Heating manifolds: variations and installation rules

The most important condition for the proper functioning of the heating system is full heating of all rooms in the house. It is much easier to divert water from one boiler to different rooms than to install a new boiler in each one. It is for the distribution of heat and serves as a collector, with which you can also control the temperature.

Device and purpose

The collector is a volumetric comb.

It works like this:

- water flows in;

- through special exits it is carried through the pipes.

Similarly, the collector works, collecting chilled water from several pipes into one and then redirecting it to a common boiler. It is possible to connect different heating devices to such group in collection,regardless of their technical parameters.

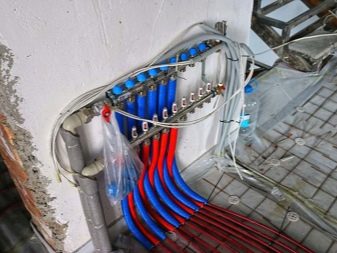

The size of the distribution manifold depends on the number of circuits - the pipes joining it. In the overwhelming majority of cases, the largest number of circuits is 12. The collector then consists not of one comb, but of two — 6 contours each. If it is necessary to obtain a larger number of contours or a single, rather than a double comb, some manufacturers are engaged in the manufacture of custom-made collectors.

Principle of operation

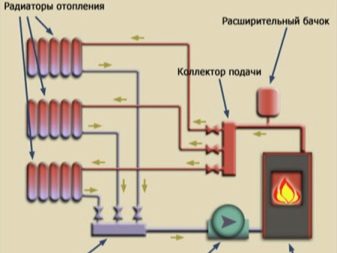

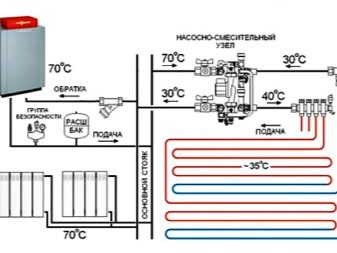

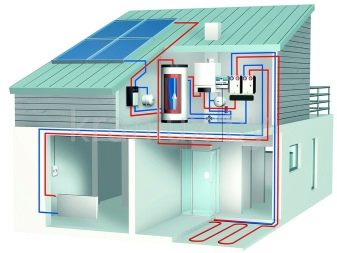

The heating unit can be connected to both classical radiators and “warm floors”. The difference will be only in the location of the collector, and not in the principle of operation. So, in any case, the collector system serves to distribute the flow of water to all heating devices, and this is achieved by a kind of collector structure and connecting pipes to it later.

An important limitation is the need to maintain the temperature. It should not change significantly, falling into the pipe. For example, a temperature of 40–50 degrees would be sufficient for a “warm floor” system, and 70–80 degrees for radiators.The collector must be designed for a temperature not lower than the appropriate one. When connected simultaneously to both the radiator and the “warm floors”, it should be possible to dilute the hot water with cold water or otherwise lower the temperature below without affecting the total flow.

Merits

The collector method has its fans both among professionals and among ordinary people.

This is due to the positive features that this method of heating guarantees.

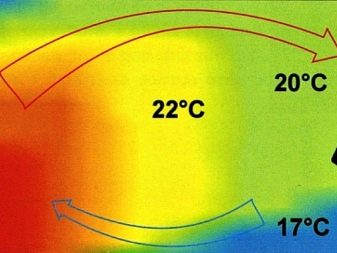

- Heat spreads evenly. A priori, it is assumed that the temperature, while entering the pipes from the collector, does not fall. In this connection, uniform heating and maintenance of temperature is achieved in all devices connected to the system. At the same time there is always an opportunity to lower the temperature, if necessary.

- Ability to customize. If you wish, you can not only regulate the temperature, but also completely disable any of the branches. For example, if one of the rooms does not need heating, then you can simply turn off the radiator, thereby preventing idle heat release. This is especially convenient if you live in a big house, for example, in a 3-storey mansion, and do not always use all the rooms. Adjustment is carried out from the collector cabinet.

- Easy to repair.If any of the parts of the system fails, you will not have to shut down the entire system (this is not a breakdown of the collector itself). It will be enough to cut off the heat supply to the damaged branch.

