Types and subtleties of the choice of heating equipment

Today, the market for heating appliances is represented by a wide variety of devices, which differ in the principle of operation, design features, performance and other parameters. All of them are designed to provide thermal energy, maintaining the temperature in the room at an optimal level.

Special features

Consider the main criteria for heating devices. Heat transfer is of the greatest importance, since with the increase in the use of energy resources, the cost of heating the room decreases.

This criterion depends on the material.

- Cast iron due to its high inertial capacity heats up for a very long time, but also cools longer than others. Therefore, this factor can be a plus and a minus for cast iron radiators.

- Steel, bimetal and aluminum are heated in the shortest possible time. According to the efficiency of heat transfer, their parameters converge slightly.

To ensure better heat transfer, it is recommended to follow the rules for installation and connection of the device, as well as not to close the heating device with curtains and screens.

Duration of operation is also an important parameter that determines how often the heating equipment needs to be replaced.

- Devices made of steel have a short service life (10 - 15 years) under the condition that the thermal agent will be in the apparatus even in the warm season to avoid the appearance of corrosion.

- Aluminum devices serve up to 20 years if high quality material was used in the manufacture. During installation and connection it is necessary to follow the instructions, since the interaction of aluminum and copper leads to the formation of corrosion.

- Cast iron models are operated for up to 30 or even 50 years. This is due to the fact that cast iron is absolutely not subject to corrosion.

- Products from bimetal are characterized by a service life of up to 40 years due to the use of quality materials.If the core is made of stainless steel or copper in bimetallic equipment, the device can last even longer.

The dimensions of the equipment are also no less important, since most often the heating apparatus is chosen for specific parameters:

- the dimensions of the devices depend on the center distance, often the difference between them is no more than 10 cm;

- the width of the equipment depends on the number of sections, so it is necessary to perform a thermal calculation in advance;

- The center distance of the equipment is 200, 300, 350, 500 cm.

Requirements

The heating equipment has requirements that determine their quality.

- Sanitation or SNiP requirements, in accordance with which the device for heating must be in a protective casing with a lower temperature, a smaller area to avoid dust accumulation, a smooth surface to remove dust deposits. As well as heating equipment must comply with the rules on fire safety.

- Economic requirements: each heating device must be manufactured at low cost, as well as have lower costs in the design and operation.

- Production and assembly requirements: in the production and installation of heating equipment must be complete mechanization of processes. Devices must be manufactured with a high level of strength.

- Operational requirements: units for heating must be adjustable, resistant to elevated temperatures, and also waterproof in conditions of high hydrostatic pressure inside the equipment.

- Thermal: the design should provide maximum heat flow, which is distributed per unit area.

- Architectural and construction: equipment must be compact and installed in accordance with the interior.

- Aesthetics requirements: the heater should not spoil the beautiful view of the room and do not take up huge space, so it can be installed in stairwells and other places.

Kinds

To date, there is a certain classification of heating equipment.

Aluminum sectional heating equipment is designed for installation in centralized heating systems.These devices are unsuitable for operation in old heating networks, since the salts that are formed destroy the polymer film on the radiator surface. As a result, this can lead to equipment rupture.

Aluminum models serve more than 25 years if the necessary conditions are met: constant monitoring of the thermal agent and avoidance of the interactions of two different metals.

The radiator can withstand increased pressure from 6 to 16 atmospheres, so that the heating device can be connected to the central heating system. These models can withstand significant loads compared to pressed products.

Positive features of aluminum radiators:

- high performance;

- small dimensions;

- easy connection to the system;

- high performance functionality.

Disadvantages of equipment:

- cannot be connected to outdated heating circuits;

- prolonged use often leads to rupture of the seams of the equipment.

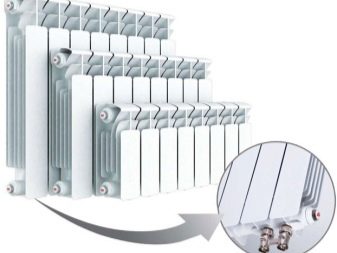

Bimetallic radiators are made of aluminum with steel or copper. To ensure protection against corrosion, the surface of the radiator is covered with a layer of polymer.The external surface of the battery is aluminum, since this metal has the greatest thermal energy. The use of steel makes it possible to manufacture equipment with low weight, but at the same time capable of withstanding an overpressure of up to 25 atmospheres.

In order to avoid the interaction of two dissimilar metals, an insulating material, paronite, is installed between them. Thanks to this, it was possible to significantly increase the service life of bimetallic radiators in comparison with other models.

Bimetallic equipment is installed to heat large rooms, and portable models also provide local thermal energy in enclosed spaces.

Advantages of bimetallic radiators:

- small sizes;

- high performance;

- quick connection to the system;

- possibility of heating large rooms;

- possibility of operation with an excess pressure up to 26 atmospheres.

Of the minuses of the equipment - a complex structure.

Bimetallic equipment lasts longer than other types of heating equipment.

