Expansion tank for heating: types, purpose and installation

The lion's share of modern private houses and city apartments are equipped with a water heating system. In order for it to function stably, without creating any problems, it is very important to competently approach its use and charting. From school physics lessons we all know that water tends to expand. To avoid unnecessary overloading of the heating system, devices such as expansion tanks are used. Today we will get to know them better and find out how to install them correctly.

What it is?

Not every owner of a private house or apartment knows exactly what the expansion tank is. In this case, the name of this device speaks for itself - under conditions of a fixed mass of heat carrier in the heating circuit and pipeline, which do not differ in elasticity, the pressure level in the entire system will necessarily change with a change in the temperature of the heat carrier. Here it is worth considering the fact that the liquid expands when heated. At that moment, when the force becomes more powerful than the strength of the flow pipe / radiator, a serious accident will occur. Its main reason in this case will be the fact that water, when its volume changes under heating conditions, becomes almost incompressible. From this property comes the definition of a water hammer.

The solution to such a serious problem is quite simple. It is necessary to place in the heating system a special reservoir (expansion tank), equipped with a substance that can be compressed without problems.

Under conditions of increasing water pressure and with the indicated reservoir, the pressure will certainly increase, but not very much.

Features and specifications

As you can see, expansion tanks play one of the most important roles in the heating system. They prolong its service life and allow you to avoid many serious problems.

Similar items are used for the following purposes:

- play the role of a heating system, which operates with the help of heat pumps and solar collectors;

- act as an autonomous heating system;

- They are an independent system connected directly to the central heating system, as well as a closed-loop system.

Provided that the temperature of the fluid in the heating system is only 15 degrees higher, due to the expansion the volume of the thermal carrier becomes more than half percent. Expansion capacitance is responsible for compensating for this expansion. Excess liquid heat carrier penetrates the tank itself. If the coolant cools, the tank design squeezes the insufficient fluid back into the overall system.

If there is a slight leakage of fluid, so that the pressure in the system does not fall too much, the tank pushes away the thermal medium to compensate for the losses.

In the case when the system is not equipped with an expansion tank, the expansion of the thermal carrier provokes an increase in pressure. In addition, these processes will certainly end with a strong deterioration of the component elements of the entire system, and also lead to breakage and even rupture of pipes and taps.

The surge tank has many positive characteristics that make it literally an indispensable element of a water heating system:

- thanks to this detail there is no water pollution;

- most expansion tanks are inexpensive;

- ensure the reliability and safety of the entire system;

- allow you to avoid excess heat loss;

- have the smallest amount of air in the system;

- in the equipment responsible for heating, there can be any thermal medium - the expansion tank is allowed to be used in all cases;

- taps, pipes and radiators can last much longer if you use an expansion tank.

As for the immediate volume of the expansion tank, then it is worth considering that it directly depends on the specific type of heat carrier. How it can be calculated, we consider below.

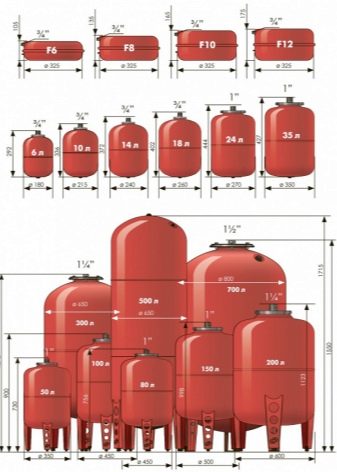

Today in the shops there are units, the size of which is:

- 5 liters;

- 8 l;

- 10 liters;

- 12 liters;

- 19 l;

- 24 liters;

- 35 liters;

- 50 liters;

- 80 l;

- 100 l.

Today there are several options for such devices. They are suitable for different heating systems and differ from each other in many ways.

Only their direct purpose remains unchanged.

Device and principle of operation

And now it is necessary to consider in detail which of the expansion tanks are composed of, and how they work. First, find out how this element is arranged.

