How to choose a dowel for drywall?

In modern construction there are many ways to fasten elements and structures to each other. For fixing heavy parts was invented dowel. For each material has its own dowels. So, for hollow drywall can not use items that are suitable for a concrete base.

Special features

Speaking of working with drywall, it is impossible to forget about the main fastener - dowel. A photo frame or a small picture can be hung on a freshly created plasterboard partition with a screw or screw, but if you decide to attach something heavy to it that requires additional load, such as a TV on a rotating mount or a wall cabinet, you need to use special fasteners.Thanks to this small element, the drywall sheet will not be deformed, its core will not collapse, and the suspended object will remain motionless in its place. For different types of dowels - different permissible load.

The construction market offers many options for dowels. They may vary in diameter and length. There are rules that are governed by GOST 28457-90. It is he who determines that the dowel should be a structure designed to install the screw.

Unlike other fasteners fasteners, which are intended for drywall, made of high quality metal or plastic and have a guaranteed fixation of the product to the gypsum board. For full fixation, fasteners are equipped with a very important element - a sleeve, which can be folded only in complete emptiness. In any other conditions the sleeve will not work.

For durable fixing of an element to drywall, you need to know the load that this fastener can withstand. To clarify this information it is necessary to know only the diameter and length of the fastener.

In "home conditions" there are usually three types of load: horizontal, vertical, dynamic.

- Horizontal load characteristic of shelves, paintings. Fasteners are chosen according to the weight of the product (6-10 mm) and the base material (30-50 mm for drywall).

- Vertical load appears when installing a chandelier or air conditioner. With a screw diameter of 6 mm, the fastener must enter the wall at least 40 mm, and into the ceiling at least 60 mm.

- Dynamic the load occurs, for example, when attaching a ladder, gymnastic rings, “pears” or other sports equipment. In this case, vibration proof fasteners are needed.

Sometimes for better grip, the dowel is pre-lubricated with glue.

There are some features of dowels that must be considered when choosing them:

- dowels of the same type, but made of different materials, for example: plastic or metal, differ only in the weight that they can withstand;

- For fastening on sheet material, the correct type of fastener must be selected, in which the sleeve is pressed tightly against the sheet.

How to use?

There is a classification of dowels according to various criteria.

According to the method of fixing emit dowels:

- fixed to the surface due to friction force;

- having various forms of dowels and bases.

Screw the dowel into the wall in two ways: by preliminary or through installation.

In case of preliminary installation, it is necessary to drill a hole in the wall with a larger diameter drill bit, then install the dowel (expansion, nail, universal) and fix the necessary part with a screw. With this method, for example, you can attach a shelf or a TV bracket for your own hands. For installation of plastic dowels in the package a special bit-nozzle is offered.

When applying through installation, there is no need to drill the base: fixing with its non-indispensable part must go through the “void” section. Usually, this method is used when attaching facades, roofs, insulation.

By the method of installation distinguish dowels:

- hammered with a hammer;

- screwed with a special construction gun.

For the production of dowels used various materials.

- Plastics, including polypropylene or nylon.

- Polyethylene. Light enough material resistant to acids. Well preserved during deformation. Plus the material is that it is anti-corrosion. Withstands temperatures up to -40 C. Minus: the appearance of cracks.

- Polypropylene. Unlike polyethylene, it has greater strength and wear resistance. Maintains temperatures up to +140 C, but still loses the integrity of the body.

- Polyamide or nylon. Resistant material, which is characterized by a special vibration resistance, practically does not wear out and is insensitive to mechanical damage. That is why nylon is considered the most reliable material. Minus: prohibited installation in a room with high humidity.

- Metal, including aluminum and stainless steel. Not deformed, has a higher wear resistance and carrying force. If the metal from which the dowel is made, is only galvanized - susceptible to corrosion. Brass or titanium alloy fasteners are very expensive, and therefore are used only in highly hazardous areas.

Drywall - a fragile material, hollow, belonging to the category of soft. When drilling it is necessary to act carefully. You cannot use the punch mode - it can damage the integrity of the sheet.

Types and characteristics

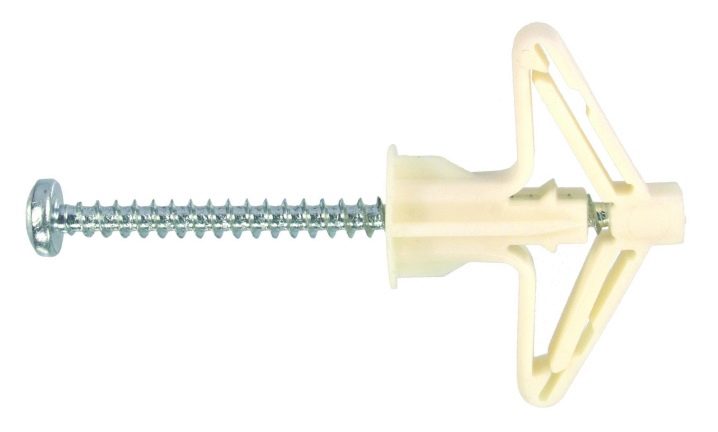

Butterfly

The fastener butterfly is made of metal or polypropylene and has two wings that are “flattened” in opposite directions, which prevent the screw from turning.It is used to fix items with low weight: paintings, lamps. Disposable - reuse is not possible. It is possible to dismantle the item.

