GVL sheet dimensions

GVL sheets are deservedly considered to be one of the best materials used in construction as an alternative to drywall. They have many positive characteristics that make them an indispensable material in the decoration. Although this is a fairly new material on the Russian market, he has already managed to recommend himself with positive aspects. Its multifunctionality and reliability have been appreciated by builders and consumers, and now GVL is used everywhere.

GVL characteristics

Gypsum fiber plates are made using a compound of gypsum and cellulose fibers obtained from treated waste paper. The form of the sheet is obtained by applying the press. Under high pressure, the components contract and turn into a gypsum fiber sheet.Although drywall is some kind of gypsum fiber analogue, sheets of GVL are much more durable and reliable and outperform drywall in many ways. These plates are used when it is necessary to perform work on the construction of strong partitions.

Gypsum fiber plates can be divided into two main types: standard (GVL) and moisture resistant (GVLV). It is also possible to distinguish plates with an edge in the form of a longitudinal straight line (denoted as PC) and an edge with a seam (marked as FC). Sheets with no edge are marked under the letter K. Sheets with a straight edge (PC) are used when sheathing frame structures are necessary, that is, for walls and ceilings. It is worth considering that for the joints of such plates it is necessary to apply reinforcement. Sheets with a folded edge (FC) are two glued sheets that are axially offset from each other by about 30-50 millimeters.

Main advantages of GVL

- Such material is environmentally friendly, because it has only cellulose and gypsum in its composition. For this reason, gypsum fiber does not emit any harmful substances and is absolutely harmless to humans.

- GVL sheets are very resistant to temperature changes, so they can be used even in a cold room.

- Such material is an excellent noise insulator. Often with the use of GVL make special screens to reflect extraneous noise.

- Gypsum fiber tolerates moisture very well, so it can be used even when finishing a bathroom or kitchen.

- The material is very resistant to fire, which reduces the likelihood of a fire.

- Gypsum fiber can be adjusted to any size by cutting it. Such material does not crumble, and, if necessary, you can safely drive in nails or screw in screws.

- GVL is also a good insulation, as it has a low thermal conductivity. Gypsum fiber plates can keep heat indoors for a long time.

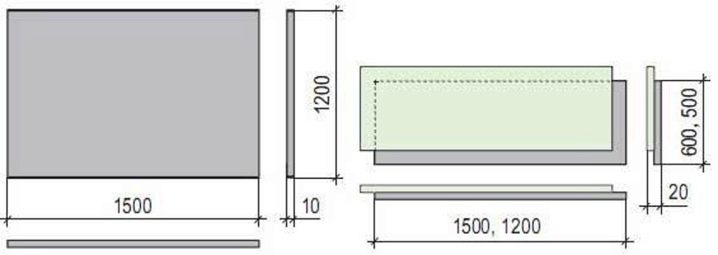

Standard sizes

GOST provides for various sizes of GVL plates in length, width and thickness. In particular, the following sizes are available in thickness: 5, 10, 12.5, 18, and 20 mm. On width allocate the sizes 500, 1000 and 1200 mm. GVL length is represented by the following standards: 1500, 2000, 2500, 2700 and 3000 mm.

Sometimes plates and non-standard sizes are produced., for example, 1200x600x12 or 1200x600x20 mm.If it is necessary to purchase a significant amount of non-standard products, it is sometimes easier to order it directly from the manufacturer than to find it in finished form in a store.

Weight

The only drawback of GVL is that it is a rather heavy material, especially in comparison with its related gypsum plasterboard. For example, a slab measuring 10 by 1200 by 2500 mm weighs approximately 36-37 kg. Therefore, when installing the GVL, you need fairly strong profiles, not to mention the really strong male hands. The mounting of such plates on the walls requires a strong frame. Sometimes wood bars are used instead.

Slabs of small sizes can be mounted on the walls without the help of a frame. They can be mounted using special glue.