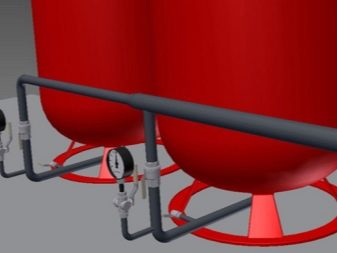

As a rule, the design of the expansion tank as a whole is placed in a stamped steel housing. It has the shape of a cylinder. Slightly less often cases in the form of original "tablets" meet. Usually for the production of these elements are used high-quality metals, coated with an anti-corrosion protective composition. The outer side of the tank is enameled.

For heating, expansion tanks with a red body are used. Also, there are blue variants, but usually water-borne batteries, which are part of the water supply system, usually wear this color.

They are not designed for high temperature parameters, and all their elements are exposed to very high sanitary requirements.

On one side of the tank is a threaded nipple. It is required to enable tapping into the heating system. There are cases when items such as fittings are also included in the package. They greatly simplify installation work.

On the other hand, there is a special nipple valve. This element is used to form the desired pressure level in the inside of the air chamber.

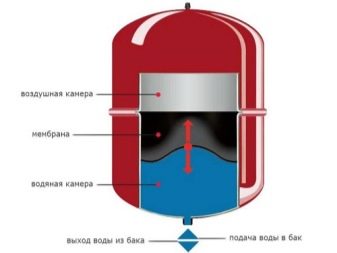

In the internal cavity, the expansion tank is divided by a membrane into 2 separate parts. Closer to the nozzle is a chamber designed for thermal media, and on the opposite side there is an air chamber. Usually, tank membranes are made of a very elastic material, which is characterized by minimal diffusion values.

This detail is given a special form, which is responsible for uniform deformation in the event of a change in pressure values in the chambers.

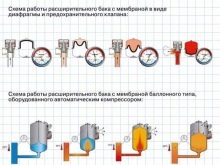

The principle of operation of the expansion tank in the heating system is very simple and straightforward. We analyze it in detail.

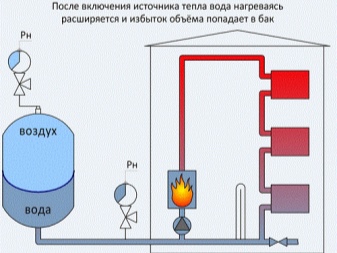

- In the initial state, at the time of connecting the tank to the system and filling it with heat carrier, a specific volume of water passes through the nozzle into the water compartment. The pressure in both compartments is gradually equalized. Further, such an uncomplicated system becomes static.

- With increasing temperature values, the thermal medium is directly expanded in volumes in the heating system. This process is accompanied by an increase in pressure. The excess liquid is sent to the tank itself, and then the membrane part is pushed by pressure. At this point, the volume of the chamber for the coolant becomes larger, and the air compartment, on the contrary, decreases (at this moment the air pressure in it increases).

- When the temperature drops and the total volume of heat carrier decreases, an excessive pressure in the air chamber causes the membrane to move backwards. The heat carrier returns to the pipeline at this time.

If the pressure parameters in the heating system reach critical points, the valve should start, which belongs to the “safety group”. In such a situation, he will be responsible for the release of excess fluid.Certain models of expansion tanks have their own individual safety valve.

Of course, it should be borne in mind that the design of the tank mainly depends on the type of specific model purchased. For example, they are non-separable or with the possibility of replacing the membrane element. Included with such products can go such details as clamps for wall mounting or special supports - small legs, with which the floor unit is easier to place on a flat plane.

