The frame of the profile for drywall: the pros and cons

Today, drywall is widespread. It is often used for finishing work in the room. Due to its versatility, structures made of this material allow not only to level the walls and ceiling, but also make it possible to create any form of arches and partitions. Frame - the basis of design. Therefore, it is important to know what types of frame from the profile for drywall are and what are the main pros and cons.

Special features

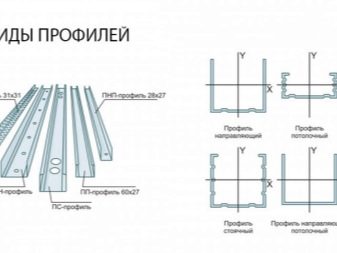

It is worth getting acquainted with the features of profiles in more detail. One of the main profiles is abutting or guiding. It has its own designation - Mon. Its shape resembles the letter P. Main dimensions: 40 * 50 * 55, 40 * 65 * 55, 40 * 75 * 55, 40 * 100 * 55. Installed such profiles on the perimeter of the whole structure.

The guide profile fixes the rack. It is basic, and the appearance of the rest of the building will depend on its installation. The main purpose of the abutting profile is to create the skeleton of a new surface for sheathing. This profile is mounted on the entire area of the main frame. The first indicator of the strength of the profiles is the volume of the metal used in the manufacture: the higher the thickness of the steel, the stronger the profile.

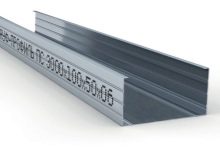

The carrier profile is used for the final construction of the frame device, it carries the main weight, so drywall is attached to it. He is also responsible for the strength of the frame. It is made of metal of different thickness. If the metal is too thin, more fasteners are needed. The size of the profile is usually 60 * 25 * 3000 or 60 * 25 * 4000 mm.

Installation on the corners of the stairs for the steps is carried out using a profile with a slide, which consists of aluminum. This profile serves as an anti-slip element and provides additional security.

A rack or galvanized profile is used to create frames, arches and other surfaces that have a bend. A ceiling guide profile is also important in installation.Its size is 27 * 60.

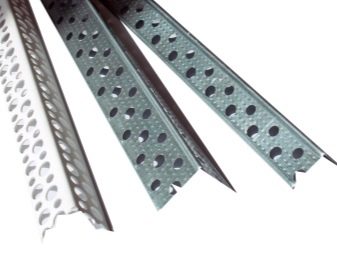

You can use other profiles, for example, angular, to create smooth corners. It is designated by the abbreviation PU. This profile makes the frame more robust, prevents the effects of external factors, facilitates the application of plaster in the corners. The main dimensions are 31 * 31, and 25 * 25 and 35 * 35 are less common.

Profile to create arches with a bend - arched, has a wide distribution. It is often weakened and has a large number of cuts and holes. The main dimensions are 60 * 27. Denoted as PA. Due to its flexibility, it creates absolutely any complex structure. Do not exceed the bend radius by more than 50 cm, as there is a risk of structural failure.

It is subdivided, as a rule, into two types:

- convex;

- concave.

The connector fastens the profiles perpendicular to each other, and the extension cords together different lengths.

Profiles for creating partitions, unlike other profiles, are large.

Advantages and disadvantages

The profile has pros and cons, which have an impact on the future project of the premises.

Let's start with the benefits of using a profile.

- There are no flaws in appearance.They have an even shape, unlike a timber, which must be well prepared (leveled) before use.

- The profile is not deformed due to the presence of moisture or temperature changes. It always keeps its shape, and as for wood, on the contrary, it changes shape, for example, from moisture.

- Long service life of the metal. Timber has no such advantage, as it is unstable to external influences.

- It is a durable material.

- Easy to purchase.

- No prior leveling of the walls is required.

- Use of galvanized steel is possible.

- Easy to replace or restore damaged profile.

- Non-flammable, resistant to fire, when using special drywall, fire safety is increased.

Disadvantages.

- the first and most important disadvantage is the high price compared to the same wood;

- it is easy to tear out fasteners due to the small number of threads;

- material may corrode.

