Moisture-proof GVL: characteristics and dimensions

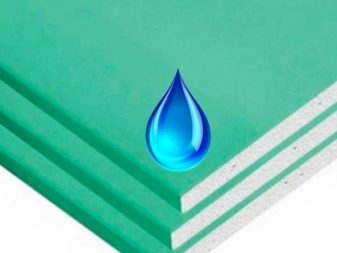

Today GVL is one of the most popular materials for finishing the room. Gypsum fiber showed a number of advantages in comparison with gypsum board, therefore its use in finishing became so widespread. With the appearance of moisture-resistant gypsum fiber on the market, it was possible to avoid trouble when using the material in rooms with high humidity.

Specifications

In the production of GVLV used a mixture of gypsum and cellulose fibers. These components are mixed to a homogeneous mass, and then compacted with a press to shape the sheet. A mixture of cellulose fibers gives GVL high strength. Moisture-resistant gypsum fibers are made about the same way, only during production they add hydrophobic components, which gives the material a high moisture resistance.

The main advantages

Of course, the main advantage of GVLV is its moisture resistance, which allows you to use the material when decorating rooms such as a kitchen or bathroom.

One of the features of waterproof gypsum fiber is its environmental friendliness.because the material does not contain any harmful chemical impurities and does not harm people.

Moisture-resistant gypsum fiber retains its properties even with temperature changes, which allows the material to be used even in cold rooms.

GVLV can be used as a warming room, because its level of thermal conductivity is low. This means that such sheets keep heat indoors for a long time.

The material, if necessary, can be easily changed and adjusted to the desired dimensions, if it is cut. GVLV does not crumble if you drive nails into it or screw in screws.

Among other things, gypsum fiber has excellent sound insulation properties.that provides room from the penetration of extraneous noise. GVLV is also resistant to fire.

The material is quite flexible, which is very convenient when applying it.

GVLV size

Sheets GVLV produced in accordance with GOST, which provides for their size:

- By thickness, mm: 5, 10, 12.5, 18, 20.

- Width GVLV represented by such dimensions, mm: 500, 1000, 1200.

- By length, the following standards can be distinguished, mm: 1500, 2000, 2500, 2700, 3000.

Material weight

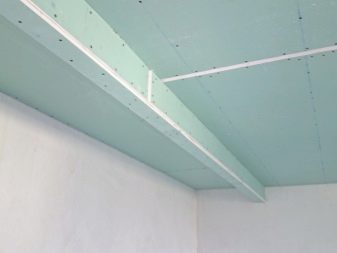

If you compare GVLV with drywall, then the latter is much easier. And this suggests that a moisture-resistant gypsum fiber requires a very strong frame that can withstand its weight. Especially, if the sheets themselves will also have a load. But if sheets GVL small size, then the frame in this case is not required. Special glue for GVLV is quite reliably able to withstand the weight of gypsum fiber sheets.

How to cut gfvs?

Sometimes, when finishing walls or floors, it becomes necessary to trim a sheet of GFVS and adjust it to the required size. Make it very easy.

You can use a knife, jigsaw or hacksaw for cutting gypsum fiber boards. Pre-worth moisten GVLV water so that the material is not very dusty.

Sheet cutting should be carried out in stages:

- A flat rail is applied on the slab GVLV, on which marking is performed.

- Then, along the intended line, several even cuts are made with a knife: it is worth to spend 5-6 times.

- Then the rail should be laid under the cut, gently break the sheet or cut it with a hacksaw.

An electric jigsaw is a tool that helps to perfectly cut a sheet of GFVL. It is especially indispensable for builders who encounter such material for the first time.

Laying on the floor

Before laying the GFVL sheets on the floor, the base must be carefully prepared. It is necessary to eliminate all irregularities and surface errors. To do this realistically, using a solution of cement or applying a mounting foam.