- Aesthetic appeal. Connecting the collector, you get the opportunity to place the pipes anywhere, and not just above the radiator. Many use this circumstance and make the pipes hidden, hiding them under the baseboard or behind the false wall.

disadvantages

In addition to all the listed advantages, hydrocollector has disadvantages.

- High price. Even choosing a model from a non-eminent manufacturer, you still spend a lot of money, since thermal collectors are made of high-strength steel. Installation of ordinary pipes is much cheaper. But it is also worth remembering that it will be necessary to purchase additional fittings, which is also quite expensive.

- A prerequisite - the presence of a circular pump. Any collector systems work only with him. This greatly increases the cost of electricity.

- A large number of pipes. The collector system implies the presence of branches for each heater.Consequently, the number of pipes will increase according to the number of heating devices. For many, it is difficult to install such a system, not to mention the fact that it is quite time-consuming exercise.

All these nuances are a reasonable reason to think about the reasonableness of installing a collector for heating, especially when it comes to an apartment building.

Kinds

To date, there is a large selection of various collectors. They differ not only in technical features, but also in the type of layout and materials. Each modern unit is equipped with an air vent designed to release air bubbles, due to which the heating efficiency is greatly reduced.

According to technical characteristics, thermal collectors are divided into five types, and some of them are suitable only for installation by specialists. It is necessary to take this fact into account before choosing one of the varieties. And you also need to remember that there are possible combined options that combine two or more types. In this case, we are talking about hydraulic systems.

Solar

Interestingly, solar collectors, which allow to save considerable funds on electricity, work not only on fine clear days, but also on inclement, overcast ones. Under the open sun, they can heat up to 80-90 degrees - a temperature almost equal to the temperature of the supply boiler.

With proper skill, the solar collector can be made independently, armed with tools and materials. To purchase ready-made models working from solar heat, are offered extremely rarely. None of the famous companies in the arsenal of such models do not.

Such collectors are vacuum.

Heat transfer occurs not through water, but with the help of antifreeze.

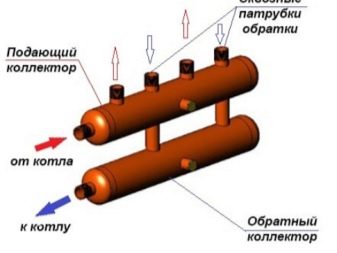

Hydro Arrow

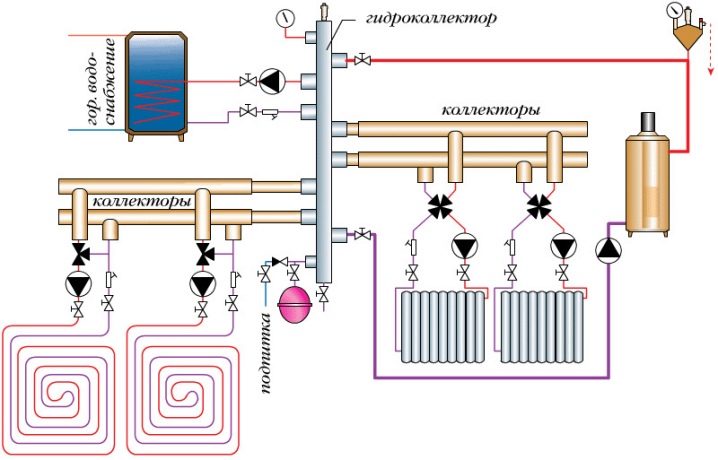

When talking about reservoirs with a hydraulic switch, they mean flow distributor. Such additions are needed if a large number of branches and contours are implied. Mostly such situations are found on large objects.

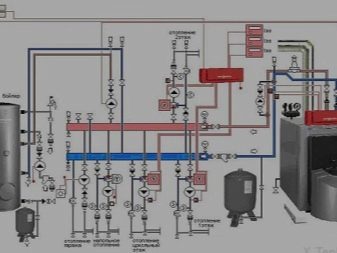

A hydraulic shooter, also called a hydraulic separator, is needed to balance the entire system. With its help, it turns out to equalize the pressure and temperature, thereby ensuring a suitable temperature between flow and return.With the help of the hydraulic needle it is even possible to mix the flows, if necessary.

