How to make a box of drywall?

To date, the construction market is represented by a huge number of various finishing materials intended for the arrangement of premises. The most common and versatile is drywall. It is with its help that it is possible to build boxes of various designs and purposes.

Special features

The undoubted advantage of a drywall box is its ability to mask unsightly interior elements. Sewer pipes, risers with cold and hot water, wires and other communications can be hidden from the eyes by such structures. In addition, they are installed to align the ceiling, correct the curvature of the walls, and it can also be the basis of built-in wardrobes.

Like any other building material, drywall has its own characteristics that must be considered when working.

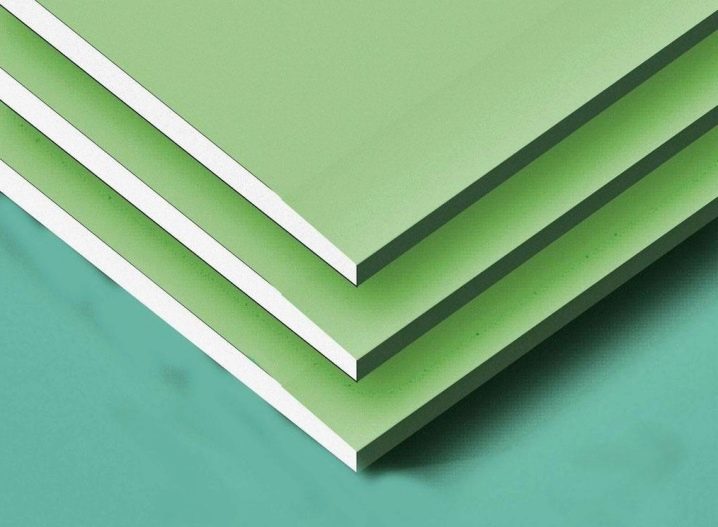

Produced drywall sheets, which are glued layers of different materials. In the middle of the sheet is a layer of gypsum, which is covered with cardboard on both sides. Gypsum refers to fragile materials. To increase the strength of its impregnated with special additives. The cardboard is also impregnated with a special reinforcing compound, so this finishing material can withstand quite large loads.

A drywall box consists not only of drywall sheets, but also of the frame on which these sheets are mounted. The frame itself can be made of both wood and metal. The wooden frame consists of bars with a section of 40x40 or 50x50 mm. To prevent the processes of decay, the bars are treated with antiseptic agents and soil compounds.

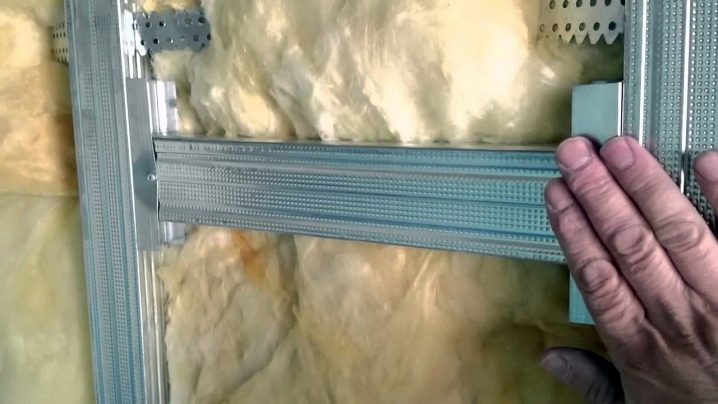

The base of another type of frame is galvanized metal profiles with a curved U-shaped form, suitable for working with such material. They do not require special treatment, and therefore are a more profitable option for the manufacture of boxes.Profiles are divided into guides and main.

Advantages and disadvantages

Installing a drywall box indoors It has many advantages due to both the material itself and the design as a whole:

- Plasterboard material is environmentally friendly, so it is used for any premises. With it, you can change the space enough in a short time, which is important for carrying out complex work.

- It is easy to handle, sheets can be given almost any configuration. Yes, and plasterboard surface facing is not a particular hassle.

- Installation of the box is carried out in both frame and frameless way. It all depends on the installation location of the structure. Wooden bars or metal profiles, which are the basis, perfectly combined with gypsum plasterboards.

- It is also important durability of the material. Properly installed design will last more than one year.

But there are downsides to the use of such facilities. In the first place - this, of course, is the loss of several centimeters of area. After all, the device, despite its attractive appearance, requires some free space,Therefore, before installing this nuance should always be considered.

Drywall sheets have some load limitations. When transporting and working with such material, care should be taken, so there is a possibility of sheet cracking.

Kinds

Plasterboard boxes are divided according to the location, purpose and number of faces. Most often it is built on the ceiling. Ceiling structures are among the most popular and widespread structures, allowing not only to hide significant defects and communications, but also to change the shape of the ceiling, creating multi-level compositions of different configurations. Ceiling box is a good location for the LED strip and spotlights mounted in the canvas.