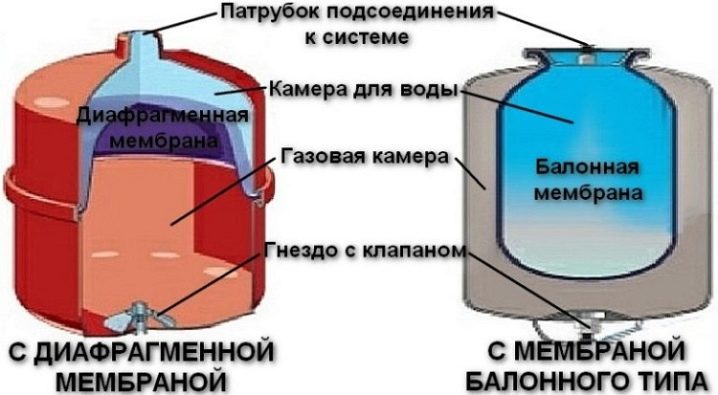

Expansion tanks with a diaphragm-membrane are usually non-separable. In many cases, they contain a balloon membrane part - it is made from ductile and elastic raw materials. At its core, this membrane is an ordinary water chamber. In the course of pressure growth, it stretches and increases in volume. Such types of tanks are usually supplemented with a folding flange, which makes it possible to change the membrane on its own if it breaks.

This fact does not affect the principle of operation.

Kinds

Do not think that all expansion tanks have identical designs and performance characteristics.In fact, there are several varieties of such units. Each of them has certain distinctive features and features of the structure. Let's get to know them better.

Depending on the specific mode of operation, the tanks are divided into:

- open-type heating tanks;

- closed expansion vessels.

Not the most popular are open variants of expansion tanks. These units are installed in systems in which the circulation of fluid is not in a forced mode (that is, without using a pump)

. The open expansion tank has a lid that opens without extra effort if you need to add water.

The main disadvantage of this unit is that the coolant in it is associated with oxygen, and this provokes the appearance of corrosion in the heating system. If there is not sufficient tightness in an open-type tank, the water evaporates several times faster, so it must be constantly refilled. According to experts, it is necessary to mount such a unit on the highest part of the heating system. It should be noted that such works are not always available.

A closed (or membrane) dilator is fixed in the system, where the movement of the thermal carrier occurs by force - using a pump. The closed vessel is usually produced in the form of a tank of steel (there is no lid in it). It is equipped with a partition inside the membrane of rubber. One half in a similar model is needed to fill it with heat carrier, and the second is a place for air and nitrogen.

These containers are treated with paint in the form of powder in order to insure against damage to the walls of the case under the action of high temperature indicators.

One of the sides of the tank itself is attached directly to the system using a fitting or flange. The opposite side is designed to pump air. The pressure indicator in the closed type model makes it possible to automatically change the flow of thermal media into the system and the tank itself.

Closed tanks are divided into:

- replaceable;

- non-replaceable.

So, replacement-type tanks have a higher cost, but they have significant advantages, which include:

- the possibility of changing the membrane, if it was damaged or torn;

- the opportunity to save on pipes, since there is no need to install a closed tank at the top of the heating system;

- replaceable options are responsible for minimal heat loss;

- since the heat carrier does not “touch” oxygen in any way, the pipes and the whole system are not subject to the formation of corrosion;

- the membrane can be positioned both vertically and horizontally;

- in this case there is no connection with the wall inside the tank of metal;

- membranes can be replaced very easily and quickly (this is done through a flange).

Non-replaceable types of containers are cheaper, but they cannot change the membrane, if necessary. This element in the expander is installed as closely as possible and reliably pressed against the inner walls of the tank. Damage or rupture of the membrane in this case can occur only if the system was started up incorrectly (the pressure grows too fast and goes beyond the normal limits).

Depending on the type of membrane part, expansion tanks are divided into models with:

- balloon membrane;

- diaphragm membrane.

So, the balloon membrane expander is very durable and reliable.In addition, it has an impressive volume. At the same time, the heat carrier does not come into contact with the tank walls; therefore, the appearance of rust on such products is excluded.

