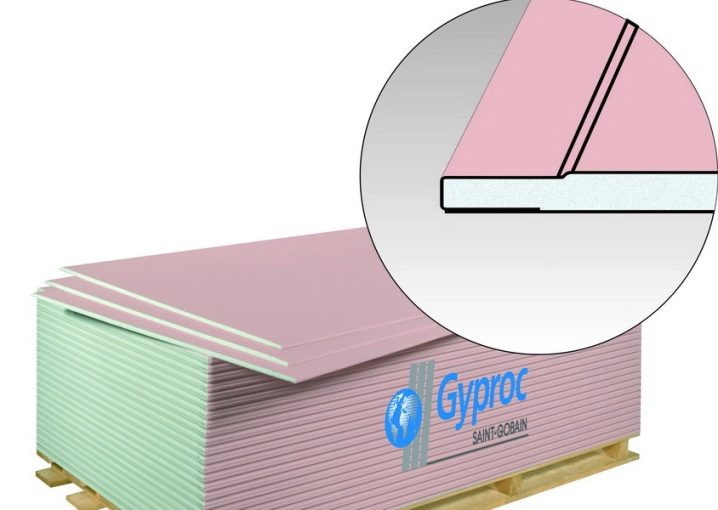

Flameproof (GKLO)

This group includes sheets of light gray color, which have standard sizes. Gypsum base is filled with reinforcing additives.Reinforced refractory cardboard fire sheets do not form a flame, and charred without destroying the structure.

Water Resistant (GKLVO)

These varieties have the properties of moisture-resistant and fire-resistant material.

Flexible (arched)

This line is represented by light gray sheets with a thickness of 6.5 mm, a length of 3 m and a standard width. The core contains fiberglass yarns that allows you to mount curved shapes with different bend radii. The high price of panels and the installation of thin sheets in two layers increase the estimated cost of work.

Manufacturers produce sheets of two quality categories: A and B. The first category is the most popular. It does not allow errors in the size of the panels. The second is produced on the old equipment, so it has a lower quality.

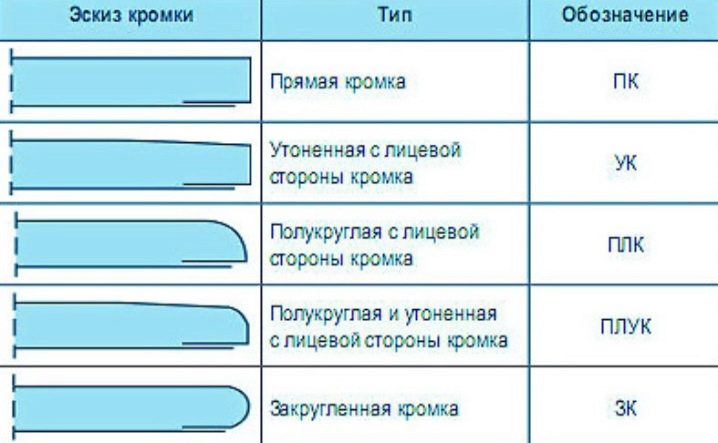

The edges of the sides of drywall can be divided into several main types:

- Straight lines;

- With thinning;

- Semicircular;

- Semicircular with thinning;

- Rounded.

When choosing a material for finishing work, taking into account all design requirements, it is necessary to pay attention to its characteristics and properties.

Denote the main ones:

- Strength when forming a bend (drywall 10 mm thick can withstand 15 kg of load).

- Fire resistance (fire-resistant sheets do not form a flame in the event of a fire, and the gypsum base is simply destroyed).

- Resilience to temperature fluctuations.

- Moisture absorption (ordinary sheets have the least resistance to moisture, it reduces their strength and can lead to deformation).

- Thermal conductivity (high coefficient of thermal insulation will allow simultaneously with the process of leveling to warm the walls).

- Load on the structure (the weight of mounted elements of the decoration should not exceed 20 kg).

- Sheet weight and thickness (different thickness and low weight of the panels give the possibility of diverse use of gypsum plasterboard in the interior).

Advantages and disadvantages

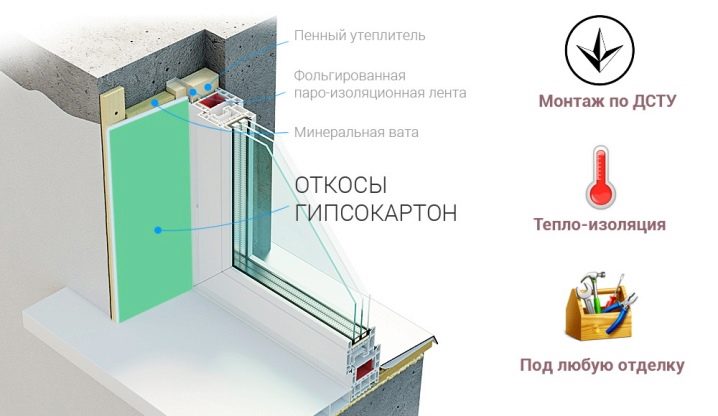

Window and balcony openings are places with a constant temperature drop and condensation. For the formation of slopes, experts recommend the use of moisture-resistant plasterboard. The design, made of gypsum panels, has several advantages.

The main ones are:

- reasonable price GKL;

- long service life;

- minimum amount of waste;

- creating a perfectly smooth surface;

- installation without the use of special tools.

In addition, it is characterized by other properties, including:

- versatility (suitable for plastic and wooden windows);

- the ability to perform finishing work in a short time without the use of plaster and putty;

- high protective performance against sound and temperature effects of the environment;

- preventing the occurrence and spread of mold and fungal pathogens;

- the possibility of using different types of finishing materials.

