Heating PLEN: principles of operation and technical characteristics

Radiant or infrared heating is a way of heating a room based on heating non-transparent objects that absorb IR waves. This type of heating is much more economical than usual, besides it does not require a long time to heat the temperature in the room to a comfortable one.

What is and how does the heating system work?

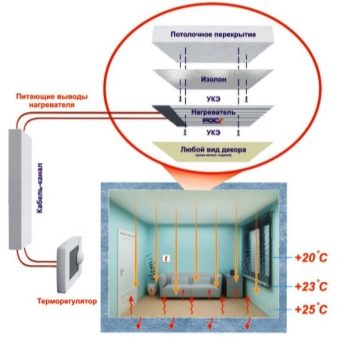

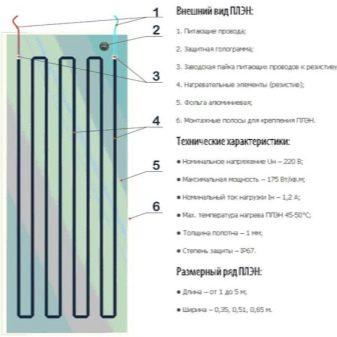

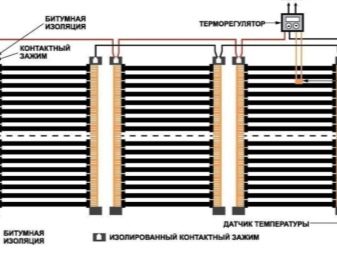

PLEN - heater radiant film type, which operates on the mains. It looks like two thin films, between which infrared emitting parts are located. The main feature of this type of electrical heating - it can be installed not only on the walls and floor, but also on the ceiling. The total thickness of the heating element does not exceed 1.5 mm, while other sizes vary depending on the manufacturer and the FLEN model.As a resistive part, a multilayer resistor circuit is used.

The work of foil heating is as follows:

- When the heater is turned on, the resistor gets the electricity needed to start work.

- Details are heated to 40-450C and begin to actively emit IR radiation.

- The rays are scattered in the room very evenly, and immediately begin to be absorbed by the opaque objects around the heater.

- The space inside the room, gradually heating up, begins to give off heat to the air. Heating the temperature at 100 degrees takes an average of 60-90 minutes. In this case, the heating occurs in layers, that is, the warmest air below, and at the level of the human head reaches a rate of 14 ° –180 ° C.

It is worth paying attention to the fact that the effectiveness of such heating is greatly influenced by thermal insulation and compliance with the rules of laying. It is important to lay a special reflecting infrared radiation substrate, which increases the return of thermal energy.

After reaching the temperature, which is set by the thermostat, the relay is activated, which turns off the heaters. Thus, the heating does not work constantly, there is a period of inactivity.

After cooling the air in the room, the PLAE switches on again and heats the room to the set temperature.

For effective heating of a room in which only infrared emitters are used, the coverage area should be at least 85%. Most PLEN systems are equipped with devices that allow emergency operation.

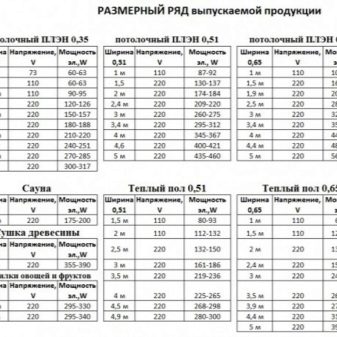

Depending on the manufacturer, heating film may look like strips with different lengths and widths. As a rule, they are divided into segments, which facilitate the installation process, and the efficiency of the PLEN is not lost. Most often on sale can be found material with a length of 5-6 meters and a width of 0.5 or 1 meter.

Advantages and disadvantages

Like any heating system, PLEN has its strengths and weaknesses. The advantages include:

- Efficiency. Despite the fact that the operation of this system requires quite expensive electricity, the costs will be comparable to those who heat homes with solid fuel or gas. It's all about the high efficiency of the film heating, as well as small heat losses and the presence of idle time.This energy-saving system does not require preventive maintenance and special maintenance, it is almost autonomous.

- Durability. At observance of all norms of installation and use of high-quality equipment, PLEN can serve for several decades. However, some manufacturers say about 50 years, during which the system will remain operational.

- Versatility. Can be used as sole or additional heat source in the room. The only condition is that if the radiant heat is the only one in the heating system of the house, then the thermal insulation of the building should be provided as much as possible in order to eliminate heat loss and optimize the operation of the infrared equipment.

- Ability to automate. If necessary, you can easily program the heating, as well as at any time adjust its work for individual needs. You can integrate FLEN into the “Smart Home” system, which will allow you to remotely control the system.

- Fireproof. Elements do not heat above 500C, heating above is not possible. Can easily be used in wooden houses without creating the danger of open fire.

- Do not overdry the air. Due to the physical properties of the IR rays, the humidity indicators in the room remain stable and comfortable for a person.

