Varieties and installation of heating registers

Without heating devices it is difficult to imagine a dwelling, a public building, or working workshops in enterprises, since comfortable air temperature inside buildings of various types is a necessary condition for human activity. In order to maintain normal conditions in the premises, various heating devices are used, among which it is necessary to single out registers.

Special features

The issue of saving and rational use of heating devices in the current situation is quite relevant. To buy registers today is quite simple, you can make a purchase through numerous online stores or in specialized departments of supermarkets.These devices for heating in most cases are an effective design that can be used in any type of premises - residential, industrial, technical and others.

In addition, registers are widely used in the heating systems of multi-residential buildings. Through the use of large-diameter pipes, even with a minimum length, it is possible to make an autonomous vertical or horizontal heating device, which, with its small dimensions, will have a high level of efficiency for heating.

There is an opinion that, in comparison with registers, radiators cope better with their main task, since they have an additional area. But the registers, in the production of which smooth-bore pipes are used, have heat transfer indices exceeding the similar values of radiators to a large extent. An additional modernization of the structure, which involves attaching metal plates to the system, will have a positive impact on the efficiency of the register.

If it is planned to install general-purpose registers, connecting thin tubes to each other,placed in parallel, a high-quality and attractive design is formed, which in some cases is called design radiators. The manufacture of such devices is important for use in public buildings.

The main area of use of registers is still enterprises, as well as various office or technical premises.

Most often, they are not separate elements for heating, but entire pipelines from pipes, which is due to the simplicity of the structures combined with good heat transfer performance.

During operation, the devices have proven themselves on the positive side, differing in durability. It would be a mistake to assume that the registers for heating can only be a coarse bundle of metal pipes, since product manufacturers offer consumers separate small-sized structures that can be installed to heat private houses without reducing the overall attractiveness of the interior.

The diameter of the pipes for the manufacture of such individual devices is usually about 32 mm, due to which their installation is facilitated at times.

Compactness and low cost of such registers are the main positive features that allow equipping the system for heating a home. The raw materials for the manufacture of devices are various materials, and the designs can have various shapes. The main feature of heating structures of this type is the possibility of making them by hand from steel, aluminum or other raw materials.

It is worth highlighting the following advantages of registers:

- long service life - steel and aluminum systems usually function effectively for 20–25 years with a minimum probability of breakage;

- high heat transfer ratewhich is explained by greater power in comparison with batteries or radiators;

- easy installation process and ease of operation. Install the device under the force of anyone who has minimal knowledge about the rules of organization of heat supply.

It should be noted that the heating registers have some drawbacks, such as:

- large volume of coolant, due to which the system cools down rapidly;

- a low level of air convection, which adversely affects the work;

- Some designs have an unattractive appearance, however, this feature is more typical for products that were made independently.

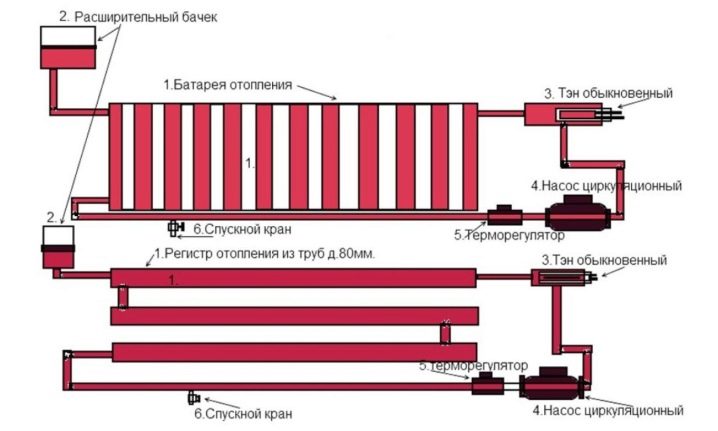

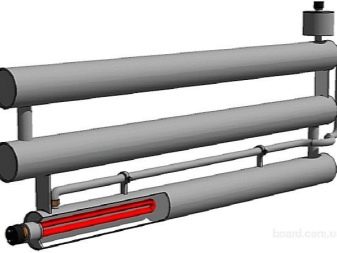

The demand for products is quite high due to the fact that the devices can be used in any heating systems, since the design works equally efficiently with both water and antifreeze. In addition, it is worth highlighting another option for connecting the device - this is the installation at the bottom of an electric type heater pipe with a thermostat, due to which the heating medium will be heated from the electrical network.