To install the dowel butterflies, press the side elements to the center. and gently hammer them into a drywall sheet with a hammer. When the dowel is installed, the wings “flatten out” on the other side of the gypsum board, evenly distributing the weight of the suspended element over the surface. After that, you can tighten the screw.

Standard sizes of such an anchor are 8/28 and 10/50. For the first option, a screw is suitable for 3.5 / 35 mm, for the second - 3.5 / 55mm. Butterfly size 10/50 mm can withstand up to 24 kg. For full disclosure, you will need a screw that has a length of no more than 55 mm.

Made of plastic. Sold in folded form.

Umbrella

Designed for heavier objects: due to its shape, it is suitable for fixing a chandelier on a gypsum plasterboard. Unable to dismantle.

When mounted, it looks like an ordinary umbrella. Insert the closed dowel into the drilled hole. Thanks to the built-in spring reaching free space, it is revealed inside the GCR.

Able to withstand up to 35 kg.

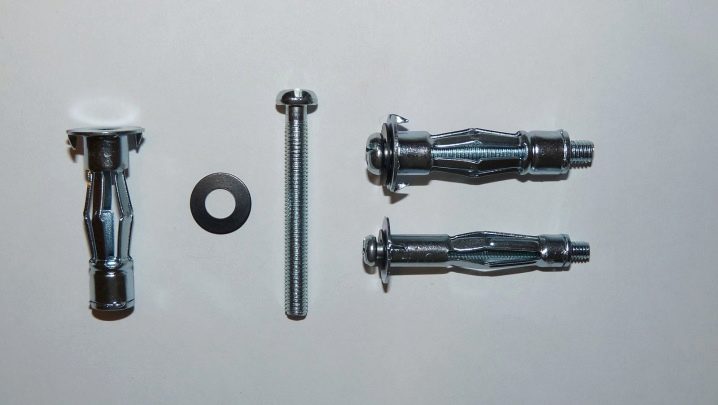

Molly

One of the expensive options for dowels, which belongs to the category of "expanding". Suitable not only for drywall, but also for suspended ceilings. When installing the dowel clamps the drywall sheet between the front and back parts. This dowel can withstand up to 35 kg. There is the possibility of dismantling.

Its advantage lies in the fact that there is no need for self-tapping screws: All necessary parts are included. For fixation, it is necessary to drill a hole of 8 mm in size, insert a dowel and press down its side so that both teeth close in the gypsum board. Then you just need to screw in the top element of the dowel so that the back end is pressed tightly against the sheet.

It is made only from metal.

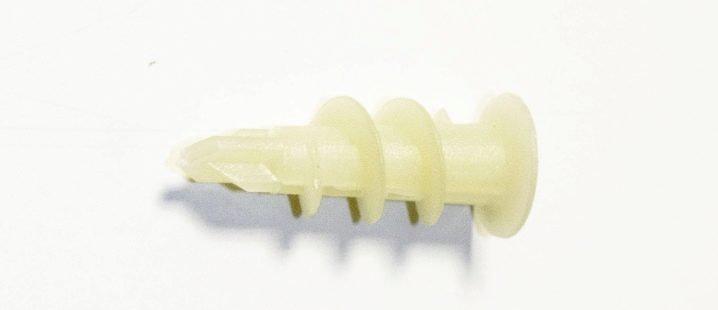

Driva

The easiest to use, so ideal for beginners who are just starting to get acquainted with such material as drywall. Driva in appearance resembles a snail and is screwed with a conventional screwdriver until it stops. To facilitate screwing in, it is possible, but not necessary, to drill a 6 mm hole. Due to the tight screwing into the core of the sheet, it can withstand loads up to 25 kg. For the driva dowel, it is necessary to choose the correct screw length, which will later also be screwed into the dowel with a screwdriver.Such a bolt, falling into the void, is twisted into a knot, allowing to hang on it something similar in weight to the kitchen cupboard.

It can be both metal and nylon.

Legs

This fastener is made of metal. It has two pointed ends with triangular plates, which are called legs in professional language. The set includes a screw.

Dowel nail

The second name of this element is DBM (dowel of quick installation). Does not require special skills and extra effort for installation. It has no screw part. Does not assume the subsequent dismantle. The dowel is inserted into the hole corresponding to its size, and then driven in with a nail until it stops. Let's apply to eaves and plinths. Reliable due to the fact that during the installation extends in three directions at once.