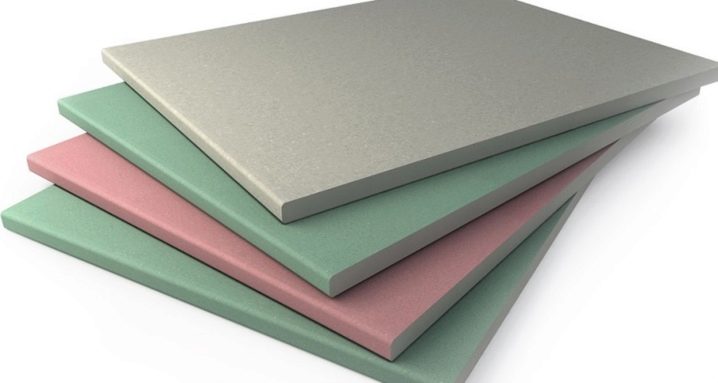

GKL is a material used in construction, which is very well-known, it is often used in various fields, it helps to build not only large elements, but also small extensions, with its help the wall surface in the house can be easily and quickly leveled out; certain shapes.

Benefits.

- Available. Drywall can be bought in all hardware stores at an affordable price.

- Easy There are differences in thickness and low weight. For ceiling structures there are lighter options - it helps a lot in work.

- Easy installation. The seams are fixed with screws to the frame or on glue. In this regard, you can install them yourself.

- Other It withstands loads of various types, thanks to which it has a long service life.

- Wide scope of application. It is used not only in designs, but also in a decor.

- Just handle. It is easy to work with him, he has the ability to create any form.

- It makes it possible to mount the LED strip in any way, as well as built-in lights.

Kinds

Consider the main types of frames on the example of ceilings.

Single level

This ceiling can be part of the interior or be the basis for other ceilings: complex, having many levels. The creation of this design is not difficult, the main thing is to secure the profile to the base. The final stage - the installation of sheets on the profile.

It is important to use additional measuring tools, observe the horizon and take care in advance of installing various communications and electrical wiring.Under the light, you need to leave a space with a margin of 10-15 cm, so it will be easier to connect it.

The main advantages of a single-level type:

- preservation of the appearance of the coated surface, despite the changes in the foundation and its subsidence;

- slight changes in the height of the room used;

- hides the flaws of the ceiling, makes it possible to hide the wiring;

- protection from the noise of neighbors living on the floor above.

Multilevel

These types are usually attached at the expense of concrete slabs or ceiling, consisting of one level. Then each is attached to the previous level. It is important that they are well combined with each other.

The main advantages of two or more levels:

- visualization of space, the ability to create the illusion of increasing or decreasing the room;

- the creation of the original author's ceiling;

- functional zoning of space;

- looks good in rooms with a height of more than three meters.

Non-standard and more complex designs are similar to single-level and multi-level varieties, differ in more complex structure, retain the ability to create unusual shapes.

The main advantages of non-standard and more complex structures:

- uniqueness of the design style;

- the possibility of replacing individual structural elements.

Instruments

The installation of the batten should be carried out after purchasing special tools and materials.

The main tools are the following:

- ruler;

- hammer;

- pencil;

- dowels;

- roulette;

- perforator;

- plumb with a load;

- self-tapping screws;

- building level;

- screwdriver;

- connectors both crosswise and straight;

- suspensions;

- metal profile.

Materials

When making the metal frame, guides are required, as well as steel elements. Sheets can not be fixed without the use of a special fastening, which will serve as the base. Basically, they are screwed to the crate or fixed with glue. For gluing, as a rule, nothing is needed except glue. Another thing is the creation of high-grade crates. For this purpose, various profiles and connecting elements are used, without which no installation of a complex structure is possible.

Main types of fasteners:

- wooden beam;

- metallic profile.

The use of wooden timber in the construction of the structure has a number of features. This material is popular, but before installing it the timber must be processed. Metal profile is the most convenient material for building structures. Instead of profiles, many other details are used when constructing a drywall frame. They are needed to connect the main frame with the main plane.