However, this configuration also requires installation of an expansion tank in the upper part of the system. With this device, the heating register will act as an autonomous heating system, which is very convenient when heating household buildings with a small area.

Kinds

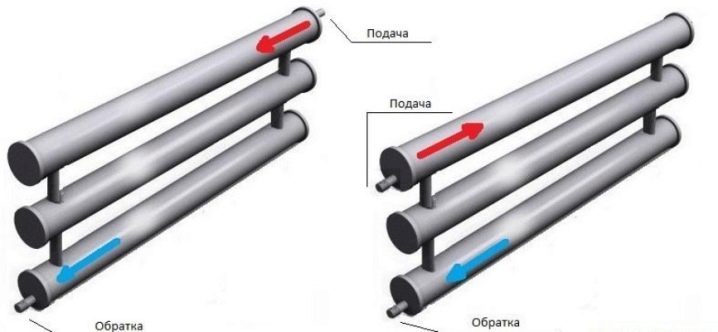

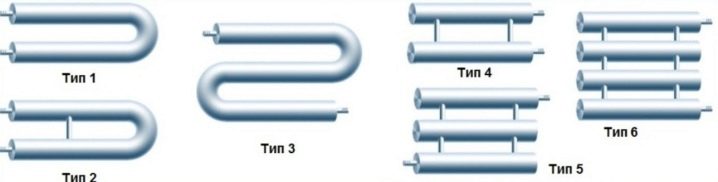

The decisive parameter when choosing such a device is the speed of the coolant in the structure, as well as the rate of heat transfer. Based on the above properties, we can distinguish two types of registers.

- Sectional Instruments - this type of product usually consists of two or more pipes having a large diameter. The elements are interconnected by branch pipes with a cross section equal to the cross section of the supply line. Such structures are recommended for systems with forced circulation of the coolant, since excessive hydraulic resistance is formed inside.

- Serpentine registers They are made from a single pipe, which is bent accordingly. Independent production of such devices is a rather time-consuming task. To increase the circulation of pipes, they can additionally be connected by nozzles, however, this is not a prerequisite for the manufacture of structures.

And also it is possible to classify heating devices, taking into account the type of material of which the unit is made. On sale you can find the following types of registers:

- steel appliances installed in the heating system by welding. The quality of the work will directly affect the service life of the device;

- cast iron products remarkable ease of installation, since the devices are equipped with flanged monolithic connections. During installation, another flange is welded to the system, and then attached to the wall with bolts;

- aluminum products widely demanded due to the minimum specific weight, resistance to corrosion processes, as well as the absence of welding seams on the structure. Production of products is carried out by monolithic casting, the main disadvantage of aluminum products is the high cost;

- bimetallic devices made of special type of heating pipes with a steel core. In addition, the system has copper or aluminum lamellar elements. As a rule, for the manufacture of products used pipes of small diameter, which does not exceed 50 mm. Due to its features, such devices are most often installed in industrial or commercial premises with a small area.

In addition to the above materials, copper is used for the manufacture of heating registers. Such devices are installed in networks with copper piping. This raw material has a high heat transfer rate, so the design does not have to be large in size.Copper is also notable for its plasticity, due to which it is easy to bend. However, copper structures have drawbacks - the high cost of products, as well as the exactingness of the material to the operating conditions.

