Pipes for heating: a variety of materials and installation technology

When the need arises to organize heating systems or their reconstruction in order to more economically and efficiently heat the room, it is recommended to correctly choose not only heating boilers, but also pipes.

Design features of the system

When arranging the heating system in apartment buildings, the requirements of SNiP and GOST must be complied with, which specify the optimal technical characteristics and service life of the equipment.

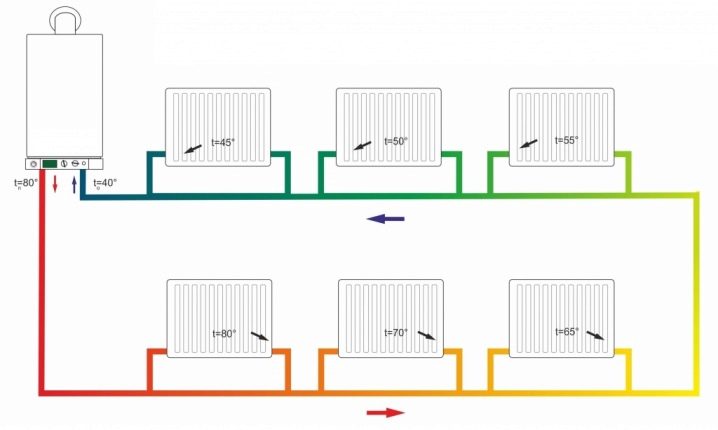

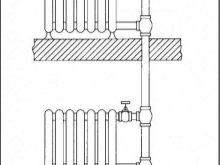

For a comfortable microclimate it is very important to choose the right heating system. Depending on the number of heat pipes, a single-pipe, two-pipe, three-pipe and four-pipe system is separated.

The one-pipe system allows significant material savings and easy installation.In this case, the heating batteries are connected in series, an overpressure and vertical filling are formed in the system.

The two-pipe system is spread quite widely due to advantages such as ease of operation. It is used in the organization and central and autonomous heating.

The three-pipe system is considered to be the most optimal, it includes a screen with a heat source, a circulation pump, and a heating device.

Four-pipe system is used only in high-rise hotels and residential premises.

When organizing heat supply, heat pipes are placed under the laminate and in the wall.

Kinds

In the past, heat pipes were used mainly in steel for heating circuits. To date, the building materials market is replete with a fairly wide range of varieties of material. Manufacturers usually do not disclose the truth to customers about how a particular material will behave in a particular situation. Therefore, it is necessary to have some ideas about the types of pipes, which ones are better to use for heating of closed and open type.

Pipes are made from materials such as:

- metals: steel, "stainless steel", copper;

- polymers: cross-linked polyethylene (PEX), polypropylene (PP), polyvinyl chloride (PVC);

- combined: metal-plastic.

In order to determine the best option for a private house and other premises, it is necessary to study the characteristics of these materials and their characteristics when specific factors influence them.

Polypropylene

Pipes made of polypropylene, reinforced with fiberglass, due to their numerous advantages have become the most popular for the organization of heat supply.

There are several types of polypropylene pipes:

- PP-N - propylene, resistant to elevated temperatures, which allows them to be installed for water supply circuits;

- РР-В - are used in the organization of heating, where the maximum temperature of the thermal carrier is less than 50 degrees;

- PPRC - the pipe consists of several layers, and in the middle - the reinforced layer. It is mounted in the contours of the heat supply at the temperature of the thermal medium more than 50 degrees.

Material advantages:

- high elasticity, which prevents depressurization of the pipe;

- no corrosive wear;

- chemical resistance, that is, polypropylene does not interact with any substances that are part of the coolant;

- quick and easy installation;

- a wide range of additional elements;

- small weight;

- dielectric properties;

- good sound insulation;

- affordable cost.

It is necessary to bear in mind the disadvantages of polypropylene products:

- in the absence of a reinforcing layer, the resistance to elevated temperature conditions and hydraulic impacts decreases;

- there is no possibility to repair them;

- in case of poor installation, the coolant will circulate unstably.

Cast iron

Cast iron has been used for many years in the creation of various purpose products. To date, there are various materials that are superior in performance to cast iron.

