Features and device of the elevator node of the heating system

The CHP, burning natural gas, fuel oil or coal, heats the water to a temperature of 115 ° C under high pressure. High-temperature water vapor enters the turbine blades, which rotates the three-phase alternator. Electricity is supplied to supply homes and industrial enterprises, exhaust steam heats apartments and enterprises.

What it is?

The elevator assembly lowers the temperature of superheated steam coming from the CHP plant and maintains pressure in the heating system. In the basement of an apartment house or cottage, the heating unit houses the control and management equipment — an elevator, temperature and pressure sensors, thermometers, pressure gauges, pumps for pumping water, a circulation pump for the heat carrier, a remote control equipment, a filter sump, a relay unit and automation.Despite its apparent simplicity, the elevator heating unit is a highly efficient device. He brings the temperature of superheated water coming from the CHP to the heating unit to the heating system to the norm to the standard values, continuous circulation of hot water in the heating system, hot water supply to the radiators and the flow of cooled water back to normal.

The advantage of the elevator is small size, no need for regular maintenance, low cost. Work does not require connection to an electric network. The lack of an elevator - it is not possible to regulate the temperature of the output stream in sufficient limits. Consider briefly the basic models of pipes used in modern systems of hot water supply.

Polypropylene

PPT made of polypropylene sheets, between which is laid a thin sheet of aluminum foil. In the manufacture of pipes, polypropylene sheets are smeared with adhesive mastic, thin aluminum foil is placed between them, rolled into a roll, put on a hollow rod, the edges at the junction are cut at a 45 degree angle, smeared with acrylic gel and heated with a special hairdryer.These pipes are not susceptible to corrosion, rust and bacterial deposits do not settle on their internal walls. The pipes are connected to each other at right angles using plastic or threaded metal fittings.

Methods for connecting plastic pipes:

- cold welding or bonding;

- connection with a threaded coupling;

- high temperature plasma welding;

- applied metal flanges;

- welding using an electric coupling.

PPTs are used in hard-to-reach places, they are easily connected, do not leak.

Advantages of polypropylene pipes:

- easily bend at an arbitrary angle;

- bacterial iron does not settle inside;

- does not precipitate calcium salts;

- PPT does not break the liquid in the cold;

- no harmful substances are emitted from plastic; pipes can be used to supply drinking water;

- do not leak, it can be used for the device of "heat-insulated floor";

- do not damage rodents, fungus, mold;

- heat resistant, can be used for hot water supply.

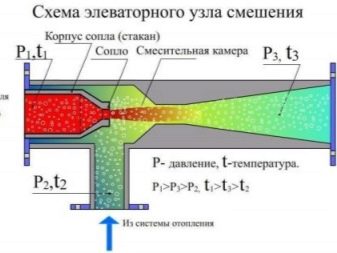

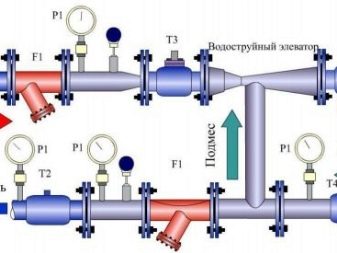

The purpose of the elevator unit is to mix the superheated coolant, which comes from the CHP, with hot water, which is returned from the return line.He is also responsible for ensuring circulation in the system, preventing pressure drops and hydraulic shocks due to a leakage of the system with the release of air bubbles, sudden changes in weather, a sharp drop in pressure in the system and boiling of the coolant.

