Antifreeze for heating systems: types, features of use and review of manufacturers

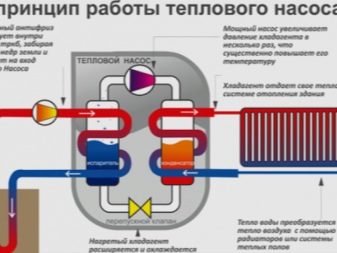

Today, in almost every house and apartment there is a heating system that allows you to provide comfort in the room during the cold season. As a rule, water is used as a coolant in such systems. But some use antifreeze in this quality. Its use can significantly reduce the likelihood of boiling or freezing of thermal media than water from time to time sinning. Water is cheaper than antifreeze and has a good specific capacity. But antifreeze has several advantages that distinguish it from water, if we talk about the coolant for the heating system.

Water is a good heat carrier due to its excellent viscosity, ideal heat capacity, and flowability.

She has two problems that level the above advantages:

- when it freezes, its volume increases by 11-13%;

- it turns to ice already at 0 degrees Celsius.

For this reason, antifreeze would be the ideal solution for any heating mechanism.

Composition and purpose

The word "antifreeze" is usually understood to mean various liquids that do not crystallize or freeze when the ambient temperature drops to 0 degrees Celsius. Now you can find a large number of varieties of antifreeze for heating mechanisms in your own house, presented in a concentrated form.

Such options before filling the heating system are diluted with distilled water to a certain concentration.

Given that antifreeze refers to different substances, its composition may be different depending on what kind of substance is used.

There are five categories of antifreeze based substances:

- alcohol;

- glycerol;

- propylene glycol;

- ethylene glycol;

- brines.

Their second component is usually water, the content of which can reach 95%.

Each category has its advantages and disadvantages, but they are united by the fact that they do not freeze at minus temperatures, which means that they can be used as a thermal carrier.

Performance properties

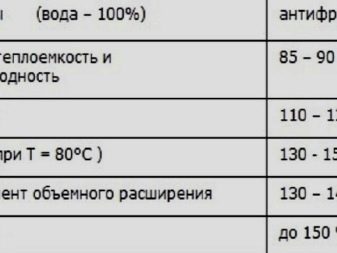

Such substances are usually realized either in the form of a concentrate, or already in a liquid form. In the case of a concentrate, it will contain only the main component - propylene - or ethylene glycol. To dilute this substance and get antifreeze, you need to take 2 parts of water, diluting them with one concentrated part of antifreeze. The finished versions are already 45% solutions of the basic component of the concentrated type. Such antifreeze is designed for use at temperatures up to -30 degrees.

By the way, before filling the heating mechanism with antifreeze, it is necessary to dilute the concentrate only with distilled or filtered water so that the concentration of ethylene glycol does not exceed the rate of one gram per liter. This will eliminate the likelihood of harm to the environment. The considered solutions are also characterized by the fact that they have a significantly lower indicator of surface tension, which ensures better fluidity and, accordingly, the speed of movement of the thermal carrier.

It is impossible to use antifreeze in heating systems where galvanized parts are present. If the temperature inside rises to 75 degrees Celsius, then the zinc layer will simply begin to peel off from the radiators and settle inside the boiler, which will lead to a significant reduction in the anti-corrosion antifreeze characteristics.

The service life of such coolants will depend on how actively the system is operated. The use of such substances is not recommended at temperatures that are close to boiling. If heating occurs above 175 degrees Celsius, the anti-freeze components simply begin to break down. When this occurs, the release of gases and the destruction of anti-corrosion additives. This can be a strong formation of burning on the heating elements.

Before filling the heating mechanism with antifreeze, it is necessary to ensure that the circulation of the coolant is appropriate. It is necessary to properly place the elements of the heating type, so that there is no risk of overheating of the heat carrier and it does not burn.

First, it is required to calculate the heat exchange processes.This is done in order to determine the performance parameters of a particular thermal carrier and in order to carry out the necessary circulation of heat fluxes.