Installation of lightweight construction of gypsum panels is possible without the need for reinforced frame profile. The porous structure of the material creates an optimal microclimate in the house, helps to regulate the humidity and stabilize the temperature drops.

Ecological safety of slopes makes it possible to apply them in children's rooms and bedrooms. Simplicity in work will allow to create complex and non-standard openings, arches and niches in the most daring design projects.

The disadvantages include:

- low structural strength;

- low moisture resistance of ordinary sheets;

- destruction under the action of sunlight;

- the inability to partially replace the deformed area;

- reduction of the light opening.

The fragility of the structure and the risk of its destruction do not allow drilling large holes to accommodate electrical fittings and other decorative elements. Work must be carried out with the use of personal protective equipment for eyes and respiratory tract. (to avoid the negative effects of gypsum particles on the mucous membrane of the eyes and respiratory organs).

How to make your own hands?

For quick and high-quality installation of the construction of plasterboard panels before starting work you need to take care of the availability of tools for finishing work.

May need:

- Bulgarian or tool for cutting metal;

- drill;

- special knife for gypsum panels;

- bubble level building;

- measuring tools.

The preparatory stage involves high-quality cleaning of the working surface:

- It is necessary to remove excess foam after sealing the window frame, remnants of old paint and plaster inside and outside the room.

- The surface inside the structure should be treated with an antifungal primer.

- It is important to cement the place with erection foam (to reduce drafts through the pores).

After that it is necessary:

- apply plaster;

- make insulation and waterproofing;

- accurately measure the depth and width of the window opening;

- cut sheets of the required size with a small margin.

The technology of cutting drywall consists of several stages. It is necessary:

- lay the sheet back on a flat horizontal surface;

- using measuring tools to apply the lines of the cut point, strictly observing the size of the window opening;

- draw 2 lines along the drawn lines with an assembly knife, trying to cut the top paper layer;

- lifting the panel, break it at the place of the cut;

- cut the front layer of cardboard.

The manufacture of adhesive composition

For solid and reliable fixation of gypsum-based panels, professional builders recommend the use of special glue, carrying out its breeding, strictly following the manufacturer's instructions. Stir the composition in a clean plastic container using an electric drill to the consistency of thick cream.

Installation of slopes provides several ways to work. Consider the main.

On the metal frame

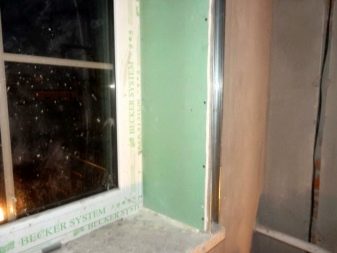

In the window opening, the metal profile is fixed, the free space is filled with filler (for thermal insulation), the resulting structure is sewn up with plaster sheets. The advantages of this method are easy installation and no joints.

By glue

The adhesive method requires experience and installation skills for proper fixing of the panels, taking into account the angle of inclination. Cut drywall sheets are glued with special mounting glue to the window openings, the upper vertical parts are fixed with wooden slats until the adhesive base is completely dry.

The advantages of the method are the lack of a profile and a beautiful appearance. Work is done quickly, you need a minimum amount of materials.

On mounting foam

Fixation on the mounting foam is used in cases where there is no possibility of mounting the metal frame, the walls do not hold the dowels, adhesive solutions can not be fixed on the surface. No additional materials are needed for this method.

The lining of the upper horizontal surface of the opening in the wall is mounted by means of guides made on three sides.

The installation of slopes in the doorways of the entrance doors is performed similarly to the slopes for windows. To sew up the place of finishing with gypsum panels is the simplest and most affordable way. Fastening the guides is necessary to hold from four sides, the cells in the structure should be filled with mineral wool. Fixed sheets need to be fixed every 25 cm..

Vertical corners should be trimmed with an angle-forming tape, which will provide protection from damage and give the structure a neat appearance. Paint the slopes with a brush or roller in a single color of the overall interior.

Final finish

Final finishing of slopes includes several technological stages of the work:

- elimination of all irregularities;

- the formation of the outer corner of the metal sloping corners with perforations, covering them with a thick layer of plaster;

- alignment of the recesses, side joints and upper parts with a putty solution;

- priming the surface, applying finishing putty;

- painting of gypsum sheets in two layers with water-based paint for interior work.

Tips

Installation of window or door openings with the use of drywall is a simple and affordable type of work for beginners.Observing the order of performance of work and the rules of the technological process, the installation will be performed efficiently and in a short time, the construction will serve for many years.

Professional tips of masters will help in the implementation of the tasks:

- Accurate measurements of the window opening - a pledge of quality work.

- Between the joining surfaces it is necessary to avoid the formation of cracks.

- Fixing plasterboard to the metal profile is carried out with special screws on the drywall.

- Antifungal solutions will help prevent mold under the installed structure.

- High-quality putty and painting will protect the surface from moisture and make it more durable.

- By applying a rule to the place of the cut, you can get perfectly smooth edges of the parts.

- Drywall - a durable material, but a strong blow can lead to its destruction.

- Moisture-resistant sheets - a versatile material for interior work, which must be preferred in the installation of slopes.

The design of plasterboard does not withstand heavy loads, so it is not recommended to use ceramic tiles or wooden panels during finishing work.Before painting the surface with paint from different cans, it must be mixed to obtain a uniform tone.

Strict observance of all norms and rules of the technological process of mounting slopes will help avoid the appearance of mold and mildew, and will maintain a neat and attractive appearance of the structure.

For how to make slopes of plasterboard, see the following video.