Despite this, this material is used in the organization of heating circuits due to its undeniable advantages:

- high strength, that is, the ability to withstand a sufficiently large pressure in the system;

- lack of corrosive wear of equipment, as cast iron is less chemically active;

- long service life;

- preservation of the original properties for several decades;

- wear resistance;

- slight thermal expansion;

- fire safety of the material;

- wide range of products;

- relatively low price compared to steel pipes.

Negative aspects of the material should be noted:

- brittleness, despite the high strength;

- big weight that complicates installation works and transportation;

- the presence of roughness on the surface, which increases the hydraulic resistance and the appearance of plaque and blockages;

- processing complexity.

Copper

Copper pipes are mainly used in the organization of autonomous heating due to its features.

Allocate annealed and non-annealed copper products. The latter are more durable and resistant to overpressure up to 400 MPa. At the same time, their flexibility is very low. Therefore, to change the characteristics of the product it is necessary to pre-heat it and cool it. The process is called annealing, and as a result of this process, annealed products are obtained.

The advantages of copper pipes for heating circuits include:

- thin walls with a small weight of pipes, which greatly facilitates their installation;

- good thermal conductivity, which provides a fast heating rate;

- resistance to high temperature conditions;

- the absence of roughness inside the pipe, thereby reducing the hydraulic resistance during movement of the heat agent, as well as the risk of the formation of deposits;

- easy processing of products due to the high plasticity of the material;

- reliable protection against the ingress of oxygen, which can oxidize the inner walls of pipes;

- low thermal expansion coefficient;

- This is an environmentally friendly material.

Copper pipes, despite the large number of advantages, have significant drawbacks:

- Incompatibility with some elements, for example, with aluminum. As a result of their interaction, a large volume of gaseous product is formed in the pipe. If there are no gas outlets in the circuit, the pipe may burst at any time.

- Mechanical abrasion of the inner surface of pipes in the presence of solid particles in a thermal carrier. Therefore, it is necessary to mount filter elements in the contour.

- The formation of eddy currents that violate the tightness of pipes.

- Electrical conductor. It is necessary to ground the system and install dielectric spacers.

- Impact resistant.

- High price of products.

Steel

Most buyers prefer time-tested steel pipes, despite the appearance of more advanced materials. Such material as steel, possesses good operational properties, long service life. However, only with high-quality installation and compliance with all the requirements of the manufacturer can you achieve durability and trouble-free operation of pipes.

Steel pipelines themselves are divided into galvanized, stainless steel and black steel. Each of them has distinctive features.

Also, pipes can be welded or seamlessly drawn, which are produced in special installations and made solid. Welded pipes are made of sheets of metal by stitching.

Among the positive characteristics of steel pipes can be noted:

- High thermal conductivity is the most important factor in the heat supply of residential premises.When the coolant circulates, when heated, they themselves release thermal energy, thereby functioning as a heating device.

- The high level of strength allows us to withstand large changes in pressure in the heating system.

- Insignificant thermal expansion provides the possibility of using thin-walled pipelines that heat up in the shortest possible time and transfer heat to the room.

- Good sealing, which provides efficient heating.

- Low price plays an important role in the case when the budget for the organization of the heating system is small.

The negative sides of steel pipes include:

- Corrosive wear. Conventional steel often undergoes oxidation and the influence of aggressive environmental factors. Galvanized options are 15 years longer than usual, thanks to the zinc coating, which, in turn, provides protection against corrosive effects.

- The complexity of transportation and installation due to the large weight of the product.

- There is no possibility to bend pipes without special tools. During the docking of pipelines there is a need for special branches with threaded connections.

- Electrically conductive properties have a significant effect when installing a heating circuit to electrical heating equipment.

Products made of black steel until the end of the last century were mounted everywhere in all heating circuits. They have the most significant drawback - susceptibility to corrosive wear. This often leads to thinning of the pipe walls and loss of initial strength. In the system, oxidative reactions occur, leading to the formation of deposits on the walls, resulting in deteriorating throughput and movement of the thermal agent. All this reduces the performance of the heating system.

To increase the service life of steel products, it is recommended to use a good-quality heat transfer fluid and regularly clean the contours.

