Moisture-resistant drywall: characteristics and application

Plain cardboard, when in contact with water, is quickly defrosted. Therefore, as a finishing material, moisture resistant plasterboard is most often used. Before buying it is important to study its basic parameters so that working with it does not cause difficulties.

What it is?

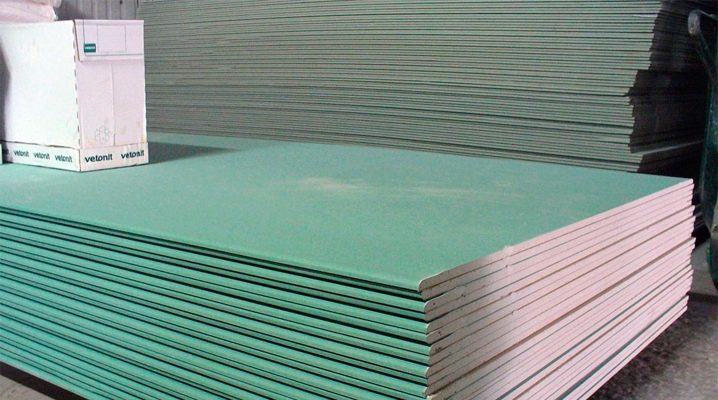

Interpretation of the abbreviation GKLV is a moisture resistant plasterboard. This coating allows you to finish the kitchen, bathroom, toilet or shower. It differs from ordinary drywall internal structure and chemical composition. Exterior color in most cases, green, light green, occasionally produced pink materials.

The use of gypsum board is very wide, it is one of the most versatile finishing materials.

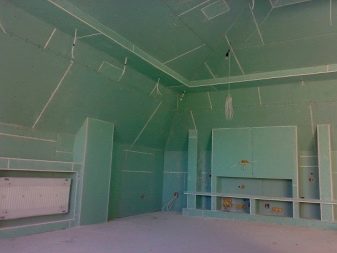

It is easy to use in residential and non-residential buildings in order to:

- sheathe the wall;

- to build a partition;

- create a complex decorative element;

- make a multi-level ceiling.

The best result is achieved when a moisture resistant plasterboard is used in rooms with excellent ventilation, which are regularly ventilated. Attention should be paid to proprietary labeling. Group A is more even than the material of category B, and it lasts longer. On the other hand, such coverage will always be more expensive.

The advantages and disadvantages of any material, and moisture resistant drywall is no exception. It is important to remember that no treatment is able to raise its resistance to water higher than 80%. This means that in the bathroom such material is undesirable to use without subsequent staining or overlapping with decorative tiles. For the rest of the indicators GCR manifests itself much better.

It is completely safe in sanitary terms, easy to install, does not require any special care.

Special features

Technical characteristics of gypsum board due to the fact that it consists of gypsum, containing hydrophobic additives, and a pair of layers of cardboard,which are processed in a special way. This solution is simultaneously protected from moisture, from the occurrence of fungi. But each manufacturer naturally has its own secrets that can not be read in the State Standards or other regulatory documents.

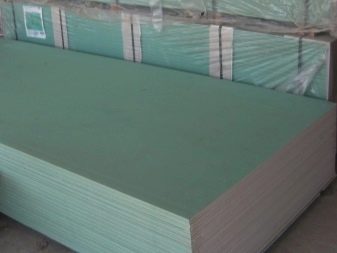

The thickness of the drywall varies from 0.65 to 2.4 cm. It is necessary to select the value according to the operating conditions and the purpose of the application. To make a wall in an apartment, you should use sheets no thinner than 1.25 cm. When arches and figured elements are created, the transverse dimensions range from 0.65 to 1.25 cm. Quality products are invariably marked.

In the notes of the manufacturer provides information about:

- type of sheets and their group;

- edge design;

- the size and standard in accordance with which the product is released.