It is not rational to use a hydraulic separator in simple systems. It is needed only for complex ones. If we are talking about factory collectors of this type, they are additionally supplied with a special branch for debris and air, thereby increasing the efficiency of the entire heating system.

Distributive

Actually, each of the described collectors, which serves to distribute water flows, is a distribution one. This is a generic name for everyone, but you can often see the “distribution manifold” as a separate species.

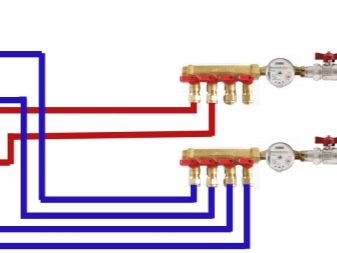

There are two combs here. One is connected to the boiler or other heat source, and the second one is fed back. It should be noted that the connection scheme here is parallel, not sequential, so that the temperature change in one of the branches does not affect the temperature in the others.

Coplanar collector is also a subspecies of the distribution, however, coplanarity is achieved simply by installing two independent units next to each other.

Simple

Simple systems do not have additional controls or adjustments. In the most primitive version, you can imagine a simple system on the example of a tube with several openings-branches. There is no way to monitor the temperature, but if necessary, it will be possible to completely disable each of the branches.

Enhanced

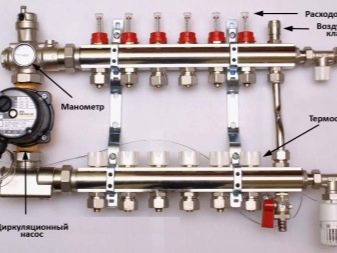

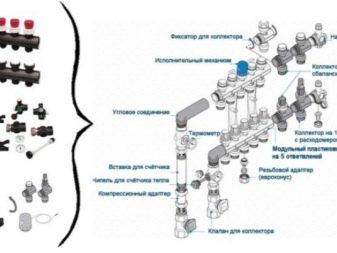

Such systems are fully equipped with everything necessary: a temperature and pressure regulator, automatic sensors, additional fittings.

If we talk about additional elements, the most popular are:

- sensors to monitor pressure and temperature;

- supply water control units;

- thermostats for automatic pressure adjustment;

- electronic valves and mixers for regulating the supply of cold and hot water, whereby it turns out to control the set temperature;

- air vent to release air bubbles from the pipes.

The collection of collector systems may vary, which affects the price and functionality.

Types of wiring

To begin with, it should be said that the collector wiring is already significantly different from all classical types.It guarantees the maintenance of the same temperature in all pipes, while there is no heat loss, and if necessary, the temperature can be artificially lowered, or even completely turned off the heating.

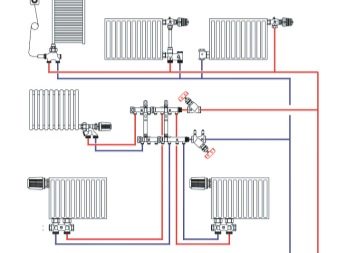

Radiator heating

In accordance with the architecture of the building you can lay pipes at the bottom or on top of the room. The most preferred option is to lay pipes from the bottom, since in this case you can hide them under the baseboard or under the floor.

Radiator heating of any type is the main source of heat in the house, in connection with which you need to remember about extreme temperatures. It is 90 degrees. In this case, the recommended temperature should be at least 70 degrees.

If a large area is being heated, it is additionally recommended to introduce a hydraulic needle. This is due to the need to adjust the pressure, because there are strong drops. Having equalized the pressure, it will be possible to prolong the service life of pipes many times.

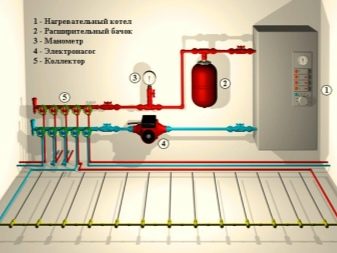

Below is a diagram of the radiator junction.