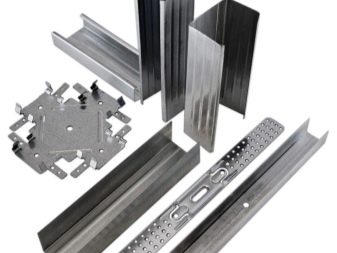

The holder is a metal perforated sheet. Its main purpose is to fasten the participating walls and the ceiling with a profile frame. The center of the bracket is attached to the sheathed plane, and the ends are fixed to the basic profile with screws.

Swivel suspension is the opposite solution to the bracket. In a situation if the usual size of the holder is not enough to install the frame, it is replaced with a swivel suspension. It is divided into two parts: the suspension and the profile, which are fastened to each other with the help of a spring. During installation itself, the location of this part relative to the location of the horizon is easily changed with the help of a spring. It is considered a defect that the spring becomes weaker over time, as a result the ceiling sags. When installing the walls it is not used.

The CD merger makes the profiles longer.Installation begins with it.

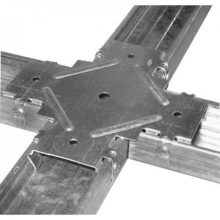

The ceiling cruciform bracket (crab) is used when mounting jumpers among the abutting main profiles with a cross connection. Crab is fixed to the profile, and then attached with screws. As for the lintel, it is placed in a similar way: it is fixed in two ceiling cross-shaped brackets. They are on other major profiles. More often for this part use about 7-8 screws.

The connector of two levels is used quite rarely., it is often needed only in one situation: for assembling a skeleton, when the holder has a moving base, for example, an overlap of wood. First, set the first level of the CD connector, which remains active, then a different level of profiles. It is positioned as a normal base, then fastened using two presented connectors. This rather complicated fixture exists in order to remove differences in the size of the tree due to temperature changes and humidity.

Subtleties of installation

Before you install the drywall on the profile, you need to collect a technically correct crate, which in the future it will be mounted. This material is quite simple, but often it is in the construction of the structure that difficulties arise.The frame is the basis, without it, the construction will be impossible, so you need to set the frame exactly.

This design must be depicted on paper in the form of a drawing.to have an idea what and where will be built. As for the frame, it is important to understand where it will be located. The frame can be mounted on walls or ceiling. Since such a frame makes it possible to correct the surface and make it flat, it is often used to use it.

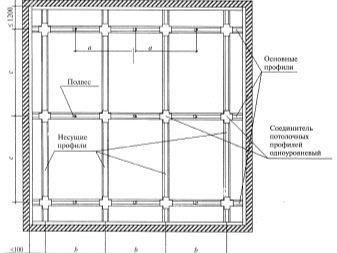

If the frame will be mounted on the walls and ceiling, you must start from the ceiling.

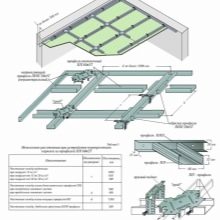

The markup is done using a tape measure in the lowest place. It is important to consider that the wiring is carried out in advance. Next is the installation of profiles on the ceiling: the supporting profile must be set horizontally. To extend the metal profile to the required length, use a conventional connector. To fix the places where the profile intersects, you need a kind of crab. When leveling the ceiling, a two-level crab is used for good fixing of the lower level profile to the ceiling profile. When using anchor suspension with a lack of length of other suspensions, for example, direct, it can be increased.

It is extremely rare for a room to have perfectly even corners. In such situations, after leveling the walls, gypsum sheets on the ceiling are very difficult to adjust to the required parameters. If you start working from the ceiling, there will be no gaps. Ease of use of profiles is that they can be docked with a small overlap.

Suspensions are fixed for mounting fasteners on screws and dowels, the distance of steps is about 60 centimeters.

The next step will be the installation of guides along the entire perimeter of this room with the help of threads fixed to the profile.

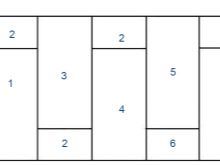

Conventionally, we divide the ceiling into identical squares, approximately 0.5 * 0.5 m. Further, the bearing parts are located. On the fixed threads they are connected to the main profiles and fixed with screws. Connectors crabs mounted on the mounting crosswise. When the installation of the frame on the ceiling is complete, you can go to the walls. In general, the profile installation technique is similar.

