Group of safety for heating: device and installation design

Any device that heats and works under pressure, immediately falls into the category of increased danger. However, a person cannot always control the operation of the boiler room (temperature, serviceability of parts, pressure). In this regard, the security group is considered the most important element, automatically ensuring the health and reliability of the entire heating system. It is a combined device or a whole mechanism consisting of a number of different devices.

Special features

Previously, throttle washers were installed to control the water pressure in the heating systems of houses. With their help, it was possible to achieve an increase in hydraulic resistance. But production does not stand still, so now such devices have faded into the background.

Emergency situations in heating systems, as a rule, occur due to excessive pressure or excessive heating of the boiler. In these cases, the consequences can be not just unpleasant, but even dangerous: a boiler rupture, complete system failure, coolant leakage, flooding or fire. In order to eliminate the possibility of such failures, a safety block is used, with the help of which the required pressure of the thermal carrier is reached. All modern devices of this type automatically regulate both temperature and pressure.

You can install this system on any kind of heating equipment, but it is not always necessary. Some boilers have their own fairly high level of safety (for example, those that burn diesel fuel or natural gas). In turn, sources of solid fuels absolutely need a security unit.

Principle of operation

Each heating system has its own specific maximum pressure values. This is directly affected by the degree of heating and cooling of the fluid that is in the network. As described above, due to the fact that the pressure begins to exceed the norm, significant damage can occur.To understand how the security unit helps to avoid the consequences of emergency situations, it is worth considering the principle of its operation.

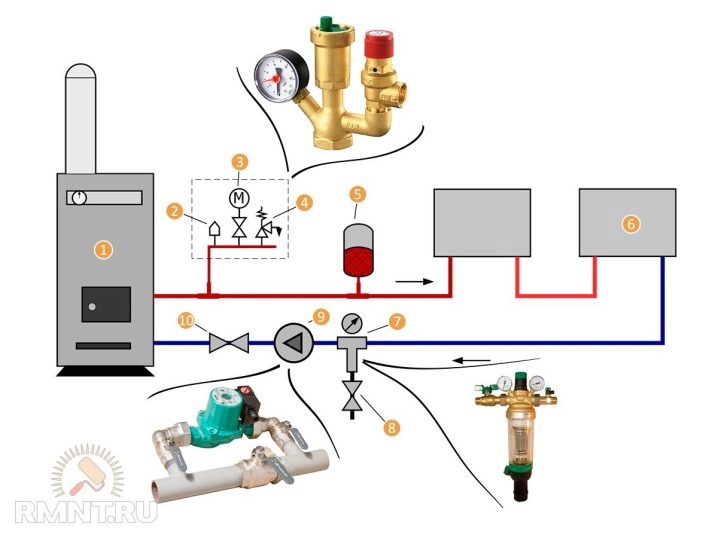

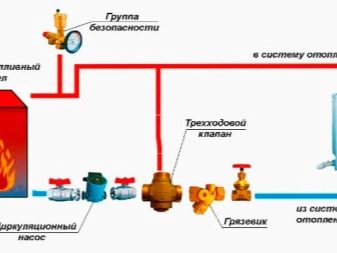

The set of parts of the safety unit may vary depending on the purpose for which the main unit is used., but in the basic configuration, the system contains only three modules that are mounted in the housing. These are manometer, air vent (Mayevsky's crane) and safety valve.

Let us consider in more detail the purpose of all three elements.

- A pressure gauge is a measuring device with which you can quickly monitor pressure readings. Its most important function is to determine the most accurate data. But, like any device, it has certain errors. Measuring units in pressure gauges are either bars or atmospheres, but the first option remains the most popular.

For each heating system, there are pressure values that are as permissible. The norm is a pressure indicator of 1.5 atmospheres.

- Automatic air vent serves to remove excess air in the system. Usually this part is made of brass.As you know, in any air heating system should not be. It accumulates for several reasons. This may be the installation of low-quality rubber seals, blockage inside the pipeline, improper installation of the heating system. Also in the water that enters the system, contains a sufficient amount of oxygen. That it contributes to the formation of traffic jams from the air.

Another function of this part is that it throws out portions of steam, which are formed in case of overheating of the boiler.

- Safety valve plays an important role. It is necessary to eliminate excess fluid from a closed system. In other words, it serves as a protection in the event that the automatic diverter does not work. For the production of this element is used brass alloy. It consists of two parts: a steel spring and a membrane. Resetting the coolant using a valve occurs in such a way that it does not get on the person. Especially important is the use of the fuse in systems that are equipped with steam boilers.