An important factor that ensures the effectiveness of the use of the substances under consideration as coolants is the tightness factor of the entire system. The fact is that ethylene glycol can be oxidized in air. And the higher the temperature, the faster this process is accelerated. Substances released in a similar situation, begin to destroy the walls of pipelines and can cause corrosion. That is why in heating systems, sealed expansion tanks should be used sealed type.

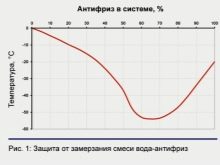

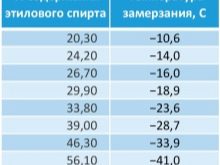

Now it is necessary to say a little about the freezing temperature. Before using antifreeze as a heat carrier, determine the ideal dilution concentration ratio.

If the percentage of ethylene glycol is too high, it will cause such phenomena as:

- increase in dynamic viscosity;

- drop in thermal transfer efficiency;

- the formation of an additional load on the equipment of the pump type;

- increases the cost of the coolant.

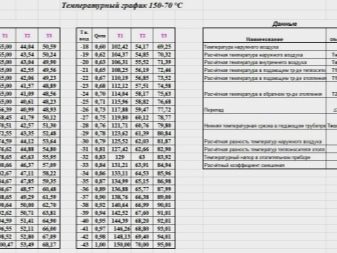

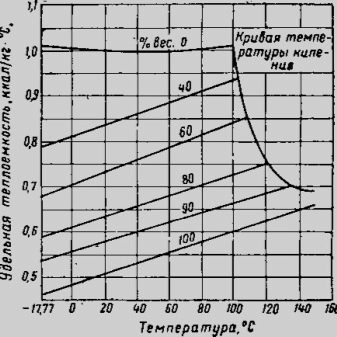

That is why the temperature should be constantly within normal limits. To do this, it will not be superfluous to know the temperature schedule for supplying heating, which can be found in the relevant division of heating networks. Then the correct formula of antifreeze consumption as a heat carrier can be developed. An important point will be that for different categories of substances it will be different, since their specific heat capacity, although it is at approximately the same level, will still be different. It is important to determine how the freezing of the ethylene glycol-aqueous liquid is performed.

It is carried out in several steps. Water is immediately transformed into ice, and antifreeze initially forms crystals, which initially move freely in the liquid. As temperature decreases, the number of crystals grows until the whole solution turns into a solid state. Moreover, it expands quite insignificantly, which should also be taken into account.

Advantages and disadvantages

As you can see, antifreeze is often more advantageous to use as a heat carrier than water.

They have the following benefits:

- their freezing point is significantly lower than that of water;

- it is possible to start the heating system at any time;

- such liquids with special additives can deduce from the construction various salts of the mineral type, as well as scum, which have a protective effect against corrosion on the metal parts and prevent deformation of the joints of the sealing type;

- Do not cause swelling and dissolution of piping or seals.

Speaking of disadvantages, it should be highlighted:

- when such liquids leak, their vapors can cause harm to human health;

- in no case can they be used in the vast majority of boilers due to the possibility of leakage;

- high activity of a chemical nature when combined with zinc does not allow the use of such liquids in pipelines with galvanized pipes;

- too high viscosity significantly increases the load on the circulation pump, for which reason this factor must be taken into account when choosing a pump.

All these advantages and disadvantages cause the heating system, where antifreeze will be applied, to differ in a number of parameters from the system where water is used.

It is that:

- for better movement of viscous substances in systems with passing traffic, one should acquire a more powerful and high-quality circulation pump;

- greater than that of water, the index of volumetric expansion during heating requires a larger expansion tank;

- due to the higher probability of leakage, greater attention should be paid to the state and quality of the assembly of sealing-type joints;

- it is required to increase the capacity of batteries by 35-40% in order to increase the heating efficiency due to the lower heat capacity of similar substances;

- too aggressive substances should not be used for galvanized pipes due to the high probability of the formation of bulky sediments, which can cause damage to the entire system;

- it is necessary to use the softest water for dilution, or the probability of salt precipitation will increase significantly;

- Be sure to add additional additives to the liquid - despite the fact that the antifreeze itself has anti-corrosive properties, its dilution in the 1: 2 ratio will reduce its characteristics by at least 50%

Species

There are various Types of substances considered on the basis of such substances:

- ethylene glycol;

- propylene glycol;

- alcohol;

- glycerol;

- brine

The most common are solutions based on the first two components, which we will discuss in more detail.