System "warm floor"

This type is almost never used as an independent source of heating, with which the temperature standards are associated.So, for a warm floor is acceptable if the temperature is 40-50 degrees. For full heating this, of course, is not enough, so be sure to establish radiator heating. However, both systems can be fed from the same collector.

There are a few limitations.

- The collector must be mixed or universal. Only such models are suitable in order to connect to them and "warm floor" and radiator.

- Be sure to have thermoregulation. In this case, it will turn out to set different temperatures for the floor and for the radiator.

In connection with the listed parameters, it is best to choose distribution manifolds.

Materials

Collectors are made from different materials, but what is important is that they all have high strength, whether it be brass or polymers. Each material is good in its own way and can be used in a particular field. Some materials have a limited range of use, for example, if they do not tolerate high temperatures.

To date, the most popular are brass, steel and polymer collectors. Let's get acquainted with each of the varieties.

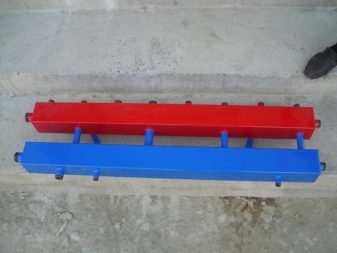

Steel

The collectors made of steel of increased durability are in great demand. This is due to the fact that steel is suitable for the manufacture of both central and local elements. Steel does not warp under the influence of high temperature. Special alloys are not subject to corrosion, as a result of which their service life increases significantly.

It should be borne in mind that steel products have their drawbacks. Many say that the price of such models is quite high due to the high material intensity and the unattractive cost of modernized steel.

There are more democratic options - from "stainless steel", but they are not suitable for the central collector, since the temperature here is much higher. When heated, these pipes are easy to deform.

Brass

Brass collectors are in demand along with steel. Even experts find it difficult to point out obvious differences between them, citing that the whole thing is only in appearance and cost. Indeed, according to the physical characteristics, brass is close to “stainless steel”, so there is no significant difference as to which collector to choose.

Like steel, brass is suitable for central and local assemblies, as it tolerates high temperatures and pressure perfectly. Still, it is preferable to use it specifically for the central hub, since brass collectors are expensive, and in the case of local variations this will prove to be an unreasonable waste of money.

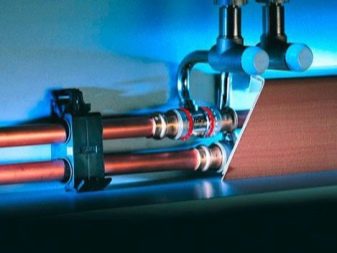

If we talk about metal options, then there are still copper counterparts. They are more expensive than others, although the characteristics are no different, and sometimes even slightly inferior to steel and brass collectors.

Polymers

The range of application of polymer systems is narrower than metal. Plastic models cannot withstand the high temperatures of the central site, so they can only be used for local variations. So, local collectors are connected to the central, and not to the boiler itself, therefore the temperature in them is slightly lower.

The rest of the polymers are not inferior to the metal. In terms of service life, they sometimes even outrun metal counterparts, not to mention hygienic. Now, most craftsmen are trying to use plastic collectors, since it is easier to work with them, they have less weight. It is also much easier to mount them, the main thing is to follow the connection rules.

Polymer pipes are not recommended to be used for connecting the “warm floor”.

Professionals recommend to give preference to the classic metal versions.

Tips for choosing

Before you choose any particular option, you need to pay attention to several important characteristics. They depend on the ease of installation, quality and service life of the collector.

Price

It is logical to conclude that a quality thing cannot be cheap. In the case of collectors, it is the high cost that shows the good quality of the product. This is due to the fact that the production uses more modern and durable materials, and the production itself is conducted in factories equipped with the latest equipment. Chinese underground factories mainly use low-quality polymers and cheap manual labor.

Availability of other parts

The entire collector system can fully function only in the presence of such components as a water circular pump, fittings, plugs, taps. Pay attention to how the chosen model compares with the existing equipment in the house.