Nails are divided into two subspecies: with a cap in the form of a fungus and a secret cap. They differ in the height of the board. Dowel with fungus reliably presses the elements. Using the example of mounting heavy skirtings, it can be proved that a hidden cap will not provide the necessary fixing of the dowel.

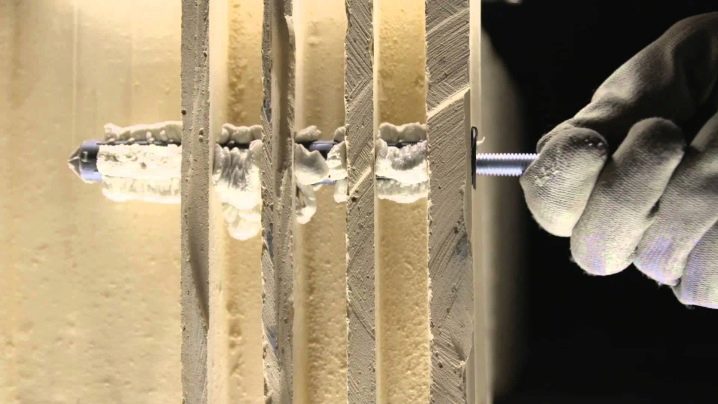

Chemical anchor

It is a capsule with adhesive liquid.The complex has a mesh sleeve that allows the element to be fastened even to a non-professional.

Double Drywall Plug

For double drywall use special fixings. They have a tip-drill, which allows you to freely twist it into a double sheet.

In addition to these, there is also a self-installing dowel, strips and other types.

Manufacturers

The construction market also offers drywall dowels, named after the maker firms.

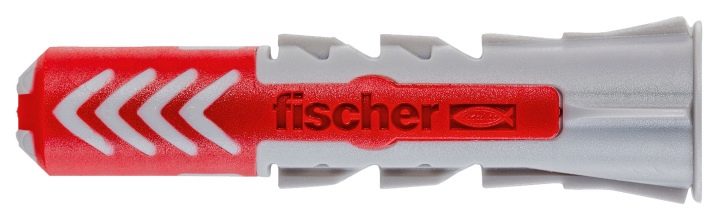

Fischer PD and PDS

Nylon plug rounded shape. Longitudinal ribs do not allow turning. During the tightening of the screw, its tapered shank enters the plastic sleeve, causing the wings to open. Maintains up to 15 kg.

Knauf-Hartmut (Knauf-yomut)

Sensation in the field of fasteners. Such a dowel in the wall can withstand up to 55 kg, in the ceiling - up to 6 kg. The set of such an anchor consists of a metal U-shaped bar, a locking sleeve, and two plastic guides.

For installation it is necessary to drill a hole of at least 13 mm, enter the bar and align the guides. Then insert the plastic sleeve through both guides all the way,then dissolve them in different directions and remove. Thus, in the drywall, the strap is securely fixed into which the screw from the kit is subsequently screwed.

Walraven BIS GOLD

Such a driving dowel is suitable for small and medium loads for screws with a diameter of 3.5 - 5.0 mm and a minimum length of 30 mm. The name of the fastener speaks for itself: you only need a hammer for installation. During the hammering into the wall, the dowel self-wedges and does not roll.

There are other manufacturers of dowels for drywall, for example: TOX and KEW (Germany), HILTI (Liechtenstein), SORMAT (Finland).

To save on the cost of dowels, most often they are purchased in bulk in China. Despite the quality, some branded dowels will vary greatly.

Be sure to find out the country of manufacture of the mount from the seller, because security depends on it.

Tips

- Before starting work, it is necessary to find out the characteristics of drywall and determine the structure and weight of the attached element.

- Based on the characteristics of the dowels, choose the one that is suitable for your particular situation.

- In addition to the characteristics of the dowel itself, it is necessary to choose the right screw: it should not deform or break the dowel inside the sheet.

- Objects weighing up to 5 kg (paintings, photo frames) can be attached to the gypsum board and without dowels - on the screw, while paying attention to preserving the integrity of the sheet.

- Be sure to control the twisting force - you can pierce through the plasterboard.

- Drill the sheet with a conventional drill bit of smaller diameter. This way you will avoid a bias when screwing in the dowels.

- It is necessary to correctly calculate the weight of one dowel and not exceed this value. On average, it is believed that the load on the attachments should not exceed 50 kg per 1 m2.

- If the drywall is lined with tiles or tiles - use a special tip and drill a hole equal to the diameter of the dowel.

- The length of the hole in the drywall should exceed the size of the screw by 5 mm.

- Be sure to clean the hole from dust and crumbs. You can do this with a regular vacuum cleaner.

- It is best to use a metal profile for fixing elements to a plasterboard ceiling. Find it on the back of the sheet will help ordinary magnet.

If for some reason you do not know which base material is in front of you, then you can check this by test drilling.If a small fraction of dust, similar to dust, begins to pour out of the hole, be sure that you are dealing with drywall.

For information on how to choose a drywall dowel, see the following video.