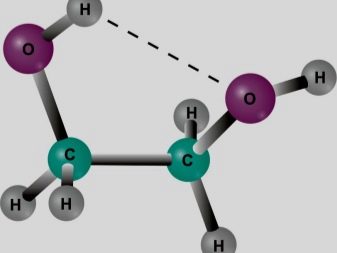

Ethylene glycol is an alcohol consisting of a large number of atoms. It has no smell, no taste, no color. In pure concentration, its characteristics start to be lost at -30 degrees Celsius. For this reason, only aqueous substances of this type of alcohol are used in different concentrations. The maximum temperature of -50 degrees, when the composition can freeze, can be achieved with its ratio to water of 6 to 4. Non-freezers based on ethylene glycol have been popular for more than a hundred years. Their main advantage will be affordability.

It is toxic in itself and has a third hazard category. For this reason, the composition is used exclusively in closed heating systems. It is extremely poorly combined with galvanized pipes. Another one of his minus - it decomposes in the solution, if the temperature indicator is above +70 degrees Celsius.

By the way, it is forbidden to use ethylene glycol in heating mechanisms of the 2-loop type due to the risk of it entering the hot water supply mechanism. It can disable it.

Propylene glycol is a liquid that has no color, but it has a sweetish taste and a rather unusual smell. Very widely used in the food industry and in the creation of substances that are used in electronic cigarettes.

This substance, in contrast to ethylene glycol, is completely safe and ecologically clean. It appeared on the market relatively recently - in the 90s of the last century, but it became popular rather quickly and began to be actively used in various fields.

Propylene glycol substances are non-aggressive, have good performance characteristics, if we consider them as a thermal carrier.

Its freezing point and density will vary depending on the content of the active substance. A serious disadvantage of solutions is the high cost.

Also on the market today can be found antifreeze based on triethylene glycol. Such a product can hardly be called widely used, but it is used from time to time for heating systems in country houses. Its main feature is that it is designed for the heating system, where the temperature can reach 180 degrees Celsius.Another characteristic of triethylene glycol antifreeze is the highest temperature stability.

Antifreeze based on ethyl alcohol usually consists of special anti-corrosion additives, as well as a concentrate of technical alcohol, the content of which in a liquid can be more than 90 percent. Before using it, mix it with water in a ratio of one to three. In this case, the freezing temperature of the resulting solution will be -19 degrees. Do not attempt to increase the alcohol content, as this can lead to vapors that are explosive in high concentrations. In such antifreeze, the heat capacity will be approximately on par with water, but higher than that of glycol-based solutions.

By viscosity, its characteristics will be close to those of water, so you should not be afraid of leaks.

In the market you can find options and on the basis of glycerin.

Such antifreezes have a number of advantages:

- they are not hazardous to health and have the highest refractory characteristics;

- have a large range of operating temperatures from -30 to +100 degrees;

- they do not need to be diluted with water, that is, you can use immediately after purchase;

- do not contribute to the formation of rust and do not have a destructive effect on the various elements of heating systems, such as galvanized pipes, aluminum batteries, rubber components;

- such liquids have a longer service life — in glycerol antifreezes, it is about eight years, while in all others it is about four to five years;

- when using them, it is not necessary to constantly flush the system;

- It is possible to apply glycerin antifreezes even after complete freezing or cooling.

On the effectiveness of such substances testify reviews. Many people write that the best antifreezes are made on the basis of propylene glycol and ethylene glycol. Such solutions do not freeze and save the heating system from failure. Moreover, many even pour antifreeze into the system and go on a business trip. Users also write that the issue of leakage is not so terrible - usually there are few of them. Also note the excellent thermal performance of antifreeze. Users note that they did not encounter corrosion when using these substances.

Despite the fact that the substances in question should be changed preferably annually or every few years, a number of users did not change it for 4-5 years and noted that even with such a period of use, these liquids behaved well and fulfilled their functions qualitatively.