Low weight allows you to use drywall without assistance and in almost any situation. The load on the supporting structures of the walls is minimal. The vapor permeability of drywall can not be ignored, because it is always made of porous gypsum. Typical drywall density is 2300 kg per 1 square. There are special variations of this material for outdoor work, but they deserve a separate discussion.

Kinds

In addition to the usual GKLV, there is also a GKLVO - this material is resistant not only to water, but also to fire. Moisture-resistant drywall invariably contains gypsum mixed with anti-fungal additives and silicone granules, which increase the resistance to water. It is important to remember, even labeled as waterproof GCR should be used only when protecting its outer layer with additional coatings.

Fire-resistant wall material, unlike simple, perfectly resists the action of open fire due to the fact that the core is reinforced with reinforcing components.

This product is used:

- in industrial premises;

- in the ventilation shafts;

- in attics;

- in the decoration of electrical panels.

For the bathroom under the tile is not suitable plasterboard with a straight edgebecause it was originally intended for dry installation. This type of material does not require to lay the joints. Refined edges are designed to facilitate the gluing of reinforcing tapes and the subsequent application of putty. The material with a rounded edge allows for puttying, but reinforcing tapes are not needed.

In those cases when it is required not just protection from moisture, but also the containment of extraneous noise, it is more correct to prefer aquapanel to moisture-resistant drywall.This material is also preferred if condensate constantly forms or the surface is in continuous contact with a liquid. In all other cases, the choice in favor of this or that option is an exclusively personal matter.

Dimensions

Typical sizes of moisture resistant gypsum sheets vary from 60x200 to 120x400 cm. In most cases, a step corresponds to 5 cm. 10 mm thick gypsum board is rarely used, much more often builders and repairmen need 12 mm material (if exactly 12.5 mm). It is these three sizes that are considered to be the best in terms of strength and sound dampening.

Colors

The color of moisture resistant drywall in most cases is green. This is primarily due to the need to identify the product category. Since in the most important rooms (bathrooms) on top of the plasterboard another coating will still be mounted, the uniformity of colors is not a drawback.

Selection and application

In addition to the accompanying documents and green color, moisture resistant GCR has another important difference from simple analogues. The gypsum part of the construction is dark, and its edges are protected by a cardboard layer, this is important for maximum resistance to water. The width and length of the sheet allows you to choose the optimal solution for almost any room.

The fewer joints you have to do, the easier the work will be and the more reliable the decorated wall will be. This is important to consider when assessing the required dimensions of the material.

Those who have already had to install regular drywall can easily cope with its waterproof counterpart. The similarity is manifested in the installation of a metal frame, as part of the necessary tools and guide parts.

Invariably need:

- self-tapping screws;

- dowels;

- profile constructions;

- markup tools;

- tool for the preparation of holes.

It should also be borne in mind that the cost of a moisture-resistant sheet is somewhat higher compared to conventional finishing material. In wet rooms, installation should be carried out only with good ventilation and with a smaller distance between the lattice parts than in a standard situation. To prepare the frame in the bathroom is used only aluminum, wooden parts can not be used. Any seam is sealed very carefully and always find out before starting work which side of the sheet is the front. Secure the screws preferably at a distance of 20 cm from each other.

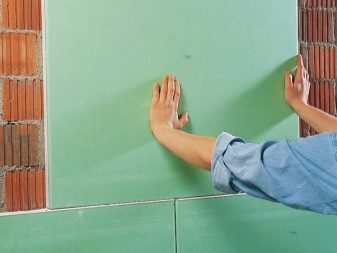

It is possible to install moisture resistant drywall with or without a frame.If the method without frame is chosen, it is required to thoroughly prepare the surface, remove all the old coating from it. Next, apply a primer, which not only prevents the development of pests, but also improves the adhesion of the adhesive composition.