Necessary conditions of use include the following factors: neutrality and purity of the coolant, the absence of other metals in the system, except those compatible with copper, such as nickel, chromium, bronze and others. In addition, the presence of grounding is considered mandatory.

Raw materials are also soft, so the design needs additional protection, which is carried out with the help of special covers or screens.

Considering the types of registers, it is worth dividing products into stationary and mobile models. Heating of the heat carrier in stationary structures occurs with the help of boilers, mobile devices are heated by heating elements operating from the power grid.

Payment

To perform the correct calculations of the register, it is first necessary to determine the type of construction. Then the geometrical parameters of the device will become clear, as well as the scheme and principle of circulation inside the coolant.There are several proven techniques to calculate the parameters of heating devices.

However, when planning to use steel or aluminum systems, it is best to entrust the calculations to professionals or to resort to using special software.

In addition to the calculations made by specialists, in some cases they prefer independent drawings and calculations, for this there is a fairly simple scheme.

Before you start working with it, you need to decide on some values that will be used. You need to know the following parameters:

- the area of the heated room;

- heat transfer coefficient of the material from which the device will be made;

- pipe diameter

The formula for counting is as follows:

Q = P • D • L • K •∆t, Where

- Q is the specific thermal power, which is measured in watts;

- P is the number of π, which is 3.14;

- D is the diameter of the pipes used;

- L - length of 1 section of the system;

- K is the coefficient of thermal conductivity;

- ∆t is the temperature difference between the air and the coolant.

To calculate each next section of the register, the resulting value will need to be multiplied by a factor of 0.9.However, there is one limitation: using such a formula, it will not be possible to calculate ridge type registers.

You will learn more about how to calculate the register of heating in the following video.

Installation

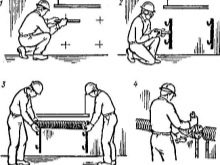

In order to properly weld and install heating registers, It is worth using the following methods:

- install on threaded connections or brackets;

- use welding equipment for work.

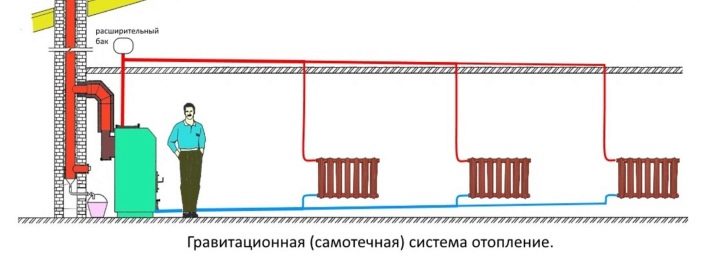

The decision in favor of one or another method is based on the weight of the structure, its size, and the parameters of the heating system. Many experts believe that the work on the installation of registers is not much different from the installation of radiators. The main difference lies only in the dimensions of the structures, as well as in some cases when they are mounted on the radiators. When installing registers to the gravitational system, it is imperative to observe the level of inclination - the device itself must be tilted in the direction in which the coolant will move through the system.

For structures that assume natural circulation, there are no such requirements.

It is worth highlighting the following recommendations that should guide the installation work:

- It is necessary to observe the minimum allowable distance of the system from the wall and window openings. It must be at least 20 centimeters. This feature of mounting structures is necessary to perform various repair and technical works in the future;

- when choosing a threaded connection during fastening, it is worth using only paronit gaskets or sanitary flax;

- any constructions from heating registers made from steel and shaped pipes must be additionally painted. Staining will help prevent rust from forming on the surface. Such systems will have a lower heat transfer rate, however, this will increase the operational life;

- all installation work with heating registers is not performed during the heating season;

- installation using a threaded connection involves mounting through a ball valve or else using a fitting and cap nut;

- connection when using welding equipment is made by connecting the nozzle and screw-in ball valve with the heating circuit pipe of the system;

- in order to extend the operational life of the structure, a series of simple audit work should be carried out regularly. If defects or leaks are detected, eliminate the malfunctions in time.