Knauf Drywall: Properties and Subtleties of Use

Knauf gypsum plasterboard is a very popular material for interior decoration and is represented on the domestic market in a large assortment. With the help of this unique raw material, you can realize the most daring design ideas and author's interior composition.

Special features

Gypsum plasterboard sheets are well cut with the help of a usual sharp knife, and also they are well sawed and perfectly bent. Elements of any shape can be cut out of the material, sawed through shaped holes of various sizes. The time required for finishing the plasterboard and labor costs are half as much as when performing the same amount of work using plaster and plaster. Installation of plasterboards is carried out using screws, screws, plaster glue and special tape.

Specifications

Knauf drywall is available in slabs and consists of plaster placed between two cardboard sheets. To give the material of certain properties in the gypsum are added various components. They improve strength, moisture resistance and ductility. As additives, reinforcing, adhesive and modifying additives are used. The material corresponds to GOST 6266-97, as well as certificates of European standard DIN-18180.

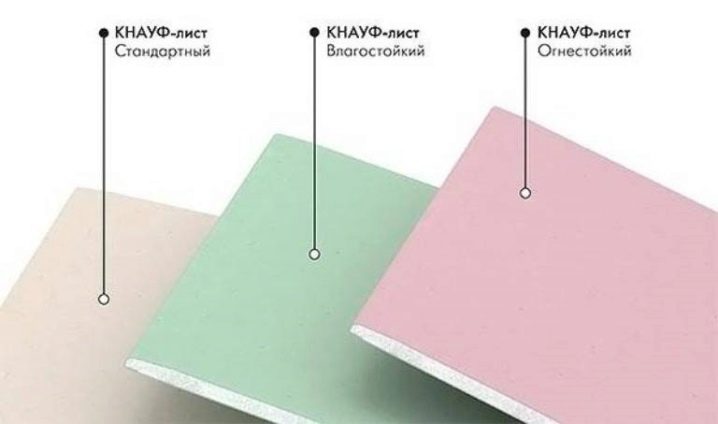

Drywall is used for the formation of multi-level ceiling structures for walls, creating niches and arches, for the construction of partitions and the creation of decorative elements of the interior. The color of the cardboard sheets corresponds to their specific properties. This facilitates the visual selection of material at construction sites and in stores.

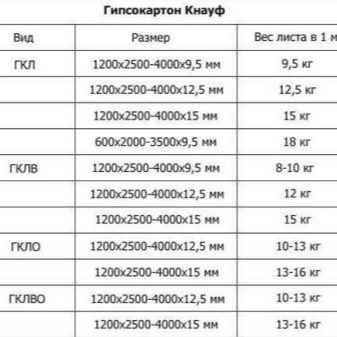

Dimensions

Sheet dimensions depend on the purpose of drywall and can vary between 2-4 meters in length with a width of 60 and 120 cm. The thickness of the material is 6.5-24 mm. The most common is the size of 2.5 x1.2 m with a thickness of 12.5 mm.

Life time

Knauf Drywall is a fairly durable and durable material. Under the conditions of installation and operation, the service life is at least 25 years.

Benefits

Knauf gypsum plasterboards are considered to be the best-selling product in their category, due to a number of its undeniable advantages:

- low coefficient of thermal conductivity of the material eliminates heat loss and helps to maintain a stable temperature in the room;

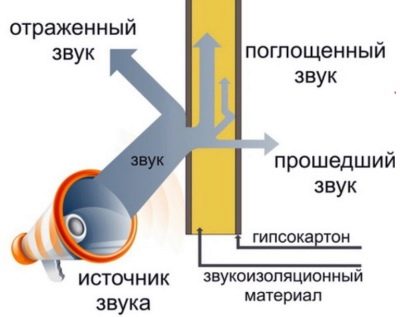

- high sound-absorbing properties allow the use of gypsum plasterboard in the finishing of all types of residential and public buildings, while ensuring high protection of the room from unwanted acoustic noise;

- complete environmental safety is due to the absence of toxic and toxic substances in the composition of the plates, which is confirmed by the necessary certificates of conformity;