Flat heating expansion tank is equipped with a separating partition, made in the form of a diaphragm.

If it is suddenly damaged, then it will be possible to change it without making special efforts.

Materials

In the manufacture of expansion tanks used various materials, but the most common models are considered to be with a steel case.

Currently, many people, in an effort to save money, construct such units independently. To do this, they often use sheet materials, which are subsequently assembled into a single structure by welding. Also for the manufacture of the expansion tank, you can use the most unexpected items, such as plastic barrels and cans or old gas cylinders. The use of such materials significantly reduces the cost of creating an expansion tank. Despite such a large selection of suitable raw materials, experts still recommend to contact the stainless steel, if you plan to collect the tank with your own hands.

As for partitions in such units, most manufacturers use high-quality rubber, synthetic rubber, raw materials from natural butyl rubber or EPDM. Membrane elements for such units are made of various materials, which, in the course of their use, seamlessly transfer the very different temperature range.

If we consider specific cases, then:

- for tanks up to 2 thousand liters, membrane labels EPDM DIN 4807 are most often used;

- tanks, having a volume exceeding the above mark, are completed with membrane elements of the brand BUTYL.

How to pick up?

The selection of the expansion tank must be approached very responsibly, since this product plays one of the most important roles in water heating systems.

We will highlight a few simple tips that will allow the buyer to choose a suitable model of good quality.

- Experts recommend stopping your choice on membrane or closed type containers. Despite the fact that these types of cisterns are usually expensive, the heating system in which they are available can work for a very long time.This is explained by the fact that in this design the coolant and oxygen do not “meet” with each other. But this is just a tip - the choice, one way or another, remains with the owner of the dwelling.

- Always pay special attention to the material from which the rubber partition is made in models of the closed type.

Above was listed raw materials, which are usually used for their manufacture.

- If you are going to use a tank together with a central heating system, then the membrane rubber should be distinguished by enhanced strength characteristics and resistance to high temperature values. This is due to the fact that in most cases central heating does not imply significant pressure drops, but the temperature will still be quite high.

- A tank with a membrane characterized by increased elasticity can be safely purchased for a private heating system, since sudden pressure surges are common for this type of heating.

- In order to use the expander not only in the heating system, but also in the system responsible for the water supply, the rubber from which the membrane is made must be food grade.This is necessary not to detract from the positive qualities of the water.

- Choosing between non-replaceable and replaceable types of membranes, it is recommended to choose the first ones, because in case of damage of the non-replaceable part, it is necessary to change the whole unit instead of one element.

- Before you purchase a surge tank, it is recommended to carefully read its specifications. Ask the seller for all necessary quality certificates. If there is no such product or they do not want to present it to you, it is better to refuse the purchase.

- Do not forget to issue a warranty card.

- Consider that one of the most important parameters to which you should pay attention when choosing a tank is its resistance to diffusion, temperature jumps. In addition, all elements of the unit (from the body to the membrane) must be made of quality materials.

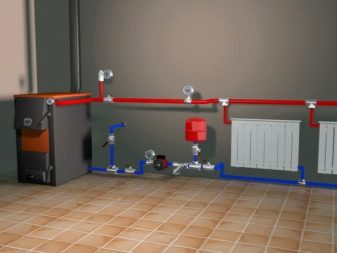

Where to put?

If the system has forced circulation, then the pressure at the device connection area will be equal to the static pressure at this point and at a given temperature mode (note that this rule only works if there is one membrane element present).If we assume that it changes, then the result is that it is not clear where the liquid has come from in a closed system, which is fundamentally wrong.

An open heating system, on the other hand, is a tank of a complex configuration with special convection currents. Absolutely all the nodes must ensure the fastest possible rise of the hot heat carrier to the highest point. In addition, they must ensure self-flowing into the boiler with the involvement of radiators. Also, the design of such a system should not interfere with the passage of air bubbles to the top point.

