Guides for drywall: types and standard sizes

Among the extensive list of modern building materials drywall has a special place. Drywall is unique, it is the only and unique when you need to align the walls, make partitions or put in order ceilings.

Drywall allows you to save a significant amount, while maintaining the quality and strength of the planes: both walls and ceilings. Consider the features of the installation of drywall, what factors are needed for this.

Purpose

Any drywall coating has a solid foundation, which is a kind of "skeleton" for all other nodes and fixtures.Guides can be of different shapes, sizes and perform various missions.

Bearing structures assume significant loads. If the material is poor in quality, then the collapse of plasterboard structures or their deformation is possible. It is recommended to purchase similar units made by well-known manufacturers, who give a guarantee on their products.

The master, before proceeding to the installation of drywall, asks a reasonable question: what material are made guides. This is a key point for the successful implementation of the project.

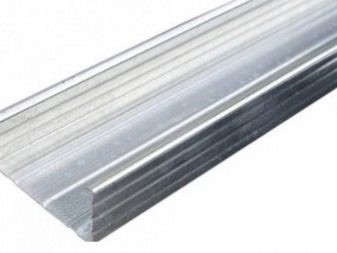

Profiles are made of durable metal treated with zinc. Such material does not rust, the guides are durable and can serve for a long time.

The construction, made as a frame is simple, consists of two types of guides:

- vertical;

- horizontal.

The first are called "rack" nodes. The second - are called horizontal or starting.

Kinds

Types of profiles are classified by the material from which they are made.

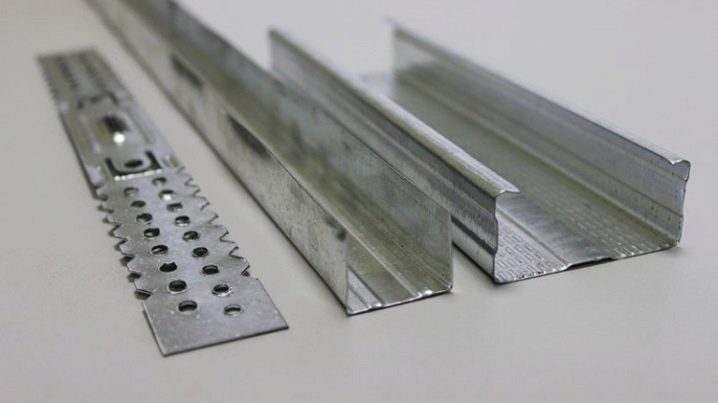

Metal profiles can be the following:

- UD;

- CD;

- CW;

- Uw.

The types of guides are quite diverse, this is due to the variety of functions that they perform.If everything is done according to technology, then the sheets of drywall are fastened quite firmly, the products are stable and durable.

In Russian transcription, metal guides are denoted by the letters: Mon. In English transcription - UW come in several forms; at least four of them can be used for mounting the frame. Such parts (including sliding ones) are made of high-grade steel, which is manufactured using cold rolled steel technology.

When mounting bulkheads between rooms, supporting structures are used, which have dimensions:

- length - 3 meters;

- sidewall height - 4 cm;

- the basis - 50 mm; - 65 mm; - 75 mm; - 100 mm;

- 7 mm holes are drilled in the backrest especially for fixing dowels.

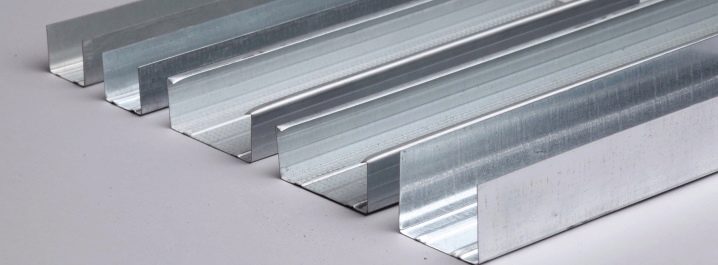

Dimensions

Guides have a diverse range of sizes.

Parameters of guide fastening PN (UW)

Rack - PS (CW)

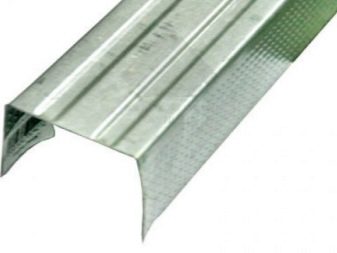

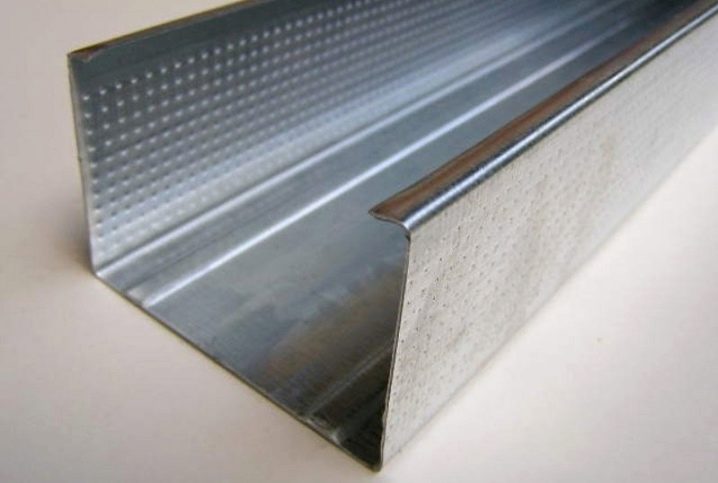

They also serve as a reference node for the formation of crates in the walls and partitions. Fasteners supporting structures suitable for the perimeter. The upper edges are shaped - C.