On the wall, a plasterboard box is more often mounted for different purposes. In addition to hiding communications. it can perform other functions: it is possible to level the surface of the walls, small structures serve as shelves or niches, the installation design is able to occupy the entire wall or a small part of it. Depending on the location of the box are divided into angular and straight.Straight views have three faces - two side and one central.

The corner option, unlike the wall and ceiling, consists of two planes. Such forms are mounted at the junction of two walls and used to hide the pipes, as well as being erected under the hood. The box itself has an L-shaped appearance, and its faces join at a right angle, having a slanting cutter.

Scope of application

The installation structure is mounted in premises of different purposes. Location depends on the functional accessories. In the kitchen, a plasterboard box is installed, as a rule, for additional illumination of the working area. Sometimes it is made and then installed to hide a battery consisting of one or more sections. This design is located around the radiator and is mounted in two ways.

In the first case, the top plane is screwed to the bottom of the sill, and the bottom is attached to the floor surface. When using the second method instead of the floor box is fixed to the wall. In order for the warm air to circulate properly, special slots are made in the box.

The box, designed for lighting, can be mounted with both sides, and with 3 sides. The modification depends on the location of the intended installation and height.

In the kitchen, install wall, ceiling and mixed types of systems. Under the hood, as a rule, ceiling ducts are used, having a stack rectangular shape and mixed-type constructions, and the walls adjacent to the corner are L-shaped.

In the toilet the box is often installed to hide the sewer drain, and in the bathroom - to close the water supply system. Due to the special microclimate of these premises, plasterboard sheets must be moisture resistant. And the pipes themselves, around which the structure is built, are often covered with condensate; therefore, the use of a moisture-resistant material is an essential necessity.

In the bedroom, living room and other living rooms, the box can be used not so much for masking unsightly interior elements, but for practical purposes as well. A small box in the shape of a shelf for TV, books and other things can significantly transform the interior without major expenses and time.

Sometimes the box in the room serves as a decorating and at the same time functional element. It is installed to hide the hanging curtain parts (hooks).Mount this option on the ceiling surface along the window opening. In addition, the design serves as a platform for placing the LED strip.

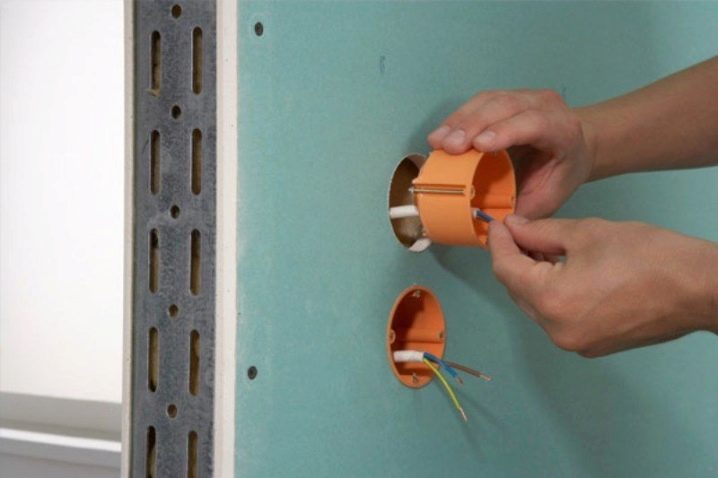

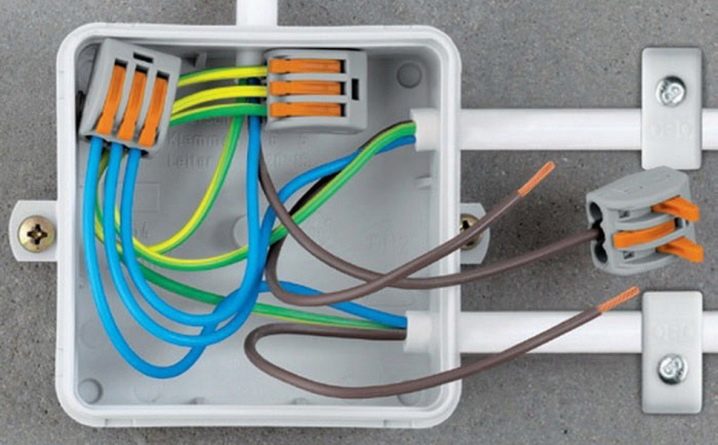

Where there is lighting, there are wires. For safety and aesthetic appearance of the room is mounted junction box. Installing the junction box is necessary to correctly organize the switching of wires and cables.

