Drywall Cutters: Types and Applications

One of the most common building materials used for finishing walls and ceilings in rooms is drywall. Its versatility allows you to create any partitions, as well as complex multi-level structures.

Kinds

Obtaining accurate parameters and forms of finishing material is provided with the help of special cutters.

There are two main types:

- Disc - used for cutting gypsum plasterboard, with the formation of straight lines of the profile without roughness or cracks. For such works, a mill called Strong is used.

- Shaped - for the formation of round, oval holes, geometrically complex chamfers. Performed with the Festool cutter.

To get the desired profile, the necessary parameters are selected, the shape, the size of the tool.

There are the following types of cutters Festool:

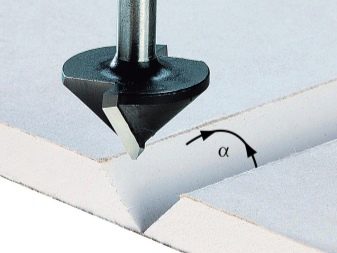

- V-shaped - on drywall for cutting out grooves at an angle of 90 degrees. It is often used for installation work.

- U-shaped tool - for the formation of grooves with a semi-oval bottom, as well as unusual shaped holes.

- T-shaped tool - allows you to create holes at an angle of 90 degrees with a large diameter for thick plates.

- Grooving tool - helps to form geometrically complex holes, grooves located at an angle of 90 degrees.

- Edge milling cutter - used for chamfering along the edge of a sheet of drywall.

It should be remembered that the dimensions of the tool should correspond to the dimensions of the cutter openings.

Manufacturers

Among the well-known manufacturers of electrical appliances for the processing of drywall, the most popular cutters of the following brands:

Bosch

The products are characterized by the release of a high-quality, convenient, safe-to-use instrument with high technical capabilities.

"Enkor"

The devices of this brand are made of durable high-quality material, contain soldering from hard alloy. Differ in reliability, long service life.

"Globe"

The brand specializes in the production of durable tools for processing products made of soft or hard wood, composite, ductile metals.

Sekira

For the manufacture of tools of this brand are used hard alloys, high-speed steel, which makes it durable, easy to use.

The choice in favor of a particular brand should be based on the technical characteristics and purpose of the tool. Depending on the characteristics of the drywall surface, the size of the milling machine, cost, frequency of use, the optimal parameters are selected.

Technology of application of V-shaped cutter festool

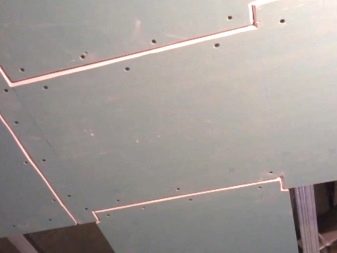

When constructing plasterboard partitions most often used V-shaped cutter. It makes it possible to form straight angular surfaces that allow quick assembly of any structure with the least number of joints. At the same time, the edge sides are tightly in contact with each other and do not require additional finishing work.

When creating a box, a V-shaped groove is formed from the inside. After that, gypsum plasterboard is easily bent at a right angle, then glued together with foam for installation.This design is characterized by durability, reliability, and evenness of angles.

For a permanent job, a mill with a power of more than 1 kW is required. For one-off - you can purchase a budget option or use the rental.

When choosing a tool, you need to check the diameter of the cutter “tail”. It must comply with the installation parameters. The diameter of the wide part of the tool can be 12, 16, 24, 32 mm. The diameter of the tail is 8, 12 mm.

Milling is carried out on a smooth hard base. Since the V-shaped mill has indirect forms, guide devices are used to obtain smooth surfaces.

Stages of work when milling

To form an angle of 90 degrees using a V-shaped cutter will require:

- machine;

- a device for collecting dust;

- template;

- cutters;

- table;

- GCR;

- polyurethane foam;

- Scotch;

- respirator, goggles, gloves.

Having prepared all the necessary tools, you can get to work.

Milling includes the following steps:

- Take the desired size sheet of drywall, put on a hard surface.

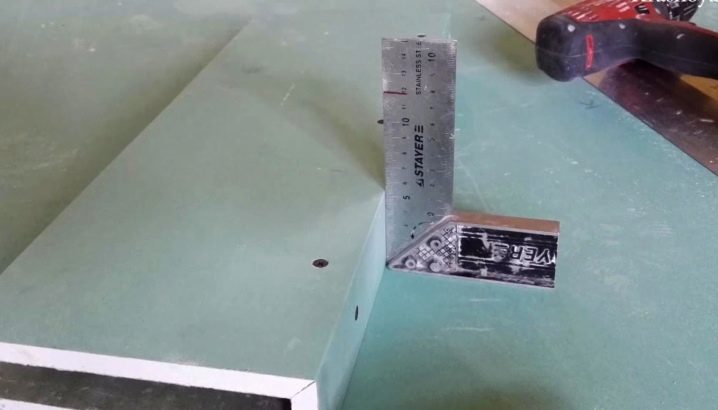

- To adjust the working stroke of the instrument is attached template.

- Milling cutter adjusts to thickness GCR.

- The number of cuts, the distance between them is determined in advance.

- For convenience, the places on which the mill will pass are marked with lines.

- To determine the accuracy of the indent use the rule. It is set to the left of the platinum.

- Smooth smooth movements produce milling.

- From a working surface particles of dust, the fulfilled material are removed.

- Adhesive foam is applied to the formed groove.

- It creates an angle of 90 degrees.

- Until the moment the foam dries, the construction is fixed with adhesive tape.

It should be remembered that you can only mill waterproof waterproof plasterboard.

Advantages and disadvantages

Milling tools for drywall allows you to create holes, geometrically complex shapes, even joints, corners in a short period of time. This greatly expands the possibilities of using GCR.

However, like any treatment method, milling a hyposocardon has its advantages and disadvantages.

Among the positive moments can be identified:

- convenience, speed of obtaining the desired result;

- possibility of cutting out complex shapes of holes, grooves;

- allows the installation of the structure without the construction of the internal frame;

- material savings;

- the formation of a different angle cut;

- getting the most even surface.

Among the negative aspects can be identified:

- for the work required special skills, knowledge;

- when processing the material, a large amount of dust is formed, which requires the use of agents that protect the mucous membranes of the upper respiratory tract and lungs;

- relatively considerable financial costs.

This method is advisable to use when the repair time is limited or you want to get a smooth exact surface of complex shape.

Application tips

Milling at home without a special device to absorb dust can turn into a real disaster. The release of huge amounts of dust leads to severe pollution of the room, and also has a negative effect on health.

For the formation of surfaces of different complexity and shape, it is necessary to use special cutters. It is not recommended to use such a tool for processing wood. Since in this case it is not suitable for processing a more dense material than drywall: the surfaces are of lower quality.

If the formation of complex configurations is required, it is better to purchase a complete set of the instrument with various nozzles that allow you to create the required geometric shapes.

Tool kit must be purchased in specialized stores.

It is not recommended to do home repair without special skills or knowledge. Before work, you must carefully study the technology of milling, practice on small pieces of drywall. If you have any questions, you should consult with experts.

For information on the types and methods of using the drywall cutter, see the following video.