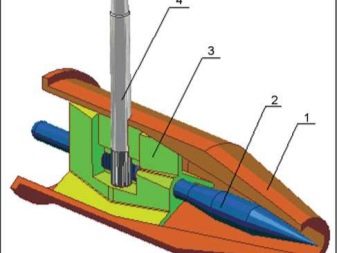

Device and principle of operation

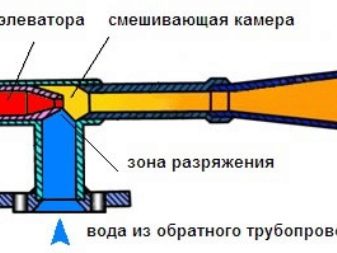

The elevator mixes very hot water from the supply line and cool water from the return. The heating elevator works according to Bernoulli's law, sucking the cooled coolant into the chamber due to the pressure drop and mixing it with the hot one in a certain proportion for pumping into the heating system. Due to the mixing of cold and hot coolant, the temperature of the working fluid is reduced to the permissible rate, its volume increases significantly, and the pressure stabilizes. Without an elevator, the operation of the heating system is impossible - increasing the volume of liquid, it increases efficiency, maintains pressure, evenly distributes heat, smoothes out sharp temperature drops. Without it, there would be cold batteries on the upper floors.

Centralized hot water systems (HWS) receive heated water from CHP plants or boilers for natural gas, liquid or solid fuels. GVS are closed and open type.In a closed system, water flows to the consumer from the heat exchanger. The advantages of a closed system - hot water can be used for cooking, defrosting products. In an open system, water flows to the consumer directly after working on the steam turbine. Such water can not be eaten - it contains polymer additives, rust, bacterial iron and other chemical reagents.

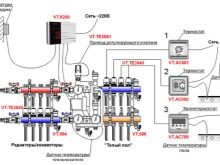

An adjustable elevator allows you to control the parameters of the heating system at home, equipped with electronic meters. They transmit to the elevator controller the temperature outside, in the room, in the supply pipe, in the return pipe. In the cone nozzle is a throttling needle. The controller, which controls the mixing of hot and cold water, moves the choke needle inside the cone nozzle with a servo. Structurally, the needle elevator is made in the form of a casing, the throttle needle moves inside. The drive rotates the gear, which moves the throttle needle, which increases or decreases the flow rate of the fluid until the nozzle opening is completely blocked.Advantages - the possibility of remote control of heating from the control room of the CHP. Disadvantages - whistling sound when working.

Thermal elevator unit number 3 - the most commonly used in practice budget option for the work of the DHW system of an apartment building or a cottage. Maintaining constant parameters of the coolant occurs by podmesa to the hot coolant chilled water from the return pipe. This automatic regulator allows you to maintain a constant temperature and pressure in the system of central and local heating without being connected to the electrical network.

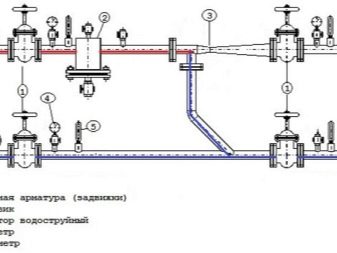

Legend:

- stop valves;

- sump;

- water elevator;

- diaphragm pressure gauge;

- alcohol thermometer.

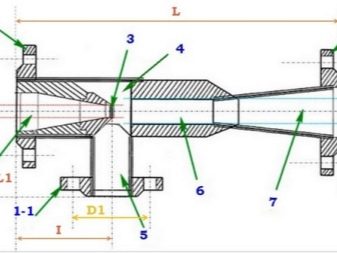

Characteristics of the node thermal elevator UTE-3:

- Elevator nozzle diameter - 5 mm;

- diffuser diameter - 25 mm;

- weight - 19 kg;

- input flange DN1 - 50;

- offset flange DN2 - 80;

- output flange DN3 - 80;

- construction length is 62.6.

The elevator regulates the temperature and pressure of the coolant in the cooling system in automatic mode.

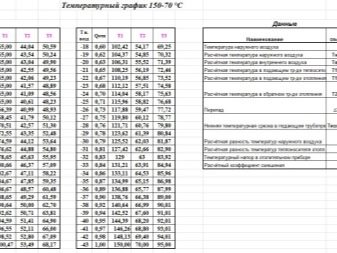

Payment

The operation of the elevator assembly depends on the correctly selected dimensions and the pressure drop between the discharge and return pipelines.To calculate the parameters of the elevator node heat engineers and programmers have created quite a lot of programs. They look like a regular screen form with a customized formula for calculations. After filling in all the rows of the table, the program calculates the parameters of the DHW scheme, the dimensions of the elevator and gives the results in the form of a diagram with the dimensions applied and in the form of a table with a calculation. The variant of results distribution is usually presented in the form of a table.