- excellent moisture resistance and good water-repellent properties allow the material to be used for finishing rooms with a high level of humidity, as well as sudden temperature fluctuations and a tendency to condensation;

- hygiene of the material ensures the absence of harmful bacteria, as well as the appearance of mold and mildew;

- plasterboard surface is universal and suitable for cladding with all kinds of finishing materials;

- the ability of the material to absorb excess moisture, and, if necessary, return it contributes to the formation of a favorable microclimate in the room;

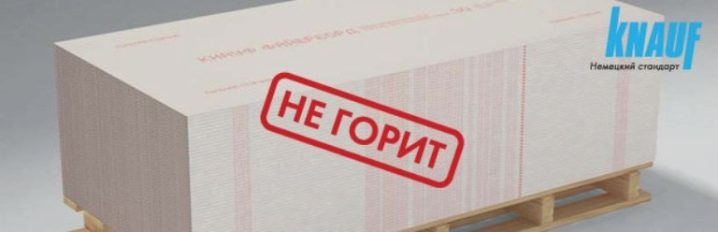

- the non-combustibility of drywall allows you to withstand the action of open fire, without igniting and not smoldering.

Scope of application

Knauf gypsum plasterboards are used for both interior and exterior finishes. The material is widely used for leveling walls and creating interior compositions. With its help, the formation of multi-level designs of ceilings, the construction of niches and the construction of interior and decorative partitions. The ability of sheets to take rounded shapes allows you to implement unusual planning decisions when creating artistic images and provides a wide scope for the work of designers.

Sheets are often used as a sound insulating material. For this purpose, straight or elongated perforated hangers are fixed to the wall or ceiling, which are mounted on a reinforced guide profile with the subsequent installation of an isolate and drywall. Sealing of seams is performed with the help of a special tape with further priming and filling of the surface.This technological solution will allow to achieve excellent sound insulation results and ensure a comfortable stay in the room.

Kinds

Knauf has launched several modifications of this flexible, waterproof and fire resistant material.

At the place of application, the following types of products are distinguished:

- wall - having a thickness of more than 12.5 mm and used for mounting vertical surfaces;

- ceiling - having a thickness of 9.5 millimeters, weight not less than 30 kg, and intended for the formation of multi-level ceiling structures;

- arched, having a thickness of 6.5 mm, and used to create curved surfaces.

According to the conditions of operation and the applied plaster fillers, the material is divided into four types.

- Drywall GSP-DFH 3IR is a very high-quality, environmentally safe product with high strength, impact resistance, high density and moisture resistance. It is used for wall cladding, installation of suspended ceilings and the construction of interior partitions. The plates are equipped with semicircular edges, ensuring the formation of tight joints. This type of gypsum board is manufactured in accordance with GOST 32 614 2012.Facing cardboard sheet has a blue color. Marking indicates the type of material, standard, type of longitudinal edges and dimensions. For example, a plate with semicircular edges having a length of 2.5 m, a width of 1.2 m and a thickness of 12.5 will be marked as follows: DFH 3IR GOST - 32 614 2012 (EN 520 - 2009) PLUK 12.5 = 12 00 = 25 00

The material is used as a base for all types of decorative finishes, including ceramic tiles and heavy wallpaper. When used in rooms with high humidity, the surface of the gypsum plasterboard should have a protective layer in the form of a waterproof primer, paint or tile. To fix this type of drywall, use XTN screws. The area of one sheet is 3 m2, weight - 37, 5 kg. The material corresponds to the fire safety class KM1.

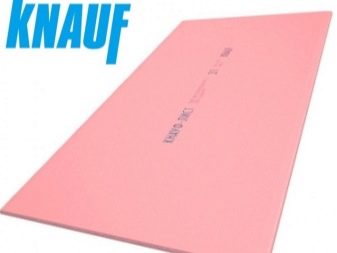

- Fireproof Gypsum Board GSP-DF is a product with a high resistance of the gypsum layer to the action of open fire. Used for the construction of interior and decorative partitions, fire retardant structures and hinged ceiling structures. The side edges are folded by the edges of the cardboard layer, the gypsum core is made using cementitious components and reinforcing agents.Adhesion of cardboard sheets to the core is carried out by means of adhesives, which ensures the stability of the integrity of the plates and significantly increases their service life. The material is suitable as a base for finishing all types of decorative finishing coatings and is allowed for use in all types of residential and public buildings.