A profile can have the following parameters:

- length - 3000 mm; 3500 mm; 4000 mm; 6000 mm;

- shelf height - 50 mm;

- width of a back corresponds to an indicator at PN - 50; 65; 75; 100 mm.

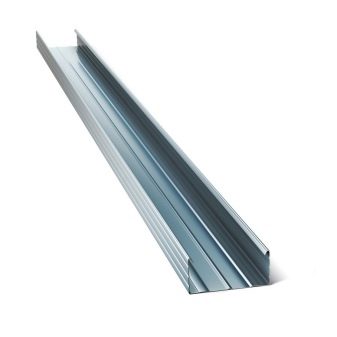

Ceiling rack profile of software (CD)

These are the most popular fasteners, in the professional environment they are called "ceiling". The same products of a gidrokarton are called software. According to the Knauf version, they are abbreviated as CDs.

Sizes of similar structures:

- length - from 2.5 to 4 m;

- width - 64 mm;

- shelf height - (27x28) cm.

Used to form ceilings.

There are differences between profiles in the type of attachment.

Stiffeners are additions that allow you to gain even greater strength.

Formats:

- length - 3 m;

- shelf height - 2.8 cm;

- back size - 6.3 cm.

Profiles for ceilings are inferior in size to the wall, shelves are also made smaller. This is done with the aim, in order to less conceal the space in height. Drywall in the area of the ceiling has a smaller thickness, it is not so massive, which significantly reduces the overall load.

- 60 x 28 mm - PP;

- 28 x 28 mm - PPN.

Plating guide profile (UD or PPN)

UW or Mon

The partitions can be made of any thickness, so a wide variety of parts are produced with different size patterns, for example widths. Bearing for partitions are marked UW or Mon. With such details it is possible to make a partition of the most different thickness.

Dimensions are usually:

- length - from 2.02 to 4.01 m;

- shelf height - from 3.5 to 4.02 cm;

- width - 4.3; five; 6.5; 7.4; ten; 12.4; 15.1 cm

Mounting technology comes down to two methods:

- GKL sheets are attached to the guides;

- GKL sheets are attached to the wall without crates.

It is very important to work with technology. It is also recommended to prepare in advance the appropriate tools, think through all the actions.

Fixing the perimeter of the frame on the floor, walls and ceiling is very important. When there is an understanding of how to arrange sheets and profiles, it is possible to mount the drywall sheets directly. The thickness that is needed is:

36 mm + 11 mm (HL) = 47 mm. The thickness is the largest that the P-bracket allows to create - it is 11 mm.

UD (or PPN) profiles are the main elements of the framework. Invented specifically for the arrangement of frame structures under the ceiling, they are the basis for the entire plasterboard module. The side parts have profiled corrugations, they are additional stiffening ribs, the base is supplied with special holes for fastening with dowels.

Usually these nodes are installed around the perimeter. Structures are perforated, it is easy to mount them.

Rack profiles are often used as main guides:

- length - 3 m;

- thickness - 0.56 mm;

- width - 2.8 cm;

- height - 2.8 cm

Ceiling profile has the following dimensions:

- length - 3 meters;

- shelf - 28 mm;

- back - 29 mm.

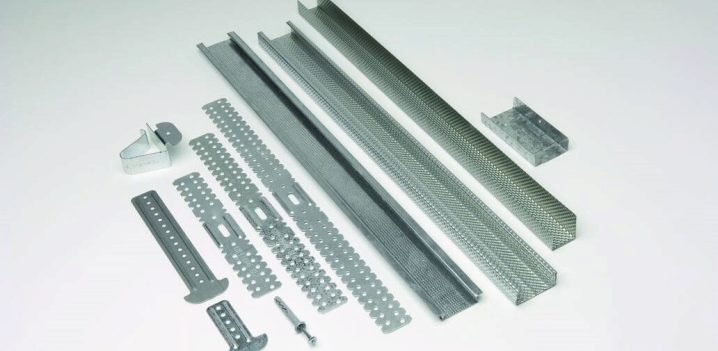

In addition to the above types, there are also guides that can further strengthen the structure.

- strengthen protective functions;

- significantly improve the finish;

- give an arched shape.

Strengthened - UA

It is used as racks when doorways should be strengthened. These profiles are made of good steel and have an effective corrosion protection.

Such reinforced profiles come in the following sizes:

- Length - 3000 mm; 4000 mm; 6000 mm.

