Features and manufacture of induction heating

Heating systems are offered by a variety of companies, there are many interesting engineering developments. Changes in the prices of the usual energy sources force us to look for alternatives. Particular attention should be paid to this type of electrical heating, as induction heating.

Special features

Unlike gas boilers, such devices can be installed without tedious, lengthy approvals. Moreover, they are ahead of most of their electrical counterparts, since they are much more economical. The only problem is that the induction boiler is expensive. You can solve this problem if you make it yourself.You should not only approach this matter lightly, you should immediately weigh the pros and cons, assess your willingness to work with electrical equipment.

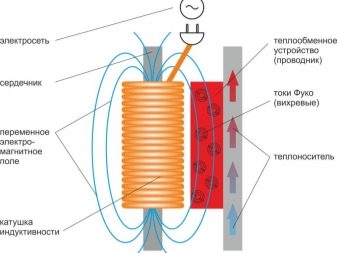

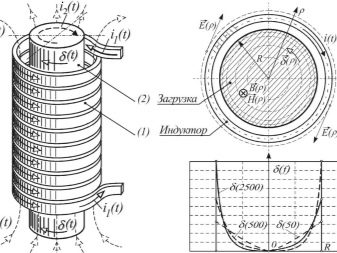

Induction heaters were first used in the 1980s, and it was not until the mid-1990s that they reached homes and apartments. Minor improvements of the last 30-40 years did not affect the basic principle of operation of devices, that is, the application of electromagnetic induction. When an alternating current impulse passes through a coil of coarse wire, a field is formed around it. The conductor in contact with the field is filled with induced current. If inside the conductor there is a core with magnetic properties, so-called Foucault stray discharges appear that are able to quickly heat the material.

How it works?

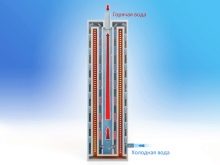

An inductive system implies the central part giving off heat to water, oil or ethylene glycol. These fluids further move along the heating circuit and give the received energy to the air in the rooms. Sometimes designers refuse from the core in the usual sense of the word. It is replaced by a complex conglomerate of pipes.This solution increases the total contact area and additionally accelerates the heating of the coolant.

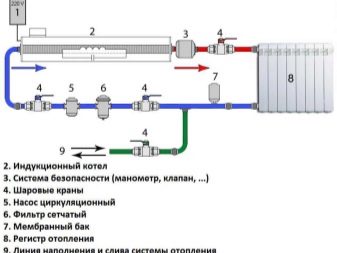

With the help of a single inductive boiler, it is possible to supply hot water to several branched heating circuits at once. But this will have to work on the arrangement of the collectors and circulating pumps. If the heating system is relatively short, the natural pressure of the heated fluid can maintain this circulation. But long highways, especially divided into several parts and having a fancy configuration, will not work this way. It is very important to understand the real characteristics of such systems.

Practical use

Induction heating for a private house can really be considered a novelty. But the physical effect underlying it was discovered in the first third of the XIX century. Since the 1950s, equipment based on this principle has been actively used by metallurgists. There is nothing strange in this, these facts show only that such a scheme has been thoroughly thought out and tested. High efficiency is confirmed by a number of practical tests and independent examinations.

What is important, even the heat losses do not evaporate outward, but remain inside the heated room.

The approximate usage period advertised by sellers from 25 years can be real., but only with high-quality electronic content. The standard warranty for semiconductor parts is 10 years. Other parts (electrical and mechanical) are worked out to the smallest detail, the technical solution is simple, so there is nothing special to break there. For a complete loss of the central heating part of its characteristics, several decades should pass.

Inductive devices when working can create low-frequency waves, annoying some people. A partial solution to the problem is vortex boilers, which, before applying voltage to the main coil, increase the frequency of the current. The rest of the noise depends primarily on the quality of the installed pump.

Induction boiler takes up less space than a conventional electrical apparatus. But here its mass is quite large, and solid brackets will be needed for wall mounting.

When assessing the required space, we must not forget that it will be necessary to install additional equipment, dissolve the contours and install the collectors.To heat a large area, sometimes you need to use several boilers at once, and you cannot put them close to each other. In terms of safety, inductive and heater equipped boilers are approximately on the same level. Rather, the type here does not solve anything at all. The main thing is how well the device is assembled and whether its connection meets the standards.