Installation difficulty

Modern high-class collectors can be easily mounted on their own, but this will require some experience.And the installation takes a lot of time, especially when it comes to systems "warm floor". If you are unsure that you will be able to do the installation yourself, it is strongly recommended that you also hire money for hiring a team of specialists. But it should also be borne in mind that it is much easier to install a collector when a house is being built and not finished.

Technical specifications

Of course, the characteristics of the reservoir have a huge impact on the decision to purchase. Despite the fact that the calculation can only be made by professionals, even an amateur will be able to roughly estimate the acceptability of a particular model for his case.

- You need to consider where the collector will be installed: in the apartment or in a private house. The pressure in the system depends on it.

- Calculate how much the collector will absorb electricity. Usually this information is available on the packaging.

- It is necessary to take into account the number of contours: 2, 3 or 4.

- Among other things, the bandwidth of the device is important. Remember that it varies depending on the area: for example, for a two-story house and for the “Khrushchev” capacity will not be the same.

- Find out if you can add circuits if you need to increase the number of heaters.

Manufacturing firm

What matters is the reputation of the company, the guarantee it provides. See how old the company is on the market. Providing a quality product is unlikely to have appeared only yesterday, as a rule, they have their own history and temporary baggage.

Manufacturers

The fact that it is not possible to save money on a collector’s purchase does not mean that you can choose it thoughtlessly, being guided only by the rule “expensive means good”. It is important to pay attention to the country that owns the manufacturing company, as well as its history.

Today, there are practically no companies on the market that offer high-quality collectors. You can look at the products made in Italy and Germany. Firms from these countries lead in the number of worthy firms. If you make a comparison, the leader, of course, Germany. The most noteworthy are the two brands: Oventrop and Rehau. They provide the best guarantees. Among other things, buyers give excellent reviews about the collectors of these brands, saying that they are relatively easy to install and repair, serve for a long time and fully pay back their cost.

Oventrop

This company offers a range of universal models to customers' attention, suitable for radiator heating as well as for “warm” and “cold floor” systems. All samples are made of stainless steel of different composition depending on the application. The most popular are the collectors for heating Multidis SF and Multidis SH, which can withstand temperatures up to 70 degrees and up to 120 degrees respectively. But it is also recommended to pay attention to related parts of the same brand.

The cost of collectors varies from 2,699 rubles per comb for 2 circuits to 28,312 rubles for a hydraulic combination for 3 heating circuits. As for combs, the maximum cost of the option for 12 contours is 10,023 rubles. Prices for end plugs start at 649 rubles.

Rehau

Many users point out one minor detail: from an aesthetic point of view, Rehau products look more attractive than Oventrop. Here collectors are made not of "stainless steel", but of brass. The company offers the HKV and HKV-D models, which differ from each other only by the presence of additional functionality in the form of flow meters, valves and valves for regulation. The number of circuits is limited to twelve.

Prices fluctuate between 1,343 rubles for a double-circuit comb and up to 31,335 rubles for a “warm floor” collector for 12 stainless steel contours.

The maximum cost of a distribution manifold for radiator heating is 12,172 rubles.

In addition to the German and Italian brands, the Russian firm North also deserves attention.offering hydraulic manifolds. Most models of mixed use, therefore, suitable for connection to the radiator, and for the "warm floor". All models are steel, and the composition of the steel depends on the selected configuration.

The cost starts from 2,140 rubles for a three-circuit model and ends with 23,130 rubles for a 12-loop stainless steel manifold. Here you can purchase additional products.

Manufacturing methods

Before you take up the manufacture of homemade collector, you need to select the material and prepare the necessary inventory. For example, to make a model of steel, you need a welding machine. But do not rush to choose polypropylene. In order to connect the polypropylene parts, you will need a special device with which you can weld such pipes. Sometimes it is easier to get an ordinary welding machine than for plastic.

Calculation and distribution of contours

From the very beginning, you need to understand how many heating circuits you need. It is necessary to take into account every available heater, so you will have to evaluate each room in the list below.

To forget nothing, use the following list:

- the presence of the system "warm floor";

- rooms in which there must be a higher or lower temperature than the rest of the rooms;

- floor heating;

- heating each wing.