A high degree of protection from exposure to external factors is provided by the soldering box, marked by manufacturers with the letters IP and two numbers indicating the level of protection against dust particles (the first digit) and humidity (the second digit).

How to do?

In order to build a drywall box with your own hands you need to properly conduct the preparatory work.

These include processes such as:

- determination of the installation site;

- markup;

- preparation of material and tools;

- installation itself.

The marking of the installation site requires auxiliary means, including pencil, tape measure, construction level, and the square ruler. For the installation of the frame you can not do without a drill, screwdriver, hammer, hacksaw and a cutter for connecting profiles.The formation of the box is impossible without a suitable construction knife and sanding planer. The materials used are plasterboard sheets with a thickness of 12.5 mm and rigid metal profiles.

Having decided on the installation site, you can start measuring the future box using the tools prepared for this process.

To determine the future size of the box is important location of the object. If you plan to install it on the ceiling, then this location is considered horizontal. The marks determining the width of the structure in this case will be located on the ceiling surface, and marks corresponding to its length will be placed on the wall. When the object is placed vertically, the marks corresponding to its length and width are deposited on the wall surface, and to determine the volume of the future structure on the floor and ceiling. To determine the boundaries of the box it is necessary to mark the most prominent parts, and it is from them that the necessary centimeters be set aside.

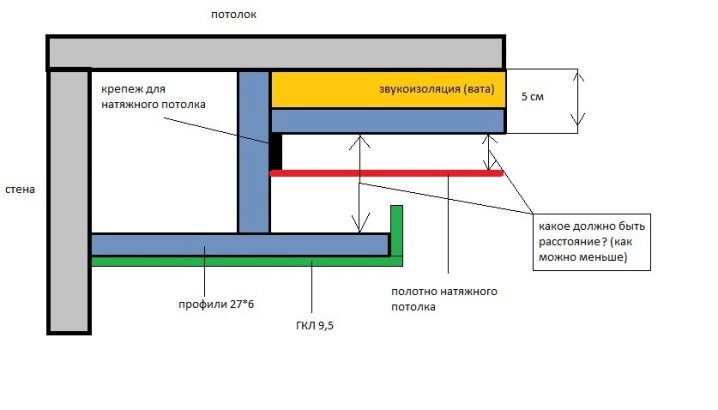

When measuring the behavior of a future design, it is worth remembering that the gap between the edges of the box and the object itself must be at least 5 cm.Consideration should also be given to the subsequent exterior finish, namely thickness and integrity. If the finishing of the outer sides of the box is supposed to be tile, then when marking it is necessary to take into account its width, so as not to customize the tile material to an already constructed model. After applying the markup, you must accurately connect all marked points. When delineating the contours of the future box, you must use the angle bracket. Correctly constructed lines running from the marks to the object must be in a strictly perpendicular position.

Layouts for a vertically positioned object start from the ceiling. To verify the accuracy of the contour, you need to lower the plumb line from the upper corner point, the lower corner point must coincide with the upper mark. After checking the markup, you can proceed to installation of the structure. In order to install the box quickly, and most importantly, correctly, you need to follow certain rules. There is a step-by-step instruction on this account, thanks to which all works are divided into stages.

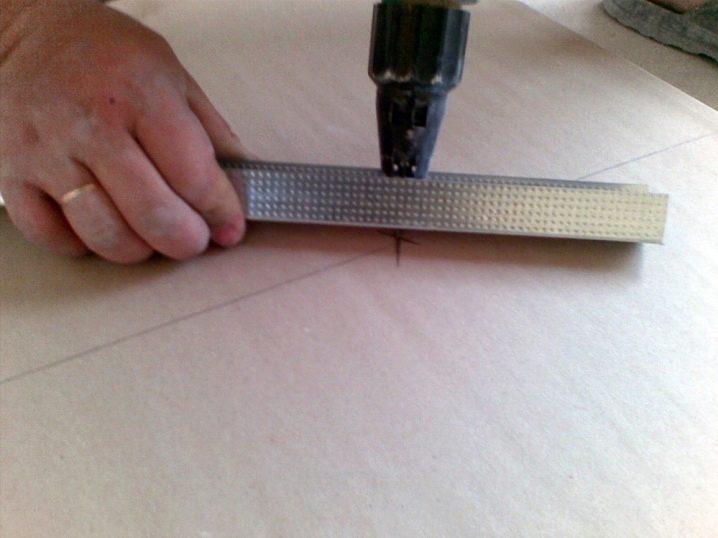

The installation of the frame is not less important than the markup. On the ready-made contours you need to install metal profiles.First, we attach the posts to the wall, pre-drilled the holes for this process, and screw in the dowels. For stronger fixing, the distance between the holes should be between 50-60 mm. Guide profiles must be fastened first on the ceiling surface and then on the floor. After you can proceed to fastening the front pillars, coming from the upper guide profiles, using slats or screws.