The glue itself is applied either around the perimeter or with our patches. The first method is chosen when the wall is in perfect condition and does not deviate from the vertical. The sides of the cardboard are coated with glue, for greater reliability they are placed in the form of two strips at equal distances from the edge. Next, the processed block is applied to the wall and leveled, focusing on the readings of the building level. Glue grease the entire surface of the sheet. Apply the adhesive mixture to the surface of the wall or not, the masters decide for themselves, but this step will help avoid the occurrence of cavities under the finishing layer.

It is necessary to glue the gypsum plasterboard in a room where there will be no drafts, otherwise the glue will dry before it provides normal adhesion. At the temperature and humidity indicated in the instructions, the freezing will occur after 24 hours. Then the finishing material is ground, after 24 hours, when it is soaked, it is treated with a universal composition and then painted or pasted wallpaper.For your information: it’s impossible to stick tiles to drywall installed using frameless technology.

When using a frame, a plaster side is attached to it, which is denser and harder. The mounting of the guide profiles is done along the lines connecting the lowest corners of the surfaces. To ensure maximum rigidity of the structure, suspensions are placed approximately every 5 cm. For the formation of figured elements, only a sheet of GCR of small format is used, which is cut into certain shares.

Tips and tricks

Many people who do not have significant experience are puzzled by the question of which side to fasten sheets of moisture-resistant drywall. The answer is quite simple: you need to look at how the groove is located, which appears when placing the end at an angle. It is possible not to pay any attention to coloring sheets, it does not allow making the right choice.

Builders need to leave the gaps between the joints GKL, in order to qualitatively process putty even the smallest part of the surface. Putty recommended twice (before applying the soil and after). Next, the surface is treated with waterproof compounds,to best guarantee its protection against the ingress of water.

Not always the uniform appearance of the drywall satisfies people. In this case, you need to create additional coverage - for example, glue the wallpaper. Professional builders do not consider such work too complicated, but as in any business, there are certain nuances that ignorance can fail.

Putting drywall under wallpaper is much easier than under subsequent painting or decorative plaster.

Cardboard is the same paper, respectively, the wallpaper glued to it without additional processing will be held very firmly, so much so that it is almost impossible to remove them without destroying the structure. The choice is obvious, because even two or three days to prepare is clearly more economically advantageous than a complete reworking of the room during the next redecoration. In addition, the green base and the markings on it will shine through, and these insignificant details may disrupt the concept of the interior as a whole.

Regardless of considerations of economy, you need to use at least two spatulas - wide and medium. If they are not there, it is worth buying a whole set at once; still, these useful tools will come in handy more than once.Instead of a screwdriver, you can do with a quality screwdriver, but without a construction knife, the work is impossible.

It is most convenient to mix the putty in plastic buckets with a capacity of 5 or 7 liters, and it is recommended to use silicone containers of small size directly for work.

The primer itself is applied with soft brushes or rollers, characterized by high absorbency. Builders try to dilute dry putty with a special mixer, and if you don’t have to do this work often and for a long time, you can limit yourself to a special nozzle on a drill. As for the compositions, then for finishing the walls of drywall is quite enough ordinary finishing putty. Classical technology (with a preliminary layer) is too expensive and not justified in this case.

To finish the drywall under the wallpaper is the most correct cement composition, because it is more resistant than plaster and polymer to the destructive action of water. Before starting work, the surface is carefully inspected to assess the quality of the assembly and correct possible defects in it. They check that all the caps of the screws are only slightly embedded in the cardboard, and not protruded out or go very deep.The smallest defects that are invisible to the naked eye will be detected by a smoothly moving spatula.

Driven too deeply, the screws require an additional fixation of the sheet with one more fastening element (but the distance between it and the problem part must be at least 5 cm). Skipping a deep-tapped screw can lead to the fact that after a while it will break out, and then the sheets will begin to crack, and the wallpaper to stretch and even tear. The fringe on the outer edge of the sheet is removed with a knife. Finally, sandpaper helps to cope with its remnants. It also eliminates visible traces of mold, but capital control of the fungus is possible only through the use of soils of complex purpose, which effectively suppress microorganisms.