It is necessary to measure the distance that will fit the width of the sheet. Next is the label where the profile will be located. Begin with the installation of guides around the perimeter of the wall. This is done using threads.The only thing worth considering is that the distance will be more than 60 centimeters than on the ceiling. The Bulgarian cut transverse lintels with a length of about 60 cm and also they are fastened with screws. A control profile is installed in the control profile and fixed to the walls. You can use a step of 0.6 m. For sale are pre-prepared profiles with holes, they are perfect for beginners. Bearing profiles must be connected to hangers. In the future, set transverse with an interval of about 60 cm.

When all the work is completed, go to the stage of installation of drywall sheets with screws. The main thing - to deepen the sheet cap no more than 4 mm, the distance between the screws - about 10-30 cm. Sheets are fixed along the entire perimeter of the profile from top to bottom. It is important for the mobility of the structure to make a gap of 1 cm between the sheet and the floor, and 0.5 cm between the ceiling. The seams close closer to the floor, the gaps are hidden by the plinth.

After mounting the ceiling, the walls are puttyed. At the beginning, a reinforcing mesh is used, the seams at the joints are closed to it, and then the entire wall is putted. For various openings, such as window, door, arched, other additional profiles are used.

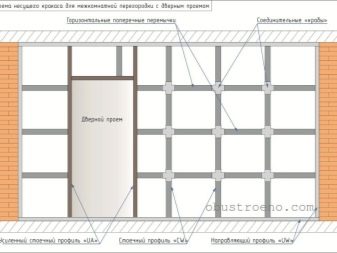

How to make a doorway?

A doorway is built, as a rule, with the help of several types of structures. Sometimes it is necessary to change the dimensions of the opening itself, for example, reducing the width or height. Additionally, there are two types of profiles: rack and starting, they differ in basic functions.

The first rule is to determine the size. If it is necessary to slightly move the doorway, it is recommended to install an additional stand on the side of the wall, a vertical element is fastened along the edges of the opening, which is screwed with self-tapping screws.

Wall profiles are required to reduce height., they will serve as the main support. Drywall after mounting profiles cut into the main sheets, as long as its edges are located in the middle of the profile. Mounted with screws.

Create an arch with metal profiles. In order to do this work with their own hands, the materials must be given an unusual shape.

These materials can create an arched structure of any complexity: ellipse, non-standard or asymmetrical, straight portal, round extended arch. Profiles need to be bent according to the project's idea.Profiles are notched with special scissors for metal, and in order to bend the drywall and give it a predetermined shape, it is passed through with a needle roller and slightly moistened with water, then the position is fixed.

If the shape of the doorway needs to be slightly corrected, the wall is covered with a layer of plaster. When it is necessary to level a large area, it is better to use drywall. The main thing is to measure the main dimensions for drywall and fix it inside the opening and on the slopes. Various defects are then hidden with the help of plaster, special profiles are used in the corners, for example, an angular profile.

For the final stage of finishing using the paint grid and putty.

You can divide the entire work into several stages.

- Primer. The entire working area is covered with primer and dried.

- Removal of various defects. The seams and screwing points of the screws are sealed with a serpyanka so that the transition from the construction to the wall is imperceptible.

- Alignment of the overall layer. It is necessary to wipe the putty after it is completely dry, then apply a second layer.

- Creating boxes and other items using the profile. The box well hides various wires and pipes, which can be closed in two ways:

- only pipes;

- in the whole wall.

If you want to close only the pipe, the process does not take much time. This is done quite simply and does not require special financial costs. In the second case, the entire plane is closed, but it can be used by creating shelves for storage at this place.

If the pipes are in the corner, the box will have only two faces, if the riser is in the middle, then three faces. It is important to create a drawing with all kinds of connections. This will help calculate the required material. The gap between the structure and the pipes should be about 30 mm.