To maintain the structure in an even position, additional profiles should be used - the so-called stiffening ribs. They must take a strictly perpendicular position with respect to the rack profiles, and be located at a distance of no more than 1 meter from each other. The installation of stiffeners is important if the height of the whole structure is more than 1.5 m, and the width of the edges is more than 25 cm. In addition, they are the basis on which sheets of drywall (FCL) are attached.

For horizontally located objects, the installation of the structure begins with the mounting of the guide profile (UD) around the entire perimeter. Then screwed vertical jumper. Having fixed them, it is necessary to start installation of the directing profile.The lower part of the box can be assembled on the floor, and only then fasten this structural element to the upper half. After preparing the frame proceed to the formation of the box itself. From the prepared sheets of drywall cut the desired size and shape of the face of the future design. First you need to make measurements of the width, length of the sides and mark these figures on the sheet. After you can proceed to the connection marks. An incision is made along the contoured contours.

In order not to spoil the material, you must follow some rules:

- Cut the sheet along the contours produced with a ruler and stationery knife. The process itself must pass without haste and excessive pressure. The edges of the cut are processed with a peeling plane with a slight bevel of 22.5 degrees. When joining the GCR, an angle of 45 degrees is formed, due to which the sheets are firmly attached to each other.

- After preparing the sheets, you can sew the frame using self-tapping screws for fixing 35-45 mm, with a pitch of 25 mm. For small frame boxes, self-tapping screws are the most acceptable method of fixing sheets. If gypsum plasterboards are used for leveling walls, then mounting foam can be used as an attachment.The total cost of foam required for fixing is lower than the cost of the used metal profiles, in addition, it contributes to the preservation of heat in the room.

But it is worth remembering that to disassemble the structure without damaging the sheets of drywall fixed with the help of assembly foam will not work, you just have to break it. Therefore, when redevelopment is easier and more profitable to dismantle sheets, bolted with screws.

Tips

Gypsum board box is, in fact, a simple design, intended in most cases to hide some decorative elements. But, during installation, you should not forget about the practical reassignment of this structure, as well as some of the nuances of the installation itself.

The installation of the box, starting with markings and ending with the fastening of the sheets, should be carried out using the building level. It is possible to use both a simple tool in the form of a ruler with a central location of a flask with a liquid, and a more accurate, modern device like a laser level.

Each stage of the work must take place under the control of this device, otherwise the constructed structure can be obtained with significant deviations, which will not have a very good effect on its operational characteristics.

For the stability and strength of the box, the size of the frame is of great importance.or rather, its stiffeners. With the length of these frame elements more than 80 cm, additional fasteners are installed - these are U-shaped holders, with the help of which the structure is kept in an even position.

When installing a box with curvilinear forms for cutting sheets it is better to use jigsaw. Thanks to him, the cuts are quite smooth, smooth and beautifully outlined. For the formation of round holes for sockets or ceiling lights it is better to use special crowns that are mounted on a drill.

Pipe Access Window

When installing a box for objects such as a sewer pipe or a water riser, it is necessary to cut a hole in the sheets, which will facilitate access to the special elements of these objects. In a sewer pipe, they are couplings that have a branch or hole that is closed by a special cap. The device is intended for clearing the clogging, therefore it is impossible to close the sheet with access to it.

In addition, the sewer pipe has a connection where the inner sewer pipe converges with the central riser.In case of an emergency or a simple replacement, it must also be accessible. This requirement applies to water meters, valves, compensators, non-return valves and gearboxes for plumbing.

For an aesthetic look of the whole structure, a hole for a special window is cut to fit the door. When forming it, it is necessary to take into account the size of the frame of the leaf, as a rule, it is smaller than the hole by 1-3 mm. Installation of the box in the box can be made both before sheet installation on the frame, and after.

Holes in the box are also formed in the places where the pipes or other sheathed object exits beyond its limits. The cut should be slightly larger in diameter than the pipe. The gap formed is filled with materials that weaken the transmission of vibrational vibrations from the pipe to the structure.

Beautiful examples in the interior

Today, durable and lightweight drywall is the best finishing material, and at the base of beautiful interpretations in the interior is a regular box. Finishing the ceiling, walls and other surfaces, the formation of interior items and installation of structures that transform the room, is possible only on the basis of the box.

Using the box, the ceiling and walls can be given any, even the most unusual form: install lighting fixtures in the right places, create beautiful shelves and niches that give the interior of an apartment or house a special unique look. Thanks to the drywall box, the disadvantages of the room turn into advantages. The main thing is to correctly position the structure, then an ordinary apartment will turn into a beautiful and comfortable dwelling.

How to make a box of plasterboard, see the following video.