An important point that homeowners encounter is depressurization of pipes at the joints. Only with proper operation of the structure can you achieve its durability. For example, in the heating circuit should always be coolant in order to avoid the ingress of oxygen into the pipe, which accelerates the effects of corrosion, increases the amount of sediment.

Despite significant shortcomings and a warranty period of 15 years, black steel pipes with proper maintenance can serve for several decades.

Galvanized pipes are covered with a special protective layer, which is designed to protect the surface from oxidation, which can significantly increase the service life of the structure. However, you should be aware that the coating only slows the formation of corrosion, but does not guarantee complete protection against this phenomenon.

Galvanized pipe versions for durability and resistance to corrosive wear and steel products are superior to black steel, but they cost an order of magnitude higher.

The protective coating on the surface of the product is applied using several technologies:

- Hot dip galvanizing involves immersing the product in a zinc alloy with a temperature of about 450 degrees for 10 minutes. In this case, the walls of the pipeline are covered with a protective layer up to 200 microns thick. This method allows to obtain reliable and corrosion resistant pipes.

- Electro-galvanic method is electrolysis, in which zinc ions form a precipitate on the walls of pipes under the influence of electric current.In this case, the thickness of the protective composition is not more than 30 microns, but it will be evenly distributed over the entire surface of the pipe. The disadvantages of this technology include a small adhesion, so the warranty period for the pipes is about 5 years. Another important minus of technology is toxicity, which limits the use of such pipes in residential areas.

- Thermal diffusion technology provides a high degree of protection. In this case, the protective layer is applied to the pipes at 470 degrees. It has sufficient hardness and is applied to particularly weak sections of the pipeline. The thickness of the layer depends on the processing time of the product.

The most important disadvantages of galvanized products include:

- destruction of the protective layer during welding with the formation of corrosion;

- The pricing policy of galvanized products is much higher than that of black steel pipes.

Pipes from the "stainless steel" have a large number of advantages, among which should be noted the maximum durability. They are produced both welded and seamless. The latter have a higher level of reliability and durability at a higher cost.

The benefits of stainless steel products include:

- Lack of reaction with aggressive components of heat agent and moisture. This means that there are no lesions for corrosion.

- Resistance to mechanical defects due to alloying components, as well as resistance to water hammering.

Despite the listed positive features of stainless steel products, they are rarely used because of the fabulous price and high labor input during installation.

Metal plastic

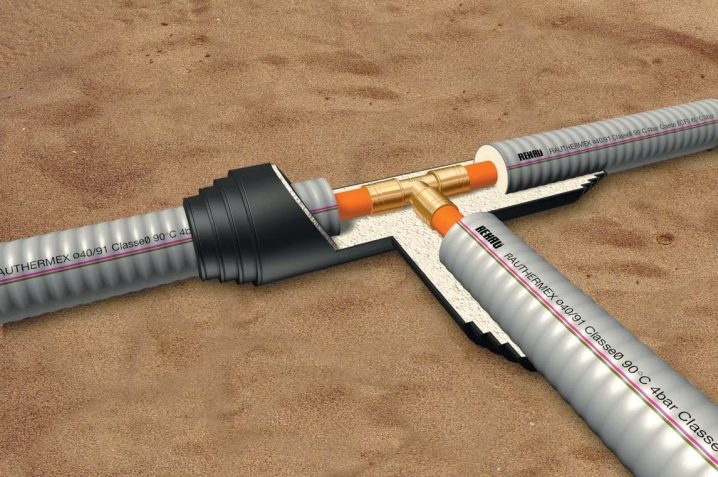

Metal-plastic pipes are very popular among consumers due to the excellent operational features. They are available in diameters 16-63 mm with wall thickness up to 3 mm. Products perfectly maintain the maximum temperature of the heat carrier to 95 degrees. They consist of several layers, which allows it to withstand the heavy loads formed in the heating circuit.

The main advantage of polymer products is its flexibility, which allows to simplify and cheapen their installation, since it is possible to do without additional bends and additional parts.

Other equally important advantages include:

- resistance to high temperature;

- possibility of combining with steel products;

- the smoothness of the inner surface avoids deposits;

- flexibility and elasticity;

- the ability to install your own hands.