An example of marking a fire resistant sheet GKL with dimensions 2500x1200x12.5 mm: DF GOST 32 614 2012 (EN 52 = 2009) PLUK 12.5 = 12 00 = 25 00. Drywall of this type can be used in conditions of low humidity. The front side of the sheet has a pink tint, and the back is painted gray. The length of the plates varies from 2 to 4 m with a width of 60 and 120 cm and a thickness of 12.5, 14 and 16 mm. The material has a very high fire resistance, flammability corresponds to G1 and is governed by GOST 30244. The plates do not contain toxic substances and have a level of acidity similar to the indicators of the acidity of the human body. Due to which GCR can be used in children's and medical institutions, as well as used for decoration of premises for people suffering from allergic reactions.

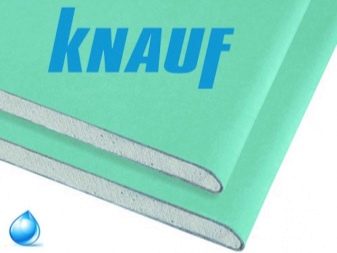

- Gypsum cardboard moisture resistant GSP-N2 is a gypsum building board, the core of which includes additives that reduce moisture absorption. HL is used for the installation of hinged ceiling structures of different levels, creating interior and decorative partitions and arches, as well as sound-absorbing structures in especially wet rooms. The semicircular thin edges are folded with cardboard edges and ensure the formation of tight joints between the plates.

The material is suitable as a base for applying any decorative topcoat, including wallpapering, tile laying or painting. The absence in the composition of harmful components allows the use of drywall in all types of residential and public buildings, including children's and medical institutions. GKLV produced in lengths from 2000 to 4000 mm with a width of 600 and 1200 mm and a thickness of 6.5, 9.5, 12.5, 14 and 16 mm, it has a green color of cardboard shells. The most common size is 2500x1200x9.5 mm. The density of gypsum is 1250 kg / m3.

- Gypsum board moisture-resistant GSP-DF H2 combines the basic properties of moisture-resistant and fire-resistant species.This universal non-combustible material, suitable for lining with any kinds of decorative coatings, is used in the formation of multi-level ceiling structures, the creation of interior and decorative partitions, the construction of arches and niches, as well as for wall decoration. The side edge is folded with a front layer of cardboard and has a semi-circular subtle design. This contributes to the creation of the most dense joints between the plates. The absence of toxic and toxic inclusions in the composition allows the use of gypsum plasterboard for finishing all types of premises.

Installation of components and installation of drywall should be done before installing a clean floor at a temperature not lower than 10 degrees, all wet, plumbing and electrical work should be already completed. Before laying the plates must undergo acclimatization in the repaired room in case they were transported or stored in low temperature conditions. The material is well ventilated and provides a comfortable microclimate in the room. Sheets comply with all international standards and have the necessary certificates and certificates. The cardboard shell of the products has a red color.The plates are produced in different sizes, the most common of which is 3000x1200x12.5 mm.

Reviews

Knauf Drywall is a popular finishing material and has many positive reviews. Consumers note high rates of environmental safety of the material and the possibility of its use in all types of residential premises, including children's rooms and bedrooms. Attention is also drawn to the improved moisture resistance of drywall, which allows it to be used for finishing the bathroom, bathroom and kitchen. This excellent sound absorbing material reduces the acoustics in the room. The advantages include good elasticity of sheets, so that this bending material provides an opportunity to implement bold architectural and planning solutions in the design of offices, apartments and public spaces. There is also the availability and low cost of the material.

The disadvantages include the discrepancy between the color of the cardboard layer and the purpose of the material, which, although rare, does happen. Therefore, when buying, you need to focus not only on the color of the cardboard shell, but also carefully read the labeling of the product.This will help to choose the right type of gypsum and to finish the room according to all necessary standards.

A master class on the installation of Knauf plasterboard ceilings, see below.