Criterias of choice

When choosing a heat carrier for a heating system, The following factors should be taken into account:

- Antifreeze in almost one hundred percent of cases can not be used with boilers. Almost all manufacturers warn users that boilers that use antifreeze as a heat carrier are not subject to warranty repair.

- The material of which the pipes and assemblies of the mechanism along which the fluid moves is made will play a significant role. Here we say that if galvanized pipes, it is better to use water, and not antifreeze as a coolant.

- It is best to opt for a product that is subject to temperature control.

- The composition of the solution should be as small as possible components that are toxic.

- When selecting, you should carefully read the instructions for a particular product.After all, there are some types of thermal media that can be used exclusively in industrial buildings. Their use for a country house is unacceptable and can have serious consequences.

- It is advisable to choose a variant with low viscosity and good heat capacity and thermal conductivity. This will make it possible to make heat transfer as efficient as possible.

- Coolant should have an affordable cost. Not always expensive solutions are the most effective.

- The product must have a long life.

- Before going for the purchase of antifreeze should figure out what freezing temperature it should have.

- It will not be superfluous to get acquainted with the opinion of the boiler manufacturers regarding the use of such liquids. There are still a small number of manufacturers who are completely against the use of antifreeze as a heat carrier in heating systems.

- Should be taken into account when choosing the toxicity and properties of a substance.

It is believed that the best solutions for physical and chemical properties of liquids as a coolant will be antifreeze and water.

Popular brands

Today, in the domestic market can find a variety of antifreeze. In some countries, the country of production is Russia, while others are products made in Europe or Asia.

If we talk about domestic products of this type, then you should definitely say about antifreeze "Warm home". It can be found in several variants. Among them, the most common is the "Eco-20". It is a substance that is green in color and is made on a propylene glycol basis. This is an excellent solution for double-circuit boilers. There is also an option called "Eco-30" from the same manufacturer. This option is made on the basis of ethylene glycol. Its peculiarity is that after its acquisition it is necessary to break it. A liquid called “Warm House-65”, which has a red color and an ethylene glycol base, will also be quite popular. Its characteristics will be even better than the two previous options.

Products of this brand have a number of advantages:

- a large range of operating temperatures, which makes it possible to choose the necessary option for each specific case;

- long service life, which is 5 years, and if it is used for the heating system, then the period is extended to 10 years;

- no reaction in contact with materials such as rubber, plastic or metal-plastic;

- absolute harmlessness to humans and other living beings.

At the same time, the products of this brand have some drawbacks:

- the inability to use in systems whose elements are electrolysis boilers;

- can cause scale formation and corrosion due to the presence of salts in its composition;

- it is possible to use compositions of this brand only in a certain range of temperatures, otherwise crystallization may occur;

- Do not mix this antifreeze with other coolants, so as not to disable the heating system.

Hot Blood will be another popular brand name. This line of antifreezes is produced by the domestic manufacturer LLC Vintkhim. All products manufactured under this brand are made on the basis of propylene glycol and ethylene glycol and are completely safe for humans. In addition, they can be used for a period of 5-6 years depending on the operating conditions.In addition, all substances in this line have an affordable price and allow you to ensure the quality of the heating system, even in the most severe frosts.

This manufacturer is interesting in that it has two lines of non-freezing liquids:

- Hot Blood M;

- "Hot Blood Eco."

The first line contains substances with an index of 20, 30, 40, 65. Each of these types has its own freezing point, but in general they are similar and are used for classical heating systems, which are practically in every home.

But the means of the second line are designed to work in closed heating systems, autonomous systems, as well as air conditioning systems. They have a slightly different structure and composition, but also effectively perform their task, like the models from the first line. It should be said that this line is represented by three models with indices 25, 30, 65.

By the way, all products of this company are manufactured in accordance with the standards of GOST, as well as ASTM.

Another well-known manufacturer of non-freezing liquids for heating systems is the company Sintezprodukt from the city of Tula. She has several lines of the products in question.