Based on the above features, you should summarize one result - the expansion tank should be fixed in the upper plane of the one-pipe system (usually - on top of the accelerating collector).

Payment

To determine the volume of the extender, you can rely on several different methods. For this, it is advised to contact the masters in special bureaus. As a rule, to carry out all the necessary calculations, they use special programs that allow to take into account all the features and nuances that affect the operation of the heating system.However, it should be noted that the services of such specialists in most cases are expensive.

The calculation of the volume of the tank can be made independently. To do this, use the generally accepted formula. In this case, you need to be as careful as possible, since even a small error can lead to incorrect values. When calculating it is important to take into account absolutely all the nuances: the volume of the heating system, and the specific type of heat carrier, and even its physical properties.

In the above formula:

- C is the total amount of heat carrier in the system;

- Pa min - an indicator of the initial absolute pressure in the tank;

- Pa max is the largest pressure parameter that can occur in an aggregate.

If you are afraid to make a mistake or you do not have time to carry out all the required calculations, then you should turn to the help of special online calculators. However, in this case, it is recommended to double-check the results obtained on several sites, so as not to encounter the wrong work of one or another portal.

Some people make it easier - they estimate the necessary parameters by eye. At the same time, the specific capacity of the heating system is equal to 15 l / kW. The result will be approximate values.But keep in mind that access to this method is allowed only in the process of a feasibility study.

Before acquiring a tank, of course, only accurate calculations will be required.

DIY installation

Before proceeding to the installation of the expander, it is important to prepare:

- Be sure to read the instructions before starting work;

- make all necessary calculations of temperatures and pressure indicators (usually all these data are indicated in special reference books on the standards for the use of units);

- prepare tools such as a wrench, a wrench for installing plastic pipes;

- if the tank has a large capacity, then you will also need to buy brackets - they are useful for mounting.

When installing and connecting such units, you should rely on some recommendations from experts:

- arrange the unit so as to further ensure free access to it;

- provide for the likely dismantling of pipes in the future;

- make sure that the diameter of the connector-pipe converges with the attached plumbing;

- correctly install the necessary temperature sensors;

- count the valve connection.

Now you can proceed to the immediate installation of the tank. It should be hung near the entrance of the flow heat carrier in the direction of the heating unit.

Mark the areas for attachment. Drill out the required number of holes needed to fix the bracket. To do this, it should be attached to the wall, and mark all parts of the connection. Having made all the necessary holes, you need to install anchor bolts in them, then hang the bracket and make sure that the fastening is reliable. If everything is done qualitatively, then you can install the tank itself, and then fix it with clamps.

Please note that such equipment should not be installed in freezing temperatures. In addition, it is important to ensure that after the completion of installation work the air valve is located in an accessible area. This is necessary so that the owners have the opportunity to set the desired level of pressure.

Absolutely all the mechanisms that require adjustment must be in the open access, and the pipes must be located so that they do not create loads on the equipment.

As for such an element as a pressure reducer, it should be installed after connecting the measuring meter in order not to encounter serious loads directed to the tank.Attach this valve to the front of the flow pipe.

After that, you need to configure the installed expansion tank. First you need to adjust the required pressure level. This should be done by air injection. The gauge will indicate when you need to stop. Thereafter, water is pumped using a pump, pressure is equalized, and the membrane part is brought to a floating state. Then the tank is acceptable to consider ready for use. You may need to turn on the system and make sure that it works.

As you can see, the installation and connection of the expansion tank is quite simple. Everyone can cope with such events.

The main thing is to rely on the instructions and be extremely attentive at every stage.

Frequent problems

Expansion tanks, like any other heating units, are subject to a number of specific problems. Let's get acquainted with them.

The most frequent failure of such units is the rupture of the membrane part. As a rule, this is due to too high pressure (above the norm) or uneven loads.Consider that replaceable elements are torn more often pressed, because for the latter, stronger materials are used, because they can be changed at any convenient time.