Disadvantages of metal and plastic products:

- low resistance to low temperatures, ultraviolet rays;

- for connection of pipes it is possible to use only reliable opressovochny joining.

Corrugated

These pipes are quite economical option.

The advantages also include:

- Easy installation. At the same time there is no need for expensive equipment, only a pipe cutter and a gas switch are needed.

- Operating temperature over 100 degrees allows them to be installed in cases where polymer products are unacceptable in terms of temperature.

- Easy to bend and keep bending. This is important when installing in hard-to-reach areas and cornering.

- Saving on the additional elements due to the high flexibility of the material, it is easy to bend.

- Loss of tightness in contact with pipes of concentrated media.

It is necessary to mention the negative sides of corrugated (ribbed) pipes:

- instability to temperature fluctuations compared with welded or seamless versions;

- lower resistance to mechanical stress, as a result of which such products are not recommended for children's rooms;

- loss of tightness when concentrated substances hit the surface.

Cross-linked polyethylene

Pipes of cross-linked polyethylene, or PEX-pipes, are installed to organize both cold and hot water supply. Pipes under the PEX marking are used in central and autonomous heating circuits.

The material is produced in four varieties that differ in the stitching method. Quality, operational properties and price policy of pipes depends on this technology.

Cross-linked polyethylene has a number of advantages:

- shock resistance;

- elasticity;

- ease of installation and transportation due to low weight;

- resistance to high temperature stresses;

- environmental Safety;

- resistance to aggressive chemical attack;

- no risk of clogging due to smooth surface;

- resistance to corrosive wear and cracking;

- service life is more than half a century;

- resistance to sunlight;

- dielectric, noise insulation properties;

- restoration of the original shape during deformation.

Negative characteristics:

- high price in comparison with polypropylene pipes;

- installation complexity as a result of curvature, so they need to be straightened, fixing on the surface with clamps.

Manufacturers

For the complete arrangement of the heating system alone it is not necessary to search for the necessary materials and tools. Most of the common options are produced by reputable manufacturers who will help with the selection of optimal products.

The most popular are:

- Valtec;

- Rehau;

- Uponor;

- Tece;

- Best;

- Ekoplastik;

- Tebo.

Choosing one manufacturer or another, first of all you should pay attention to the warranty period of the material. The best option in a few years. The operating conditions for each manufacturer are different, but the pipes must work in the system without failures.

Criterias of choice

From the criteria for the choice of pipes according to GOST and SNiP depends on the efficiency of space heating.

These include:

- Section of pipe.

- Heating capacity of heating equipment and type of fuel used for the boiler.

- The area of the heated room.

- Depending on which heating system is selected (closed or open type), certain pipe models are selected.

- Type of coolant (on which the corrosive deterioration of heat pipes depends. In this case, stainless steel pipes will be the best choice).

- Open or hidden circuit laying is also important when choosing pipes. The first method implies fixing on the wall surface, while in the second method the pipes are embedded in the floor or wall. It is recommended for installation in heating systems "warm floor".

- The presence of the pump unit, as well as the method of movement of the heat agent (forced or natural circulation).

- Temperature mode of the heating circuit.

- Maximum pressure generated in the system. This factor is of great importance in cases with frequent pressure drops and hydraulic shocks. Independent heating involves the automatic control of any changes, and, as a rule, the stabilization of parameters. However, not all types of pipes are recommended to be installed in autonomous circuits.

- The presence of a pump, that is, the principle of operation of the coolant forced or natural.

- The temperature difference in different parts of the pipeline.

- The method of connecting pipes in the heating system. Some types of pipes have to work only with special tools and only if they have skills.

After selecting the pipe according to the above criteria, you can proceed to the choice of material of manufacture, wall thickness and resistance to external factors.

Necessary tool

Replacing the old heating system wiring is fairly simple. For the installation of the pipeline itself requires a set of tools and small technical skills.

The special tools include:

- welding unit;

- pipe cutter;

- shaver;

- fasco-picker and calibrator;

- nozzles for heating soldered parts.

Also, to install the pipeline, you will need a wrench, felt tip pen and tape measure.

Connection methods

The connection of the heating pipes is made by various methods that directly depend on the material of the product.