The next stage is markup. First you need to find the most convex places of the pipes, which will create the border of the new design. Then we mark them: from the main mark on the ceiling we draw lines perpendicular to the walls. From the main mark we lower the plumb line, this will help to find the main mark on the floor. From this label lay the transverse lines to the walls. Next, we connect all the lines along the walls and get a straight line, and a rack profile will be installed on it.

Next, you need to install the baskets. With the help of a drill, we make holes, where further, using a hammer, we place plastic rods. With the help of bolts, we attach this profile to the wall, and fix the control profile to the ceiling or walls. We start with the installation of the front side of the box, which is located at the junction of the abutting profiles on the ceiling and the floor. Everything is fixed, as a rule, with the help of screws, then plasterboard sheets are installed. It is important to place the connections on the same line, forming one common surface for the edges of the structure, otherwise there will be distortions.

Making the installation of drywall on the structure, first we cut the sheets on the sides, mark the correct size of the side that remains, and cut off the strip so that it fits in with the rest. The sheet is attached to the metal profile with screws to the main posts. Do not forget about such a hole as the hatch.

As this construction will be finished, you can putty it. As for materials for finishing, you can use any material.

The convenience of drywall designs also lies in the factthat with their help, you can create different partitions, thereby zone the space and separate the work area from the rest area.

Important nuances

The basic rules that must be observed when constructing a structure:

- before facing the cardboard, it is important to arrange the electrical cable and all plumbing pipes;

- the construction must be fairly stable and rigid in order to withstand absolutely any load;

- slabs GK fastened in height staggered;

- all subsequent sheets are connected in the center of the profile.

Before laying drywall, it is necessary to fasten the entire crate with self-tapping screws. Particular attention should be paid to the corners and their preparation. It is necessary to take into account when calculating that for the strength of structures it is necessary to set the angle and sheathe it with drywall with a minimum pitch of 30 cm.

It is worth paying attention to the durability of the material and use only high quality raw materials. When marking the framework for both the walls and the ceiling, one condition must be taken into account: all joints of the gypsum plasterboard must be on the profile. With the recommendations we can saythat this framework from a profile - the excellent decision for finishing repair work. Thanks to its multitasking, the framework can help to embody absolutely any idea.

Tips and tricks

It is necessary to properly observe the technology of construction work, the quality of repair depends on it. Builders and people who do these jobs on their own often make technological mistakes, trying to reduce work time or save on goods in the store.

Let us dwell on the main mistakes that should be avoided in the manufacture of structures.

- Incorrect calculation of the length of profiles. If it is produced incorrectly, this construction will be constructed with errors.

- Errors in the installation of the framework. If you do not follow the technique of using the profile, you can use profiles that are not intended, you can allow very gross errors in the work.

- When fixing the ceiling materials, it is imperative to use suspensions: the smooth side should be located downwards, it is the base to which the drywall is screwed.

- Invalid cutting. You can not use the grinder, it contributes to the burning of galvanized, which further lead to corrosion.For this fit special scissors for cutting metal. They are of two types: manual and electric.

- The use of the profile for its intended purpose in the design. For example, if you use a ceiling profile to build partitions. In this case, it is correct to apply the profile abutting.

- Lack of suspensions when building a ceiling more than two levels. This will lead to the formation of cracks around the perimeter of the ceiling. If you comply with the technology, then the bearing profile will be fixed from the walls used in length of about 10 cm. Be sure to use suspensions in the suspended ceiling.

- Fixing the sheet with the wrong side. For example, if you use GKLV (protects from moisture) incorrectly, then this will affect its positive properties, which will not be able to manifest itself due to improper installation.

- Incorrect connection GCR. It is not recommended to use small pieces of sheets. The main thing - to fix large sheets to prevent the destruction of the material.

- It is necessary to exclude the use of special profiles for the corners in order to protect the corners from moisture and external damage. It is recommended to use an external profile here.

It is worth noting that before repairing it is necessary once again to study the surface where the structure will be installed, to determine the type of future project from the metal profile and to make the drawing correctly. It is also important to understand the types of profiles and their attachment.

How to make a frame from the profile, see the following video.