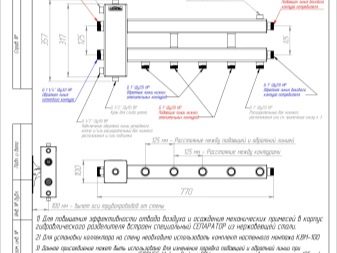

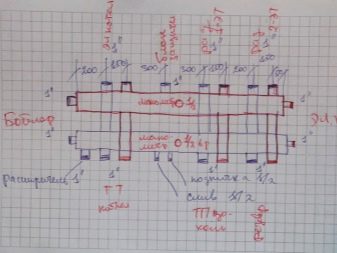

The rules for the manufacture of a collector for heating are as follows: the distance between the layering is 10-15 mm, the distance between the supply and return collectors is 25-30 cm.

The diameter of the pipes must be 12.7 mm. The collector itself is made with a diameter of 25.4-38.1 mm, depending on which boiler is installed.

From polypropylene

To make a collector assembly of polypropylene with your own hands, you will have to use the remains of pipes and fittings.

You will need:

- pipe with a diameter of 32 mm;

- tees 32/32/16 mm.

On one side you need to install a tee. To it you need to connect the top of the air vent, and the bottom - a faucet for draining. On the other hand, fix the valve and pipe. The pipe can be supply or discharge depending on the purpose of the collector. The supply pipe goes to the boiler.

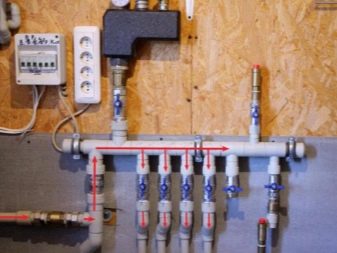

The remaining outlet with a diameter of 16 mm must be provided with a valve or flow meter, depending on whether the collector is for water supply or drainage. This is the end of the work, and it remains only to fix the received collector systems on the wall with the help of brackets.

Brass Fitting Assembly

If a ready-made brass collector is quite expensive, then you will spend much less money on a homemade one. For the construction of a similar design will need tees and fittings. They are connected to each other, using flaky tow or a liquid fixative as a gasket material. Parts must be connected in accordance with the assembly scheme. An example can be seen in the picture below.

After the collector is assembled, it must be tested. Making the connection is difficult, so there is a high probability of leakage.

From the profile pipe

Making a manifold out of pipes with different sections is the most difficult, because welding work is required here. This model can be called the most "tricked". It is suitable for heating large areas, it may have a lot of pipe layouts. Often, such samples are supplied with a hydraulic arrow.

You will need the following samples:

- profile tube 8x8 cm or 10x10 cm;

- round tube.

The calculation of the pipe section is performed in special programs. It is necessary to set the required heat output of heating, water speed, temperature difference during supply and return.

In this case, you will need to build a circuit, given the number of contours. Remember that the distance between the layouts should be about 15 cm, and between the collectors - not less than 20 cm. A typical scheme looks the same way.

Next, you need to mark the pipe with a rectangular cross-section according to the scheme, and then make holes for wiring using a gas cutter. Weld pre-prepared small parts of threaded pipes to the holes. The block is ready, it remains to weld the brackets to it, prepare and paint it.

Installation

Before carrying out installation work, you need to check the place of future installation for any interference. Nothing should impede the process of operating the collector.

Next, take into account what kind of collector you fix: radiator or for the “warm floor”. The undoubted plus is that the installation height does not play any role: in the case of a collector, this is not critical.On the other hand, some restrictions are imposed by the strapping scheme. For example, in the case of classical radiation piping, it must be remembered that it works most effectively only in houses with a large number of rooms or floors.

Temperature adjustment is made after the installation of the collector node and the heating pipes from the collector. It is easiest to regulate the temperature using a thermal head. Even at the construction stage you need to attend to the installation of such additional equipment.

The variant with the installation of the light drive and the thermostat is equally well suited both for adjusting the radiator and for adjusting the “warm floors”.

Installation of such equipment requires special knowledge and skills, so it is better to entrust it to professionals.

How to install a collector for heating, see the following video.