How to bend drywall?

Each of us when carrying out repair work at home had various ideas on the original decorative design of a particular part of the room. Most of them seemed to us absolutely impossible to implement, due to the occurrence of such a problem as bending of drywall.

The ability to work correctly with drywall makes it possible to apply such design solutions as installation of various arches, columns, curved ceilings. In the absence of proper skills, a false impression is created that this type of work can only be performed by a professional. However, this is far from the case and our article will help you to make sure of it.

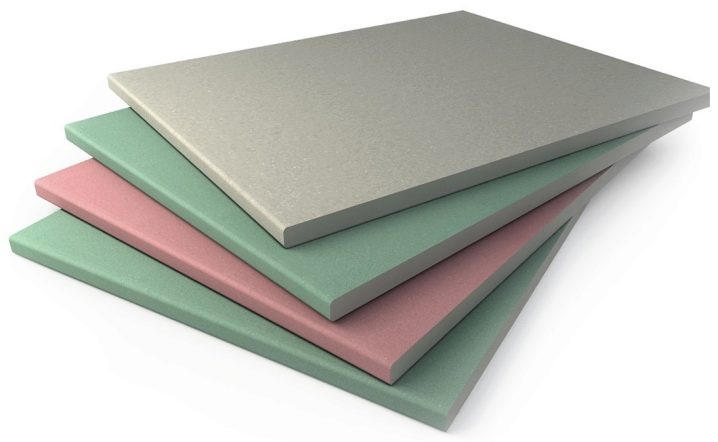

Material Features

Gypsum plasterboard is a type of building material formed from plasterboard and cardboard sheets. These sheets cover the plaster from two sides.There are different types of drywall. Each of them is used, depending on the purpose of the room. Gypsum is included in the group of the least elastic materials, but at the same time it has the ability to change, depending on humidity.

The very process of bending drywall does not require special skills. All that is needed is care in order to avoid a break in the sheet of drywall, which will lead to its unsuitability.

Advantages and disadvantages

Advantages of the material:

- It has high environmental properties.

- It has excellent vapor permeability.

- Gypsum plasterboard is a completely flat and smooth surface.

- It has high sound and heat insulation properties.

- Does not cause much trouble during installation work.

- Wide size range.

- A small proportion.

- Flexibility sheets. This property allows you to create various unique shapes in the interior.

Cons of application:

- In rooms with a humidity of more than eighty percent, the use of this material is impossible.

- The relative fragility, which during the construction work significantly complicates the process, requiring special care and accuracy.

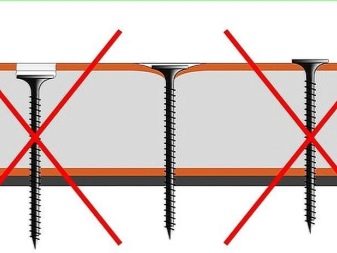

- The difficulty of using screws, screws and other bolts on the walls of this type.

Sheet bending

Before proceeding directly to the process of bending the cardboard, it is necessary to decide how steep the desired bend will be. Depending on the parameter we choose, the way in which this process will be performed will be selected.

Execution methods depend on the bend radius and are divided as follows:

- Bending radius from one thousand to two thousand seven hundred and fifty millimeters.

- Bending radius from five hundred to a thousand millimeters.

- Bending radius from one hundred and fifty to three hundred millimeters.

Consider each of the methods described. As we have already found out, the first of the three methods is applicable to arcs from one thousand to two thousand seven hundred and fifty millimeters. The easiest way to create such an arc is to use the so-called dry method. We study it in more detail.

It contains several stages. The first step is the selection of the desired thickness of plasterboard.

In the ratio of thickness and radius there are the following options:

- With a radius of two thousand seven hundred and fifty millimeters using drywall,whose thickness is twelve and a half millimeters.

- With a radius of two thousand millimeters, the thickness is nine millimeters.

- If the bending radius is one thousand five hundred fifty millimeters, then the drywall sheet should be eight millimeters thick.

- The smallest thousand-meter bend in this category is made from only six and a half millimeters of drywall.