GVL cutting

Sometimes during construction it is necessary to trim a sheet of GVL. Even ordinary knives can be used for cutting gypsum fiber boards.

The procedure is as follows:

- To sheet GVL you need to attach a flat rail, on which it is necessary to make the markup.

- A few times to hold a knife on the markup (5-6 times).

- Further, the rail fits under the incision. After that, the plate must be broken gently.

For inexperienced builders, the best way to cut a sheet of GVL is jigsaw. Only this tool is able to provide an even and clear cut of the plate.

Laying GVL on the floor

Before mounting the GVL sheets on the floor, it is necessary to carefully prepare the base. The old coating must be removed, and all the garbage must be removed. Separate attention is deserved even pollution, which, ideally, should not be - they do not contribute to adhesion. Irregularities and defects must be eliminated with a cement mortar, from which the screed is made. Then a waterproofing layer is laid on the floor. If necessary, resort to adding expanded clay, this is done for additional thermal insulation of the floor. After the above actions, you can proceed directly to the laying of sheets of gypsum fiber.

This is done as follows:

- At first it is necessary to perform the sticking of the damper tape.

- Then the sheets themselves are laid on the floor. Their fastening is carried out by the use of glue or screws. It is important to remember that the screws should be twisted, keeping a certain distance between them (recommended approximately 35-40 cm).The new row is laid with a seam shift of at least 20 cm.

- At the final stage, it is necessary to carefully process all the joints between the sheets. This can be done with glue residue, but it is better to use putty. Then on the sheets of gypsum fiber can lay any coating.

GVL for walls

In this case, there are two ways to mount sheets to the wall.

Frameless method

With this method, sheets GVL fastened to the walls with a special glue. The type of glue and its amount will depend on the irregularities on the walls. If the defects on the wall are small, plaster glue is applied to the sheets and pressed against the surface. If the irregularities on the wall are significant, then it is worth applying a special durable glue around the perimeter of the sheet, and then in the middle dotted every 30 cm. for greater reliability.

Frame method

For this method, you first need to make an iron frame that can withstand a large load. Also under the frame you can put additional insulation or sound insulation, you can also hide the wiring and other communications. The sheets GVL themselves must be fixed to the frame with the help of special self-tapping screws with double-row threads.

The main mistakes when installing GVL

There are some subtleties that need to be taken into account when working with gypsum fiber sheets.

To avoid the most common mistakes, follow these tips:

- before applying the putty does not need to chamfer;

- for fastening sheets to the base there are special screws with double-row thread, which must be used;

- it is important to leave gaps in the joints of the sheets, which are equal to half the plate thickness;

- such gaps are filled with plaster putty or special glue;

- Before the installation of gypsum fiber sheets, it is important to prepare the walls, that is, to level them, remove irregularities, and make a primer.

What should be considered when choosing

Buying sheets GVL, you should pay extreme attention to the manufacturer. Sheets of Knauf, which has long established itself in the building materials market, have very good quality. Although the analogs of domestic manufacturers will be cheaper, their quality is noticeably inferior to the German one. When buying moisture resistant sheets you should carefully read the labeling of the goods. Such moisture-proof sheets in appearance may not differ from the standard ones, therefore it is important to read,what is written on the packaging.

When choosing any building materials, the cost should be the last argument. in favor of the choice of a product. Good moisture resistant sheets Knauf, depending on the size, can cost up to 600 rubles per piece, but it’s better not to be greedy, because the stingy pays twice.

Conclusion

Sheets GVL are very high quality and easy to handle material. Their weight is quite significant, which has a large load on the walls of the room, however, the advantages are numerous. To carry out the installation of GVL can and do it yourself. Also, the material is very resistant to temperature changes, and even to high frost. Most sheets are able to withstand up to 8-15 cycles of freezing and not lose their properties. Such material is indispensable in the finishing of various surfaces, is guaranteed to meet all expectations and will please with a long service life.

All about the properties of sheets GVL see below in the video.