The old floor covering should be removed and the surface cleaned of debris. Then a layer of waterproofing is installed, and if necessary, a layer of expanded clay is filled up.

It should be remembered that for gypsum fiber you need to use glue, which is produced specifically for this type of material.

To carry out the installation of sheets can be as follows:

- To begin with, the tape is glued.

- Then you should start laying the sheets themselves. Fix them to the floor using special screws or glue. The distance recommended when screwing in the screws is about 35-40 cm from each other.It is important to know that each new row should be laid with a seam shift. It must be at least 20 cm.

- In the final work should proceed to the processing of all joints between the plates. Sometimes the same glue is used for this, and it happens that putty is also used. After the leveling compounds have dried, the main coating can already be laid on the gypsum fiber.

For walls

At installation of GVLV for walls it is possible to use two main methods:

Frameless method

In this case, the sheets are attached using glue. The irregularities on the wall become an extremely important factor for applying glue. In case of significant defects, it is necessary to apply the composition around the entire perimeter of the plate, and then it is necessary to make a point application in the middle part every 30 cm.

Frame method

Also used the frame method, which is more complicated. For mounting sheets used metal frame. Under the frame itself, if necessary, you can attach additional noise insulation or insulation. GVLV sheets are mounted on a support using special screws.

Some features of installation

There are a number of common errors when working with moisture-resistant gypsum fiber, which should be avoided.

Here are some tips:

- Chamfer, before applying the putty, is not removed.

- For fastening sheets, ordinary self-tapping screws cannot be used, their special shapes are produced, which should be used.

- It is recommended to leave gaps at the junction points. Their distance should be equal to half the thickness of the sheet of GVLV.

- Next, the remaining gaps should be filled with plaster putty, and you can apply for these purposes and the remnants of glue.

- Before the installation of a GVL is carried out, it is necessary to carefully prepare the base of the wall, which includes removing irregularities, applying a primer and leveling.

What to consider when choosing?

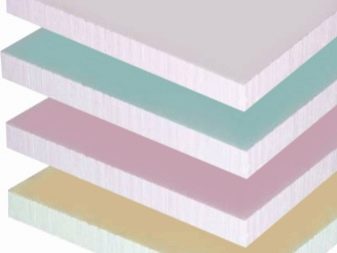

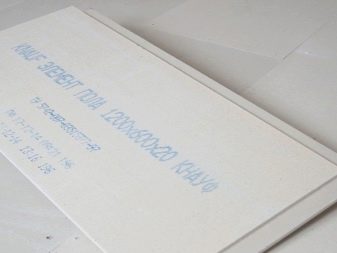

The main criterion when purchasing sheets GVLV is the manufacturer of the goods. German gypsum fibers, in particular, Knauf, have high rates. This brand does not cause serious complaints from buyers. The important point is also the labeling of sheets. The fact is that in terms of their external features, moisture-resistant GVLs are no different from standard ones.For this reason, it is important to read the information on the packaging of the product.

To finish the arched structures, you can also use GVLV. For these purposes, even produced special types of sheets to create arches and curved structures - GKLV.

Prices

Prices for gypsum sheets will depend on their size.

The approximate price tag for the following sizes GVL are as follows:

- Knauf-Superpol 1200x600x20mm - approximately 300 rubles per page (5 in.);

- Knauf-Superlist (GVL) 2500x1200x10 mm - 460 rubles, (7.5 u. E.);

- Knauf-Superlist (GVL) 2500x1200x12.5 mm - 530 rubles, (8.8 in.).

findings

GVLV is an indispensable material when finishing a room, especially for rooms with high humidity. Such sheets are resistant to moisture and resistant to low temperatures.

GVL can withstand up to 15 freezing cycles and not lose their properties. The life of such a material is very high, which will help to forget about the further repair of the walls for a long time.

Installation of sheets is quite simple and it is quite possible to cope with it on its own.

The advantages of moisture-resistant gypsum fiber sheet, see the following video.