- Sidewall height - 40 mm.

- Width - 50; 75; 100 mm.

- Profile thickness 2.5 mm.

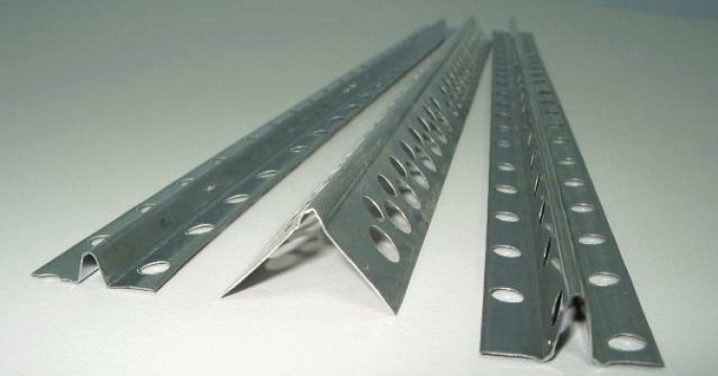

Corner - PU (protective)

This unit is mounted on the outer corner parts of the structure and effectively protects them from a variety of damage. The shelves are equipped with special holes, plaster solution penetrates them. In this way it guarantees a greater attachment to the surface.

Corner profiles are of such sizes:

- length - 3 meters;

- cross section - 24x24x0.5 cm; 32x32x0.4 cm, 32x32x0.5 cm.

Corner - PU (plastering)

It is mounted on the corner parts of the openings, as well as on the end sides of the partitions, which will later be covered with plaster.There are also holes that will be filled with gypsum mortar. The guides themselves are made in such a way that they are not afraid of corrosion / galvanized steel /.

Plaster profile can be a size:

- length 3000 mm;

- section 34Х34 mm. Mounting angular especially for plaster.

Beacon PM

Often a support guide can be used to get a smoother plane during plastering. All material is galvanized, making it inaccessible to the effects of corrosion. The GKL beacon profile is very popular.

Beacon mount to align the plaster, there are sizes:

- length - 3000 mm;

- section - 23x6, 22x10 and 63x6.6 mm.

Arch type - PA

Usually such a node is made of PP 60/28.

It happens of two types and is used for the installation of uneven ceiling structures:

- Based on GCR.

- Arok.

- Columns

- Domes.

- Such structures can be bent arc.

- The “concave” parameters are 3 meters.

- The parameters of the "convex" - 6 meters.

Prostani

Profiles that are designed to create walls, are marked with the abbreviation CW or PS. In width, they usually correspond to starting parts.There is an engraving on all company details, so it’s pretty easy to determine compliance during installation. Products from PS gypsum plasterboard have in addition one more stiffening rib, which forms a bent edge. Used for the installation of the frame itself in the construction of partitions.

Profile under the arch

Professional builders prefer to use products from proven materials. They are used in cases when a more complex structure should be made, they are not always urgently needed, masters can manage with simple profiles, making them arched.

There are quite a number of different additional nodes, a few dozen, it is impossible to list them all.

The quality standard can be called the products of the German company Knauf, in fact, this name has long become a household name. All the variety of guides are produced by this corporation, as well as drywall.

It is also very often used the necessary parts, without which there can not be a full mounting: suspensions, extension cords.

Connector "crab" allows you to attach all kinds of profiles. Usually used for mounting ceilings.Two-level connectors fix the PP strip at an angle of 90 degrees, you can also create several levels. Mounts are made with dowels and screws. All of the above components and parts allow you to create a plasterboard coating of any degree of complexity.

Installation

Installation of gypsum cardboard is quite affordable even for a person who is far from construction and repair.

These are simple works, such as:

- wall leveling;

- creating bulkheads.

They really create their own hands.

Drywall as a wall finishing material is very effective, it is also possible to create various multi-level coatings from it.

Alignment using drywall is done in two ways:

- Drywall mounted on the crate;

- Sheets of drywall are fixed on the wall.

It is very important in the installation process to comply with technology. Also, in order for everything to be done correctly, you must prepare the appropriate tools and study the installation manual.

Tips

When finishing walls the length of sheets is considered taking into account the height of the room. Joints need to leave a minimum amount. In our country, the most widely used moisture resistant GCR, as well as - standard.

The wooden frame is used in extreme cases, the wood is deformed, so it is also likely that the deformation of the coating will occur.

For successful installation, you must have in stock a special glue of the “Perflix” type, as well as a special “Fugenfuler” putty. Internal guides should be as close as possible to the labels, this will allow to preserve the volume of the room as much as possible.

When mounting the rails should take into account what will be insulation.

Between the floor and the plasterboard, a gasket must be put no thinner than eight millimeters. After installation, the remaining gap is filled with moisture-resistant sealant.

Screws are placed at a distance of not less than 20 cm from each other, a distance from the edge of not less than 10 cm. The primer of the joints is made with a special primer (typhoid).

You can find out how to make a plasterboard ceiling with your own hands from the video below.