The line called “Bautherm” is a water based ethylene glycol solution., which contains a large number of various additives of the anti-corrosion type, as well as defoamers, which reduces the risk of foaming such a coolant inside the heating system. Usually the products of this line are used in autonomous heating mechanisms of the closed type.

This also includes the eponymous antifreeze line with the prefix "Eco", which is based on propylene glycol. These products can be used not only in closed as well as open heating systems and air conditioning and ventilation mechanisms.

The second line, which should be said a little, has the name "Moscow Standard". This is an ethylene glycol solution, which contains various additives. Its distinctive feature will be versatility, since it is possible to use antifreezes from this series in any heating mechanisms.

The line "Moscow Standard Eco" is represented by non-freezing liquids already based on propylene glycol, which is produced according to the USP standard. It also has a large number of additives. This version of the coolant does not harm the environment and living organisms.

NPO Sintezprodukt also produces specific products of this type. It is united under the brand name "Sun Power". This type of antifreeze coolant is a liquid that is responsible for the transfer of thermal energy from the solar collector to the battery capacity.

All models about which it was told, have special designations in the names. This makes it possible to understand the freezing point of a product and find the best option in each case.

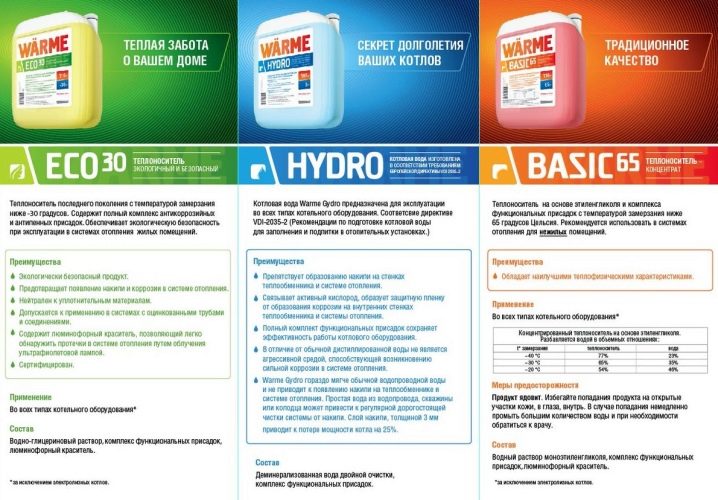

Will also be interesting products of the company Warme. By name it may seem that this brand is foreign. In fact, it is domestic, although it produces its products from foreign raw materials. This makes it possible to provide excellent European quality at an affordable price.

Consider the option "Warme Eco 30", which is used in various heating systems as a working substance in various kinds of heat exchange units that operate at low temperatures. As it was said, its basis will be high-quality raw materials of imported type, where various functional additives have already been added, allowing to provide protection against the occurrence of scale, foam formation and corrosion.This heat carrier is made on a glycerol basis, which means it is completely harmless to the environment, as well as animals and people. Its advantage is that it can even be used in galvanized pipes. It should be said that it also contains a special dye on a phosphor base, which makes it possible to detect various kinds of leaks using an ultraviolet lamp. This solution makes it possible to significantly accelerate the commissioning of the work of the commissioning type.

In addition, such a thermal carrier has received a lower viscosity, which gives it an advantage when using the heating mechanism in idle mode.

In general, the domestic market is dominated by products of domestic companies that produce fairly high-quality non-freezing liquids that are not inferior to European ones. Moreover, their use will be even the best solution due to the fact that foreign antifreezes are often not adapted to domestic heating systems either in their composition or in their characteristics. And this may be the cause of disabling the entire heating system or the occurrencemalfunctions on some specific sites.

Filling the system

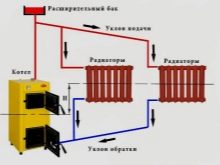

Conventionally, the filling system is divided into 3 stages:

- training;

- concentrate dilution;

- direct filling.