As can be understood from the descriptions, every detail of a security unit performs its specific functions. Elements can either be placed separately, in different parts of the pipeline, or be in a single bundle. There is also another option to complete the system. A hydraulic shock absorber has been added to protect the pressure gauge from the environment.

The equipment as a whole works according to a certain simple scheme. If for some reason the expansion tank cannot compensate for the expansion of the coolant, and the closed system is subjected to high pressure, then pressure also increases in the depths of the equipment. At this point, the safety valve is activated. Its spring is compressed, the valve opens. So the excess coolant gets the opportunity to exit, the excess air comes out through the air vent.

It should be noted that the use of this group is especially necessary in private houses and apartments in which old-style boiler houses or gas boilers are installed.

This is due to the fact that in such systems there is often too little traction inside the chimney. In the pipeline itself, the pressure can also become either too small or very large. Due to these problems, the room can become polluted.

Installation

As a rule, the system is sold as standard with all the necessary parts and devices. Assembling and installing a security unit can be effortlessly with your own hands. This is a fairly quick process. You can not buy a ready-made set, but in this case, each part must be carefully selected. The cost of a self-made group of security will be less than approximately 2 times lower. To install the unit correctly, you need to familiarize yourself with some of the nuances of the work.

For self-assembly will require:

- emergency valve;

- automatic air vent;

- pressure gauge;

- a pair of corners (one with internal, and the second with external thread);

- adapters;

- crosspiece;

- nipple;

- gas wrenches;

- sealing agent;

- linen.

The process of assembling the structure begins with the fact that the corners are connected to the crosspiece. Flax is used at this stage, they should cover the entire perimeter of the thread. After that, a small amount of sealant is distributed, the corners are screwed with wrenches. The installation of the three remaining main elements also takes place.

If a security group for heating is acquired or already assembled,it is necessary to make a check on the correct operation of all its parts and to ensure that there are no leaks. Then you can put the system.

It is necessary to choose a place for installation so that you can easily see the readings of the pressure gauge. In addition, there must be no other elements between the boiler and the safety unit, as this may contribute to an accident.

The crane also should not be located in front of the structure. This error is very common. If it is allowed, the group will not be able to fulfill its intended purpose.

There are two ways to mount a security group:

- mounting on the sleeve coming from the boiler;

- by plunging into the pipeline, which is located at the outlet of the heat generator.

It is necessary to connect a plastic tube to the emergency valve so that the other end is connected to a tank or directly to the sewer. Due to this, the use of equipment will be even safer. When installing, it should also be noted that the safety valve and the air vent must be positioned in a vertical position. At the end of the installation, the safety group is activated using a cap on the duct.It needs to be opened, but not removed at all.

Thus, for a competent installation of emergency equipment it is necessary to follow a few simple rules, then installation will be easy and without any consequences.

- The safety unit must be installed on the pipeline first. This is the most important point to remember.

- The distance from the pipe to the system should be no more than 1.5 meters.

- Different shut-off valves can not be installed, otherwise the safety system will be cut off.

It is recommended to conduct regular inspection of the equipment, clean it from contamination. This should be done about 1 time per month and before the start of each heating season.

Tips

The most important thing in choosing a safety unit is its full compliance with the characteristics of the heating system. In this regard, the best solution would be to buy a complete set. In some models, such as a gas or electric boiler, a security group is already there.

When selecting a design, it is necessary to take into account the diameter of the pipes to which the connection will take place. It is necessary to determine in advance from which side the group will be installed, and decide how you will conduct pipes to it.

Special attention should be paid to the emergency valve and pressure gauge.Their selection depends on the maximum pressure. It is usually indicated in the instructions to the boiler.

It is also worth considering the type of material from which the console itself is made. Usually it is bronze, cast iron, nickel or stainless steel. If the system is purchased for a private house, then the last two options will be most suitable.

In conclusion, it should be said about the price of equipment. Currently, many manufacturers are trying to equip security groups with any additional details that make them even more functional and modern. But such variations are much higher in price, and for security, a standard ready-made set is enough that will cost you approximately 2-3 thousand rubles. Of course, this cost is much less than that which would have been spent on replacing the damaged equipment of the heating system in the absence of protection.

About the features of the installation of a security group for heating, see below.