The last of the options presented allows you to save quite a lot of time. when bending drywall, but the financial costs will have to increase. The first three methods require more free time due to the complexity of the work.

Once we have decided on the choice of bending radius, we proceed directly to the bending of drywall.

There are also two options for action:

- The first of them fell in love with the townsfolk for its lightness, simplicity and small amount of time spent. The essence of this method consists in fastening the section onto a profile that has already been bent and installed beforehand. All manipulations on securing the section must be done slowly and carefully.Also required to comply with the step between fasteners, amounting to no more than fifty millimeters. To achieve the desired result of the curvature of the profile, scissors are used for cutting into metal. With the help of them we make cuts on the profile.

Under no circumstances is it allowed to bend the drywall across. This can cause sheet breakage.

- Now consider the second, more complex and time consuming method. Its complexity lies in the fact that the preparation of the layout of the desired fold is required, which requires time. The peculiarity of the structure being created is that its radius should be smaller than that of the future semicircle. The width, in turn, must be less than the width of the sheet, which we will bend. This method allows you to facilitate the process of bending drywall and increase the chances of leaving the material without damage. After the template is ready (or you had it initially), with a careful movement the sheet bends in shape and remains in this position until the desired result is obtained.

Now consider the following option, used in the manufacture of the arch size of the radius, not reaching one meter.In the people, this method is called wet. For this method, we will need the following tools and aids: a needle roller; water; wide brush (can also be used roller or sponge); roulette; pencil.

During the work with gypsum cardboard, by means of the needle roller we will make its punching. Wetting is performed using ordinary water and a wide brush or roller, sponge. When using a needle roller, the following recommendations should be observed: the needles should be no longer than half the thickness of the sheet that we bend, but not shorter than one third. If these proportions are violated, when using the first option, the drywall will be damaged, in the second case the desired result will be absolutely out of reach.

The compressible part is processed with a needle roller.

In this case, the needles will perform several functions at once:

- produce a weakening of the rigidity of the cardboard;

- provide liquid access (in this case, water) to the core of gypsum.

In the absence of a roller, it is possible to replace it with an ordinary awl. Of course, this does not save you time and is a rather time-consuming process, but at the same time it will be possible to save on the purchase of a special roller.When using awls, holes are made alternately at a distance of ten to fifteen millimeters.

The next step will be wetting the area punctured by us with water. To do this, use a sponge, roller or cloth (depending on your choice). The procedure is repeated for ten to fifteen minutes. Wetting is necessary in order to unlock the additional possibilities of drywall, namely, its flexibility. After drying, drywall absolutely does not lose any of its previous properties.

Next sheet must be bent and attach it with screws on a pre-prepared frame. Manipulations are carried out carefully to avoid damage to the sheet. Leave it dry for about a day. After drying, all technical properties will remain, and drywall will remain in the desired position.

The latter method is applicable to the bending of drywall with a radius of one hundred and fifty to five hundred millimeters. This method is the most radical of all three. This is due to the small size of the sheet.

The process is divided into several stages:

- Using a knife on the back of the sheet, we make deep transverse cuts.The process is repeated every thirty to fifty millimeters. The pitch depends on the size of the arch. The smaller it is, the smaller the step, and the larger, the larger the step, respectively. In the end, only a minimal layer of cardboard will bond into a single sheet.

The cuts should be made with special care and accuracy, in order to avoid damage to the face of the drywall. Upon receipt of such damage, the sheet becomes unsuitable for further use.

- On the place prepared by us we fix the construction with screws. Begin fixing should be from the middle of the structure, and finish accordingly on the edges. Each slotted part is fastened. The disadvantage of this method is the high consumption of self-tapping screws.

- We produce high-quality putty for the whole structure (cuts, slots).

It is possible the use of the template. This is due to the fact that after fixing our structure on the frame, it will be very difficult to putty all the necessary holes. But if in advance to prepare the surface for laying our sheet, the probability of sealing up all the necessary recesses increases significantly.

Now you know how to bend drywall correctly and turn it into the most complex and original forms. Bending the gypsum with your own hands at home is not difficult if you approach this process with special attention and accuracy.

In the following video you will learn how to bend the drywall for the arch in the doorway.