- Safety for human health. However, in addition to the absence of negative effects on the body, infrared radiation is also attributed to certain medicinal properties. Thus, research by scientists shows that these rays improve blood circulation in the capillaries and stimulate metabolic processes in the human body. PLEN are allowed for use in kindergartens and medical institutions. This fact is evidence of the safety of the equipment.

- No drafts. Due to the special algorithm of work, separate air flows are not created, the temperature is distributed more evenly than when using conventional heating systems.

- No noise and other soundsable to break the silence in the room.

- High heating rate.

- Easy installation. For arrangement of heating with the help of PLEN, special knowledge (with the exception of electrical engineering) and tools will not be required. All materials are lightweight, which simplifies their transportation and installation work.

- Resistance to external influences. This system can not be frozen, it is not afraid of moisture and power surges.

- Easy to decorate. Since the sheets of the radiant heater are very thin, they can be hidden under any finish, which expands the possible design solutions for the room.

The disadvantages of PLEN include only a few minor points, including:

- The need for good wiring and sufficient power to connect the system. If the wiring is old, it makes sense to replace it, since when the voltage is lost, the radiant heater produces less heat. This will not affect the temperature in the room, however, the cost of electricity will increase, as the operating time of the equipment will increase.

- Restrictions in the decor. It will not be possible to glue wallpaper onto sheets that emit infrared energy or putty them. It is necessary to sheathe the walls with any material, for example, plastic panels or clapboard.

These minuses are insignificant and easily overlapped by the advantages that heating with a radiant radiator gives.

Specifications and variations

The characteristics of PLEN may vary depending on the manufacturer and model,but have common features. Technical capabilities of radiant heat are characterized by the following indicators:

- maximum heating temperature - 450 degrees;

- coefficient of performance - 98%;

- power consumption - 150-170 W;

- average mass of 1 m2 of material - 500-550 g .;

- average thickness - 0.4-0.5 mm.

PLEN-systems can be represented by several types of heaters. Each of them has its own characteristics and allows you to choose the necessary equipment option for any operating conditions. By design features, heaters are divided into the following:

Floor models

Allow to transfer and install the device in any place. They have an ascetic appearance and a functional compartment under the cord, as well as a handle or wheels for easy movement. Virtually all models, even economy class, are equipped with a system to prevent tipping. The remote control and thermostat are usually found only in the premium line of heaters of this type.

Used as an additional source of heat in the room.

Wall heaters

These devices can easily replace the classic water convectors and are usually installed instead of them in the appropriate places in the wall. These models weigh a lot, however, it is not so significant, given the way they are installed.The front panel of the device can be decorated with Himalayan salt, airbrushing, artificial stone. But in such an external decoration there is a significant disadvantage. Firstly, the efficiency of the heater decreases, and secondly, the paint can emit harmful substances into the air when heated.

Ceiling models

They have a unitary appearance, so they are rarely used without finishing in residential areas. Most often they are used in offices, warehouses, garages, as well as greenhouses, which can significantly increase the time of harvest.

According to the degree of heating, which depends on the power of the radiator, the following varieties can be distinguished:

- 100-400 W - used in preschool institutions, they can heat up to 600 degrees;

- 400-600 W - mainly used in office buildings;

- 600–1000 W — used for heat curtains over windows or doorways;

- 1 thousand W and above - are intended for heating open terraces and other street, cold rooms.

By the type of heating element used, models can be distinguished:

- Ceramic. The resistive cable consists of a ceramic panel that does not conduct current, but passes infrared radiation.Thus, there is the effect of magnetic induction, which ensures uninterrupted operation of this type of heater. It is applied only in wall and ceiling designs. Usually represent a thin panel, equipped with thermoregulation.

- Carbonated. Represented by a quartz element that is filled with carbon. This is one of the most economical models, as they consume very little electricity. Due to the small size of quartz tubes, they can be installed somewhat under one panel, which also increases their heat transfer. The only downside is the high price.

- Halogen. Infrared radiation in them is created using halogen lamps. Can be used for heating outdoor objects.

- Foil. Heats up with a flexible resistive cable that transfers heat to the top metal plate. Thanks to the flexible surface, this heater can be installed on any surface on its own. May heat up to 750 ° C.

- Gas. It works as follows - the gas burns and heats the radiating element. The advantages of such models are that electrical energy is not required for their work, that is, they are autonomous.They can be used in campaigns, at dachas, and also at shutdown of the main heating. Most models are equipped with a piezoelectric element for ease of ignition, as well as a security system that cuts off the gas supply in case the fire goes out.

- Diesel. This type of infrared heaters is used only in industry, construction, in the construction of large buildings. The principle of operation is similar to gas models, however, they have more modest dimensions and a wider range of temperature settings.

The choice of one or another type of radiant heater will directly depend on the conditions and for what purposes it will be used.

Wiring diagram

Film type IR heaters is one of the most popular. And not the least role in this was played by the fact that such models can be easily installed at home with your own hands. The most widespread installation of PLEN on the ceiling or under the floor covering. However, if desired, you can place the panels on the walls, but at the same time, the efficiency of the heater will decrease, due to the limited range of the device. It is most often used as an additional source of heat, but not the main one.