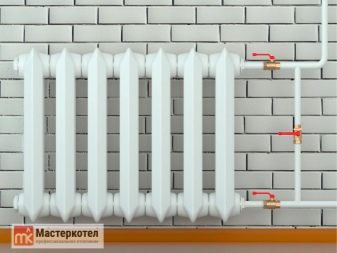

The pig-iron heating equipment is not afraid of corrosion influence, and also possesses a high thermolysis.Due to the wide variety of types of cast iron radiators, it is possible to make an optimal selection of the model, taking into account operating conditions.

Cast iron batteries come in a variety of sections: single, double, triple, enlarged, classic and standard.

Positive features of cast iron radiators:

- not subject to corrosive wear;

- good heat dissipation;

- possibility of operation with increased pressure;

- possibility of joining additional sections;

- the possibility of using any coolant;

- The operating temperature of the heat agent is up to 135 degrees.

Disadvantages:

- too much weight;

- fragile material.

Steel panel construction is equipment with a lower side feed. Built-in temperature controllers allow regular monitoring of the temperature of the heat agent. Thanks to an improved mounting system, you can install the heater on the wall or on the floor of a private house.

Since the maximum sustained pressure in steel radiators reaches only 9 atmospheres, this limits their use in centralized heating systems with largeloads.

Advantages of devices:

- transfer heat energy well;

- ease of maintenance;

- convenient installation;

- small dimensions.

Cons of steel panel radiators:

- if the material used is ordinary steel, this leads to corrosive wear;

- low pressure of the panels does not allow them to be mounted to a centralized heating system with loads.

Steel tubular batteries are considered the most expensive because of the high cost of the material used. The beautiful appearance of the radiators allows them to be installed in accordance with the design ideas.

Since the material is corrosive, treatment with anti-corrosion agents significantly increases the cost of radiators. Separate sections of the battery are interconnected by welding, the finished equipment is installed without distributing pipelines. With a pressure of less than 12 atmospheres, the steel tubular structure copes well with loads, which allows it to be installed in high-rise buildings.

Positive features of the equipment:

- increased heat transfer;

- structural strength;

- noble appearance.

From minuses of steel tubular devices high price policy is marked.

Convector heating equipment operates on the basis of air convection. The circulation of air mass occurs due to the stimulator - a copper tube with aluminum plates. They are designed to provide heating of cold air, which is converted into thermal energy. The process takes place inside a metal box, which itself is not capable of heating. To increase the flow of air mass sometimes installed intake fans.

Convector equipment is installed in cottages in the form of a wall unit, bench or baseboard. There are also in-floor appliances. Devices will be the best option when installing in rooms with low window sills or wide windows. Each model works up to a maximum pressure of 10 atmospheres, which allows them to be installed in a central heating system.

Pros:

- low inertia capacity:

- small sizes;

- fast space heating.

Disadvantages of convector devices:

- low thermal energy;

- availability of requirements for thermal agent.

Water heated towel rails are made of steel, brass or copper. Brass devices operate on coolants with only neutral acidic properties, and steel and copper - on any coolants. Due to the possibility of operation at high pressure up to 16 atmospheres, they can be installed both in the heating system and in the hot water supply system. In both cases, the device will work without any complaints.

Electric towel warmers are designed to provide the same functions as water equipment. However, water devices and electrical appliances have not found wide application among consumers, since it is not recommended to use equipment in the absence of liquid in the system.

Advantages:

- a wide range of colors and geometric shapes;

- increased pressure.

Minus - when interruptions in the water supply system cease to function.

How to choose?

When selecting heating equipment, first of all it is necessary to pay attention to the practicality of the product, as well as take into account technical features:

- dimensions of the model;

- performance (per 1 m2 area 0.1 kW);

- equipment pressure (centralized systems - more than 10 atmospheres, closed - more than 6 atmospheres);

- acid properties of the heat carrier and water.

Lastly, it is recommended to pay attention to the aesthetic parameters of the device and the possibility of its reconstruction.

Tips

Installation of heating equipment is not a big deal. The heating apparatus is the basis of the circuit. The right choice of design is influenced by such factors as the area of the room, technical characteristics of the equipment and personal preferences of the owners.

Installation of the heating system begins with the calculation and planning of heating. To do this, it is recommended to contact the specialists, since even minor mistakes will lead to irreversible consequences. And for wooden premises, you can pick up the brackets where the heating unit is hung.

Fasteners are used to install the battery indoors.

When operating the heating equipment, it is necessary:

- maintain the estimated air temperature in the room;

- equipment tightness;

- ensure an optimal noise level not exceeding the permissible threshold.

Regular maintenance of the heating circuit, which includes:

- inspection of distribution pipes - once a month;

- temperature control and coolant pressure.

In case of equipment breakdown, repair or replacement is carried out in accordance with the project or the rules of the setup organization. After the completion of repair work or with the onset of the summer season, deposits, scale, dirt, and then washed out are removed from the inner surface of the equipment.

To reduce the consumption of heat, fuel and water, it is recommended to use a system of automated regulation and control over the functioning of the heating system, to maintain optimal values of temperature and pressure, and thermal insulation in a good position.

How to install a radiator, see the following video.