Making your own hands

The general conclusion is: induction equipment is a simple and worthy solution to many heating problems. But we must approach its preparation carefully and clearly. Products equipped with a hob, belong to the experimental class. Such equipment copes with the heating of rooms in 20-25 square meters. The installation is recommended as part of the heating circuits of radiators based on aluminum or a pair of metals that will heat up rapidly and give off heat better.

As a generator of a changing magnetic field, cooktops were used that were removed from old stoves when they were replaced or upgraded.

To work will require:

- profile steel pipes with a section of 5x2.5 and 5x3 cm;

- sheets of steel 0.3-0.4 cm thick;

- polypropylene pipes (the need for them is calculated according to the specific scheme chosen);

- ball valves.

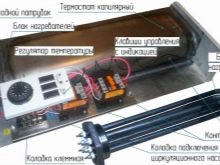

In most cases, it is impossible to do without circulation pumps. In the process of construction and installation of a homemade induction boiler, welding machines and gas switches, soldering irons for polypropylene, electric drills and grinders are used. In most cases, the induction panel is placed horizontally, and heat exchangers are placed on top of it.

They are best made from ferromagnetic materials, these elements are similar in shape to some kind of pots, so the installation procedure is intuitively clear.

Heating takes place in the same way as in conventional hotplates for water, just not using the usual increased resistance, but using a different physical effect. In addition, the similarity of the shape of the tank and the pan should not be misleading. The lid will not be removed, because the container must be 100% sealed. Alternatively, the use of high frequency welding inverters is allowed. The best models are those that are equipped with a flexible current adjustment function.

The power of the inverters is also not accidental, they select such equipment, which coincides with the power of serial heating boilers. Most experts believe that home-made should be mounted on the inverter 15A. But no one forbids taking more powerful devices.

Connecting water heaters to the terminals of the welding wires is strictly unacceptable. All that happens when you start such a device is two fireworks, first from the boiler, and then from the house as a whole.

The first winding is connected after the converter on the RF, instead of the default inductive coil of the inverter located there. You can increase safety by placing the entire product inside the casing, becoming an insulating unit. Of course, the casing is made of dielectrics, most often it is just a pipe of large diameter. There must be prepared holes for the output of the ends of the network cables, as well as areas for the output of pipes. A connection with heating and water circuits is carried out through the pipes.

The ends are usually sealed with plugs using heat resistant glue. At the ends or sides of the covers are made holes for the pipes. How to implement all this, what diameter, how visually to submit, depends on personal taste.

For your information: inductive heating can only be experienced in the form connected to the heating circuit, when filled with coolant to 100%. Failure to comply with this requirement will, at best, lead to the melting of plastic parts, and at worst - to a serious fire.

To the coolant does not cause problems, it must be passed through the filter in the form of a grid. As practice shows, it helps to increase the resource of boilers, pipes and radiators. Even an inductive boiler, like ordinary products, requires an expander. It is also necessary to mount the line through which the system will be fed by water. The same connection will allow emptying the system if it is necessary to check, repair or stop it due to the onset of warm days.

Tips

- Only a thorough knowledge of physics and the principles of electrical engineering, plumbing and plumbing allows you to take on such work. If there is no such preparation, it is much more correct and safer to use finished products connected by professionals.

- Corrugated pipes through which the water supply is carried out are usually bent like a cochlea or helix.Important: the total area of the circle occupied by the cochlea must be higher than that of the heating circuit on the panel.

- Inductive boilers are applicable only in closed heating systems.

- Between the heater and the floor should be at least 0.7 m, the distance to the wall should be at least 0.3 m.

- Installing an induction heater in the bathroom means that it must be stopped during hygiene procedures. Microscopic pulses are harmful, even if relatively small. Therefore, being close to such a boiler for a long time (within a radius of 50-70 cm) is not recommended. Even in safer places, it is worthwhile to surround the device with a special screen, which is formed from magnetic materials.

- As well as to a usual electric boiler, it is necessary to block access of children.

- Induction heating is fundamentally incompatible with cast iron batteries. They should be replaced or a different solution should be selected.

- The inverter is grounded and connected to the RCD circuit with carefully calculated characteristics.

- According to safety standards, it is strictly forbidden to use wires and connections with artisanal insulation;

How to make an induction boiler with your own hands, see below.