The problem of damaged membranes can lead to many unpleasant consequences. For example, because of this, often water flows from the air valve.

If the membrane is not replaced in time, its rupture will lead to the fact that over time the tank will simply fail. This is due to the fact that the liquid gets on the inner surface of the tank, after which it can become rusty and become unusable.

Note that the old membrane should be replaced with the same part. It is advisable to contact for this specialized service center.

Also, users often face damage to the tank body. If such a problem happened to your equipment, you should contact a specialist for help. Do not undertake to repair damaged body parts yourself, especially if you have never encountered such work before.

There are also such cases when the expander boils. Most often, such a problem overtakes homemade designs opentype The main essence of this problem is the absence of circulating velocity (or its complete absence).

Here are the main reasons for such failures.

- Reduced wiring diameter. The main circuit of one-pipe heating is usually installed with a pipe that is not less thin than the DN 32.

- Lack of bias. After the heating boiler you need to do the so-called accelerating collector. To do this, the pipe must be raised to the upper part of the contour, where the expander is installed. The rest of the contour should be laid with a slope down.

Many users are wondering how to fix such a serious problem without starting to completely dismantle and reinstall the heating system. The answer is simple - you need to install a circulation pump. This detail functions remarkably in many systems (especially open type). The pump must be placed on the return pipe directly in front of the boiler.

Another problem of expansion tanks is air blockage of the heating system circuit. To avoid it, you need to monitor the volume of water.

If you do not replenish it, the resulting evaporation will lead to the above problems.

How to replace?

From the above information, we can conclude that the main problem of expansion tanks is a damaged membrane. Such a problem faced by many users. Experts recommend replacing these items in special service centers, but it is possible to carry out such work independently.

This is done as follows.

- First you need to disconnect the tank from the heating system.

- Next, you need to reduce (reset) the pressure of the gas cavity using a nipple on top of the unit.

- Remove the membrane flange located near the nozzle to connect the pipeline. When unscrewing the nut on top of the housing, you need to release the holder of the membrane part.

- Remove the membrane part from the cavity at the bottom of the housing.

- Next, you need to examine the surface of the insides of the hull structure. There should be no dirt or rust. If there are any, they should be removed and the surfaces should be washed with water. Then you need to dry the case.

- It is important to take into account the fact that the membrane is not resistant to oil.For this reason, it is not possible to use oil-containing agents to ensure the preservation of the internal parts of the unit from the appearance of corrosion.

- Install the membrane element holder in the cavity located at the top of the membrane itself, if such fasteners should be present in the design of a particular device.

- Screw the bolt into the retaining element, put the membrane in the housing. The holder must be inserted into the cavity located at the bottom of the housing.

- The retaining part must be fixed with a nut.

- Set the preliminary air pressure values in the expander. Check the design for leaks, after which you need to connect the expander directly to the heating system.

Useful tips

Please note that if the safety valve is triggered with a high frequency, this may indicate that you have made a mistake with the selected volume. You may have incorrectly made the necessary calculations.

In order for the distribution of pipes to be installed according to all the rules, it is necessary to pay close attention to the main components of the system: the area where the thermal carrier enters directly into the container, as well as the place of its departure.

In order to never boil water in the expansion tank, choose a loop pipe with the correct diameter. In addition, it is important to take care of the slope of the contours.

Please note that if the vacuum expander does not function for a long time, then it should be kept only in a dry space; drain the liquid from it beforehand.

At least once every six months, check the unit for damage and defects. These include dents, rust or leaks. If you suddenly find such things, then you will need to eliminate the cause of their occurrence as soon as possible.

Remember that it is necessary to install expansion tanks exclusively in accordance with the prepared plan and scheme.

If you doubt your abilities, it is better not to risk - contact the experts.

On how to make an expansion tank for heating with your own hands, you can learn from the video below.