If the sheet has suffered from fungus, it is primed twice in a row.

External corners are reinforced necessarily, as metal or plastic perforated corners are excellent as reinforcing elements. Experts do not recommend using galvanized steel, because with the slightest violation of the protective layer, rust will soon be noticeable through any wallpaper.An aluminum corner is best for home use, it is light and strong enough at the same time.

Corner structures are pressed to the planes after applying a uniform primer layer to them. The pressure must be sure, but not too energetic, because otherwise the corner will bend. Even if there is no rule at hand, any durable strap can replace it. It is important to keep the spatula ready and level with its help protruding portions of the substance.

Putty need using medium spatula (blade width - 20 cm). The finished composition in small doses neatly distributed along the length. Work is carried out from top to bottom until the reinforcement structure is hidden under the layer of putty.

It is recommended to prepare a sketch before starting work and subsequently act strictly on it.

In each of the corners you need to place the support strips, only then the frame will qualitatively and fully perform its task. The profile should not be in contact with the edge of the sheet, so as not to create additional problems.

When creating a frame, a profile of various configurations (called after similar letters of the Latin alphabet) can be used:

- W - large for common frameworks;

- D - is needed to make the lattice plane;

- UA is a product of increased strength and with the thickest wall possible.

A shape like the letter “P” indicates that the ends of the support profiles should be inserted into such a product. For moisture-resistant gypsum plasterboard, the profile installation step is 0.6 m. In cases where there is a gap to the wall, it should be covered with cardboard or wood products. Alternative solutions - mineral wool and foam rubber (the second option is more convenient and practical). Partitions and other separate structures do not need special insulation, they only need to close the voids that serve as a refuge for insects and impair sound insulation.

When selecting fasteners (self-tapping screws), it is necessary to clearly distinguish between products intended for fastening on metal and on wood, since they cannot replace each other. The screw closest to the edge should move at least 0.5 cm away from it, otherwise cracking and delamination are inevitable.

Regardless of how well the work is performed, it is very important to warm the walls under a layer of drywall in a number of rooms.In the bathroom or in the basement, it is quite enough to retreat from the wall during installation, so that the resulting air layer fulfills its task. But on the balconies and loggias to use GCR, even moisture-resistant, it is possible only under the condition of high-quality glazing - at least two-chamber glass. When additional insulation is used, an air gap is left that avoids getting wet of that and other material.

Manufacturers and reviews

The undisputed leader in quality is the product German concern Knauf. After all, it was he who first started creating a drywall of the modern sample and still controls almost three-quarters of the world market. Consumers most of all appreciate the options with a thickness of 12.5 mm, but in addition to them there are lots of options that differ in their characteristics. Any parameter of the production of a German company is estimated very high, and the only problem is only its significant cost.

Russia has its own leader - Volma company. This company has production facilities in Volgograd, where production of all types of gypsum boards is arranged.For more than ten years, products under the Volma brand have been supplied to all major cities of the Russian Federation, so there is no risk when buying it. And this is a better recommendation than any rave reviews.

A rather serious competition to the Volga manufacturer is the Urals gifas enterprise group. She specializes in waterproof plasterboard, and builders note its high quality, which is no worse than that of foreign suppliers.

Successful examples and options

The possibilities for finishing with moisture-resistant drywall in wet spaces, including semi-basements, are quite large. White ceramic tile effectively helps to increase the resilience of structures to the destructive effect of moisture. And in the bathrooms, they can be used for walls and for shielding the space under the bathroom.

By following the simplest recommendations, you can reliably mount the drywall. Whether to focus on the wishes of designers or on their own preferences when finishing it - the choice of the owner of the room. But all the technical aspects must be strictly observed.

On the use of moisture-resistant drywall, see the following video.