The first thing to do is to check how tight the connections are in the heating mechanism. If necessary, the gaskets and materials should be replaced, which are incompatible with non-freezing. Now you should check for leaks, scale on heat exchangers, as well as lime deposits on batteries and piping. Next, you need to make a calculation of how much antifreeze will need to be pumped so that the system will be filled to a certain indicator. It is very simple to do this - it is necessary to pour water into the system, then it is necessary to add the required amount to the tank in order to reach the special mark, to drain it and measure the quantity using a special measuring container. If suddenly a leak has not been noticed by you, then at the same time you will be able to notice and eliminate it. By the way, it will not be superfluous to add liquid for flushing the heating system as a preventive measure.This will remove even minimal scaling.

Now it is necessary to carry out the dilution of the concentrate. Of course, today there are liquids ready for use, but it will not be superfluous to talk about this. If you know the concentration and the volume of solution you need, you need to prepare a certain amount of filtered or distilled water. Now prepare the container. Best of all, if it is a barrel of plastic or stainless steel. Pour there the right amount of water and concentrate. In no case should not mix them, so as not to form a foam, which will be saturated with oxygen. We lower the pump into the container, which will pump the liquid. To it we attach a hose connected to the drainage valve. Now we carry out the output and lowering of the second hose into the barrel with the discharge of the expansion tank.

Here it is necessary to say that the technology of filling the system of open and closed versions will be different.

If we are talking about an open-type mechanism, then it is better to take thermal carriers on propylene glycol basis. It's all about the expansion tank that fits in with the environment.Since it is located within the house, a certain amount of evaporation may be in the building. But then the concentrate is poured through an expansion tank or a make-up valve using a pump. At this point, Mayevsky's faucets, each of which is embedded in the radiator, must be exclusively in the open position. As soon as the level of the thermal carrier reaches one third of the expansion tank, all valves should be closed. After filling and warming up the boiler, release the remaining air through the radiators. If the level of heat carrier in the expansion tank has decreased, then there is the possibility to regulate it to the desired level by adding the required amount to the 50% mark.

In order to pour an antifreeze liquid into the closed type mechanism, it is necessary to perform several more actions. It is best to fill with pumping equipment, which is connected to the fitting of the feeding mechanism. If there is no pumping equipment at hand, then antifreeze will have to be poured through the highest point after unscrewing the automatic air vent. It is good if you have an assistant who will let the air out of the batteries as you get the non-freeze.

Before starting the system you should check that:

- shut-off valves are in the open position;

- the boiler cut-off valves are in the closed position;

- the concentrate was diluted according to the instructions;

- Mayevsky's cranes are closed;

- The expansion valve for the expansion tank is open.

It is necessary to begin the process of pumping antifreeze until the pressure on the pressure gauge reaches the level of 1.5 Bar. Now the helper should start blowing air from the batteries upwards. At this time, it is necessary to monitor the information on the pressure gauge and pump out the thermal medium in order not to allow the pressure to reach the indicator below 1 Bar. When the air is released, the antifreeze should be restored to the level of 1.5 Bar. Now it is necessary to open the taps one by one, which cut off the boiler - first on the back, and then already on the line with passing traffic. The second valve must be opened very slowly, so that the air has time to go through the air outlet. If the pressure continues to fall, antifreeze must be added again.

When starting the heat generator and warming up the heat carrier, you should closely monitor the arrow of the pressure gauge. At operating temperature, pressure values should not be higher than 1.8 bar.It now remains to clear the air from the heaters and make pressure adjustments. It is necessary to work with Mayevsky valves very carefully, since the mechanism is already heated antifreeze, which can cause burns. This will be especially important if you pour a non-freezing liquid on an ethylene glycol basis into the heating mechanism.

At the end of the process, all connections and equipment should be carefully inspected for leaks. If they are, then it is not necessary to drain everything from the pipelines. It is enough just to cut off the necessary branch or part with the help of valves, and after the problem is fixed, increase the pressure again and release air. By the way, the replacement compressor can be used in a similar case.

The scheme of using antifreeze as a heat carrier for a heating system has the right to life.

But the process of selecting antifreeze as a coolant, as well as the process of filling the heating system with it, should be approached as carefully as possible so as not to spoil the heating system in a private house.

See the following video for the pros and cons of the atifreeze heating system.