The main technological steps are as follows:

- Create protection from any thermal insulation material. This is necessary in order to direct the infrared radiation in the right direction.

- Installation of the film to the base. It can be both thermal insulation and a special crate. It is important that the front side of the PLEN "looked" into the room. Fastening is done with screws or a construction stapler.

- Work on connecting PLEN to the source of electricity. This stage will require some experience in conducting such work.

- Installation of a decorative layer.

It is important to remember that for the most efficient operation of infrared heaters, they must occupy from 60 to 80% of the total surface area for installation. Particular attention should be paid to the window and door openings, as through them a large amount of heat is lost.

Before installation, several important points should be observed, on which the final quality of work will depend:

- check the integrity of the heating element before installation using a special tester;

- optimize the wiring diagram by directing the contact leads towards the shield;

- pay attention to the mounting zones on the sheets, and in no case do not violate these boundaries, otherwise it will lead to breakdown of the PLEN.

The installation of the film on the ceiling can be carried out directly on the insulation (conceals about 15 cm from the ceiling height), and on the batten (takes more height). The course of work is as follows:

- Ceiling is measured and divided into equal sections. Thermal insulation is cut into sheets of the desired size and mounted to the ceiling with a stapler. The seams are taped. Excess insulation material is cut with a stationery knife.

- Install PLEN. This will require a soldering iron, the heater itself, wires, thermostat, screwdriver and a plastic box. The film is fixed in increments of 25-30 cm using a stapler. The wires at the same time lead to one side. Further, the wires are neatly placed in a plastic box, which is located in a convenient place. Fixed box with a screwdriver.

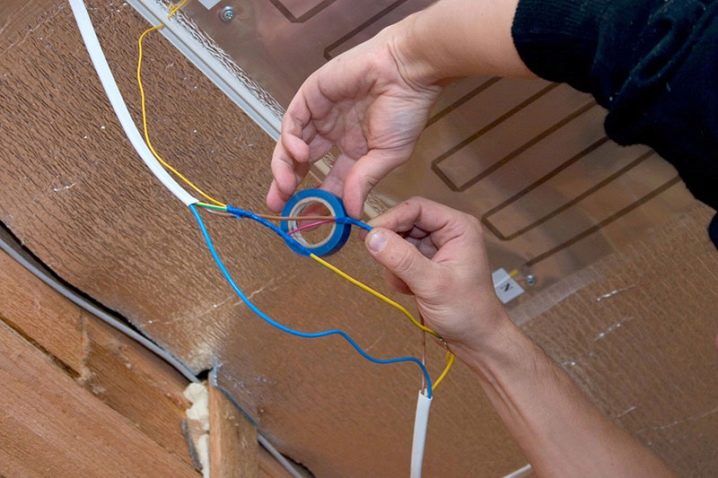

- Soldering wires. To do this, expose the wires. This should be done as carefully as possible without damaging the wires. The veins are divided into 2 parts of 2.5 cm. After 2 wires we connect (twist) between themselves to ensure good contact between them. Excess wires to cut and remove the insulation with a soldering iron and a piece of plastic.Similarly, we connect all the remaining wires to each other.

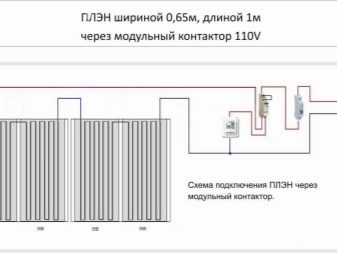

- Connection In order for the PLEN to work, the two main wires must be connected to the panel and connected. Connection diagrams for IR heaters involve the use of a contactor. It is important to note that when the total power is 5 kW and below, single-phase input is made, and for values above 5 kW - three-phase input. After that, the thermostat is installed, usually to a height of 1.4-1.5 meters.

To install FLEN as a “warm floor” type, you must perform the following steps:

- Prepare the surface for work. The floor must be flat, clean and dust-free.

- Decking insulation. The material is fixed with a stapler, the joints are glued with aluminum tape. It is important to cut the material of the right size, since the smaller the joints will have a coating, the better.

- PLEN mounted with indents from places where put furniture and other interior items. The wires are drawn in the direction of the baseboards and stretched to the power cable.

- Installation of thermostat. You can use remote models or place the equipment directly on the floor surface.

- Connection performed in the same way as when connecting ceiling infrared heaters.

Reviews of real owners

Most buyers are satisfied with radiant heaters and note their durability, efficiency, and uninterrupted operation. Some owners say that when they are first turned on, full warming up of the room takes place only after 24 hours, which can cause some discomfort, however, this is a temporary phenomenon and can be easily eliminated by using additional heating devices (electric heating or oil radiators). Many buyers recognize the need to replace the old wiring before installing the PLEN, and this can also entail considerable financial and time costs.

Only a small percentage of radiant heat owners point out that the efficiency of this heater is no different from ordinary electric heating.

Radiant heat is a modern high-tech alternative to classic water heaters. Manufactured by new technologies, they are economical and safe, as evidenced by certificates, and this type of heaters can be safely used both in everyday life and on an industrial scale.

See the following video for economical PLEN heating.