When using polypropylene pipes of small diameter (up to 6.3 cm), the following methods of joining are used:

- socket welding;

- coupling welding.

In the case of pipes of larger diameter, docking and socket welding are used using fittings of suitable size.

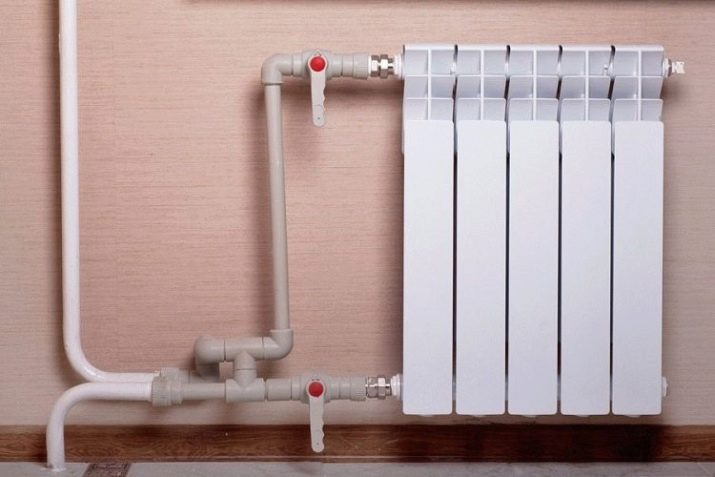

Pipes from metal-plastic and PEX-pipes are connected by a single principle using compression fittings and press fittings. Steel products are connected by methods such as threaded, welding, socket and flange.

Copper pipes are joined by folding and non-folding method. In the first case, flange connections, thread, automatic fittings are used. In the second resort to pressing, soldering and welding.

Installation rules

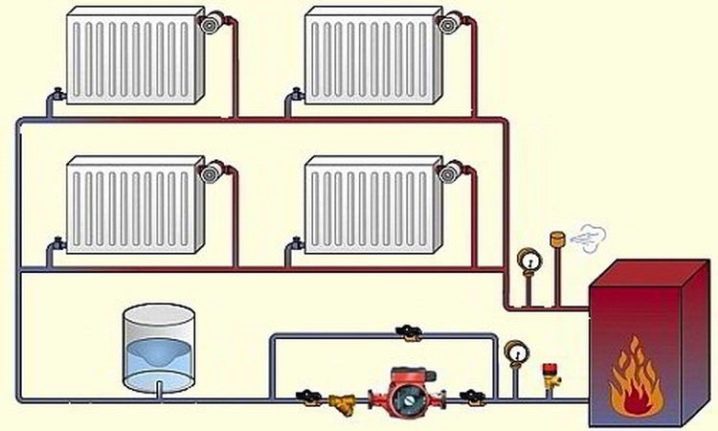

The initial stage of work in the apartment of a multi-storey building includes drawing up a calculation and a plan for the future heating circuit. In this case, a drawing is developed with the designation of the length of the pipeline, the location of heating radiators, batteries, angles and diameters of parts. When the organization of heating is carried out before finishing, the marking can be done on the wall.

Installation of pipes is made according to the following plan:

- marking the desired length of the product and the segment;

- elimination of defects;

- docking pipes and fittings;

- installation of pipes on the wall - bypass;

- connection of heating devices.

By the principle of connecting heating equipment, there are several types of wiring:

- collector - a direct and reverse pipeline is connected to the riser;

- tee-piece - several batteries are connected to each riser;

- one pipe - one heating unit is connected to one tower, the pad is suitable for apartments with a total area of less than 150 m2.

Products from cross-linked polyethylene are mounted with press fittings and equipment for pressing. In this case, you need to purchase a calibration tool, cable channel and clamp.

Metal products are joined using crimp flanges with adjustable wrench and gas wrench. The pipes are cut with special scissors and then they are calibrated with the elimination of defects.

Polypropylene pipes are joined using couplings, fittings and a soldering iron. In the latter case, you need a socket for connecting the soldering iron to work.

Metal pipes are best left to professionals. They by means of welding correctly mount the heating pipes.

How to choose a pipe for heating, shown in the video.