The calculation of the heating system and the choice of the elevator is quite detailed in the Building Regulations and Rules:

- SNiP 23-01-99 “Construction Climatology”, 2000;

- SNiP II-3-79 “Construction Heat Engineering”, 1998;

- SNiP 2.04.05-91 "Heating, ventilation and air conditioning", 1987;

- V. Bogoslovsky. “Internal sanitary facilities”, 1990.

Mixing thermostat - an alternative to the standard elevator unit. It works in exactly the same way as an elevator - it mixes the hot water coming from the CHP and cooled, which is returned from the radiators. Three channels are connected to the thermostat: one for hot water, the second for return, and the third for supplying the prepared mixture to radiators.If the temperature of the water from the main pipeline is within acceptable limits - the cold flow is completely blocked. As soon as the temperature starts to rise - the valve gradually begins to open, a portion of cool water is mixed with hot water, lowering the temperature of the mixture. The hotter the water, the larger the volume of cool water is mixed. A three-way thermostat valve for mixing is necessary to control the proportion of cold and hot water in order to obtain the optimal coolant temperature. Advantages - small size, no moving parts, easy temperature adjustment.

Tips

The selection of the required parameters of the heating system in a multi-unit or private house (cottage) depends on the project and the money allocated to solve this issue. Most often, financial opportunities and local conditions are decisive in this case.

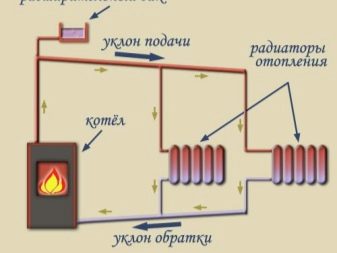

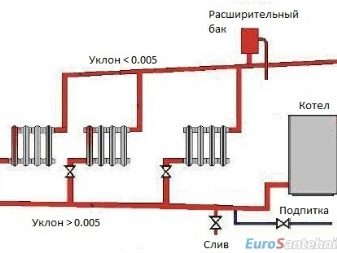

Gravity heating system is the most simple and cheap. The heat source for such a system is a water boiler with wood, coal or natural gas. There is no pump in this system - convective circulation of water is ensured by the tank-expander and pipe underlayment.

The density of cold water is slightly higher than the density of hot water, the difference in density leads to a slight overpressure, which, together with the force of gravity, leads to the flow of coolant through the pipes of the system. Manual adjustment of the system is done using valves and gate valves.

Semiautomatic system based on thermal heads and thermostats. The system parameters are set manually, in the future they are supported automatically. A system using microcontrollers and self-learning programs can operate completely autonomously for a long time. To analyze the events in the system, a monitoring log is kept. If you want to save as much as possible on the installation of the heating system, having done all the work yourself, but you do not know how to use electric welding, you need to choose polypropylene pipes for the heating system and hot water supply. Installation of polypropylene pipes can be done with an ordinary wrench. These pipes are significantly cheaper than others. Installation errors can be quickly and cheaply repositioned.Welding of polypropylene pipes on a machine can be easily mastered by a person who has never done this before.

Polypropylene pipes can be easily laid in hard-to-reach places. Their essential disadvantage is that a welding machine is needed to install the heating system, which you will have to buy or rent. It is best to use polypropylene pipes with glass fiber reinforcement, they are much stronger and more durable.

Having chosen metalplastic pipes for installation of a water heating system, you will be 100% sure of the reliability of the pipelines and the durability of the pipes laid in the cement screed of the “warm floor”.

Independent troubleshooting of the elevator unit:

- Littering debris. Signs - after a light tapping on the body of the sump, turbidity of water or the appearance of a stagnant odor is observed. Sump need to rinse.

- Corrosion or clogging of the nozzle. Signs - strong noise is heard, when working, the pressure in the system changes dramatically. The nozzle requires replacement.

- Clogged sump on the return pipe. Signs - the pressure in the return pipe is growing. Sump need to rinse.

- Corrosion nozzle.Signs - different water temperatures on the floors. Nozzle replacement required.

How the elevator heating unit works, see the next video.